Abstract

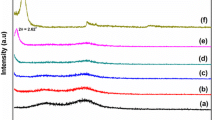

In the present paper, three ammonium salts namely, tetraethylammonium bromide (TEAB), tetrabutylammonium bromide (TBAB), and cetyltrimethylammonium bromide (CTAB) were employed to prepare organoclay by cation exchange process. Polystyrene (PS) /clay nanocomposites were prepared by melt blending using commercial nanoclay and organoclays prepared using above mentioned salts. X-ray diffraction (XRD) and transmission electron microscopy (TEM) analysis indicated that the modified clays were intercalated and/or exfoliated into the polystyrene matrix to a higher extent than the commercial nanoclay. Further, amongst the modified organoclays, TBAB modified clay showed maximum intercalation of clay layers and also exfoliation to some extent into the polystyrene matrix. TEM micrograph exhibited that TBAB modified clay had the best nanoscale dispersion with clay platelet thickness of ∼6–7 nm only. The mechanical properties of the nanocomposites such as tensile, flexural and izod impact strength were measured and analyzed in relation to their morphology. We observed a significant improvement in the mechanical properties of polystyrene/clay nanocomposites prepared with modified clays as compared to commercial organoclay, which followed the order as; PS/TBAB system > PS/CTAB system > PS/TEAB system. Thermogravimetric analysis (TGA) demonstrated that T10, T50 and Tmax were more in case of polystyrene nanocomposites prepared using modified organoclays than nanoclay [nanolin DK4] and maximum being in the case of PS/CTAB system. The results of Differential Scanning Calorimetry (DSC) confirmed that the glass transition temperature of all the nanocomposites was higher as compared to neat polystyrene. The nanocomposites having 2% of TBAB modified clay showed better oxygen barrier performance as compared to polystyrene.

Similar content being viewed by others

References

Bhiwankar NN, Weiss RA (2006) Polymer 47:6684–6691

Messersmith PB, Giannelis EP (1994) Chem Mater 6:1719–1725

Wang MS, Pinnavaia TJ (1994) Chem Mater 6:468–474

Hasegawa N, Okamoto H, Kawasumi M, Usuki A (1999) J Appl Polym Sci 74:3359–3364

Burmistr MV, Sukhyy KM, Shilov VV, Pissis P, Spanoudaki A, Sukha IV, Tomilo VI, Gomza YP (2005) Polymer 46:12226–12232

Su S, Jiang DD, Wilkie CA (2004) Polym Degrad Stab 84:269–277

Su S, Wilkie CA (2003) J Polym Sci Part A: Polym Chem 41:1124–1135

Kong Q, Lv R, Zhang S (2008) J Polym Res 15:453–458

Dazhu C, Haiyang Y, Pingsheng H, Weian Z (2005) Compos Sci Technol 65:1593–1600

Lan T, Kaviratna PD, Pinnavaia TJ (1994) Chem Mater 6:573–575

Chen G, Liu S, Chen S, Qi Z (2001) Macromol Chem Phys 202:1189–1193

Essawy HA, Badran AS, Youssef AM, Hakim A (2004) Macromol Chem Phys 205:2366–2370

He J, Shen Y, Evans DG (2008) Microporous Mesoporous Mater 109:73–83

Ren J, Casanueva BF, Mitchell CA, Krishnamoorti R (2003) Macromolecules 36:4188–4194

Morgan AB, Harris JD (2004) Polymer 45:8695–8703

Zha W, Choi S, Lee KM, Han CD (2005) Macromolecules 38:8418–8429

Shi S, Zhang L, Li J (2009) J Polym Res 16:395–399

Chiu F, Chu P (2006) J Polym Res 13:73–78

Dimitry QIH, Abdeen ZI, Ismail EA, Saad ALG (2009) J Polym Res. doi:10.1007/s10965-009-9371-Y

Turri S, Alborghetti L, Levi M (2008) J Polym Res 15:365–372

Mirmohseni A, Zavareh S (2010) J Polym Res 17:191–201

Dennis HR, Hunter DL, Chang D, Kim S, White JL, Cho JW (2001) Polymer 42:9513–9522

Nshuti C, Wilkie CA (2007) Polym Degrad Stab 92:1803–1812

Mukherji M, Bose S, Nayak GC, Das CK (2010) J Polym Res 17:265–272

As’habi L, Jafari SH, Khonakdar HA, Baghaei B (2010) J Polym Res. doi:10.1007/s10965-010-9407-3

Chow WS, Ooi KH (2007) Malaysian Polym J 2:1–9

Frankowski DJ, Capracotta MD, Martin JD, Khan SA, Spontak RJ (2007) Chem Mater 19:2757–2767

Gilman JW, Awad WH, Davis RD, Shields J, Harris RH Jr, Davis C, Morgan AB, Sutto TE, Callahan J, Trulove PC, Dulong HC (2002) Chem Mater 14:3776–3785

Stretz HA, Paul DR (2006) Polymer 47:8527–8535

Ishida H, Campbell S, Blackwell J (2000) Chem Mater 12:1260–1267

Li LY, Li CY, Ni CY, Rong LX, Hsiao B (2007) Polymer 48:3452–3460

Marales-Teyssier O, Sanchez-Valdes S, Ramos-de Valle LF (2006) Macromol Mater Eng 291:1547–1555

Gryshchuk O, Karger-Koesis J, Thomann R, Konya Z, Kiriesi J (2006) Compos Part A 37:1252–1259

Ghose S, Watson KA, Delozuer DM, Working DC, Siochi EJ, Connell JW (2006) Compos Part A 37:465–475

Mrozek RA, Kim BS, Holmberg VC, Taton TA (2003) Nano Lett 3:1665–1669

Bliznyuk VN, Singamaneni S, Sangford RL, Chiappetta D, Crooker B, Shibaev PV (2006) Polymer 47:3915–3921

Zhao B, Hu H, Haddon RC (2004) Adv Funct Mater 14:71–76

Ago H, Petritseh K, Shaffer MSP, Windle AH, Friend RH (1999) Adv Mater 11:1281–1285

Sonawane S, Chaudhari P, Ghodke S, Ambade S, Gulig S, Mirikar A, Bane A (2008) Ultrason Sonochem 15:1033–1037

Garcia-Lopez D, Gobernado-mitre I, Fernandez JF, Merin JC, Paslor JM (2005) Polymer 46:2758–2765

Dong Y, Bhattacharyya D (2008) Composites: Part A 39:1177–1191

Brostow W, Hagg Lobland HE (2008) Predicting wear from mechanical properties of thermoplastic polymers. Polym Eng Sci 48:1982–1985

Rabello M (2000) Aditivacao de polimeros, Artliber, Sao Paulo, pp 242–247

Maiti SN, Singh G, Ibrahim MN, Appl J (2003) Polym Sci 87:1511–1518

Osman MA, Atallah A, Schweizer T, Ottinger HC (2004) J Rheol 48:1167–1184

Mishra S, Sonawane S, Mukherji A, Mruthyun-jaya HC (2006) J Appl Polym Sci 100:4190–4196

Brostow W, Gorman BP, Olea-Mejia O (2007) Mater Lett 61:1333–1336

Zhelezny L, Kobylyansky Y, Mishchuk O (2007) Chem Technol 1:97–101

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arora, A., Choudhary, V. & Sharma, D.K. Effect of clay content and clay/surfactant on the mechanical, thermal and barrier properties of polystyrene/organoclay nanocomposites. J Polym Res 18, 843–857 (2011). https://doi.org/10.1007/s10965-010-9481-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9481-6