Abstract

We present a general internal state variable (ISV) elastic-viscoplastic constitutive model that was initially applied to amorphous polymers (Bouvard et al J Eng Mater Technol 131(4), 041206, 2013) but has been extended to apply to semi-crystalline polymers along with a fracture criterion. In this work, we experimentally calibrated and validated the mechanical behavior of two semi-crystalline polymers (a polypropylene (PP) and a copolymer polypropylene (co-PP)) under different stress states, temperatures, and nominal strain rates. The experiments included compression, tension, impact, and three point bending tests with the notion of capturing the time, temperature, stress state dependence, and failure mechanisms under large strains. The ISV model was integrated into a finite element (FE) code and the FE simulations agreed very well with the PP and co-PP mechanical behavior under compression, impact, and three point bending thus exercising the model under different nominal strain rates, temperatures, and stress states. Two failure criteria were determined from the numerical simulations to build failure criteria maps that distinguished brittle and ductile failure as validated by the experimental observations. This study illustrates the generality of the Bouvard et al. (J Eng Mater Technol 131(4), 041206, 2013), which was previously employed to analyze an amorphous polycarbonate polymer.

Similar content being viewed by others

References

Aboulfaraj M, G’sell C, Ulrich B, Dahoun A (1995) In situ observation of the plastic deformation of polypropylene spherulites under uniaxial tension and simple shear in the scanning electron microscope. Polymer 36(4):731–742

Ahzi S, Makradi A, Gregory RV, Edie DD (2003) Modeling of deformation behavior and strain-induced crystallization in poly (ethylene terephthalate) above the glass transition temperature. Mech Mater 35(12):1139–1148

Ames NM, Srivastava V, Chester SA, Anand L (2009) A thermo-mechanically coupled theory for large deformations of amorphous polymers. Part II: Applications. Int J Plast 25(8):1495–1539

Arruda EM, Boyce MC (1993) A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J Mech Phys Solids 41(2):389–412

Bédoui F, Diani J, Régnier G, Seiler W (2006) Micromechanical modeling of isotropic elastic behavior of semicrystalline polymers. Acta Mater 54(6):1513–1523

Bouvard JL, Ward DK, Hossain D, Nouranian S, Marin EB, Horstemeyer MF (2009) Review of hierarchical multiscale modeling to describe the mechanical behavior of amorphous polymers. J Eng Mater Technol 131(4):041206

Bouvard JL, Francis DK, Tschopp MA, Marin EB, Bammann DJ, Horstemeyer MF (2013) An internal state variable material model for predicting the time, thermomechanical, and stress state dependence of amorphous glassy polymers under large deformation. Int J Plast 42:168–193

Bowden PB, Young RJ (1974) Deformation mechanisms in crystalline polymers. J Mater Sci 9(12):2034–2051

Boyce MC, Montagut EL, Argon AS (1992) The effects of thermomechanical coupling on the cold drawing process of glassy polymers. Polym Eng Sci 32(16):1073–1085

Chiu HT, Shiau YG, Chiu WM, Syau SS (1995) Toughening isotactic polypropylene and propylene-ethylene block copolymer with styrene-ethylene butylene-styrene triblock copolymer. J Polym Res 2(1):21–29

Chou CJ, Vijayan K, Kirby D, Hiltner A, Baer E (1988) Ductile-to-brittle transition of rubber-modified polypropylene. J Mater Sci 23(7):2533–2545

Daiyan H, Andreassen E, Grytten F, Lyngstad OV, Luksepp T, Osnes H (2010) Low-velocity impact response of injection-moulded polypropylene plates–part 1: effects of plate thickness, impact velocity and temperature. Polym Test 29(6):648–657

Delhaye V, Clausen AH, Moussy F, Hopperstad OS, Othman R (2010) Mechanical response and microstructure investigation of a mineral and rubber modified polypropylene. Polym Test 29(7):793–802

Drozdov AD (2008) Cyclic elastoplasticity of solid polymers. Comput Mater Sci 42(1):27–35

Drozdov AD, Gupta RK (2003) Constitutive equations in finite viscoplasticity of semicrystalline polymers. Int J Solids Struct 40(23):6217–6243

Dusunceli N, Colak OU (2008) Modelling effects of degree of crystallinity on mechanical behavior of semicrystalline polymers. Int J Plast 24(7):1224–1242

Ebert C, Hufenbach W, Langkamp A, Gude M (2011) Modelling of strain rate dependent deformation behaviour of polypropylene. Polym Test 30(2):183–187

ExxonMobil TM AXO3BE3 Datasheet. 2012

ExxonMobil TM PP1105E1 Datasheet. 2012

Gensler R, Plummer CJG, Grein C, Kausch HH (2000) Influence of the loading rate on the fracture resistance of isotactic polypropylene and impact modified isotactic polypropylene. Polymer 41(10):3809–3819

Gent AN (1996) A new constitutive relation for rubber. Rubber Chem Technol 69(1):59–61

Ghorbel E (2008) A viscoplastic constitutive model for polymeric materials. Int J Plast 24(11):2032–2058

Hongjun C, Xiaolie L, Xiangxu C, Dezhu M, Jianmin W, Hongsheng T (1999) Structure and properties of impact copolymer polypropylene. II. Phase structure and crystalline morphology. J Appl Polym Sci 71(1):103–113

Horstemeyer MF, Bammann DJ (2010) Historical review of internal state variable theory for inelasticity. Int J Plast 26(9):1310–1334. doi:10.1016/j.ijplas.2010.06.005

Ishikawa M, Narisawa I, Ogawa H (1977) Criterion for craze nucleation in polycarbonate. J Polym Sci Polym Phys Ed 15(10):1791–1804

Jourdan C, Cavaille JY, Perez J (1989) Mechanical relaxations in polypropylene: a new experimental and theoretical approach. J Polym Sci B Polym Phys 27(11):2361–2384

Kolarik J, Pegoretti A, Fambri L, Penati A (2000) Polypropylene/elastomer/poly(styrene-co-acrylonitrile) blends: manifestation of the critical volume fraction of SAN in dynamic mechanical, tensile and impact properties. J Polym Res 7(1):7–14

Krempl E, Khan F (2003) Rate (time)-dependent deformation behavior: an overview of some properties of metals and solid polymers. Int J Plast 19(7):1069–1095

Lee BJ, Parks DM, Ahzi S (1993) Micromechanical modeling of large plastic deformation and texture evolution in semi-crystalline polymers. J Mech Phys Solids 41(10):1651–1687

Makradi A, Ahzi S, Gregory RV, Edie DD (2005) A two-phase self-consistent model for the deformation and phase transformation behavior of polymers above the glass transition temperature: application to PET. Int J Plast 21(4):741–758

Marchal Y, Oldenhove B, Daoust D, Legras R, Delannay F (1998) Characterization of the fracture toughness of rubber‐toughened polypropylene thin plates. Polym Eng Sci 38(12):2063–2071

Narisawa I, Yee A (2006) Crazing and fracture of polymers. Mater Sci Technol

Nikolov S, Doghri I (2000) A micro/macro constitutive model for the small-deformation behavior of polyethylene. Polymer 41(5):1883–1891

Nikolov S, Doghri I, Pierard O, Zealouk L, Goldberg A (2002) Multi-scale constitutive modeling of the small deformations of semi-crystalline polymers. J Mech Phys Solids 50(11):2275–2302

Nimmer RP, Woods JT (1992) An investigation of brittle failure in ductile, notch‐sensitive thermoplastics. Polym Eng Sci 32(16):1126–1137

Pawlak A, Galeski A (2005) Plastic deformation of crystalline polymers: the role of cavitation and crystal plasticity. Macromolecules 38(23):9688–9697

Pouriayevali H, Arabnejad S, Guo YB, Shim VPW (2013) A constitutive description of the rate-sensitive response of semi-crystalline polymers. Int J Impact Eng 62:35–47

Regrain C, Laiarinandrasana L, Toillon S, Saï K (2009) Multi-mechanism models for semi-crystalline polymer: constitutive relations and finite element implementation. Int J Plast 25(7):1253–1279

Soni RK, Singh H, Dutt K, Arora P (2010) Effect of dynamic cross-linking on mixing torque behavior and tensile yield behavior of isotactic polypropylene (iPP) / ethylene-propylene diene rubber (EPDM) /nitrile rubber (NBR) elastomeric blends. J Polym Res 17:411–427

Stern C, Frick A, Weickert G (2007) Relationship between the structure and mechanical properties of polypropylene: effects of the molecular weight and shear‐induced structure. J Appl Polym Sci 103(1):519–533

Tai CM, Li RK, Ng CN (2000) Impact behaviour of polypropylene/polyethylene blends. Polym Test 19(2):143–154

Tam WY, Cheung T, Li RKY (1996) An investigation on the impact fracture characteristics of EPR toughened polypropylene. Polym Test 15(4):363–380

Temimi-Maaref N, Burr A, Billon N (2008) Damaging processes in polypropylene compound: experiment and modeling. Polym Sci Ser A 50(5):558–567

Tomita Y, Uchida M (2005) Computational characterization of micro-to mesoscopic deformation behavior of semicrystalline polymers. Int J Mech Sci 47(4):687–700

Uchida M, Tokuda T, Tada N (2010) Finite element simulation of deformation behavior of semi-crystalline polymers with multi-spherulitic mesostructure. Int J Mech Sci 52(2):158–167

Van der Wal A, Gaymans RJ (1999) Polypropylene–rubber blends: 3. The effect of the test speed on the fracture behaviour. Polymer 40(22):6045–6055

Van der Wal A, Nijhof R, Gaymans RJ (1999) Polypropylene–rubber blends: 2. The effect of the rubber content on the deformation and impact behaviour. Polymer 40(22):6031–6044

Van Dommelen JV, Parks DM, Boyce MC, Brekelmans WAM, Baaijens FPT (2003) Micromechanical modeling of the elasto-viscoplastic behavior of semi-crystalline polymers. J Mech Phys Solids 51(3):519–541

Weng G-S, Bao J-B, Xu Y-C, Chen Z-R (2013) New insight into stretch induced structural evolution of α trans-1,4-polyisoprene characterized by real time synchrotron WAXS and SAXS measurements. J Polym Res 20:104

Woods JT, Nimmer RP (2001). Design aids for preventing brittle failure in polycarbonate and polyetherimide. Plastics Failure Analysis and Prevention 267

Woods JT, Trantina GG (1999) Material characterization for predicting impact performance of plastic parts (No. 1999-01-3178). SAE Technical Paper

Wu PD, Van der Giessen E (1995) On neck propagation in amorphous glassy polymers under plane strain tension. Int J Plast 11(3):211–235

Acknowledgments

We would like to thank Mr. Jim Kolb, senior director of Automotive for the American Chemistry Council for funding this effort under Grant No. 011104-001 as well as Dr. Mike Wyzgoski, consultant for American Chemistry Council, for his guidance in this project. The authors would also like to thank ExxonMobil Chemical Company for providing the different thermoplastics investigated in this project and the Center for Advanced Vehicular Systems (CAVS) at Mississippi State University for its support. CAVS acknowledges the collaboration provided through the SIMULIA Research & Development program under which licenses of ABAQUS were provided.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Ductile failure strain

Figure 21 displays the determination of the equivalent plastic strain-to-failure for the impact tests. Applying the ductile failure criterion to the impact tests, the displacement at the point of maximum loading, Udisp, is determined first. The peak load is chosen as the point of failure since the time when cracks or tears begin to appear is unknown. The equivalent plastic strain at this displacement is then found using results from the simulation. The failure strain as a function of strain rate can then be plotted.

Appendix B. Brittle failure criteria

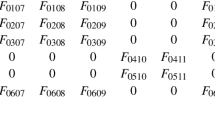

The values for maximum principal stress were calculated from ABAQUS simulations. For each geometry, the maximum principal stress is plotted as a function of displacement as shown in Fig. 22. The maximum principal stress curves display a plateau which has been marked by a dashed line. After the plateau, several of the curves begin to increase again. This increase is the result of a lack of damage in the model and element distortion as the simulation progresses. The stress ratio used by [50] is achieved by normalizing the maximum principal stress obtained from the simulation of the three point bending tests (and estimated from the plateau of the curve) to the yield stress determined from the compression test results. If the stress ratio of a future test is below the stress ratio required for craze initiation, then brittle failure is not a concern.

Rights and permissions

About this article

Cite this article

Bouvard, J.L., Denton, B., Freire, L. et al. Modeling the mechanical behavior and impact properties of polypropylene and copolymer polypropylene. J Polym Res 23, 70 (2016). https://doi.org/10.1007/s10965-016-0947-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-0947-z