Abstract

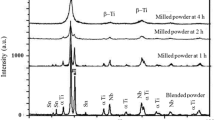

We report on an alternative route for the synthesis of crystalline Co–28Cr–6Mo alloy, which could be used for surgical implants. Co, Cr and Mo elemental powders, mixed in an adequate weight relation according to ISO Standard 58342-4 (ISO, 1996), were used for the mechanical alloying (MA) of nano-structured Co-alloy. The process was carried out at room temperature in a shaker mixer mill using hardened steel balls and vials as milling media, with a 1:8 ball:powder weight ratio. Crystalline structure characterization of milled powders was carried out by X-ray diffraction in order to analyze the phase transformations as a function of milling time. The aim of this work was to evaluate the alloying mechanism involved in the mechanical alloying of Co–28Cr–6Mo alloy. The evolution of the phase transformations with milling time is reported for each mixture. Results showed that the resultant alloy is a Co-alpha solid solution, successfully obtained by mechanical alloying after a total of 10 h of milling time: first Cr and Mo are mechanically prealloyed for 7 h, and then Co is mixed in for 3 h. In addition, different methods of premixing were studied. The particle size of the powders is reduced with increasing milling time, reaching about 5 μm at 10 h; a longer time promotes the formation of aggregates. The morphology and crystal structure of milled powders as a function of milling time were analyzed by scanning electron microscopy and XR diffraction.

Similar content being viewed by others

References

Katti KS. Biomaterials in total joint replacement. Colloids Surf B: Biointerfaces. 2004;39:133–42.

Okazakia Y, Gotoh E. Comparison of metal release from various metallic biomaterials in vitro. Biomaterials. 2005;26:11–21.

Hsua RW, Yang CC, Huangc CA, Chenb YS. Electrochemical corrosion studies on Co–Cr–Mo implant alloy in biological solutions. Mater Chem Phys. 2005;93:531–8.

Runkle JC, Nicholson J, Rice J. A comparison of the fatigue performances of cast, wrought and HIP P/M cobalt-chromium prosthetic alloys. Mod Dev Powder Metall. Proc Int P/M Conf 1984 MPIF. 1985;16:705–25.

Bhat SV. Biomaterials. 2nd ed. Harrow, UK: Alpha Science International Ltd; 2005.

Cordey J. An introduction to selected chapters in bone biomechanics. Injury. 1999;30(Suppl 1):SA1–6.

Kulmburg A, Kvas G, Wiedner G, Golob P, Warbichler P, Schmied M, et al. The microstructure of Co–Cr–Mo-(Nb) dental alloys. Prakt Metall. 2001;9:514–31.

Ramírez-Vidaurri LE, Castro-Román M, Herrera-Trejo M, García-López CV, Almanza-Casas E. Cooling rate and carbon content effect on the fraction of secondary phases precipitate in as-cast microstructure of ASTM F75 alloy. J Mater Proc Technol. 2009;209:1681–7.

Tandon R. Net-shaping of Co–Cr–Mo (F-75) via metal injection molding. In: Disegi JA, Kennedy RL, Pilliar R, editors. Cobalt-base alloys for biomedical Applications. ASTM STP 1365 American Society for Testing and Materials; 1999. pp. 3–10.

German RM. Powder metallurgy and particulate materials. 6th ed. New Jersey: Metals Powder Industries Federation (MPIF); 2005.

Dourandish M, Godlinski D, Simchi A, Firouzdor V. Sintering of biocompatible P/M Co–Cr–Mo alloy F75 for fabrication of porosity-graded composite structures. Mater Sci Eng A. 2008;472:338–46.

Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci. 2001;46:1–184.

El-Eskandarany MS. Mechanical alloying for fabrication of advanced engineering materials. New York: Noyes Publication; 2001.

Amigó V, Vicente A, Romero F, Paolini A, et al. Influence of hip treatment in the evolution of Co–Cr–Mo prothesis carbides. Bol Soc Esp Ceram Vidr. 2004;43:573–7.

Oksiuta Z, Dabrowski JR, Olszyna A. Co–Cr–Mo-based composite reinforced with bioactive glass. J Mater Proc Technol. 2009;209:978–85.

ISO 5832-4:1996(E). Implants for surgery – metallic materials – Part 4. Cobalt–chromium–molybdenum casting alloy; 1996.

Rietveld HM. A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr. 1969;2:65–71.

Lutterotti L, Matthies S, Wenk HR. MAUD: a friendly Java program for material analysis using diffraction. IUCr Newsl CPD. 1999;21:14–5.

Acknowledgments

The authors want to gratefully acknowledge Leticia Baños of the Institute of Materials of UNAM, México for the technical support for X-ray diffraction.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sánchez-De Jesús, F., Bolarín-Miró, A.M., Torres-Villaseñor, G. et al. Mechanical alloying of biocompatible Co–28Cr–6Mo alloy. J Mater Sci: Mater Med 21, 2021–2026 (2010). https://doi.org/10.1007/s10856-010-4066-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-010-4066-9