Abstract

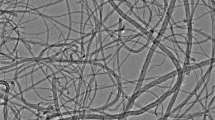

This work analysed the effect of physical and chemical interactions between the modified mutiwalled carbon nanotubes (MWCNTs) and the Polyetherimide/Liquid crystalline polymer (PEI/LCP) blend matrix, on the dispersion of MWCNTs and deformation of LCP particles. Silicon Carbide (SiC) and TiO2 coated MWCNTs were prepared from polycarbosilane and titanium (IV) n- butoxide precursors, respectively, by sol–gel process to improve their dispersion in the polymer matrix. Formation of both was confirmed by X-Ray diffraction (XRD), Transmission Electron Microscope (TEM) and X-Ray photoelectron Spectroscopy (XPS) studies. Polyetherimide (PEI)/liquid crystalline polymer (LCP) blends with unmodified and modified MWCNTs were prepared by melt blending. TEM and Field Electron Scanning Electron microscope (FESEM) studies revealed better dispersion of modified MWCNT in the polymer matrix than the unmodified one. Rheological analysis of hybrid composite systems containing modified and unmodified MWCNT revealed that nano composite containing TiO2 coated MWCNT has the lowest viscosity and this is due to fibrillation of LCP. Superior thermal stability of modified MWCNT added composites was confirmed from thermo-gravimetric analysis (TGA). Dynamic mechanical thermal analysis (DMTA) and Differential Scanning Calorimetry (DSC) studies showed the variation in glass transition temperature (Tg) of the composites in presence of pure and modified MWCNT. Mechanical properties of nanocomposites with TiO2 coated MWCNTs were found to be higher than that of pure MWCNTs added nanocomposite.

Similar content being viewed by others

References

Iijima S (1991) Nature 354:56

Griffith AA (1920) Philos Trans R Soc A 221:163

Weibull WJ (1951) J Appl Mech 293

Liu J, Rinzler AG, Dai H, Hafner JH, Bradley RK, Boul PJ, Lu A, Iverson T, Shelimov K, Huffman CB, Macias FR, Shon YS, Lee TR, Colbert DT, Smalley RE (1998) Science 280:1253

Mawhinney DB, Naumenko V, Kuznetsova A, Yates JT, Liu J, Smalley RE (2000) J Am Chem Soc 122:2383

Dujardin E, Ebbesen TW, Krishnan A, Treacy MMJ (1998) Adv Mater 10:611

Vaccarini L, Goze C, Aznar R, Micholet V, Journet C, Bernier P (1999) Synth Met 103:2492

Hirsch A, Vostrowsky O (2005) Top Curr Chem 245:193

Breuer O, Sundararaj U (2004) Polym Compos 25:630

Gacitua W, Ballerini EA, Zhang AJ (2005) Maderas Ciencia y Tecnologıa 7:159

Bae SW, Kim K, Han YD, Kim SH, Joo J, Choi JH, Lee CJ (2009) Synth Met 159:2034

Abdalla M, Dean D, Adibempe D, Nyairo E, Robinson P, Thompson G (2007) Polymer 48:5662

Yuan WZ, Sun JZ, Dong Y, Haussler M, Yang F, Xu HP (2006) Macromolecules 39:8011

Jiang L, Gao L, Sun J (2003) J Colloid Inter Sci 260:89

Hu H, Yu A, Kim E, Zhou B, Itkis ME, Bekyarova E, Haddon RC (2005) J Phys Chem B 109:11520

Chung TS (2001) CRC Press, London

Demus D, Gray GW, Speiss HW, Goodby JW, Vill V (1998) Handbook of liquid crystals. Wiley-VCH, Weinheim

Datta A, Baird DG (1995) Polymer 36:505

Mukharjee M, Bose S, Nayak GC, Das CK (2010) J Polym Res 17:265

He J, Bu W (1994) Polymer 35:5061

Kim JY, Kim DK, Kim SH (2009) 45:316

Lee MW, Hu X, Li L, Yue CY, Tam KC (2003) Polym Int 52:276

Lee MW, Hu X, Li L, Yue CY, Tam KC, Cheong LY (2003) Comput Sci Technol 63:1921

Chen P, Chen J, Zhang B, Zhang J, He J (2006) J Polym Sci B 44:10

Chen J, Chen P, Wu L, Zhang J, He J (2006) Polymer 47:5402

Nayak GC, Rajasekar R, Das CK (2010) Compos: Part A 41:1662

Nayak GC, Sahoo S, Rajasekar R, Das CK (2012) Compos: Part A 43:1242

Bose S, Mukherjee M, Pal K, Nayak GC, Das CK Polym Adv Technol. doi:10.1002/pat.1425

Huang BS, Chang FY (2010) J Nanopart Res 12:2503

Georgios P, Wolfgang SM (2010) 162:163

Katar SL, Labiosa AB, Plaud AE, Vargas EM, Fonseca L, Weiner BR, Morell G (2010) Nanoscale Res Lett 5:74

Liu JW, Zhong DY, Xie FQ, Sun M, Wang EG, Liu WX (2001) Chem Phy Lett 348:357

Zhuang P, Kyu T, White JL (1988) Polym Eng Sci 28:1095

Siegmann A, Dagan A, Kenig S (1985) Polymer 26:1325

Goel M, Singhal R, Nagpal AK, Kandpal LD (2001) Mater Manuf Process 16:427

Wang D, Li Y, Xie X, Guo BH (2011) Polymer 52:191

Nayak GC, Rajasekar R, Das CK (2010) J Mater Sci 46:165

Lee S, Hong SM, Seo Y, Park TS, Hwang SS (1994) Polymer 35:519

Chatterjee A, Deopura BL (2006) J App Polym Sci 100:3574

Kashiwagi T, Grulke E, Hilding J, Harris R, Awad W, Douglas J (2002) Macromol Rapid Commun 23:761

Marosfoi BB, Szabo A, Marosi G, Tabuani D, Camino G, Pagliari S (2006) J Therm Anal Calorim 86:669

Bose S, Mukharjee M, Das CK, Saxena AK (2010) Polym Compos 31:543

Eshaghi A, Pakshir M, Mozaffarinia R (2010) Mater Sci 33(4):365–369

Zhang L, Tam KC, Gan LH, Yue CY, Lam YC, Hu X (2003) J Appl Polym Sci 87:1484

Lee MW, Hu X, Li L, Yue CY, Tam KC, Cheong LY (2003) Compos Sci Technol 63:1921

Chen P, Chen J, Zhang B, Zhang J, He J (2006) J Polym Sci Part B 44:1020

Saikrasun S, Limpisawasdi P, Amornsakchai T (2009) J Polym Res 16:443

Sun J, Gao L (2006) J Electroceram 17:91

Acknowledgments

We specially thank to UGC New Delhi, India, for granting the kind financial support for the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hatui, G., Das, C.K. Modification of CNT and its effect on thermo mechanical, morphological as well as rheological properties of Polyether Imide (PEI)/Liquid Crystalline Polymer (LCP) blend system. J Polym Res 20, 77 (2013). https://doi.org/10.1007/s10965-013-0077-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0077-9