Abstract

The present work reports on the development of a range of poly(methyl methacrylate)/poly(ethylene glycol) (PMMAPEG)-based materials, characterized by different elasticity moduli in order to study the influence of the substrate’s mechanical properties on the response of human umbilical vein endothelial cells (HUVECs). To render the selected materials cell-interactive, a polydopamine (PDA)/gelatin type B (Gel B) coating was applied. Prior to the in vitro assay, the success of the PDA and Gel B immobilization onto the materials was confirmed using X-ray photoelectron spectroscopy (XPS) as reflected by the nitrogen percentages measured for the materials after PDA and Gel B deposition. Tensile tests showed that materials with E-moduli ranging from 37 to 1542 MPa could be obtained by varying the ratio between PMMA and PEG as well as the PEG molecular weight and its functionality (i.e. mono-methacrylate vs. di-methacrylate). The results after 1 day of cell contact suggested a preferred HUVECs cell growth onto more rigid materials. After 1 week, the material with the lowest E-modulus of 37 MPa showed lower cell densities compared to the other materials. No clear correlation could be observed between the number of focal adhesion points and the substrate stiffness. Although minor differences were found, these were not statistically significant. This last conclusion again highlights the universal character of the PDA/Gel B modification. The present work could thus be valuable for the development of a range of cell substrates requiring different mechanical properties in line with the envisaged application while the cell response should ideally remain unaffected.

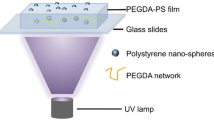

Graphical abstract

Similar content being viewed by others

References

Huang XY, Brittain WJ. Synthesis and characterization of PMMA nanocomposites fby suspension and emulsion polymerization. Macromolecules. 2001;34(10):3255–60.

Zheng W, Wong SC. Electrical conductivity and dielectric properties of PMMA/expanded graphite composites. Compos Sci Technol. 2003;63(2):225–35.

Chen GH, Weng WG, Wu DJ, Wu CL. PMMA/graphite nanosheets composite and its conducting properties. Eur Polym J. 2003;39(12):2329–35.

Mishra SK, Tripathi SN, Choudhary V, Gupta BD. SPR based fibre optic ammonia gas sensor utilizing nanocomposite film of PMMA/reduced graphene oxide prepared by in situ polymerization. Sens Actuators B-Chem. 2014;199:190–200.

Wang T, Shen J-n, Wu L-g, Van der Bruggen B. Improvement in the permeation performance of hybrid membranes by the incorporation of functional multi-walled carbon nanotubes. J Memb Sci. 2014;466:338–47.

Park SJ, Cho MS, Lim ST, Choi HJ, Jhon MS. Synthesis and dispersion characteristics of multi-walled carbon nanotube composites with poly(methyl methacrylate) prepared by in-situ bulk polymerization. Macromol Rapid Commun. 2003;24(18):1070–3.

Sung JH, Kim HS, Jin HJ, Choi HJ, Chin IJ. Nanofibrous membranes prepared by multiwalled carbon nanotube/poly(methyl methacrylate) composites. Macromolecules. 2004;37(26):9899–902.

Jia ZJ, Wang ZY, Xu CL, Liang J, Wei BQ, Wu DH, et al. Study on poly(methyl methacrylate)/carbon nanotube composites. Mater Sci Eng a-Struct Mater Prop Microstruct Process. 1999;271(1-2):395–400.

Hammer P, dos Santos FC, Cerrutti BM, Pulcinelli SH, Santilli CV. Carbon nanotube-reinforced siloxane-PMMA hybrid coatings with high corrosion resistance. Prog Org Coat. 2013;76(4):601–8.

Weng B, Xu F, Salinas A, Lozano K. Mass production of carbon nanotube reinforced poly(methyl methacrylate) nonwoven nanofiber mats. Carbon. 2014;75:217–26.

Wang B, Zhou K, Jiang S, Shi Y, Wang B, Gui Z, et al. Poly(methyl methacrylate)/layered zinc sulfide nanocomposites: preparation, characterization and the improvements in thermal stability, flame retardant and optical properties. Mater Res Bull. 2014;56:107–12.

Li Y, Zhang S, Gao L, Chen W, Gao L, Zhang W, et al. The preparation and characterization of ZnS/PMMA nanocomposites. Synth React Inorg Metal-Org Nano-Metal Chem. 2014;44(7):942–5.

Zhou K, Liu J, Wang B, Zhang Q, Shi Y, Jiang S, et al. Facile preparation of poly(methyl methacrylate)/MoS2 nanocomposites via in situ emulsion polymerization. Mater Lett. 2014;126:159–61.

Okamoto M, Morita S, Taguchi H, Kim YH, Kotaka T, Tateyama H. Synthesis and structure of smectic clay/poly(methyl methacrylate) and clay/polystyrene nanocomposites via in situ intercalative polymerization. Polymer. 2000;41(10):3887–90.

Biasci L, Aglietto M, Ruggeri G, Ciardelli F. Functionalization of montmorillonite by methyl-methacrylate polymers containing side-chain ammonium cations. Polymer. 1994;35(15):3296–304.

Lee DC, Jang LW. Preparation and characterization of PMMA-clay hybrid composite by emulsion polymerization. J Appl Polym Sci. 1996;61(7):1117–22.

Zeng CC, Lee LJ. Poly(methyl methacrylate) and polystyrene/clay nanocomposites prepared by in-situ polymerization. Macromolecules. 2001;34(12):4098–103.

Ash BJ, Schadler LS, Siegel RW. Glass transition behavior of alumina/polymethylmethacrylate nanocomposites. Mater Lett. 2002;55(1-2):83–7.

Landry CJT, Coltrain BK, Brady BK. In situ polymerization of tetraethoxysilane in poly(methyl methacrylate) - morphology and dynamic mechanical properties. Polymer. 1992;33(7):1486–95.

Mu J, Zhou YM, Bu XH, Zhang T. Preparation and characterization of micron-sized PMMA/SiO2 composite microspheres. J Inorg Organomet Polym Mater. 2014;24(4):776–9.

Morales Nieto V, Navarro CH, Moreno KJ, Arizmendi Morquecho A, Chavez Valdez A, Chávez Valdez A, et al. Poly(methyl methacrylate)/carbonated hydroxyapatite composite applied as coating on ultra high molecular weight polyethylene. Prog Org Coat. 2013;76(1):204–8.

Rao M, Su Q, Liu Z, Liang P, Wu N, Quan C, et al. Preparation and characterization of a Poly(methyl methacrylate) based composite bone cement containing poly(acrylate-co-silane) modified hydroxyapatite nanoparticles. J Appl Polym Sci. 2014;131:15.

Mano JF, Sousa RA, Boesel LF, Neves NM, Reis RL. Bloinert Biodegradable and injectable polymeric matrix composites for hard tissue replacement: state of the art and recent developments. Compos Sci Technol. 2004;64(6):789–817.

Kong H, Jang J. Antibacterial properties of novel poly(methyl methacrylate) nanofiber containing silver nanoparticles. Langmuir. 2008;24(5):2051–6.

Araújo E, Hage JrE, Carvalho A. Morphological, mechanical and rheological properties of nylon 6/acrylonitrile-butadiene-styrene blends compatibilized with MMA/MA copolymers. J Mater Sci. 2003;38(17):3515–20.

Fukuda T, Ma YD, Inagaki H. Free‐radical copolymerization, 6. new interpretation for the propagation rate versus composition curve. Die Makromol Chem, Rapid Commun. 1987;8(10):495–9.

Eisa T, Sefton MV. Towards the preparation of a MMA-PEO block copolymer for the microencapsulation of mammalian cells. Biomaterials. 1993;14(10):755–61.

Lloyd AW, Faragher RGA, Denyer SP. Ocular biomaterials and implants. Biomaterials. 2001;22(8):769–85.

El Khadali F, Helary G, Pavon-Djavid G, Migonney V. Modulating fibroblast cell proliferation with functionalized poly(methyl methacrylate) based copolymers: chemical composition and monomer distribution effect. Biomacromolecules. 2002;3(1):51–6.

Evans MDM, Pavon-Djavid G, Helary G, Legeais JM, Migonney W. Vitronectin is significant in the adhesion of lens epithelial cells to PMMA polymers. J Biomed Mater Res A. 2004;69A(3):469–76.

Bar FW, van der Veen FH, Benzina A, Habets J, Koole LH. New biocompatible polymer surface coating for stents results in a low neointimal response. J Biomed Mater Res. 2000;52(1):193–8.

Yang CY, Cao Y, Smith P, Heeger AJ. Morphology of conductive, solution-processed blends of polyanailine and poly(methyl methacrylate). Synth Met. 1993;53(3):293–301.

Tanaka K, Takahara A, Kajiyama T. Film thickness dependence of the surface structure of immiscible polystyrene/poly(methyl methacrylate) blends. Macromolecules. 1996;29(9):3232–9.

Jian X-x, Xiao L-q, Zhou W-l, Xu F-m. Synthesis and characterization of PMMA/PEG-TPE semi-interpenetrating polymer networks. Polym Bull. 2009;63(2):225–33.

Yeung T, Georges PC, Flanagan LA, Marg B, Ortiz M, Funaki M, et al. Effects of substrate stiffness on cell morphology, cytoskeletal structure, and adhesion. Cell Motil Cytoskelet. 2005;60(1):24–34.

Nemir S, West JL. Synthetic materials in the Study of cell response to substrate rigidity. Ann Biomed Eng. 2010;38(1):2–20.

Discher DE, Janmey P, Wang YL. Tissue cells feel and respond to the stiffness of their substrate. Science. 2005;310(5751):1139–43.

Wells RG. The role of matrix stiffness in regulating cell behavior. Hepatology. 2008;47(4):1394–400.

Reinhart-King CA. How matrix properties control the self-assembly and maintenance of tissues. Ann Biomed Eng. 2011;39(7):1849–56.

Lee H, Dellatore SM, Miller WM, Messersmith PB. Mussel-inspired surface chemistry for multifunctional coatings. Science. 2007;318(5849):426–30.

Van de Walle E, Nieuwenhove I, Vanderleyden E, Declercq H, Gellynck K, Schaubroeck D, et al. Polydopamine-gelatin as universal cell-interactive coating for methacrylate-based medical device packaging materials: when surface chemistry overrules substrate bulk properties. Biomacromolecules. 2016;17(1):56–68.

Giol ED, Schaubroeck D, Kersemans K, De Vos F, Van Vlierberghe S, Dubruel P. Bio-inspired surface modification of PET for cardiovascular applications: case study of gelatin. Colloids Surf B-Biointerfaces. 2015;134:113–21.

Zhang K, Bai YX, Wang XF, Li Q, Guan FX, Li JG. Surface modification of esophageal stent materials by a polyethylenimine layer aiming at anti-cancer function. J Mater Sci-Mater Med. 2017;28(8):8.

Singh S, Wu BM, Dunn JCY. Delivery of VEGF using collagen-coated polycaprolactone scaffolds stimulates angiogenesis. J Biomed Mater Res A. 2012;100A(3):720–7.

Anderson SM, Siegman SN, Segura T. The effect of vascular endothelial growth factor (VEGF) presentation within fibrin matrices on endothelial cell branching. Biomaterials. 2011;32(30):7432–43.

Van De Walle E, Van Nieuwenhove I, Vanderleyden E, Declercq H, Gellynck K, Schaubroeck D, et al. Polydopamine–gelatin as universal cell-interactive coating for methacrylate-Based Medical device packaging materials: when surface chemistry overrules substrate bulk properties. Biomacromolecules. 2016;17(1):56–68.

De Vos W, Van Neste L, Dieriks B, Joss G, Van Oostveldt P. High content image cytometry in the context of subnuclear organization. Cytom Part A. 2010;77(1):64–75.

The R Foundation for Statistical Computing. http://www.r-project.org/index.html. 2014.

McGann CL, Dumm RE, Jurusik AK, Sidhu I, Kiick KL. Thiol-ene photocrosslinking of cytocompatible resilin-like polypeptide-peg hydrogels. Macromol Biosci. 2016;16(1):129–38.

Hwang JW, Noh SM, Kim B, Jung HW. Gelation and crosslinking characteristics of photopolymerized poly(ethylene glycol) hydrogels. J Appl Polym Sci. 2015;132(22):6.

Van Vlierberghe S, Schacht E, Dubruel P. Reversible gelatin-based hydrogels: finetuning of material properties. Eur Polym J. 2011;47(5):1039–47.

Zhang QC, Kratz K, Lendlein A. Shape-memory properties of degradable electrospun scaffolds based on hollow microfibers. Polym Adv Technol. 2015;26(12):1468–75.

Van Vlierberghe S, Dubruel P, Lippens E, Masschaele B, Van Hoorebeke L, Cornelissen M, et al. Toward modulating the architecture of hydrogel scaffolds: curtains versus channels. J Mater Sci-Mater Med. 2008;19(4):1459–66.

Primo GA, Igarzabal CIA, Pino GA, Ferrero JC, Rossa M. Surface morphological modification of crosslinked hydrophilic co-polymers by nanosecond pulsed laser irradiation. Appl Surf Sci. 2016;369:422–9.

Pelham RJ, Wang YL. Cell locomotion and focal adhesions are regulated by substrate flexibility. Proc Natl Acad Sci USA. 1997;94(25):13661–5.

Bott K, Upton Z, Schrobback K, Ehrbar M, Hubbell JA, Lutolf MP, et al. The effect of matrix characteristics on fibroblast proliferation in 3D gels. Biomaterials. 2010;31(32):8454–64.

Fioretta ES, Fledderus JO, Baaijens FPT, Bouten CVC. Influence of substrate stiffness on circulating progenitor cell fate. J Biomech. 2012;45(5):736–44.

Califano JP, Reinhart-King CA. A balance of substrate mechanics and matrix chemistry regulates endothelial cell network assembly. Cell Mol Bioeng. 2008;1(2-3):122–32.

Acknowledgements

Sandra Van Vlierberghe would like to acknowledge the Research Foundation-Flanders (FWO, Belgium) for financial support under the form of Research Grants (FWOKN273, G005616N, G0F0516N, FWOAL843). Peter Dubruel would like to acknowledge the Alexander von Humboldt Foundation for financial support in the form of a granted Research Fellowship, as well as the Hercules Foundation (grant AUGE09025). This research has benefitted from a statistical consult with Ghent University FIRE (Fostering Innovative Research based on Evidence).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Van De Walle, E., Van Nieuwenhove, I., De Vos, W. et al. Cell response of flexible PMMA-derivatives: supremacy of surface chemistry over substrate stiffness. J Mater Sci: Mater Med 28, 183 (2017). https://doi.org/10.1007/s10856-017-5994-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-017-5994-4