Abstract

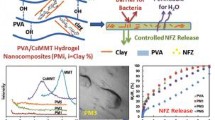

The present study investigates the development of methyl cellulose (MC)–sodium alginate (SA)–montmorillonite (MMT) clay based bionanocomposite films with interesting wound healing properties. The differential scanning calorimetry analysis of the composite films revealed presence of single glass transition temperature (Tg) confirming the miscible nature of the ternary blended films. The increase in MMT ratio in the composite films reduced the mobility of biopolymer chains (MC/SA) which increased the Tg of the film. Thermogravimetric analysis showed that dispersion of clay (MMT) at nano level significantly delayed the weight loss that correlated with higher thermal stability of the composite films. It was observed that the developed films were able to exhibit antimicrobial activity against four typical pathogenic bacteria found in the presence of wound. The developed films were able to significantly inhibit (10 mg/ml) the growth of Enterococcus faecium and Pseudomonas aeruginosa. In vitro scratch assay indicated potential wound closure activities of MC-2–4 bionanocomposite films at their respective highest subtoxic doses. In conclusion, these ternary bionanocomposite films were found to be promising systems for wound healing applications.

Similar content being viewed by others

References

Zahedi P, Rezaeian I, Ranaei-Siadat SO, Jafari SH, Supaphol P. A review on wound dressings with an emphasis on electrospun nanofibrous polymeric bandages. Polym Adv Technol. 2010;21:77–95.

Gupta A, Kumar R, Pal K, Singh V, Banerjee PK, Sawhney RC. Influence of sea buckthorn (Hippophae rhamnoides L.) flavone on dermal wound healing in rats. Mol Cell Biochem. 2006;290:193–8.

Clark RAF. Wound repair: overview and general considerations. In: Clark RA, Henson PM, editors. The molecular and cellular biology of wound repair. New York: Plenum Press; 1996. p. 3–50.

William W, Vincent W. Angiogenesis in wound healing. In: Supplement to contemporary surgery. Montvale: Dowden Health Media; 2003.

Sudheesh Kumar PT, Abhilash S, Manzoor K, Nair SV, Tamura H, Jayakumar R. Preparation and characterization of novel b-chitin/nanosilver composite scaffolds for wound dressing applications. Carbohydr Polym. 2010;80:761–7.

Shuangyun L, Wenjuan G, Gu HY. Construction, application and biosafety of silver nanocrystalline chitosan wound dressing. Burns. 2008;34:623–8.

Sikareepaisan P, Ruktanonchai U, Supaphol P. Preparation and characterization of asiaticoside-loaded alginate films and their potential for use as effectual wound dressings. Carbohydr Polym. 2011;83:1457–69.

Jayakumar R, Prabaharan M, Nair SV, Tamura H. Novel chitin and chitosan nanofibers in biomedical applications. Biotechnol Adv. 2010;28:142–50.

Lin WC, Lien CC, Yeh HJ, Yu CM, Hsu SH. Bacterial cellulose and bacterial cellulose–chitosan membranes for wound dressing applications. Carbohydr Polym. 2013;94:603–11.

Mishra RK, Majeed ABA, Banthia AK. Development and characterization of pectin/gelatin hydrogel membranes for wound dressing. Int J Plast Technol. 2011;15:82–95.

Arockianathan PM, Sekar S, Kumaran B, Sastry TP. Preparation, characterization and evaluation of biocomposite films containing chitosan and sago starch impregnated with silver nanoparticles. Int J Biol Macromol. 2012;50:939–46.

Park JS, Park JW, Ruckenstein E. Thermal and dynamic mechanical analysis of PVA/MC blend hydrogels. Polymer. 2001;42:4271–80.

Teli SB, Gokavi GS, Aminabhavi TM. Novel sodium alginate–poly(N-isopropylacrylamide) semi-interpenetrating polymer network membranes for pervaporation separation of water + ethanol mixtures. Sep Purif Technol. 2007;56:150–7.

Yang L, Ma X, Guo N. Sodium alginate/Na+–rectorite composite microspheres: preparation, characterization, and dye adsorption. Carbohydr Polym. 2012;90:853–8.

Smitha B, Sridhar S, Khan AA. Chitosan–sodium alginate polyion complexes as fuel cell membranes. Eur Polym J. 2005;41:1859–66.

Caykara T, Demirci S, Eroglu MS, Guven O. Poly(ethylene oxide) and its blends with sodium alginate. Polymer. 2005;46:10750–7.

Kong Q, Yu Z, Ji Q, Xia Y. Electrospinning of sodium alginate with poly(ethylene oxide), gelatin and nanometer silver colloid. Mater Sci Forum. 2009;610:1188–91.

Li Z, Zhang M. Chitosan–alginate as scaffolding material for cartilage tissue engineering. J Biomed Mater Res A. 2005;75A:485–93.

Alsberg E, Kong HJ, Hirano Y, Smith MK, Albeiruit A, Mooney DJ. Regulating bone formation via controlled scaffold degradation. J Dent Res. 2003;82:903–8.

Divyarani VV, Ramachandran R, Chennazhi KP, Tamura H, Nair SV, Jayakumar R. Fabrication of alginate/nanoTiO2 needle composite scaffolds for tissue engineering applications. Carbohydr Polym. 2010;83:858–64.

Yang J, Chung TW, Nagaoka M, Goto M, Cho CS, Akaike T. Hepatocyte-specific porous polymer-scaffolds of alginate/galactosylated chitosan sponge for liver-tissue engineering. Biotechnol Lett. 2001;23:1385–9.

Liu H, Chaudhary D, Yusa S, Tade MO. Glycerol/starch/Na+–montmorillonite nanocomposites: a XRD, FTIR, DSC and H NMR study. Carbohydr Polym. 2010;83:1591–7.

Meng N, Zhou NL, Zhang SQ, Shen J. Synthesis and antimicrobial activities of polymer/montmorillonite–chlorhexidine acetate nanocomposite films. Appl Clay Sci. 2009;42:667–70.

Emami-Razavi SH, Esmaeili N, Forouzannia SK, Amanpour S, Rabbani S, Alizadeh AM, Mohagheghi MA. Effect of bentonite on skin wound healing: experimental study in the rat model. Acta Med Iran. 2006;44:235–40.

Gómez-Estaca J, López de Lacey A, López-Caballero ME, Gómez-Guillén MC, Montero P. Biodegradable gelatin–chitosan films incorporated with essential oils as antimicrobial agents for fish preservation. Food Microbiol. 2010;27:889–96.

Wang Q, Hu X, Du Y, Kennedy JF. Alginate/starch blend fibers and their properties for drug controlled release. Carbohydr Polym. 2010;82:842–7.

Pereda M, Ponce AG, Marcovich NE, Ruseckaite RA, Martucci JF. Chitosan–gelatin composites and bi-layer films with potential antimicrobial activity. Food Hydrocoll. 2011;25:1372–81.

Salcedo I, Aguzzi C, Sandri G, Bonferoni MC, Mori M, Carezo P, Sanchez R, Viseras C, Carmella C. In vitro biocompatibility and mucoadhesion of montmorillonite chitosan nanocomposite: a new drug delivery. Appl Clay Sci. 2012;55:131–7.

Popryadukhin PV, Dobrovolskaya IP, Yudin VE, Mvankova IE, Smolyaninov AB, Smirnova NV. Composite materials based on chitosan and mont-morillonite prospects for use as matrix for culturing of stem and regenerative cells. Cell Tissue Biol. 2012;6:82–8.

Yoshii F, Zhanshan Y, Isobe K, Shiozaki K, Makunchi K. Electron beam crosslinked PEO and PEO/PVA hydrogels for wound dressing. Radiat Phys Chem. 1999;55:133–8.

Gao D, Heimann RB. Structure and mechanical properties of superabsorbent poly(acrylamide) montmorillonite composite hydrogels. Polym Gels Netw. 1993;1:225–46.

Churochkina NA, Staroduubstev SG, Khokhlov AR. Swelling and collapse of the gel composite based on neutral and slightly charged poly(acrylamide) gels containing Na–montmorillonite. Polym Gels Netw. 1998;6:205–15.

Viseras C, Aguzzi C, Cerezo P, Bedmar MC. Biopolymer–clay nanocomposites for controlled drug delivery. Mater Sci Technol. 2008;24:1020–6.

Viseras C, Cerezo P, Sanchez R, Salcedo I, Aguzzi C. Current challenges in clay minerals for drug delivery. Appl Clay Sci. 2010;48:291–5.

Sandri G, Bonferoni MC, Ferrari F, Rossi S, Aguzzi C, Mori M, Grisoli P, Cerezo P, Tenci M, Viseras C, Caramella C. Montmorillonite–chitosan–silver sulfadiazine nanocomposites for topical treatment of chronic skin lesions: in vitro biocompatibility, antibacterial efficacy and gap closure cell motility properties. Carbohydr Polym. 2014;102:970–7.

Lee KY, Shim J, Lee HG. Mechanical properties of gellan and gelatin composite films. Carbohydr Polym. 2004;56:251–4.

Rao MS, Kanatt SR, Chawla SP, Sharma A. Chitosan and guar gum composite films: preparation, physical, mechanical and antimicrobial properties. Carbohydr Polym. 2010;82:1243–7.

Eloff JN. A sensitive and quick microplate method to determine the minimal inhibitory concentration of plant extracts for bacteria. Planta Med. 1998;64:711–3.

Hazalin NAMN, Ramasamy K, Lim SM, Wahab IA, Cole ALJ, Majeed ABA. Cytotoxic and antibacterial activities of endophytic fungi isolated from plants at the National Park, Pahang, Malaysia. BMC Complement Altern Med. 2009;5:1–5.

Rimdusit S, Jingjit S, Damrongsakkul S, Tiptipakorn S, Takeichi T. Biodegradability and property characterizations of methyl cellulose: effect of nanocompositing and chemical crosslinking. Carbohydr Polym. 2008;72:444–55.

Ul-Islam M, Khan T, Park JK. Nanoreinforced bacterial cellulose–montmorillonite composites for biomedical applications. Carbohydr Polym. 2012;89:1189–97.

Miura K, Kimura N, Suzuki H, Miyashita Y, Nishio Y. Thermal and viscoelastic properties of alginate/poly(vinyl alcohol) blends cross-linked with calcium tetraborate. Carbohydr Polym. 1999;39:139–44.

Olabishi O, Robeson LM, Shaw MT. Methods for determining polymer–polymer miscibility. In: Polymer–polymer miscibility. New York: Academic Press; 1979. p. 117–193.

Kumar P, Sandeep KP, Alavi S, Truong VD, Gorga RE. Preparation and characterization of bio-nanocomposite films based on soy protein isolate and montmorillonite using melt extrusion. J Food Eng. 2010;100:480–9.

Zohuriaan MJ, Shokrolahi F. Thermal studies on natural and modified gums. Polym Test. 2004;23:575–9.

Tunc S, Angellier H, Cahyana Y, Chalier P, Gontard N, Gastaldi E. Functional properties of wheat gluten/montmorillonite nanocomposite films processed by casting. J Membr Sci. 2007;289:159–68.

Wang SF, Shen L, Tong YJ, Chen L, Phang IY, Lim PQ, Liu TX. Biopolymer chitosan/montmorillonite nanocomposites: preparation and characterization. Polym Degrad Stab. 2005;90:123–31.

Darder M, Colilla M, Ruiz-Hitzky E. Biopolymer–clay nanocomposites based on chitosan intercalated in montmorillonite. Chem Mater. 2003;15:3774–80.

Gunister E, Pestreli D, Unlu CH, Atici O, Gungor N. Synthesis and characterization of chitosan–MMT biocomposite systems. Carbohydr Polym. 2007;67:358–65.

Kanti P, Srigowri K, Madhuri J, Smitha B, Sridhar S. Dehydration of ethanol through blend membranes of chitosan and sodium alginate by pervaporation. Sep Purif Technol. 2004;40:259–66.

Barth C, Goncalves MC, Pires ATN, Roeder J, Walf BA. Asymmetric PS and PES membranes: effect of thermodynamic conditions during formation on their performance. J Membr Sci. 2000;169:287–99.

van de Witte P, Dijkstra PJ, Van den Berg JWA, Feijen J. Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci. 1996;117:1–31.

Agag T, Koga T, Takeichi T. Studies on thermal and mechanical properties of polyimide–clay nanocomposites. Polymer. 2001;42:3399–408.

Xu Y, Zhou J, Hanna MA. Melt-intercalated starch acetate nanocomposite foams as affected by type of organoclay. Cereal Chem. 2005;82:105–10.

Park HM, Misra M, Drzal LT, Mohanty AK. “Green” nanocomposites from cellulose acetate bioplastic and clay: effect of eco-friendly triethyl citrate plasticizer. Biomacromolecules. 2004;5:2281–8.

Prasanth R, Shubha N, Hng HH, Srinivasan M. Effect of nano-clay on ionic conductivity and electrochemical properties of poly(vinylidene fluoride) based nanocomposite porous polymer membranes and their application as polymer electrolyte in lithium ion batteries. Eur Polym J. 2013;49:307–18.

Tunç S, Duman O. Preparation of active antimicrobial methyl cellulose/carvacrol/montmorillonite nanocomposite films and investigation of carvacrol release. LWT Food Sci Technol. 2011;44:465–72.

Tunç S, Duman O. Preparation and characterization of biodegradable methyl cellulose/montmorillonite nanocomposite films. Appl Clay Sci. 2010;48:414–24.

Haq M, Burgueño R, Mohanty AK, Misra M. Processing techniques for bio-based unsaturated-polyester/clay nanocomposites: tensile properties, efficiency, and limits. Composites A. 2009;40:394–403.

Pielesz A, Machnicka A, Sarna E. Antibacterial activity and scanning electron microscopy (SEM) examination of alginate-based films and wound dressings. Ecol Chem Eng. 2011;18:197–210.

Covarrubias SA, de-Bashan LE, Moreno M, Bashan Y. Alginate beads provide a beneficial physical barrier against native microorganisms in wastewater treated with immobilized bacteria and microalgae. Appl Microbiol Biotechnol. 2012;93:2669–80.

Lee YH, Chen B, Lin F, Lin K. Cytotoxic assessment of l-Ascorbic acid/Montmorillonite upon human dermal fibroblasts. In vitro: MTT activity assay. BME. 2008;20:337–43.

Lee YH, Kuo TF, Chen BY, Feng YK, Wen YR, Lin WC, Lin FH. Toxicity assessment of montmorillonite as a drug carrier for pharmaceutical applications: yeast and rats model. BME. 2005;17:72–8.

Haroun A, Gamal-Eldeen A, Harding DRK. Preparation, characterization and in vitro biological study of biomimetic three-dimensional gelatin–montmorillonite/cellulose scaffold for tissue engineering. J Mater Sci Mater Med. 2009;20:2527–40.

Bijman MN, Van Nieuw Amerongen GP, Laurens N, Van Hinsbergh VW, Boven E. Microtubule-targeting agents inhibit angiogenesis at subtoxic concentrations, a process associated with inhibition of Rac1 and Cdc42 activity and changes in the endothelial cytoskeleton. Mol Cancer Ther. 2006;5:2348–57.

Canal-Raffin M, L’azou B, Martinez B, Sellier E, Fawaz F, Robinson P, Brochard P. Physicochemical characteristics and bronchial epithelial cell cytotoxicity of Folpan 80 WG(R) and Myco 500(R), two commercial forms of folpet. Part Fibre Toxicol. 2007;4:1–13.

Vaiana CA, Leonard MK, Drummy LF, Singh KM, Bubulya A, Vaia RA, Naik RR, Kadakia MP. Epidermal growth factor: layered silicate nanocomposites for tissue regeneration. Biomacromolecules. 2011;12:3139–46.

Porter S. The role of the fibroblast in wound contraction and healing. Wounds UK. 2007;3:33–40.

Brem H, Kodra A, Golinko MS, Entero H, Stojadinovic O, Wang VM, Sheahan CM, Weinberg AD, Woo SLC, Ehrlich HP, Tomic-Canic M. Mechanism of sustained release of vascular endothelial growth factor in accelerating experimental diabetic healing. J Investig Dermatol. 2009;129:2257–87.

Acknowledgments

The Universiti Teknologi MARA (UiTM) is thanked for the financial support under the Research Intensive Fund (RIF) 600 RMI/DANA 5/3/RIF (734/2012) and Long Term Research Grant Scheme (600-RMI/LRGS 5/3, 2/2012).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mishra, R.K., Ramasamy, K., Lim, S.M. et al. Antimicrobial and in vitro wound healing properties of novel clay based bionanocomposite films. J Mater Sci: Mater Med 25, 1925–1939 (2014). https://doi.org/10.1007/s10856-014-5228-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-014-5228-y