Abstract

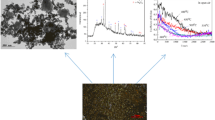

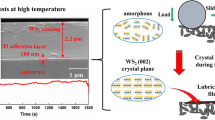

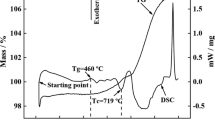

In this paper, Ag-doped γ-Fe2O3@SiO2 nanocomposite coatings have been prepared by sol–gel method and deposited on steel substrate. The microstructure, surface topography, and high-temperature tribological properties of these coatings were measured and investigated by X-ray diffraction (XRD), Raman spectroscopy, scanning electron microscope with energy- dispersive spectrometer (SEM/EDS), transmission electron microcopy (TEM), and a high-temperature tribometer. The results show that the γ-Fe2O3 core is coated with an amorphous SiO2 shell and Ag nanoparticles are evenly distributed in the γ-Fe2O3@SiO2 nanocomposites. The tribological properties of the coatings against ZrO2 balls have been investigated by a tribometer at room temperature (RT), 100, 300, 500, and 600 °C, respectively. It is found that the nanocomposite coatings exhibit low and stable coefficients of friction (CoF) (in the range from 0.25 to ~0.06) from RT to 600 °C, respectively. CoF of the friction pair decreases with the increase of temperature. XRD, Raman spectroscopy, and SEM measurements show that the antifriction behaviors of nanocomposite coatings are owing to the soft phases of metal Ag and γ-Fe2O3. The presence of γ-Fe2O3 with high-temperature plasticity is beneficial to form low-shear interface and to achieve low and stable friction at high temperature. The core–shell microstructure of the nanocomposite coatings inhibits the soft γ-Fe2O3 phase, changing it into the α-Fe2O3 phase.

Highlights

-

The Ag-doped γ-Fe2O3@SiO2 nanocomposites have a core–shell microstructure and Ag nanoparticles are evenly distributed in the γ-Fe2O3@SiO2 nanocomposite.

-

The adhesion strength of Ag-doped γ-Fe2O3@SiO2 nanocomposite coatings is high.

-

Ag-doped γ-Fe2O3@SiO2 nanocomposite coatings exhibit excellent tribological properties over a wide temperature range.

Similar content being viewed by others

References

Sliney H (1982) Solid lubricant materials for high temperatures—a review. Tribol Int 15(5):303–315

Cinca N, Cygan S, Senderowski C et al. (2018) Sliding wear behavior of Fe-Al coatings at high temperatures. Coatings 8(8):268

Zhang Y, Zhang D, Wei X et al. (2018) Enhanced tribological properties of polymer composite coating containing graphene at room and elevated temperatures. Coatings 8(3):91

Li B, Jia J, Han M et al. (2017) Microstructure, mechanical and tribological properties of plasma-sprayed NiCrAlY-Mo-Ag coatings from conventional and nanostructured powders. Surf & Coat Technol 324:552–559

Fu Y, Li H, Li J et al. (2017) Preparation and high-temperature tribological properties of CrAlVYN-Ag nanocomposite coatings. Adv Manuf Process 32(4):409–415

Torres H, Vuchkov T, Slawik S, et al. (2018) Self-lubricating laser claddings for reducing friction and wear from room temperature to 600°C. Wear: 22–33.

Zeng Q, Eryilmaz O, Erdemir A (2011) Analysis of plastic deformation in diamond like carbon films–steel substrate system with tribological tests. Thin Solid Films 519(10):3203–3212

Zeng Q, Yu F, Dong G (2013) Superlubricity behaviors of Si3N4/DLC Films under PAO oil with nano boron nitride additive lubrication. Surf Interface Anal 45(8):1283–1290

Erdemir A (2004) Genesis of superlow friction and wear in diamondlike carbon films. Tribol Int 37(11-12):1005–1012

Zeng Q, Erdemir A, Erylimaz O (2017) Ultralow friction of ZrO2 ball Sliding against DLC Films under various environments. Appl Sci 7(9):938

Zeng Q (2018) Thermally induced superlow friction of DLC films in ambient air. High Temp Mater Process 37(8):725–731

Zeng Q, Eryilmaz O, Erdemir A (2015) Superlubricity of the DLC films-related friction system at elevated temperature. RSC Adv 5(113):93147–93154

Wang C, Yin L, Zhang L et al. (2009) Magnetic (γ-Fe2O3@SiO2) n@TiO2 functional hybrid nanoparticles with actived photocatalytic ability. J Phys Chem C113(10):4008–4011

Păcurariu C, Tăculescu EA, Ianoş R et al. (2015) Synthesis and characterization of γ-Fe2O3@SiO2 composites as possible candidates for magnetic paper manufacture. Ceram Int 41(1):1079–1085

Zeng Q, Chen T (2018) Superlow friction and oxidation analysis of hydrogenated amorphous silicon films under high temperature. J Non-Cryst Solids 493:73–81

Zeng Q, Cai S, Li S (2018) High-temperature low-friction behaviors of γ-Fe2O3@SiO2 nanocomposite coatings obtained through sol–gel method. J Sol-Gel Sci Technol 85(3):558–566

Erdemir A (2000) A crystal-chemical approach to lubrication by solid oxides. Tribol Lett 8(2-3):97–102

Ouyang JH, Sasaki S, Umeda K (2002) The friction and wear characteristics of low-pressure plasma-sprayed ZrO2-BaCrO4, composite coating at elevated temperatures. Surf & Coat Technol 154(2):131–139

Bondarev AV, Kiryukhantsev-Korneev PV, Sidorenko DA et al. (2016) A new insight into hard low friction MoCN–Ag coatings intended for applications in wide temperature range. Mater Des 93:63–72

Bílek P, Jurči P, Hudáková M et al. (2014) Cr2N7Ag nanocomposite thin films deposited on Vanadis 6 tool steel. Appl Surf Sci 307:13–19

ASTM International (2002) ASTM D3359-02 standard test methods for measuring adhesion by tape test. ASTM International, West Conshohocken, PA, USA

Tian B, Wang T, Dong R et al. (2014) Core–shell structured γ-Fe2O3@SiO2@AgBr: Ag composite with high magnetic separation efficiency and excellent visible light activity for acid orange 7 degradation. Appl Catal B: Environ 147:22–28

Borchert H, Shevchenko E, Robert A et al. (2005) Determination of nanocrystal sizes: a comparison of TEM, SAXS, and XRD studies of highly monodisperse CoPt3 particles. Langmuir 21(5):1931–1936

de Faria DLA, Silva SV, de Oliveira MT (1997) Raman microspectroscopy of some iron oxides and oxyhydroxides. J Raman Spectrosc 28:873–878

Taylor DJ, Fabes BD (1992) Laser processing of Sol-Gel coatings. J Non-Cryst Solids 47:457–462

Malay O, Yilgor I, Menceloglu YZ (2013) Effects of solvent on TEOS hydrolysis kinetics and silica particle size under basic conditions. J Sol-Gel Sci Technol 67(2):351–361

Shuang Zhou et al. (2018) Dissolved silica effects on adsorption and co-precipitation of Sb(III) and Sb(V) with ferrihydrite. Minerals 8(3):101–113

Acknowledgements

We acknowledge the School of Science of Xi’an Jiaotong University for the technical support on XRD measurements.

Funding

This work is financially supported by the National Natural Science Foundation of China (51675409 and 51305331), the Fundamental Research Funds for the Central Universities (xjj2017163), and the key project of Shaanxi province Science and Technology Department (2017ZDXM-GY-115).

Author contributions

Qunfeng Zeng led the project, designed the experiments, and provided scientific and technical advice. Most of the experiments were performed by Shuangli Cai with contributions from both authors. Both authors contributed significantly to the analysis and discussion of the data and the writing of the paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, Q., Cai, S. Low-friction behaviors of Ag-doped γ-Fe2O3@SiO2 nanocomposite coatings under a wide range of temperature conditions. J Sol-Gel Sci Technol 90, 271–280 (2019). https://doi.org/10.1007/s10971-019-04943-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-04943-2