Abstract

In this paper, the effects of micro-arc oxidation (MAO) surface modification (alumina coatings) on the phase transformation behavior, shape memory characteristics, in vitro haemocopatibility and cytocompatibility of the biomedical NiTi alloy were investigated respectively by differential scanning calorimetry, bending test, hemolysis ratio test, dynamic blood clotting test, platelet adhesion test and cytotoxicity testing by human osteoblasts (Hobs). The results showed that there were no obvious changes of the phase transformation temperatures and shape memory characteristics of the NiTi alloy after the MAO surface modification and the coating could withstand the thermal shock and volume change caused by martensite-austenite phase transformation. Compared to the uncoated NiTi alloys, the MAO surface modification could effectively improve the haemocopatibility of the coated NiTi alloys by the reduced hemolysis ratio, the prolonged dynamic clotting time and the decreased number of platelet adhesion; and the rough and porous alumina coatings could obviously promote the adherence, spread and proliferation of the Hobs with the significant increase of proliferation number of Hobs adhered on the surface of the coated NiTi alloys (P < 0.05).

Similar content being viewed by others

References

Otsuka K, Wayman CM. Shape memory materials. Cambridge: Cambridge University Press; 1998.

Duerig T, Pelton A, Stöckel D. An overview of nitinol medical applications. Mater Sci Eng A. 1999;273–275:149–60.

Shabalovskaya SA. On the nature of the biocompatibility and on medical applications of NiTi shape memory and superelastic alloys. Biomed Mater Eng. 1996;6:267–89.

Kang SB, Yoon KS, Kim JS, Nam TH, Gjunter VE. In vivo result of porous TiNi shape memory alloy: bone response and growth. Mater Trans. 2002;43:1045–8.

Kujala S, Ryhänen J, Jämsä T, et al. Bone modeling controlled by a nickel-titanium shape memory alloy intramedullary nail. Biomaterials. 2002;23:2535–43.

McKay GC, Macnair R, MacDonald C, Grant MH. Interactions of orthopaedic metals with an immortalized rat osteoblast cell line. Biomaterials. 1996;17:1339–44.

Wataha JC, Lockwood PE, Marek M, Ghazi M. Ability of Ni-containing biomedical alloys to activate monocytes and endothelial cells in vitro. J Biomed Mater Res. 1999;45:251–7.

Shabalovskaya S, Anderegg J, Humbeeck JV. Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater. 2008;4:447–67.

Yang CL, Chen FL, Chen SW. Anodization of the dental arch wires. Mater Chem Phys. 2006;100:268–74.

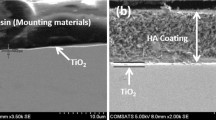

Xu JL, Liu F, Wang FP, Yu ZD, Zhao LC. Microstructure and corrosion resistance behavior of ceramic coatings on biomedical NiTi alloy prepared by micro-arc oxidation. Appl Surf Sci. 2008;254:6642–7.

Xu JL, Liu F, Wang FP, Yu ZD, Zhao LC. The corrosion resistance behavior of Al2O3 coating prepared on NiTi alloy by micro-arc oxidation. J Alloy Compd. 2009;472:276–80.

Liu F, Xu JL, Yu DZ, Wang FP, Zhao LC. Effects of cathodic voltages on the structure and properties of ceramic coatings formed on NiTi alloy by micro-arc oxidation. Mater Chem Phys. 2010;121:172–7.

Liu F, Xu JL, Wang FP, Zhao LC, Shimizu T. Biomimetic deposition of apatite coatings on micro-arc oxidation treated biomedical NiTi alloy. Surf Coat Techol. 2010;204:3294–9.

Liu F, Shimizu T. Effect of NaAlO2 concentrations on structure and characterization of micro-arc oxidation coatings formed on biomedical NiTi alloy. J Ceram Soc Jpn. 2010;118:113–7.

Xu JL, Luo JM, Liu F. Effects of hypophosphate concentrations on the characteristics of micro-arc oxidation coatings formed on biomedical NiTi alloy. Adv Mater Res. 2011;314–316:240–4.

Xue WB, Deng ZW, Lai YC, Chen RY. Analysis of phase distribution for ceramic coatings formed by microarc oxidation on aluminum alloy. J Am Ceram Soc. 1998;81:1365–8.

Yerokhin AL, Leyland A, Matthews A. Kinetic aspects of aluminium titanate layer formation on titanium alloys by plasma electrolytic oxidation. Appl Surf Sci. 2002;200:172–84.

Yerokhin AL, Nie X, Leyland A, Matthews A, Dowey SJ. Plasma electrolysis for surface engineering. Surf Coat Technol. 1999;122:73–93.

Krysmann W, Kurze P, Dittrich KH, Schneider HG. Process characteristics and parameters of anodic oxidation by spark discharge (ANOF). Cryst Res Technol. 1984;19:973–9.

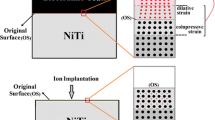

Firstov GS, Vitchev RG, Kumar H, Blanpmn B, Humbeeck JV. Surface oxidation of NiTi shape memory alloy. Biomaterials. 2002;23:4863–71.

Chu CL, Hu T, Chu PK, et al. Surface structure and properties of biomedical NiTi shape memory alloy after Fenton’s oxidation. Acta Biomater. 2007;3:795–806.

Armitage DA, Parker TL, Grant DM. Biocompatibility and hemocompatibility of surface-modified NiTi alloys. J Biomed Mater Res A. 2003;66:129–37.

Yuhta T, Kikuta Y, Mitamura Y, et al. Haemocopatibility of sputter-deposited alumina films. J Biomed Mater Res A. 1994;28:217–24.

Plant SD, Grant DM, Leach L. Surface modification of NiTi alloy and human platelet activation under static and flow conditions. Mater Lett. 2007;61:2864–7.

Zareidoost A, Yousefpour M, Ghaseme B, Amanzadeh A. The relationship of surface roughness and cell response of chemical surface modification of titanium. J Mater Sci Mater Med. 2012;3:1479–88.

Zhao BH, Lee IS, Han IH. Effects of surface morphology on human osteosarcoma cell response. Curr Appl Phys. 2007;7S1:e6–10.

Li LH, Kim HW, Lee SH, et al. Biocompatibility of titanium implants modified by microarc oxidation and hydroxyapatite coating. J Biomed Mater Res A. 2005;73:48–54.

Sul YT. The significance of the surface properties of oxidized titanium to the bone response: special emphasis on potential biochemical bonding of oxidized titanium implant. Biomaterials. 2003;24:3893–907.

Karlsson M, Pålsgård E, Wilshaw PR, Silvio LD. Initial in vitro interaction of osteoblasts with nano-porous alumina. Biomaterials. 2003;24:3039–46.

Finch DS, Oreskovic T, Ramadurai K, Hermann CF, George SM, Mahajan RL. Biocompatibility of atomic layer-deposited alumina thin films. J Biomed Mater Res A. 2008;87:100–6.

Takami Y, Nakazawa T, Makinouchi K, Glueck J, Nose Y. Biocompatibility of alumina ceramic and polyethylene as materials for pivot bearings of a centrifugal blood pump. J Biomed Mater Res. 1997;36:381–6.

Acknowledgments

The work described in this paper was supported by National Natural Science Foundation of China (Project No. 51101085), the science and technology plan projects of Jiangxi Province (Project No. 20111BBG70007-2) and the National Natural Science Foundation of Jiangxi Province (Project No. 20114BAB216014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J.L., Zhong, Z.C., Yu, D.Z. et al. Effect of micro-arc oxidation surface modification on the properties of the NiTi shape memory alloy. J Mater Sci: Mater Med 23, 2839–2846 (2012). https://doi.org/10.1007/s10856-012-4755-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4755-7