Abstract

The enhancement of mechanical properties of immiscible blend, i.e. polypropylene/ cyclic natural rubber (PP/CNR), could be achieved by incorporating a compatibilizer into the blend system. The main challenge is how to compatibilize the two materials with distinct characteristic of saturated and apolar structures. As compatibilizers, copolymer of maleic anhydride-grafted polypropylene (POLYBOND 3002 and POLYBOND 3200) and maleic anhydride-grafted cyclic natural rubber (CNR-g-MA) were incorporated with PP/CNR (80/20 wt.%) blends in different weight ratios. The impact of those compatibilizers were analysed using Scanning Electron Microscope (SEM), which shows a homogenous phase of PP matrix indicating a homogenous dispersion of CNR into PP matrix. Thermogravimetry (TGA) analysis confirmed that the addition of compatibilizers improved the thermal stability of blends. The Differential Scanning Calorimetry (DSC) curve shows that the glass transition temperature (Tg) was significantly decreased due to the maleic anhydride-grafted polymers incorporation. The decrease of CNR’s Tg value implies that the incorporation of maleic anhydride-grafted polymer into PP/CNR blends can improve blend compatibility. The compatibilization was further confirmed by an increase in tensile strength of compatibilized blends.

Similar content being viewed by others

References

Inuwa IM, Hassan A, Samsudin SA, Haafiz MKM, Jawaid M (2017) Interface modification of compatibilized polyethylene terephthalate/polypropylene blends: effect of compatibilization on thermomechanical properties and thermal stability. J Vinyl Addit Technol 23:45–54. https://doi.org/10.1002/vnl.21484

Lima MS, Matias ÁA, Costa JRC, Fonseca AC, Coelho JFJ, Serra AC (2019) Glycidyl methacrylate-based copolymers as new compatibilizers for polypropylene / polyethylene terephthalate blends. J Polym Res 26:127–141. https://doi.org/10.1007/s10965-019-1784-7

Oswald HJ, Turi E (1965) The deterioration of polypropylene by oxidative degradation. Polym Eng Sci 5:152–158. https://doi.org/10.1002/pen.760050312

Mahendra IP, Wirjosentono B, Tamrin, Ismail H, Mendez JA Characterization and study on compatibility of polypropylene/ cyclic natural rubber blend. Manuscr Submitt Publ

Santos P, Pezzin SH (2003) Mechanical properties of polypropylene reinforced with recycled-pet fibres. J Mater Process Technol 143–144:517–520. https://doi.org/10.1016/S0924-0136(03)00391-1

Barlow JW, Paul DR (1984) Mechanical compatibilization of immiscible blends. Polym Eng Sci 24:525–534. https://doi.org/10.1002/pen.760240804

Martin JD, Velankar SS (2007) Effects of compatibilizer on immiscible polymer blends near phase inversion. J Rheol (N Y N Y) 51:669–692. https://doi.org/10.1122/1.2742391

Utracki LA (2002) Compatibilization of polymer blends. Can J Chem Eng 80:1008–1016. https://doi.org/10.1002/cjce.5450800601

Bagheri-Kazemabad S, Fox D, Chen Y, Geever LM, Khavandi A, Bagheri R, Higginbotham CL, Zhang H, Chen B (2012) Morphology, rheology and mechanical properties of polypropylene/ethylene-octene copolymer/clay nanocomposites: effects of the compatibilizer. Compos Sci Technol 72:1697–1704. https://doi.org/10.1016/j.compscitech.2012.06.007

Chen H, Shi XH, Zhu YF, Zhang Y, Xu JR (2008) Polypropylene surface modification by entrapment of polypropylene-graft-poly(butyl methacrylate). Appl Surf Sci 254:2521–2527. https://doi.org/10.1016/j.apsusc.2007.09.077

Amanizadeh F, Naderi A, Jarestani YC, Kaptan N (2014) Rheologically determined phase behavior and miscibility of reactively compatibilized poly(ethylene terephthalate)/polypropylene blends. Polym Bull 71:1315–1329. https://doi.org/10.1007/s00289-014-1124-3

Papadopoulou CP, Kalfoglou NK (2000) Comparison of compatibilizer effectiveness for PET/PP blends: their mechanical, thermal and morphology characterization. Polymer (Guildf) 41:2543–2555. https://doi.org/10.1016/S0032-3861(99)00442-5

Anjos EGR, Backes EH, Marini J, Pessan LA, Montagna LS, Passador FR (2019) Effect of LLDPE- g -MA on the rheological , thermal , mechanical properties and morphological characteristic of PA6 / LLDPE blends. J Polym Res 26:134–143

Hofmann S (2011) Adhesion promoter system, and method of producing the same

December TS, Nguyen B, Menovcik GG, Merritt WH (2009) Coatings and methods for improved adhesion to plastic

Franco-Marquès E, Méndez JA, Pèlach MA, Vilaseca F, Bayer J, Mutjé P (2011) Influence of coupling agents in the preparation of polypropylene composites reinforced with recycled fibers. Chem Eng J 166:1170–1178. https://doi.org/10.1016/j.cej.2010.12.031

Feng D, Caulfield DF, Sanadi AR (2001) Effect of compatibilizer on the structure-property relationships of kenaf-fiber/polypropylene composites. Polym Compos 22:506–517. https://doi.org/10.1002/pc.10555

Lu B, Chung TC (2000) Synthesis of maleic anhydride grafted polyethylene and polypropylene, with controlled molecular structures. J Polym Sci Part A Polym Chem 38:1337–1343. https://doi.org/10.1002/(SICI)1099-0518(20000415)38:8<1337::AID-POLA18>3.0.CO;2-8

Savas LA, Tayfun U, Dogan M (2016) The use of polyethylene copolymers as compatibilizers in carbon fiber reinforced high density polyethylene composites. Compos Part B Eng 99:188–195. https://doi.org/10.1016/j.phytochem.2016.07.012

Siregar MS (2014) Modifikasi dan Karakterisasi Karet Alam Siklis Substituen Bahan Pengikat Cat Sintetis Modifikasi dan Karakterisasi Karet Alam Siklis. Universitas Sumatera Utara

Esmaeilian F, Sahba Yaghmaee M, Riahifar R, Raissi B (2017) Comparison of wetting models and geometrical analysis in describing the effect of cavity number, size, and position on apparent contact angle. J Adhes Sci Technol 31:1338–1347. https://doi.org/10.1080/01694243.2016.1256633

Yildirim E, Yurtsever M (2012) A comparative study on the efficiencies of polyethylene compatibilizers by using theoretical methods. J Polym Res 19:9771. https://doi.org/10.1007/s10965-011-9771-7

Salleh FM, Hassan A, Yahya R, Lafia-Araga RA, Azzahari AD, Nazir MNZM (2014) Improvement in the mechanical performance and interfacial behavior of kenaf fiber reinforced high density polyethylene composites by the addition of maleic anhydride grafted high density polyethylene. J Polym Res 21:439. https://doi.org/10.1007/s10965-014-0439-y

Tjong SC, Xu SA (1998) Impact and tensile properties of SEBS copolymer compatibilized PS/HDPE blends. J Appl Polym Sci 68:1099–1108. https://doi.org/10.1002/(SICI)1097-4628(19980516)68:7<1099::AID-APP7>3.0.CO;2-A

Rek V, Vranješ N, Šlouf M, Fortelný I, Jelčić Ž (2008) Morphology and properties of SEBS block copolymer compatibilized PS/HDPE blends. J Elastomers Plast 40:237–251. https://doi.org/10.1177/0095244307084906

Dobrovszky K, Ronkay F (2016) Investigation of compatibilization effects of SEBS-g-MA on polystyrene/polyethylene blend with a novel separation method in melted state. Polym Bull 73:2719–2739. https://doi.org/10.1007/s00289-016-1618-2

García-López D, Gobernado-Mitre I, Merino JC, Pastor JM (2007) Effect of the amount and Funtionalization grade of PPgMA Compatibilization agent in polypropylene/clay nanocomposites. Polym Bull 59:667–676. https://doi.org/10.1007/s00289-007-0810-9

Triacca VJ, Gloor PE, Zhu S, Hrymak AN, Hamielec AE (1993) Free radical degradation of polypropylene: random chain scission. Polym Eng Sci 33:445–454. https://doi.org/10.1002/pen.760330802

Braun D, Richter S, Hellmann GP, Ra M (1998) Peroxy-initiated chain degradation, crosslinking, and grafting in PP – PE blends. J Appl Polym Sci 68:2019–2028. https://doi.org/10.1002/(SICI)1097-4628(19980620)68:12<2019::AID-APP16>3.0.CO;2-W

Andreassen E, Myhre OJ, Hinrichsen EL, Grøstad K (1994) Effects of processing parameters and molecular weight distribution on the tensile properties of polypropylene fibers. J Appl Polym Sci 52:1505–1517. https://doi.org/10.1002/app.1994.070521015

Kallel T, Massardier-Nageotte V, Jaziri M, Gérard J-F, Elleuch B (2003) Compatibilization of PE/PS and PE/PP blends. I Effect of processing conditions and formulation. J Appl Polym Sci 90:2475–2484. https://doi.org/10.1002/app.12873

Jurkowski B, Kelar K, Ciesielska D (1998) Influence of chemical and mechanical compatibilization on structure and properties of polyethylene/polyamide blends. J Appl Polym Sci 69:719–727. https://doi.org/10.1002/(SICI)1097-4628(19980725)69:4<719::AID-APP10>3.0.CO;2-K

Das V, Kumar V, Singh A, Gautam SS, Pandey AK (2012) Compatibilization efficacy of LLDPE-g-MA on mechanical, thermal, morphological and water absorption properties of Nylon-6/LLDPE blends. Polym Plast Technol Eng 51:446–454. https://doi.org/10.1080/03602559.2011.639840

Mirzataheri M (2000) The cyclization of natural rubber. Iran J Chem Chem Eng 19:91–96

Patterson DJ, Koenig JL (1987) A Fourier transform infrared and nuclear magnetic resonance study of cyclized natural rubber. Die Makromol Chemie 188:2325–2337

Riyajan SA, Tanaka Y, Sakdapipanich JT (2007) Preparation of cyclized Deproteinized natural rubber in latex state via a combination of Benzotrichloride and sulfuric acid system, and its properties. Rubber Chem Technol 80:365–377. https://doi.org/10.5254/1.3539412

Taeger A, Hoffmann T, Butwilowski W, Heller M, Engelhardt T, Lehmann D (2014) Evidence of chemical compatibilization reaction between poly(ether ether ketone) and irradiation-modified poly(tetrafluoroethylene). High Perform Polym 26:188–196. https://doi.org/10.1177/0954008313506724

Fuentes CA, Zhang Y, Guo H, Woigk W, Masania K, Dransfeld C, de Coninck J, Dupont-Gillain C, Seveno D, van Vuure AW (2018) Predicting the adhesion strength of thermoplastic/glass interfaces from wetting measurements. Colloids Surfaces A 558:280–290. https://doi.org/10.1016/J.COLSURFA.2018.08.052

Jia S, Zhu Y, Wang Z, Chen L, Fu L (2015) Influences of PP-g-MA on the surface free energy, morphologies and mechanical properties of thermoplastic polyurethane / polypropylene blends. J Polym Res 22. https://doi.org/10.1007/s10965-015-0800-9

Ray SS, Bousmina M, Maazouz A (2006) Morphology and properties of organoclay modified polycarbonate/poly(methyl methacrylate) blend. Polym Eng Sci 46:1121–1129. https://doi.org/10.1002/pen.20598

Nam B, Min K, Son Y (2015) Investigation of the nanostructure , thermal stability , and mechanical properties of polylactic acid / cellulose acetate butyrate / clay nanocomposites. Mater Lett 150:118–121. https://doi.org/10.1016/j.matlet.2015.03.019

Acknowledgements

Author thanks the Indonesian Ministry of Research, Technology and Higher Education (KEMENRISTEKDIKTI) for the PMDSU scholarship program and the financial support to conduct the research in Universitat de Girona, Spain through PKPI PMDSU Batch 2 program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

1. The maleic anhydride-grafted polymers can enhance the compatibility of PP/CNR blend

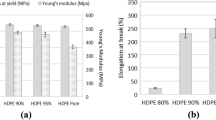

2. The highest mechanical properties were shown by the addition of 1 wt.% of CNR-g-MA

3. Thermal stability was enhanced with the incorporation of maleic anhydride-grafted polymer

Rights and permissions

About this article

Cite this article

Mahendra, I.P., Wirjosentono, B., Tamrin et al. The influence of maleic anhydride-grafted polymers as compatibilizer on the properties of polypropylene and cyclic natural rubber blends. J Polym Res 26, 215 (2019). https://doi.org/10.1007/s10965-019-1878-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1878-2