Abstract

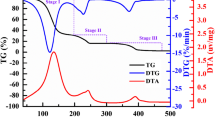

The catalytic effect of SnO2 doping on the hydrogen thermal desorption of MgH2 was investigated by coupled thermogravimetric–mass spectrometric (TG–MS) analyses, among a set of samples prepared with different SnO2/MgH2 molar ratios. A small release of water and carbon dioxide was detected at temperatures preceding to the reductive thermal decomposition of MgH2 yielding molecular hydrogen. While TG and DTA data collected at different heating rate provided an apparent activation energy for the entire thermal process, appropriate ion-current signals from the MS-data were used to obtain the activation energies of the single chemical reactions yielding the formation of H2O, CO2, and H2. The most common equations derived from model-free isoconversion methods (Kissinger–Akahira–Sunose; Flynn–Wall–Ozawa; Starink) were used by processing temperatures referred to the different kinds of signals (TG-, DTG-, DTA-, TIC-, molecular-ion IC-curves) for isoconversion points corresponding to the maximum rate of transformation. Temperature and activation energy values were used to compare the kinetic behavior of MgH2 powder with the best performance of a doped sample, prepared by high energy grinding of SnO2/MgH2 mixture. Doped-MgH2 samples prepared with SnO2 mass ratio of 0.2 showed the best kinetic thermal decomposition behavior, with respect to the pristine MgH2 powder: a decreasing of the main thermal decomposition event of ca. 51–57 °C associated to a coherent decreasing of ca. 20 % (ca. 30 kJ mol−1) of its activation energy value.

Similar content being viewed by others

References

Jain IP, Lal C, Jain A. Hydrogen storage in Mg: a most promising material. Int J Hydrogen Energy. 2010;35:5133–44.

Varin RA, Zbroniec L, Polanski M, Bystrzycki J. A review of recent advances on the effects of microstructural refinement and nano-catalytic additives on the hydrogen storage properties of metal and complex hydrides. Energies. 2011;24(4):1–25.

Evard E, Gabis I, Yartys VA. Kinetics of hydrogen evolution from MgH2: experimental studies, mechanism and modelling. Int J Hydrogen Energy. 2010;35:9060–9.

Varin RA, Czujko T, Wronski ZS. Particle size, grain size and γ-MgH2 effects on the desorption properties of nanocrystalline commercial magnesium hydride processed by controlled mechanical milling. Nanotechnology. 2006;14(17):3856–65.

Hanada N, Ichikawa T, Fujii H. Catalytic effect of nanoparticle 3d-transition metals on hydrogen storage properties in magnesium hydride MgH2 prepared by mechanical milling. J Phys Chem B. 2005;21(109):7188–94.

Hanada N, Ichikawa T, Orimo S-I, Fujii H. Correlation between hydrogen storage properties and structural characteristics in mechanically milled magnesium hydride MgH2. J Alloys Compd. 2004;366:269–73.

Bazzanella N, Checchetto R, Miotello A. Atoms and nanoparticles of transition metals as catalysts for hydrogen desorption from magnesium hydride. J Nanomater. 2011;2011:1–11.

Imamura H, Tanaka K, Kitazawa I, Sumi T, Sakata Y, Nakayama N, et al. Hydrogen storage properties of nanocrystalline MgH2 and MgH2/Sn nanocomposite synthesized by ball milling. J Alloys Compd. 2009;484:939–42.

Imamura H, Yoshihara K, Yoo M, Kitazawa I, Sakata Y. Dehydriding of Sn/MgH2 nanocomposite formed by ball milling of MgH2 with Sn. Int J Hydrogen Energy. 2007;32:4191–4.

Dufour J, Huot J. Rapid activation, enhanced hydrogen sorption kinetics and air resistance in laminated Mg–Pd2 5 at.%. J Alloys Compd. 2007;439:L5–7.

Bassetti A, Bonetti E, Pasquini L, Montone A, Grbovic J, Vittori Antisari M. Hydrogen desorption from ball milled MgH2 catalyzed with Fe. Eur Phys J B. 2005;11(43):19–27.

Zaluska A, Zaluski L, Ström-Olsen JO. Nanocrystalline magnesium for hydrogen storage. J Alloys Compd. 1999;288:217–25.

Patah A, Takasaki A, Szmyd JS. Influence of multiple oxide (Cr2O3/Nb2O5) addition on the sorption kinetics of MgH2. Int J Hydrogen Energy. 2009;34:3032–7.

Kojima Y, Kawai Y, Haga T. Magnesium-based nano-composite materials for hydrogen storage. J Alloys Compd. 2006;424:294–8.

Barkhordarian G, Klassen T, Bormann R. Effect of Nb2O5 content on hydrogen reaction kinetics of Mg. J Alloys Compd. 2004;364:242–6.

Oelerich W, Klassen T, Bormann R. Metal oxides as catalysts for improved hydrogen sorption in nanocrystalline Mg-based materials. J Alloys Compd. 2001;315:237–42.

Malka IE, Czujko T, Bystrzycki J. Catalytic effect of halide additives ball milled with magnesium hydride. Int J Hydrogen Energy. 2010;35:1706–12.

Campostrini R, Abdellatief M, Leoni M, Scardi P. Activation energy in the thermal decomposition of MgH2 powders by coupled TG–MS measurements. Part 1. Comparison among TG- and MS-data processing. J Therm Anal Calorim. 2014. doi:10.1007/s10973-013-3539-8 (in press).

Campostrini R, Sicurelli A, Ischia M, Carturan G. Pyrolysis study of a hydride–sol–gel silica. Part I. Chemical aspects. J Therm Anal Calorim. 2007;19(89):633–41.

Campostrini R, Sicurelli A, Ischia M, Carturan G. Pyrolysis study of a hydride–sol–gel silica. Part II. Kinetic aspects. J Therm Anal Calorim. 2007;22(90):179–84.

Campostrini R, Ischia M, Palmisano L. Pyrolysis study of sol–gel derived TiO2 powders: part I. TiO2-anatase prepared by reacting titanium(IV) isopropoxide with formic acid. J Therm Anal Calorim. 2003;71:13.

Campostrini R, Ischia M, Palmisano L. Pyrolysis study of sol–gel derived TiO2 powders: part II. TiO2-anatase prepared by reacting titanium(IV) isopropoxide with oxalic acid. J Therm Anal Calorim. 2003;71:1011–22.

Campostrini R, Ischia M, Palmisano L. Pyrolysis study of sol–gel derived TiO2 powders: part III. TiO2-anatase prepared by reacting titanium(IV) isopropoxide with acetic acid. J Therm Anal Calorim. 2004;75:13–24.

Campostrini R, Ischia M, Palmisano L. Pyrolysis study of sol–gel derived TiO2 powders: part IV. TiO2-anatase prepared by hydrolysing titanium(IV) isopropoxide without chelating agents. J Therm Anal Calorim. 2004;75:25–34.

Young RA. “Ray.” The Rietveld method. IUCr Monograph on Crystallography. New York: Oxford University Press; 1993.

Abdellatief M, Campostrini R, Leoni M, Scardi P. Effects of SnO2 on hydrogen desorption of MgH2. Int J Hydrogen Energy. 2013;38:4664–9.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;57:217.

Flynn JH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci B. 1966;4:323–8.

Ozawa T. Estimation of activation energy by isoconversion methods. Thermochim Acta. 1992;203:159–65.

Starink MJ. A new method for the derivation of activation energies from experiments performed at constant heating rate. Thermochim Acta. 1996;288:97–104.

Murray P, White J. Kinetics of the thermal dehydration of clays: part IV. Interpretation of the differential thermal analysis of clay minerals. Trans Br Ceram Soc. 1955;54:204–37.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Starink MJ. Activation energy determination for linear heating experiments: deviations due to neglecting the low temperature end of the temperature integral. J Mater Sci. 2007;11(42):483–9.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Campostrini, R., Abdellatief, M., Leoni, M. et al. Activation energy in the thermal decomposition of MgH2 powders by coupled TG–MS measurements. J Therm Anal Calorim 116, 865–874 (2014). https://doi.org/10.1007/s10973-013-3557-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3557-6