Abstract

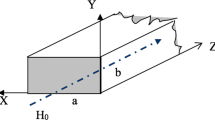

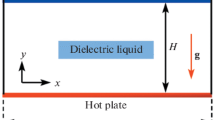

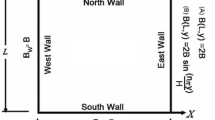

In this paper, the problems of two-dimensional temperature distribution for the microwave heating process are analyzed and discussed. Different from the traditional models in previous literature, the paper proposes several two-dimensional global temperature models which consist of explicit dissipation powers. By analyzing microwave propagation characteristics and spatial distribution of dominant modes into the rectangular medium, the different dissipation powers in different microwave applications are derived, such as the short waveguide, long waveguide and resonant cavity. Then, substituting the proposed dissipation powers into heat transport equation, the simplified temperature models are obtained. For further validation, traditional finite element models in COSMOL® Multiphysics are used to compare the proposed temperature models in the same parameters. The comparative results show that the mathematical models can approximately predict the global temperature variation and hot spot distribution in two-dimensional rectangular medium.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Akkari E, Chevallier S, Boillereaux L. A 2D non-linear “grey-box” model dedicated to microwave thawing: theoretical and experimental investigation. Comput Chem Eng. 2005;30(2):321–8.

Ayappa KG, Davis HT, Crapiste G, Davis EA, Gordon J. Microwave heating: an evaluation of power formulations. Chem Eng Sci. 1991;46(4):1005–16.

Beale GO, Mengli L. Robust temperature control for microwave heating of ceramics. IEEE Trans Ind Electron. 1997;44(1):124–31.

Campanone LA, Zaritzky NE. Mathematical analysis of microwave heating process. J Food Eng. 2005;69(3):359–68.

Campañone LA, Zaritzky NE. Mathematical modeling and simulation of microwave thawing of large solid foods under different operating conditions. Food Bioprocess Technol. 2010;3(6):813–25.

Chaiyo K, Rattanadecho P. Numerical analysis of heat–mass transport and pressure buildup of unsaturated porous medium in a rectangular waveguide subjected to a combined microwave and vacuum system. Int J Heat Mass Transf. 2013;65:826–44.

Chandrasekaran S, Ramanathan S, Basak T. Microwave material processing-a review. AIChE J. 2012;58(2):330–63.

Farag S, Sobhy A, Akyel C, Doucet J, Chaouki J. Temperature profile prediction within selected materials heated by microwaves at 2.45 GHz. Appl Therm Eng. 2012;36:360–9.

Fouad E. Analysis of power formulations for the thawing of frozen wood using microwave energy. Chem Eng Sci. 2013;98:317–30.

Goodwin GC, Middleton RH, Seron MM, Campos B. Application of nonlinear model predictive control to an industrial induction heating furnace. Annu Rev Control. 2013;37(2):271–7.

Liang S, Zhong J, Yuan Y, Wang Z, Zeng C. A two-dimensional temperature distribution model for microwave heating in rectangular cavity. In: 33rd Chinese control conference (CCC). 2014. p. 6583–6587, Nanjing, China.

Liu S, Fukuoka M, Sakai N. A finite element model for simulating temperature distributions in rotating food during microwave heating. J Food Eng. 2013;115(1):49–62.

Magee TRA, McMinn WAM, Farrell G, Topley L, Al-Degs YS, Walker GM, Khraisheh M. Moisture and temperature dependence of the dielectric properties of pharmaceutical powders. J Therm Anal Calorim. 2013;111(3):2157–64.

Outifa L, Delmotte M, Jullien H. Dielectric and geometric dependence of electric field and power distribution in a waveguide heterogeneously filled with lossy dielectrics. IEEE Trans Microw Theory Techn. 1997;45(8):1154–61.

Pal D, Chatterjee S. MHD mixed convection stagnation-point flow of a micropolar fluid in a porous medium towards a heated stretching sheet with thermal radiation. Math Model Anal. 2012;17(4):498–518.

Rybakov KI, Olevsky EA, Krikun EV. Microwave sintering: fundamentals and modeling. J Am Ceram Soc. 2013;96(4):1003–20.

Santos T, Valente MA, Monteiro J, Sousa J, Costa LC. Electromagnetic and thermal history during microwave heating. Appl Therm Eng. 2011;31(16):3255–61.

Shi Q, Zheng Y, Zhao Y. Thermal transition and state diagram of yacon dried by combined heat pump and microwave method. J Therm Anal Calorim. 2015;119(1):727–35.

Sun TS, Shi JF, Zhang ZS. Heat transfer model and solution of microwave hot recycling for asphalt pavem. J Traffic Transp. 2008;8(5):49–53.

Suwannapum N, Rattanadecho P. Analysis of heat–mass transport and pressure buildup induced inside unsaturated porous media subjected to microwave energy using a single (TE10) mode cavity. Dry Technol. 2011;29(9):1010–24.

Thostenson ET, Chou TW. Microwave processing: fundamentals and applications. Compos Part A Appl Sci Manuf. 1999;30(9):1055–71.

Vadivambal R, Jayas DS. Non-uniform temperature distribution during microwave heating of food materials—a review. Food Bioprocess Technol. 2010;3(2):161–71.

Yasuoka M, Nishimura Y, Nagaoka T, Watari K. Influence of different methods of controlling microwave sintering. J Therm Anal Calorim. 2006;83(2):407–10.

Yin HM, Buttlar WG, Paulino GH. Simplified solution for periodic thermal discontinuities in asphalt overlays bonded to rigid pavements. J Transp Eng. 2007;133(1):39–46.

Yousefi T, Mousavi SA, Saghir MZ, Farahbakhsh B. An investigation on the microwave heating of flowing water: a numerical study. Int J Therm Sci. 2013;71:118–27.

Zhao H, Turner IW. The use of a coupled computational model for studying the microwave heating of wood. Appl Math Model. 2000;24(3):183–97.

Zhao X, Yan L, Huang K. Review of numerical simulation of microwave heating process. In: Advances in induction and microwave heating of mineral and organic materials. INTECH; 2011. p. 27–48.

Acknowledgements

The authors would like to thank the National Basic Research Program of China for financial support (No. 2013CB328903).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, J., Liang, S., Xiong, Q. et al. Approximate microwave heating models for global temperature profile in rectangular medium with TE10 mode. J Therm Anal Calorim 122, 487–495 (2015). https://doi.org/10.1007/s10973-015-4713-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4713-y