Abstract

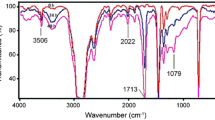

This study shows the effect of a pro-oxidant (oxo-biodegradable) additive on the oxidative thermomechanical degradation of high-density polyethylene (HDPE). It also allows us to predict the behavior of the material when subjected to mechanical recycling or to biodegradation. When HDPE, one of the most consumed thermoplastics worldwide, is transformed into a product or when subjected to primary and/or secondary recycling it will undergo thermomechanical degradation. According to current standards HDPE is not biodegradable, therefore pro-oxidants are added to many HDPE products, which can compromise the product's life. Knowledge on the influence of pro-oxidants on HDPE in the melt is limited and the objective of this study is to assess the behavior of HDPE containing pro-oxidant manganese stearate (MnSt) in the oxidative thermomechanical degradation process. Thermomechanical degradation tests were conducted in a closed-chamber torque rheometer. FTIR and SEC results agreed with those of torque rheometry and showed that oxidative thermomechanical degradation of HDPE increases with increasing manganese stearate concentration. Degradation resulted in an increase in the number of oxygenated functional groups, mainly ketones, aldehydes and carboxylic acids, and reduction in the weight-average molar mass of HDPE. MnSt may have acted both as a lubricant and pro-oxidant during processing with predominance of one or the other effect at different stages along the oxidative thermomechanical degradation of HDPE.

Similar content being viewed by others

References

Malpass DB (2010) Introduction to industrial polyethylene: properties, catalysts, processes. Wiley, Hoboken

Plastic shopping bags Options paper (2016) Environment Protection Authority, Sydney NSW

Robertson GL (2013) Food packaging: principles and practice. Taylor & Francis, Boca Raton

The new plastics economy: rethinking the future of plastics (2016) World Economic Forum

Plastics—the Facts 2018. https://www.plasticseurope.org/en/resources/publications/619-plastics-facts-2018 (accessed august 28, 2018).

Albertsson A-C, Andersson SO, Karlsso S (1987) The mechanism of biodegradation of polyethylene. Polym Degrad Stab 18:73–87

Albertsson A-C, Karlsso S (1988) The three stages in degradation of polymers-polyethylene as a model substance. J Appl Polym Sci 35:1289–1302

Klemchuk PP (1990) Degradable plastics: a critical review. Polym Degrad Stab 27:183–202

Albertsson A-C, Erlandsson B, Hakkarainen M, Karlsson S (1998) Molecular weight changes and polymeric matrix changes correlated with the formation of degradation products in biodegraded polyethylene. J Environ Polym Degrad 6(4):187–195

Vazquez YV, Ressia JA, Cerrada ML, Barbosa SE, Vallés EM (2019) Prodegradant additives effect onto comercial polyolefins. J Polym Environ 27:464–471

Lucas N, Bienaime C, Belloy C, Queneudec M, Silvestre F, Nava-Saucedo J-E (2008) Polymer biodegradation: mechanisms and estimation techniques. Chemosphere 73:429–442

Montazer Z, Habibi-Najafi MB, Mohebbi M, Oromiehei A (2018) Microbial degradation of uv-pretreated low-density polyethylene films by novel polyethylene-degrading bacteria isolated from plastic-dump soil. J Polym Environ 26:3613–3625

Ammala A, Bateman S, Deana K, Petinakis E, Sangwan P, Wong S, Yuana Q, Yu L, Patrick C, Leong KH (2011) An overview of degradable and biodegradable polyolefins. Prog Polym Sci 36:1015–1049

Luckachan GE, Pillai CKS (2011) Biodegradable polymers- A review on recent trends and emerging perspectives. J Polym Environ 19:637–676

Vázquez-Morillas A, Beltrán-Villavicencio M, Alvarez-Zeferino JC, Osada-Velázquez MH, Moreno A, Martínez L, Yañez JM (2016) Biodegradation and ecotoxicity of polyethylene films containing pro-oxidant additive. J Polym Environ 24:221–229

Roy PK, Hakkarainen M, Albertsson A-C (2014) Exploring the biodegradation potential of polyethylene through a simple chemical test method. J Polym Environ 22:69–77

Roy PK, Singh P, Kumar D, Rajagopal C (2010) Manganese stearate initiated photo-oxidative and thermo-oxidative degradation of ldpe, lldpe and their blends. J Appl Polym Sci 117:524–533

Focke WW, Mashele RP, Nhlapo NS (2011) Stabilization of low-density polyethylene films containing metal stearates as photodegradants. J Vinyl Addit Technol 27:21–27

Antunes MC, Agnelli JAM, Babetto AS, Bonse BC, Bettini SHP (2017) Abiotic thermo-oxidative degradation of high density polyethylene: Effect of manganese stearate concentration. Polym Degrad Stab 143:95–103

Maryudi DN, Beg MDH, Yunus RM (2017) Comparison of manganese laurate, manganese palmitate and manganese stearate on accelerating degradation of hdpe during natural weathering. J Teknol (Sciences & Engineering) 79(7):123–130

Antunes MC, Agnelli JAM, Babetto AS, Bonse BC, Correlating BSHP (2018) Different techniques in the thermooxidative degradation monitoring of high density polyethylene containing pro-degradant and antioxidants. Polym Test 69:182–187

Nikolic M, Gauthier E, George K, Cash G, Jonge MD, Howard DL, Paterson D, Laycock B, Halley PJ, George G (2012) Antagonism between transition metal pro-oxidants in polyethylene films. Polym Degrad Stab 97:1178–1188

Osawa Z (1988) Role of metals and metal-deactivators in polymer degradation. Polym Degrad Stab 20:203–236

Liu X, Gao C, Sangwan P, Yu L, Tong Z (2014) Accelerating the degradation of polyolefins through additives and blending. J Appl Polym Sci 131:40750

Portillo F, Yashchuk O, Hermida É (2016) Evaluation of the rate of abiotic and biotic degradation of oxodegradable polyethylene. Polym Test 53:58–69

Jakubowicz I, Enebro J (2012) Effects of reprocessing of oxobiodegradable and non degradable polyethylene on the durability of recycled materials. Polym Degrad Stab 97:316–321

Glowik-Lazarczyk K, Jurczyk S, Chmielnicki B, Konieczny J, Labisz K (2017) Influence of oxo-degradable pe recyclate Addition on the degradation of comercial low density polyethylene (PE-LD). J Environ Prot Ecol 18(3):947–961

Aldas M, Paladines A, Valle V, Pazmiño M, Quiroz F (2018) Effect of the prodegradant-additive plastics incorporated on the polyethylene recycling. Int J Polym Sci. https://doi.org/10.1155/2018/2474176

Ignatyev IA, Thielemans W, Beke BV (2018) Recycling of polymers: a review. Chemsuschem Rev. https://doi.org/10.1002/cssc.201300898

Perugini F, Mastellone ML, Arena U (2005) A life cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environ Prog 24(2):137–154

Menikpura SNM, Gheewala SH, Bonnet S, Chiemchaisri C (2013) Evaluation of the effect of recycling on sustainability of municipal solid waste management in Thailand. Waste Biomass Valor 4:237–257

Dauvergne P (2018) Why is the global governance of plastic failing the oceans? Glob Environ Chang 51:22–31

Wang W, Themelis NJ, Sun K, Bourtsalas AC, Huang Q, Zhang Y, Wu Z (2019) Current influence of China’s ban on plastic waste imports. Waste Dispos Sustain Energy 1:67–78

Al-Salem SM (2019) Influential parameters on natural weathering under harsh climatic conditions of mechanically recycled plastic film specimens. J Environ Manag 230:355–365

Greene JP (2014) Sustainable plastics: Environmental assessments of biobased, biodegradable, and recycled plastics. Wiley, Hoboken

Gugumus F (1999) Physico-chemical aspects of polyethylene processing in open mixers 1: review of published work. Polym Degrad Stab 66:161–172

Epacher E, Tolvétha J, Kröhnke C, Pukánszky B (2000) Processing stability of high density polyethylene: effect of adsorbed and dissolved oxygen. Polymer 41:8401–8408

Pinheiro LA, Chinelatto MA, Canevarolo SV (2004) The role of chain scission and chain branching in high density polyethylene during thermo-mechanical degradation. Polym Degrad Stab 86:445–453

Pinheiro LA, Chinelatto MA, Canevarolo SV (2006) Evaluation of Philips and ZieglereNatta high-density polyethylene degradation during processing in an internal mixer using the chain scission and branching distribution function analysis. Polym Degrad Stab 91:2324–2332

Pielichowski K, Njuguna J (2005) Thermal degradation of polymeric materials. Rapra Technology Limited, Shropshire

Kriston I, Orbán-Mester A, Nagy G, Staniek P, Földes E, Pukánszky B (2009) Melt stabilisation of Phillips type polyethylene, part I: the role of phenolic and phosphorous antioxidants. Polym Degrad Stab 94:719–729

Kriston I, Orbán-Mester A, Nagy G, Staniek P, Földes E, Pukánszky B (2009) Melt stabilisation of Phillips type polyethylene, part II: correlation between additive consumption and polymer properties. Polym Degrad Stab 94:1448–1456

Crompton TR (2010) Thermo-oxidative degradation of polymers. iSmithers Shawbury, Shropshire

Gugumus F (2000) Physico-chemical aspects of polyethylene processing in an open mixer 2. Functional group formation on PELD processing. Polym Degrad Stab 67:35–47

Gugumus F (2000) Physico-chemical aspects of polyethylene processing in an open mixer 3. Experimental kinetics of functional group formation. Polym Degrad Stab 68:21–33

Gugumus F (2000) Physico-chemical aspects of polyethylene processing in an open mixer 5. Kinetics of hydroperoxide formation. Polym Degrad Stab 68:327–336

Gugumus F (2000) Physico-chemical aspects of polyethylene processing in na open mixer 6. Discussion of hydroperoxide formation and decomposition. Polym Degrad Stab 68:337–352

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 17: effect of oxygen availability. Polym Degrad Stab 91:324–338

Gugumus F (2002) Physico-chemical aspects of polyethylene processing in an open mixer 7. Polyethylene hydroperoxide distribution in the melt. Polym Degrad Stab 75:55–71

Gugumus F (2005) Physico-chemical aspects of polyethylene processing in an open mixer. Part 10: mechanisms and formal kinetics of hydroxyl group formation. Polym Degrad Stab 87:245–256

Gugumus F (2005) Physico-chemical aspects of polyethylene processing in an open mixer. Part 11: heterogeneous kinetics of hydroxyl group formation. Polym Degrad Stab 87:449–463

Gugumus F (2005) Physico-chemical aspects of polyethylene processing in an open mixer. Part 13 mechanisms and formal kinetics of ketone formation. Polym Degrad Stab 89:220–232

Gugumus F (2005) Physico-chemical aspects of polyethylene processing in an open mixer. Part 14: product yield on reaction of hydroperoxide with alcohol groups. Polym Degrad Stab 89:240–251

Gugumus F (2005) Physico-chemical aspects of polyethylene processing in an open mixer. Part 15: product yields on bimolecular hydroperoxide decomposition. Polym Degrad Stab 89:517–526

Gugumus F (2005) Physico-chemical aspects of polyethylene processing in an open mixer. Part 16: mechanisms and kinetics of ketone formation at low temperature. Polym Degrad Stab 90:53–66

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 18: mechanisms and kinetics of trans-vinylene group formation. Polym Degrad Stab 91:957–974

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 19: mechanisms and kinetics of vinyl and vinylidene group formation. Polym Degrad Stab 91:1333–1345

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 20: additional product yields on bimolecular hydroperoxide decomposition with an alcohol group. Polym Degrad Stab 91:1346–1355

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 21: improved product yields on true bimolecular hydroperoxide decomposition. Polym Degrad Stab 91:1606–1618

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 22: mechanisms and kinetics of vinyl and vinylidene group consumption. Polym Degrad Stab 91:2061–2078

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 23: mechanisms and kinetics of trans-vinylene group consumption. Polym Degrad Stab 91:2079–2092

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 24: experimental kinetics of aldehyde and carboxylic acid formation. Polym Degrad Stab 91:2499–2512

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 25: mechanisms of aldehyde and carboxylic acid formation. Polym Degrad Stab 91:3416–3428

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 26: formal kinetics of aldehyde and carboxylic acid formation at a constant rate. Polym Degrad Stab 91:2698–2714

Gugumus F (2006) Physico-chemical aspects of polyethylene processing in an open mixer. Part 27: formal kinetics of aldehyde and carboxylic acid formation in the initial stages. Polym Degrad Stab 91:3429–3447

Gugumus F (2007) Physico-chemical aspects of polyethylene processing in an open mixer. Part 28: formal kinetics of aldehyde and carboxylic acid formation in the advanced stages. Polym Degrad Stab 92:125–142

Gugumus F (2007) Physico-chemical aspects of polyethylene processing in an open mixer. Part 32: formal kinetics of g-lactone formation from secondary products Heterogeneous kinetics. Polym Degrad Stab 92:703–719

Sánchez KT, Allen NS, Liauw CM, Johnson B (2011) Effects of type of polymerization catalyst system on the degradation of polyethylenes in the melt state. Part 1: unstabilized polyethylenes (including metallocene types). J Vinyl Addit Technol 17:28–39

Instruction Manual (2007) HAAKE Polylab OS Rheomix 600 OS, Version 1.1. Thermo Electron (Karlsruhe) GmbH, Dieselstraβe 4, D-76227 Karlsruhe, Germany

Meissner J, Hostettler J (1994) A new elongational rheometer for polymer melts and other highly viscoelastic liquids. Rheol Acta 33:1–21

ASTM D2765 (2016) Standard test methods for determination of gel content and swell ratio of crosslinked ethylene plastics

ASTM D11 (2017) Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves

Thompson JM (2018) Infrared spectroscopy. Pan Stanford Publishing, Singapore

Bower DI, Maddams WF (1989) The vibrational spectroscopy of polymers. Cambridge University Press, Cambridge

Rideal GR, Padget JC (1976) The thermal-mechanical degradation of high density polyethylene. J Polym Sci 57:1–15

Al-Malaika S, Peng X, Watson H (2006) Metallocene ethylene-1-octene copolymers: influence of comonomer content on thermo-mechanical, rheological, and thermo-oxidative behaviours before and after melt processing in an internal mixer. Polym Degrad Stab 91:3131–3148

Salvalaggio M, Bagatin R, Fornaroli M, Fanutti S, Palmery S, Battistel E (2006) Multi-component analysis of low-density polyethylene oxidative degradation. Polym Degrad Stab 91:2775–2785

Yang R, Liu Y, Yu J, Wang K (2006) Thermal oxidation products and kinetics of polyethylene composites. Polym Degrad Stab 91:1651–1657

Roy PK, Surekha P, Rajagopal C, Chatterjee SN, Choudhary V (2007) Studies on the photo oxidative degradation of LDPE films in the presence of oxidised polyethylene. Polym Degrad Stab 92:1151–1160

Shen J, Costa L, Xu Y, Cong Y, Cheng Y, Liu X, Fu J (2014) Stabilization of highly crosslinked ultra high molecular weight polyethylene with natural polyphenols. Polym Degrad Stab 105:197–205

Yagoubi W, Abdelhafidi A, Sebaa M, Chabira SF (2015) Identification of carbonyl species of weathered LDPE films by curve fitting and derivative analysis of IR spectra. Polym Test 44:37–48

Measurement Methods for Films and Plastic. Shimadzu Corporation. https://www.shimadzu.com/an/ftir/support/ftirtalk/talk11/intro.html. Accessed 28 Aug 2019

Celina MC (2013) Review of polymer oxidation and its relationship with materials performance and lifetime prediction. Polym Degrad Stab 98:2419–2429

Orden MU, Montes JM, Urreaga JM, Bento A, Ribeiro MR, Pérez E, Cerrada ML (2015) Thermo and photo-oxidation of functionalized metallocene high density polyethylene: effect of hydrophilic groups. Polym Degrad Stab 111:78–88

Mass S, Zweifel H (1989) Degradation and stabilization of high density Polyethylene during multiple extrusions. Polym Degrad Stab 25:217–245

Gugumus F (2002) Re-examination of the thermal oxidation reactions of polymers 2. Thermal oxidation of polyethylene. Polym Degrad Stab 76:329–340

Gugumus F (2002) Re-examination of the thermal oxidation reactions of polymers 3. Various reactions in Polyethylene and Polypropylene. Polym Degrad Stab 77:147–155

Zweifel H, Maier RD, Schiller M (2009) Plastics additives handbook. Carl Hanser Verlag, Munich

Tolinski M (2015) Additives for polyolefins. William Andrew (Elsevier), Oxford

Winter HH (1977) Viscous dissipation in shear flows of molten polymers. Adv Heat Transf 13:205–267

Rauwendaal C (2014) Polymer Extrusion. Carl Hanser Verlag, Munich

Sir Stokes GG (1880–1905) On the effect of the internal friction of fluids on the motion of pendulums. Read december 9, 1850. From the Transactions of the Cambridge Philosophical Society, vol. IX. p. 8. Reprinted in Mathematical and Physical Papers, Sir George Gabriel Stokes and Sir J. Larmor, vol. 3

Valera TS, Demarquette NR, Toffoli SM (2004) Effect of filling factor on the determination of shear rate and viscosity from batch mixer. J Polym Eng 24(4):409–433

Cheremisinoff NP (1993) An introduction to polymer rheology and processing. Taylor & Francis, Boca Raton

Timóteo GAV, Fechine GJM, Rabello MS (2008) Stress cracking and photodegradation behavior of polycarbonate. The combination of two major causes of polymer failure. Polym Eng Sci. https://doi.org/10.1002/pen.21067

Sperling LH (2006) Introduction to physical polymer science. Wiley, Hoboken

Yaday LDS (2005) Organic spectroscopy. Springer, Dordrecht

Sun K, Chen J, Zhao H, Sun W, Chen Y, Luo Z (2019) Dynamic thermomechanical analysis on water tree resistance of crosslinked polyethylene. Materials 12(746):1–11

Reinitz SD, Carlson EM, Levine RAC, Franklin KJ, Van Citters DW (2015) Dynamical mechanical analysis as an assay of cross-link density of orthopaedic ultra high molecular weight polyethylene. Polym Test 45:174–178

Cardoso ECL, Scagliusi SR, Parra DF, Lugão AB (2013) Gamma-irradiated cross-linked LDPE foams: characteristics and properties. Radiat Phys Chem 84:170–175

Morrison RT, Boyd RN (2002) Organic chemistry. Asoke K. Ghosh, Prentice-Hall of India Private Limited, New Delhi

Acknowledgements

The authors acknowledge Centro Universitário FEI and Universidade Federal de São Carlos for the support and infrastructure offered for the accomplishment of this study.

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil (CAPES) – Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Babetto, A.S., Antunes, M.C., Bettini, S.H.P. et al. A Recycling-Focused Assessment of the Oxidative Thermomechanical Degradation of HDPE Melt Containing Pro-oxidant. J Polym Environ 28, 699–712 (2020). https://doi.org/10.1007/s10924-019-01641-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01641-6