Abstract

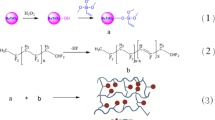

Hybrid materials from poly(vinyl chloride) (PVC) and silica have been prepared using different conditions by the sol–gel technique. In situ generation of silica network in the PVC matrix was carried out by hydrolysis/condensation of tetraethoxysilane (TEOS) in the matrix. Morphology of the silica particles produced in hybrid films was studied by scattering electron microscopy. The shape of silica particle produced in the matrix was modified by carrying out the sol–gel process under steam on the hybrid films using TEOS. The films were subjected to strain conditions during this process, which produced lamellar shaped particles in the matrix. It was possible to produce platelet type of structure with different aspect ratio by changing the composition and the stress conditions on the films during the steaming process. Addition of a very small amount of γ-glycidoxypropyltrimethoxysilane as compatibilizer drastically reduced the silica particles size in the matrix to nano-level. Thermal–mechanical properties of some of these hybrids were studied and related to the composition, structure and inter-phase interaction between the silica and the matrix.

Similar content being viewed by others

References

Braun D (2004) J Polym Sci Part A Polym Chem 42:578–586

Wilkes Charles E, Summers J, Anthony C, Berard Mark T (2005) Handbook. Hanser Verlag, Munich

Titow WV (1986) PVC techanology. Elsevier Applied Science Publisher, London

Narkis M, Shach-Caplan M, Haba Y, Silverstein S (2005) J Vinyl Addit Tech 10:109–120

Ateia E (2005) J Appl Polym Sci 95(4):916–921

Pielichowski K (1999) Eur Polym J 35:27–34

Park IH, Jang J, Chujo Y (1995) Die Ange Makromol Chem 226:1–12

Xu WB, Zhou ZF, Ge ML, Pan WP (2004) Therm Anal Calorim 78:91–99

Gong F, Feng M, Hao C, Shang S, Yang M (2004) Polm Degrad Stab 84:289–294

Ogoshi T, Chujo Y (2003) Bull Chem Soc Japan 76:1865–1871

Cao YM, Sun J, Yu DH (2002) J Appl Polym Sci 83:70–77

Xie XL, Liu QX, Li RKY, Zhou XP, Zhang QX, Yu ZZ (2004) Polymer 45:6665–6673

Hsiue GH, Kuo WH, Huang YP, Jeng RG (2000) Polymer 41:2813–2825

Bialk M, Prucker O, Ruhe J (2002) Colloids Surf A Phsicochem Eng Asp 198–2:543–549

Yoshinaga K, Shimada J, Nishida H, Komatsu M (1999) J Colloid Interf Sci 214(2):180–188

Werne TV, Patten TE (2001) J Am Chem Soc 123:7497–7505

Brinker CJ, Scherer GW (1990) Sol gel science’ the physics and chemistry of sol gel processing. Academic Press, Boston

Al-Sagheer F, Ahmad Z, Muslim S (2008) Int J Polym Mater 57:1–16

Pukanszky B (1990) Composites 21:255–262

Zhu A, Cai A, Zhou W, Shi Z (2008) Appl Surf Sci 254:3745–3752

Zhu A, Cai A, Zhang J, Wang J (2008) J Appl Polym Sci 108:2189–2196

Wu D, Wang X, Song Y, Jin R (2004) J Appl Polym Sci 92:2714–2723

Kelnar I, Schatz M (1993) J Appl Polym Sci 48:669–676

Kelnar I, Schatz M (1993) J Appl Polym Sci 48:657–668

Jorn S, Bard S, Steinar P (1998) J Appl Polym Sci 67:849–853

Gilbert M, Haghighat S, Chua SK, Ng SY (2006) Macromol Symp 233(1):198–202

Gilbert M, Rodriguez-Fernandez OS (1997) J Appl Polym Sci 66:2111–2119

Khan MK, Sarwar MI, Rafiq S, Ahmad Z (1998) Polym Bull 40:583–590

Acknowledgments

The authors wish to acknowledge the financial support provided by the Kuwait University under the project SC03/05. They would also like to appreciate the technical support from the E. M unit and the general facilities projects GS01/01, GS01/05 under the SAF program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Sagheer, F.A., Ahmad, Z. PVC-silica hybrids: effect of sol–gel conditions on the morphology of silica particles and thermal mechanical properties of the hybrids. J Sol-Gel Sci Technol 61, 229–235 (2012). https://doi.org/10.1007/s10971-011-2618-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-011-2618-1