Abstract

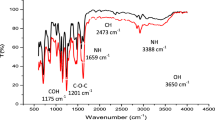

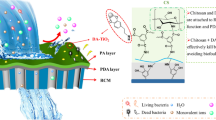

Biofouling is one of the major challenges of membrane technology in water and wastewater treatments. In this work, we investigated the potential of chitosan/chitosan powder activated carbon (PAC) composite to reduce biofouling of membrane. Polyethersulfone (PES) membrane was modified with chitosan/chitosan-PAC composite and the performance of the modified membrane in river water treatment was evaluated. The effect of different concentration of polymer [(chitosan: 2.0% (w/v), 1.0% (w/v), 0.5% (w/v), 0.1% (w/v), and chitosan-PAC composite: 1.5% (w/v) − 1.0 (w/v), 0.5% (w/v) − 0.2% (w/v)] on the membrane performance was examined. The properties of the modified membrane such as roughness, morphology, surface functional groups wettability, swelling ration and contact angle were analyzed. The membrane water flux increased with increasing chitosan concentration from 0.1% (w/v) (7.36 mL/cm2 m) to 1.0% (w/v) (9.46 mL/cm2 m), but decreased at (2.0 w/v) (5.30 mL/cm2 m). However, the water flux for chitosan-PAC-modified membrane was about 6.86 mL/cm2 m, which was slightly lower than unmodified membrane (7.36 mL/cm2 m). The chitosan-modified membrane resulted in 28% reduction in total coliform bacteria while the chitosan-PAC-modified membrane reduced 45% of the total coliform bacteria. These results indicated that chitosan and chitosan-PAC composite could enhance the anti-microbial properties of PES membrane, which would prevent biofilm formation during water treatment.

Similar content being viewed by others

References

Bick A, Gillerman L, Manor Y, Oron G (2012) Economic assessment of an integrated membrane system for secondary effluent polishing for unrestricted reuse. Water 4:219–236. https://doi.org/10.3390/w4010219

Ng YL, Mohammed AW, Leo CP, Hilal N (2013) Polymeric membranes incorporated with metal/metal oxide nanoparticles: a comprehensive review. Desalination 308:15–33. https://doi.org/10.1016/j.desal.2010.11.033

Zhao C, Liu X, Rikimaru S, Nomizu M, Nishi N (2003) Surface characterization of polysulfone membranes modified by DNA immobilization. J Membr Sci 214:179–189

Balta S, Sotto A, Luis P, Benea L, Van Der Bruggen B, Kim J (2012) A new outlook on membrane enhancement with nanoparticles: the alternative of ZnO. J Membr Sci 389:155–161. https://doi.org/10.1016/j.memsci.2011.10.025

Ji H, Xu H, Jin L, Song X, He C, Liu X, Xiong L, Zhao W, Zhao C (2019) Surface engineering of low-fouling and hemocompatible polyethersulfone membranes via in situ ring-opening reaction. J Membr Sci 581:373–382. https://doi.org/10.1016/j.memsci.2019.03.082

Zhao W, Huang J, Fang B, Nie S, Yi N, Su B, Li H, Zhao C (2011) Modification of polyethersulfone membrane by blending semi-interpenetrating network polymeric nanoparticles. J Membr Sci 369:258–266. https://doi.org/10.1016/j.memsci.2010.11.065

Arthanareeswaran G, Mohan D, Raajenthiren M (2010) Preparation, characterization and performance studies of ultrafiltration membranes with polymeric additive. J Membr Sci 350:130–138. https://doi.org/10.1016/j.memsci.2009.12.020

Mierzwa JC, Vecitis CD, Carvalho J, Arieta V, Verlage M (2012) Anion dopant effects on the structure and performance of polyethersulfone membranes. J Membr Sci 421–422:91–102. https://doi.org/10.1016/j.memsci.2012.06.039

Ahn J, Chung W, Pinnau I, Guiver MD (2008) Polysulfone/silica nanoparticle mixed-matrix membranes for gas separation. J Membr Sci 314:123–133. https://doi.org/10.1016/j.memsci.2008.01.031

Kim J, Van Der Bruggen B (2010) The use of nanoparticles in polymeric and ceramic membrane structures: review of manufacturing procedures and performance improvement for water treatment. Environ Pollut 158:2335–2349. https://doi.org/10.1016/j.envpol.2010.03.024

Anadão P, Sato LF, Wiebeck H, Valenzuela-díaz FR (2010) Montmorillonite as a component of polysulfone nanocomposite membranes. Appl Clay Sci 48:127–132. https://doi.org/10.1016/j.clay.2009.12.011

Toledo L, Rivas LB (2015) Quaternised chitosan in conjunction with ultrafiltration membranes to remove arsenate and chromate ions. Polym Bull 72:1341–1344. https://doi.org/10.1007/s00289-015-1341-4

Shao S, Liang H, Qu F, Li K, Chang H, Yu H, Li G (2016) Combined influence by humic acid (HA) and powdered activated carbon (PAC) particles on ultrafiltration membrane fouling. J Membr Sci 500:99–105. https://doi.org/10.1016/j.memsci.2015.11.036

Wang Z, Dong B, Liu J, Zhao D, Tian J, Jia F (2017) Mechanism analysis of powdered activated carbon controlling microfiltration membrane fouling in surface water treatment. Colloids Surf A Physicochem Eng Asp 517:45–51. https://doi.org/10.1016/j.colsurfa.2017.01.009

Oh H, Yu M, Takizawa S, Ohgaki S (2006) Evaluation of PAC behavior and fouling formation in an integrated PAC—UF membrane for surface water treatment. Desalination 192:54–62. https://doi.org/10.1016/j.desal.2005.07.034

Zhang M, Li C, Benjamin MM, Chang Y (2003) Fouling and natural organic matter removal in adsorbent/membrane systems for drinking water treatment. Environ Sci Technol 37:1663–1669. https://doi.org/10.1021/es0260418

Campinas M, Rosa MJ (2010) Assessing PAC contribution to the NOM fouling control in PAC/UF systems. Water Res 44:1636–1644. https://doi.org/10.1016/j.watres.2009.11.012

Cheng X, Li P, Zhou W, Wu D, Luo C (2019) Effect of peroxymonosulfate oxidation activated by powdered activated carbon for mitigating ultrafiltration membrane fouling caused by different natural organic matter fractions. Chemosphere 221:812–823. https://doi.org/10.1016/j.chemosphere.2019.01.081

Salam MA, Makki MSI, Abdelaal MYA (2011) Preparation and characterization of multi-walled carbon nanotubes/chitosan nanocomposite and its application for the removal of heavy metals from aqueous solution. J Alloys Compd 509:2582–2587. https://doi.org/10.1016/j.jallcom.2010.11.094

Bakandritsos A, Kouvelos E, Steriotis T, Petridis D (2005) Aqueous and gaseous adsorption from montmorillonite—carbon composites and from derived carbons. Langmuir 21:2349–2355. https://doi.org/10.1021/la047495g

Yang L, Ma X, Guo N (2012) Sodium alginate/Na+-rectorite composite microspheres: preparation, characterization, and dye adsorption. Carbohydr Polym 90:853–858. https://doi.org/10.1016/j.carbpol.2012.06.011

Hou H, Zhou R, Wu P, Wu L (2012) Removal of Congo red dye from aqueous solution with hydroxyapatite/chitosan composite. Chem Eng J 211–212:336–342. https://doi.org/10.1016/j.cej.2012.09.100

Zhao S, Zhou F, Li L, Cao M, Zuo D, Liu H (2012) Removal of anionic dyes from aqueous solutions by adsorption of chitosan-based semi-IPN hydrogel composites. Compos Part B 43:1570–1578. https://doi.org/10.1016/j.compositesb.2012.01.015

Sheha RR (2012) Preparation and performance of a novel composite as a reactive resin for copper retention. Chem Eng J 213:163–174. https://doi.org/10.1016/j.cej.2012.09.113

Ma J, Jia Y, Jing Y, Yao Y, Sun J (2012) Dyes and pigments kinetics and thermodynamics of methylene blue adsorption by cobalt-hectorite composite. Dye Pigment 93:1441–1446. https://doi.org/10.1016/j.dyepig.2011.08.010

Zhou C, Zhang D, Tong D, Wu L, Yu W, Ismadji S (2012) Paper-like composites of cellulose acetate–organo-montmorillonite for removal of hazardous anionic dye in water. Chem Eng J 209:223–234. https://doi.org/10.1016/j.cej.2012.07.107

Wang Q, Minh A, Cui Y, Delage P, Gatmiri B (2012) Experimental study on the swelling behaviour of bentonite/claystone mixture. Eng Geol 124:59–66. https://doi.org/10.1016/j.enggeo.2011.10.003

Hegab HM, Wimalasiri Y, Ginic-markovic M, Zou L (2015) Improving the fouling resistance of brackish water membranes via surface modification with graphene oxide functionalized chitosan. Desalination 365:99–107. https://doi.org/10.1016/j.desal.2015.02.029

Zinadini S, Zinatizadeh AA, Rahimi M, Vatanpour V, Zangeneh H, Beygzadeh M (2014) Novel high flux antifouling nanofiltration membranes for dye removal containing carboxymethyl chitosan coated Fe3O4 nanoparticles. Desalination 349:145–154. https://doi.org/10.1016/j.desal.2014.07.007

Fini MN, Soroush S, Montazer-Rahmati MM (2018) Synthesis and optimization of chitosan ceramic-supported membranes in pervaporation ethanol dehydration. Membranes (Basel) 8:119. https://doi.org/10.3390/membranes8040119

Zodrow K, Brunet L, Mahendra S, Li D, Zhang A, Li Q, Alvarez PJJ (2009) Polysulfone ultrafiltration membranes impregnated with silver nanoparticles show improved biofouling resistance and virus removal. Water Res 43:715–723. https://doi.org/10.1016/j.watres.2008.11.014

Mnasri N, Moussaoui Y, Elaloui E, Salem R, Lagerge S, Douillard JM, de Menorval LC (2012) Study of interaction between chitosan and active carbon in view of optimising composite gels devoted to heal injuries Study of interaction between chitosan and active carbon in view of optimising composite gels devoted to heal injuries. In: EPJ Web of Conference. 29:1–12. https://doi.org/10.1051/epjconf/20122900028

Elizalde CNB, Al-Gharabli S, Kujawa J, Mavukkandy M, Hasan SW, Arafat HA (2018) Fabrication of blend polyvinylidene fluoride/chitosan membranes for enhanced flux and fouling resistance. Sep Purif Technol 190:68–76. https://doi.org/10.1016/j.seppur.2017.08.053

Çay A, Miraftab M, Akçakoca EP (2014) Characterization and swelling performance of physically stabilized electrospun poly (vinyl alcohol)/chitosan nanofibres. Eur Polym J 61:253–262. https://doi.org/10.1016/j.eurpolymj.2014.10.017

Kyriakopoulos G, Doulia D (2007) Morphology of polymeric resins in adsorption of organic pesticides. Fresenius Environ Bull 16:731–734

Kyriakopoulos G, Doulia D, Hourdakis A (2006) Effect of ionic strength and pH on the adsorption of selected herbicides on Amberlite. Int J Environ Anal Chem 86:207–214. https://doi.org/10.1080/03067310500247678

Kyriakopoulos G, Doulia D, Anagnostopoulos E (2005) Adsorption of pesticides on porous polymeric adsorbents. Chem Eng Sci 60:1177–1186. https://doi.org/10.1016/j.ces.2004.09.080

Ghaee A, Shariaty-Niassar M, Barzin J, Ismail AF (2013) Chitosan/polyethersulfone composite nanofiltration membrane for industrial wastewater treatment. Int J Nanosci Nanotechnol 9:213–220

Cui L, Gao S, Song X, Huang L, Dong H, Liu J, Chen F, Yu S (2018) Preparation and characterization of chitosan membranes. RSC Adv 8:28433–28439. https://doi.org/10.1039/c8ra05526b

Van Der Mei HC, Bos R, Busscher HJ (1998) A reference guide to microbial cell surface hydrophobicity based on contact angles. Colloids Surf B Biointerfaces 11:213–221

Rivas LA, Parro V, Moreno-paz M, Mellado RP (2000) The Bacillus subtilis 168 csn gene encodes a chitosanase with similar properties to a streptomyces enzyme. Microbiology 146:2929–2936

Wieczorek AS, Hetz SA, Kolb S (2014) Microbial responses to chitin and chitosan in oxic and anoxic agricultural soil slurries. Biogeoscience 11:3339–3352. https://doi.org/10.5194/bg-11-3339-2014

Nakashima T, Nakano Y (2005) Biodegradation characteristics of chitin and chitosan films. J Home Econ Jpn 56:889–897

Acknowledgements

The authors acknowledge financial supports from the Institut Pengurusan dan Pemantauan Penyelidikan, University of Malaya, Malaysia under Government Agency [PPP Grant Number, PG345-2016A].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gafri, H.F., Zuki, F.M., Aroua, M.K. et al. Enhancing the Anti-biofouling Properties of Polyethersulfone Membrane Using Chitosan-Powder Activated Carbon Composite. J Polym Environ 27, 2156–2166 (2019). https://doi.org/10.1007/s10924-019-01505-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01505-z