Abstract

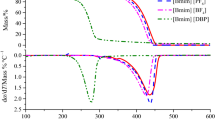

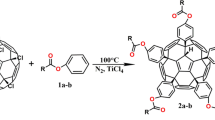

This paper aims to investigate the effects of plasticizer dibutyl phthalate (DBP) on the thermal decomposition of nitrocellulose (NC) by using a series of analytical apparatuses. In the present study, the detailed structures of pure NC (NC-P) and NC with DBP (NC-D) were revealed by scanning electron microscope. It was found that the fibers in NC-D are more closely aligned than those in NC-P, which makes the thermal behaviors of NC-D different from NC-P. The thermal stability of both NC-P and NC-D was examined by means of simultaneous TG-DSC apparatus (STA). Three different kinetic methods (Kissinger–Akahira–Sunose method, Ozawa–Flynn–Wall method, and Friedman method) were applied for determining the activation energy E of these two NC samples. Moreover, the experimental data were compared with sigmoidal models and pre-exponential factor was calculated by compensation effect. Besides, in situ Fourier transform infrared (FTIR) and a TGA instrument coupled with Frontier FTIR spectrometer were employed to investigate the characteristic functional groups of decomposition residues and gaseous products at different temperatures, respectively. The results show that NC-P and NC-D have similar decomposition products and decomposition mechanisms.

Similar content being viewed by others

Abbreviations

- A :

-

Pre-exponential factor

- c :

-

A parameter of random scission kinetic functions

- a − b :

-

Compensation effect parameters

- E :

-

Activation energy (kJ mol−1)

- f(α):

-

The dependence of the reaction rate on the extent of conversion

- g(α):

-

The integral form of the reaction model

- k(T):

-

The dependence of the reaction rate on temperature

- m :

-

A parameter of random scission kinetic functions

- m t :

-

Real-time sample mass in TG (mg)

- m f :

-

Mass after the reaction in TG (mg)

- m i :

-

Initial sample mass in TG (mg)

- n :

-

A constant in describing reaction model

- p(x):

-

Temperature integral

- R :

-

One part of nitrocellulose, i.e., [C6H7O2(OH)3–x(ONO2)x–1]n

- R 0 :

-

Gas constant (J mol−1 K−1)

- R 2 :

-

Pearson’s correlation coefficient

- t :

-

Time

- T :

-

Temperature (°C)

- T α :

-

Temperature at an fixed α

- T on :

-

Onset decomposition temperature

- T max :

-

Maximum decomposition temperature

- V :

-

Stretching

- W :

-

Normalized mass

- α :

-

Extent of conversion

- β :

-

Heating rate

- τ :

-

Deformation

- ω :

-

Wag

- i:

-

Different heating rates

- max:

-

Maximum

- n:

-

Degree of polymerization

- on:

-

Onset

- s:

-

Symmetric

- as:

-

Antisymmetric

- x:

-

The number of –ONO2

- 0.5:

-

α = 0.5

References

Ossa MÁFDL, López-López M, Torre M, García-Ruiz C, et al. Analytical techniques in the study of highly-nitrated nitrocellulose. TrAC Trends Anal Chem. 2010;30(11):1740–55.

Katoh K, Ito S, Ogata Y, Kasamatsu JI, Miya H, Yamamoto M, et al. Effect of industrial water components on thermal stability of nitrocellulose. J Therm Anal Calorim. 2010;99(1):159–64.

Wei R, He Y, Zhang Z, He J, Yuen R, Wang J. Effect of different humectants on the thermal stability and fire hazard of nitrocellulose. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7235-6.

Fu G, Wang J, Yan M. Anatomy of Tianjin Port fire and explosion: process and causes. Process Saf Prog. 2016;35(3):216–20.

Zhao B. Facts and lessons related to the explosion accident in Tianjin Port, China. Nat Hazards. 2016;84(1):707–13.

Katoh K, Soramoto T, Higashi E, Kawaguchi S, Kumagae K, Ito S, et al. Influence of water on the thermal stability of nitrocellulose. Sci Technol Energ Mater. 2014;75(1–2):44–9.

Hassan MA. Effect of malonyl malonanilide dimers on the thermal stability of nitrocellulose. J Hazard Mater. 2001;88(1):33–49.

Lindblom T. Reactions in stabilizer and between stabilizer and nitrocellulose in propellants. Propellant Explos Pyrotech Int J Dealing Sci Technol Asp Energ Mater. 2002;27(4):197–208.

Trache D, Tarchoun AF. Stabilizers for nitrate ester-based energetic materials and their mechanism of action: a state-of-the-art review. J Mater Sci. 2018;53(1):100–23.

He Y, He Y, Liu J, Li P, Chen M, Wei R, et al. Experimental study on the thermal decomposition and combustion characteristics of nitrocellulose with different alcohol humectants. J Hazard Mater. 2017;340:202–12.

Liu JH, Wang J, Xie QM, Wang JH, Tao CF, Yuen R. Effect of bulk density on the combustion property of nitrocellulose with isopropanol humectant. Propellants Explos Pyrotech. 2018;43(5):445–52.

Wei R, Huang S, Huang Q, Ouyang D, Chen Q, Yuen R, et al. Experimental study on the fire characteristics of typical nitrocellulose mixtures using a cone calorimeter. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7410-9.

Guo S, Wang Q, Sun J, Liao X, Wang ZS. Study on the influence of moisture content on thermal stability of propellant. J Hazard Mater. 2009;168(1):536–41.

Wei R, He Y, Liu J, He Y, Mi W, Yuen R, et al. Experimental study on the fire properties of nitrocellulose with different structures. Mater (Basel). 2017;10(3):316.

Liu J, Chen M. A simplified method to predict the heat release rate of industrial nitrocellulose materials. Appl Sci. 2018;8(6):910.

Shao ZQ, Wang WJ. Structure and properties of cellulose nitrate. Beijing: National Defense Industry Press; 2011 (in Chinese).

Phillips RW, Orlick CA, Steinberger R. The kinetics of the thermal decomposition of nitrocellulose. J Phys Chem. 1955;59(10):1034–9.

Jutier JJ, Harrison Y, Premont S, Prud’Homme RE. A nonisothermal Fourier transform infrared degradation study of nitrocelluloses derived from wood and cotton. J Appl Polym Sci. 1987;33(4):1359–75.

Kumita Y, Wada Y, Arai M, Tamura M. A study on thermal stability of nitrocellulose. J Jpn Explos Soc. 2002;63(5):271–4.

Makashir P, Mahajan R, Agrawal J. Studies on kinetics and mechanism of initial thermal decomposition of nitrocellulose. J Therm Anal. 1995;45(3):501–9.

Wang Y, Liu R, Ning B, Pan Q, Hu R. A study of the thermal decomposition mechanism of nitrocellulose. Energ Mater Chengdu. 1998;6:157–68.

Jin M, Luo N, Li G, Luo Y. The thermal decomposition mechanism of nitrocellulose aerogel. J Therm Anal Calorim. 2015;121(2):901–8.

Binke N, Rong L, Xianqi C, Yuan W, Hu RZ, Qingsen Y. Study on the melting process of nitrocellulose by thermal analysis method. J Therm Anal Calorim. 1999;58(2):249–56.

Drysdale D. An introduction to fire dynamics. Hoboken: Wiley; 2011.

Jessup RS, Prosen E. Heats of combustion and formation of cellulose and nitrocellulose (cellulose nitrate). J Res Natl Bur Stand. 1950;44:387.

Jiang L, Xiao HH, He JJ, Sun Q, Gong L, Sun JH. Application of genetic algorithm to pyrolysis of typical polymers. Fuel Process Technol. 2015;138(7):48–55.

Xu L, Jiang Y, Wang L. Thermal decomposition of rape straw: pyrolysis modeling and kinetic study via particle swarm optimization. Energy Convers Manag. 2017;146:124–33.

Jiang L, Zhang D, Li M, He J-J, Gao Z-H, Zhou Y, et al. Pyrolytic behavior of waste extruded polystyrene and rigid polyurethane by multi kinetics methods and Py-GC/MS. Fuel. 2018;222:11–20.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520(1–2):1–19.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol (Sci Technol). 1971;16:22–31.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29(11):1702–6.

Flynn JH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci, Part C: Polym Lett. 1966;4(5):323–8.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38(11):1881–6.

Friedman HL (ed). Kinetics of thermal degradation of char–forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Polym Symp. 1964;6(1):183–95.

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Criado JM. Generalized master plots as a straightforward approach for determining the kinetic model: the case of cellulose pyrolysis. Thermochim Acta. 2013;552:54–9.

Sánchezjiménez PE, Pérezmaqueda LA, Perejón A, Criado JM. Generalized kinetic master plots for the thermal degradation of polymers following a random scission mechanism. J Phys Chem A. 2010;114(30):7868–76.

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Criado JM. A new model for the kinetic analysis of thermal degradation of polymers driven by random scission. Polym Degrad Stab. 2010;95(5):733–9.

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Criado JM. Constant rate thermal analysis for thermal stability studies of polymers. Polym Degrad Stab. 2011;96(5):974–81.

Mamleev V, Bourbigot S, Bras ML, Yvon J, Lefebvre J. Model-free method for evaluation of activation energies in modulated thermogravimetry and analysis of cellulose decomposition. Chem Eng Sci. 2006;61(4):1276–92.

Varhegyi G, Jakab E Jr, Antal MJ. Is the Broido–Shafizadeh model for cellulose pyrolysis true? Energy Fuels. 1994;8(6):1345–52.

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Pascual-Cosp J, Benítez-Guerrero M, Criado JM. An improved model for the kinetic description of the thermal degradation of cellulose. Cellulose. 2011;18(6):1487–98.

Mamleev V, Bourbigot S, Bras ML, Yvon J. The facts and hypotheses relating to the phenomenological model of cellulose pyrolysis: interdependence of the steps. J Anal Appl Pyrol. 2009;84(1):1–17.

Vyazovkin S. Advanced isoconversional method. J Therm Anal Calorim. 1997;49(3):1493–9.

Anca-Couce A, Berger A, Zobel N. How to determine consistent biomass pyrolysis kinetics in a parallel reaction scheme. Fuel. 2014;123:230–40.

Herzberg G Jr, Bryce L. Infrared and Raman spectra of polyatomic molecules. Journal of Chemical Physics. 1941;9(11):780–5.

Ling-Xue YI, Gao L, Zhao LJ, Jiang C, Zhao K. Dibutyl phthalate theoretical analysis and detection in infrared. Spectrosc Spectr Anal. 2016;36(9):2782–92.

Moharram MA, Nasr TZAE, Hakeem NA. X-Ray diffraction and infrared studies on the effect of thermal treatments on cotton celluloses I and II. J Polym Sci Polym Lett Ed. 1981;19(4):183–7.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 51376172) and the Grant from the Research Grant Council of the Hong Kong Special Administrative Region, China (contract Grant Number CityU 11301015).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Rights and permissions

About this article

Cite this article

Wei, R., Huang, S., Wang, Z. et al. Effect of plasticizer dibutyl phthalate on the thermal decomposition of nitrocellulose. J Therm Anal Calorim 134, 953–969 (2018). https://doi.org/10.1007/s10973-018-7521-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7521-3