Abstract

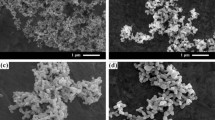

High-purity Y2O3 nanopowder has been prepared by the Pechini sol–gel method using citric acid and ethylene glycol as the chelating agent and complexant of Y3+ cations. The crystal structure of the powder has been studied by means of X-ray diffraction (XRD). In order to evaluate the bonding characteristics of the obtained gel, Fourier transform infrared spectroscopy (FTIR) was carried out. Morphological properties of the nanopowders were examined through field emission scanning electron microscopy (FE-SEM) and transmission electron microscopy (TEM), respectively. Using spark plasma sintering (SPS) at 1100 °C for 5 min under the uniaxial pressure of 100 MPa, the consolidation of the nanopowder was accomplished. Scanning electron microscopy (SEM) was used to investigate the microstructure of compacted pellets. The compacted specimen was made up of grains in the size range of approximately 40 µm. Furthermore, the optical properties of compacted powder were investigated by means of spectrophotometer. The final obtaining Y2O3 pellet exhibited the in-line transmittance of 60 % at the wavelength of 700 nm.

Graphical Abstract

Similar content being viewed by others

References

Suárez M, Fernández A, Torrecillas R, Menéndez JL (2012) Sintering to transparency of polycrystalline ceramic materials. In: Lakshmanan A (ed) Sintering of ceramics–new emerging techniques. InTech, Rijeka, pp 527–552

Harris DC (1998) Durable 3–5μ m transmitting infrared window materials. Infrared Phys Technol 39(4):185–201

Willingham C, Hogan P, Stefanik T, Gentilman R (2004) Transparent yttria for IR windows and domes-past and present. Raytheon integrated Defense Systems, Andover

Skrikanth V, Sato A, Yoshimoto J, Kim J, Ikegami T (1994) Synthesis and crystal structure study of Y2O3 high-pressure polymorph. Crystal Res Technol 29(7):981–984

Zhang P, Navrotsky A, Guo B, Kennedy I, Clark AN, Lesher C, Liu Q (2008) Energetics of cubic and monoclinic yttrium oxide polymorphs: phase transitions, surface enthalpies, and stability at the nanoscale. J Phys Chem C 112(4):932–938

Munoz R (2011) Co-precipitation of Y2O3 powder. Research Thesis, KTH, Stockholm, Sweden

Van Schaik W, Blasse G (1992) Influence of defects on the luminescence quantum yield of yttrium europium oxide (Y1. 94Eu0. 06O3). Chem Mater 4(2):410–415

Som S, Sharma S (2012) Eu3+/Tb3+-codoped Y2O3 nanophosphors: Rietveld refinement, bandgap and photoluminescence optimization. J Phys D Appl Phys 45(41):415102

Sakka S (2005) Handbook of sol-gel science and technology. 1. Sol-gel processing, vol 1. Springer, Berlin

Loghman-Estarki MR, Hajizadeh-Oghaz M, Edris H, Razavi RS (2013) Comparative studies on synthesis of nanocrystalline Sc2O3–Y2O3 doped zirconia (SYDZ) and YSZ solid solution via modified and classic Pechini method. CrystEngComm 15(29):5898–5909

Oghaz MH, Razavi RS, Loghman-Estark MR, Ghasemi R (2012) Optimization of morphology and particle size of modified sol gel synthesized YSZ nanopowder using Taguchi method. In: Journal of nano research, vol 21. Trans Tech Publications, pp 65–70

Hajizadeh-Oghaz M, Razavi RS, Khajelakzay M (2015) Optimizing sol–gel synthesis of magnesia-stabilized zirconia (MSZ) nanoparticles using Taguchi robust design for thermal barrier coatings (TBCs) applications. J Sol-Gel Sci Technol 73(1):227–241

Hajizadeh-Oghaz M, Razavi RS, Estarki ML (2014) Large-scale synthesis of YSZ nanopowder by Pechini method. Bull Mater Sci 37(5):969–973

Hajizadeh-Oghaz M, Razavi RS, Loghman-Estarki MR (2014) Synthesis and characterization of non-transformable tetragonal YSZ nanopowder by means of Pechini method for thermal barrier coatings (TBCs) applications. J Sol-Gel Sci Technol 70(1):6–13

Hajizadeh-Oghaz M, Razavi RS, Ghasemi A (2015) Synthesis and characterization of ceria–yttria co-stabilized zirconia (CYSZ) nanoparticles by sol–gel process for thermal barrier coatings (TBCs) applications. J Sol-Gel Sci Technol 74(3):603–612

Hajizadeh-Oghaz M, Razavi RS, Ghasemi A (2015) The effect of solution pH value on the morphology of ceria–yttria Co stabilized zirconia particles prepared using the polymerizable complex method. J Clust Sci. doi:10.1007/s10876-015-0942-2

Mangalaraja RV, Mouzon J, Hedström P, Camurri CP, Ananthakumar S, Odén M (2009) Microwave assisted combustion synthesis of nanocrystalline yttria and its powder characteristics. Powder Technol 191(3):309–314

Mangalaraja RV, Ramam K, Ravi J, Camurri CP (2008) Synthesis of nanocrystalline yttria by microwave-assisted citrate-gel decomposition technique. J Mater Process Technol 197(1):292–295

Tessari G, Bettinelli M, Speghini A, Ajò D, Pozza G, Depero LE, Allieri B, Sangaletti L (1999) Synthesis and optical properties of nanosized powders: lanthanide-doped Y2O3. Appl Surf Sci 144:686–689

Chavan S, Pillai K, Tyagi A (2006) Combustion synthesis of nanocrystalline yttria: tailoring of powder properties. Mater Sci Eng, B 132(3):266–271

Dasgupta N, Krishnamoorthy R, Jacob KT (2001) Glycol–nitrate combustion synthesis of fine sinter-active yttria. Int J Inorganic Mater 3(2):143–149

Ekambaram S, Patil KC (1995) Combustion synthesis of yttria. J Mater Chem 5(6):905–908

Roy S, Sigmund W, Aldinger F (1997) Grain modification in Y2O3 powders–coarse to nanoporous. J Mater Sci Lett 16(13):1148–1150

Kottaisamy M, Jeyakumar D, Jagannathan R, Mohan Rao M (1996) Yttrium oxide: Eu3+ red phosphor by self-propagating high temperature synthesis. Mater Res Bull 31(8):1013–1020

Saito N, Si Matsuda, Ikegami T (1998) Fabrication of transparent yttria ceramics at low temperature using carbonate-derived powder. J Am Ceramic Soc 81(8):2023–2028

Rulison AJ, Flagan RC (1994) Synthesis of yttria powders by electrospray pyrolysis. J Am Ceramic Soc 77(12):3244–3250

Skandan G, Hahn H, Parker J (1991) Nanostructured Y2O3: synthesis and relation to microstructure and properties. Scr Metall Mater 25(10):2389–2393

Tang Q, Liu Z, Li S, Zhang S, Liu X, Qian Y (2003) Synthesis of yttrium hydroxide and oxide nanotubes. J Crystal Growth 259(1):208–214

Davolos MR, Feliciano S, Pires AM, Marques RF, Jafelicci M Jr (2003) Solvothermal method to obtain europium-doped yttrium oxide. J Solid State Chem 171(1):268–272

Tomaszewski H, Weglarz H, De Gryse R (1997) Crystallization of yttria under hydrothermal conditions. J Eur Ceramic Soc 17(2):403–406

Sharma PK, Jilavi MH, Nar252 R, Schmidt H (1998) Seeding effect in hydrothermal synthesis of nanosize yttria. J Mater Sci Lett 17(10):823–825

Li Q, Feng C, Jiao Q, Guo L, Liu C, Xu HB (2004) Shape‐controlled synthesis of yttria nanocrystals under hydrothermal conditions. Phys Status Solidi (A) 201(14):3055–3059

Richardson K, Akinc M (1987) Preparation of spherical yttrium oxide powders using emulsion evaporation. Ceramics Int 13(4):253–261

Lee M-H, Oh S-G, Yi S-C (2000) Preparation of Eu-doped Y2O3 luminescent nanoparticles in nonionic reverse microemulsions. J Colloid Interface Sci 226(1):65–70

Huang Z, Sun X, Xiu Z, Chen S, Tsai C-T (2004) Precipitation synthesis and sintering of yttria nanopowders. Mater Lett 58(15):2137–2142

Sohn S, Kwon Y, Kim Y, Kim D (2004) Synthesis and characterization of near-monodisperse yttria particles by homogeneous precipitation method. Powder Technol 142(2):136–153

Wen L, Sun X, Lu Q, Xu G, Hu X (2006) Synthesis of yttria nanopowders for transparent yttria ceramics. Opt Mater 29(2):239–245

Li J, Liu W, Jiang B, Zhou J, Zhang W, Wang L, Shen Y, Pan Y, Guo J (2012) Synthesis of nanocrystalline yttria powder and fabrication of Cr, Nd:YAG transparent ceramics. J Alloys Compd 515:49–56

Wen L, Sun X, Xiu Z, Chen S, Tsai C-T (2004) Synthesis of nanocrystalline yttria powder and fabrication of transparent YAG ceramics. J Eur Ceramic Soc 24(9):2681–2688

Sordelet D, Akinc M (1988) Preparation of spherical, monosized Y2O3 precursor particles. J Colloid Interface Sci 122(1):47–59

Khajelakzay M, Shoja Razavi R, Barekat M, Naderi M, Milani M (2016) Synthesis of yttria nanopowders by two precipitation methods and investigation of synthesis conditions. Int J Appl Ceramic Technol 13(1):209–218

Dupont A, Largeteau A, Parent C, Le Garrec B, Heintz JM (2005) Influence of the yttria powder morphology on its densification ability. J Eur Ceramic Soc 25(12):2097–2103

Subramanian R, Shankar P, Kavithaa S, Ramakrishnan S, Angelo P, Venkataraman H (2001) Synthesis of nanocrystalline yttria by sol–gel method. Mater Lett 48(6):342–346

Chen W, Li F, Liu L, Li Y (2006) Synthesis of nano-sized yttria via a sol-gel process based on hydrated yttrium nitrate and ethylene glycol and its catalytic performance for thermal decomposition of NH4ClO4. J Rare Earths 24(5):543–548

Duran P, Tartaj J, Moure C (2002) Sintering behaviour of Y2O3 powders prepared by the polymer complex solution method. Ceramics Int 28(7):791–803

Back M, Massari A, Boffelli M, Gonella F, Riello P, Cristofori D, Riccò R, Enrichi F (2012) Optical investigation of Tb3+-doped Y2O3 nanocrystals prepared by Pechini-type sol–gel process. J Nanopart Res 14(4):1–10

Dupont A, Parent C, Le Garrec B, Heintz J-M (2003) Size and morphology control of Y2O3 nanopowders via a sol–gel route. J Solid State Chem 171(1):152–160

Seaverson L, Luo SQ, Chien PL, McClelland J (1986) Carbonate associated with hydroxide sol-gel processing of yttria. J Am Ceram Soc 69(5):423–429

Jt Langford, Wilson A (1978) Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J Appl Crystallogr 11(2):102–113

Naghibi S, Faghihi Sani MA, Madaah Hosseini HR (2014) Application of the statistical Taguchi method to optimize TiO2 nanoparticles synthesis by the hydrothermal assisted sol–gel technique. Ceramics Int 40(3):4193–4201

Vivekanandhan S, Venkateswarlu M, Satyanarayana N (2005) Effect of different ethylene glycol precursors on the Pechini process for the synthesis of nano-crystalline LiNi0.5 Co0.5VO4 powders. Mater Chem Phys 91(1):54–59

Ejehi F, Marashi S, Ghaani M, Haghshenas D (2012) The synthesis of NaSICON-type ZrNb (PO4)3 structure by the use of Pechini method. Ceramics Int 38(8):6857–6863

Wang S, An C, Zhang Y, Zhang Z, Qian Y (2006) Ethanothermal reduction to MoO2 microspheres via modified Pechini method. J Crystal Growth 293(1):209–215

Worayingyong A, Kangvansura P, Ausadasuk S, Praserthdam P (2008) The effect of preparation: Pechini and Schiff base methods, on adsorbed oxygen of LaCoO3 perovskite oxidation catalysts. Colloids Surf A Physicochem Eng Aspects 315(1):217–225

Tsay J-D, Fang T-T, Gubiotti T, Ying J (1998) Evolution of the formation of barium titanate in the citrate process: the effect of the pH and the molar ratio of barium ion and citric acid. J Mater Sci 33(14):3721–3727

Kakihana M, Arima M, Nakamura Y, Yashima M, Yoshimura M (1999) Spectroscopic characterization of precursors used in the Pechini-type polymerizable complex processing of barium titanate. Chem Mater 11(2):438–450

Abreu A Jr, Zanetti S, Oliveira M, Thim G (2005) Effect of urea on lead zirconate titanate—Pb (Zr0.52 Ti0.48) O3—nanopowders synthesized by the Pechini method. J Eur Ceramic Soc 25(5):743–748

Cullity BD (1957) Elements of X-ray diffraction. Am J Phys 25:394–395

Ghasemi A, Mousavinia M (2014) Structural and magnetic evaluation of substituted NiZnFe2O4 particles synthesized by conventional sol–gel method. Ceramics Int 40(2):2825–2834

ASM Handbook (1979) Metals handbook. Powder metallurgy, vol 9, p 230

Zhang H, Kim BN, Morita K, Yoshida H, Hiraga K, Sakka Y (2011) Fabrication of transparent yttria by high-pressure spark plasma sintering. J Am Ceramic Soc 94(10):3206–3210

Mouzon J, Maitre A, Frisk L, Lehto N, Odén M (2009) Fabrication of transparent yttria by HIP and the glass-encapsulation method. J Eur Ceramic Soc 29(2):311–316

Dressel M, Grüner G (2002) Electrodynamics of solids: optical properties of electrons in matter. Cambridge University Press, Cambridge

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hajizadeh-Oghaz, M., Razavi, R.S., Barekat, M. et al. Synthesis and characterization of Y2O3 nanoparticles by sol–gel process for transparent ceramics applications. J Sol-Gel Sci Technol 78, 682–691 (2016). https://doi.org/10.1007/s10971-016-3986-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-3986-3