Abstract

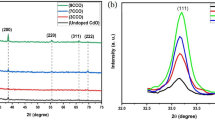

In this work, effects of thickness towards volume proportion of TiO2 nanofilms were deposited on a glass substrate at 500 °C by using ANSP method. The optical profilometer shows the coated films thicknesses were increased (186, 234, 311, 397 and 433 nm) by increasing the volume proportion. Based on the thickness, The XRD reveals a polycrystalline tetragonal anatase phase with decreased particle sizes. The topographical study (AFM) of 3D surface view shows the incremented average roughness (Ra) values. The surface morphological variations with decremented particle size were examined by FESEM. The maximum transmittance ~78.5% (λ = 612.8 nm) is obtained to 186 nm thickness and further increment of thickness shows the decremented value of transmittance with an absorption edge shifted from lower to higher wavelength (blue shift) and the calculated band gap value Eg = 3.65–3.26 eV. The gas sensing performances of films was studied by using a various sensing parameters, obviously C2H6O gas shows highest response (Sm = 13% as 397 nm) at 300 °C for 150 ppm gas concentration against other gasses (NH3, CH4O, C3H8O and C3H6O).

Similar content being viewed by others

References

D. Mardare, N. Iftimie, D. Luca, J. Non-Cryst. Solids 354, 4396–4400 (2008)

I. Vaiciulis, M. Girtan, et al., Proc. Rom. Acad. Seri. A 13(4), 335–342 (2012)

H. Ichiura, T. Kitaoka, H. Tanaka, Chemosphere 50(1), 79–83 (2003)

M.O. Abou-Helal, W.T. Seeber, Appl. Surf. Sci. 195, 53 (2002)

N.E. Stankova, I.G. Dimitrov, et al., Appl. Surf. Sci. 254, 1268 (2007)

I. Poulios, P. Spathis, et al., J. Environ. Sci. Health. A, 34(7), 1455–1471 (1999)

G.P. Burns, J. Appl. Phys. 65, 2095 (1989)

H.G. Choi, S. Yong, D.K. Kim, Kor. J. Mater. Res. 22(7), 352–357 (2012)

V. Gopala Krishnan, P. Elango, et al., Optik-Int. Light Electron Optics 127, 11102–11110 (2016)

H. Tang, K. Prasad, et al., Sens. Actuators B Chem. 26–27(1–3), 71–75 (1995)

K.L. Choy, B. Su, J. Mater. Sci. Lett. 18, 943–945 (1999)

M. Bockmeyer, B. Herbig, et al., Thin Solid Film 517, 1596–1600 (2009)

N. Rausch, E.P. Burte, J. Electrochem. Soc. 140(1), 145–149 (1993)

J-C Orlianges, et al., J. Appl. Surf. Sci. 263, 111–114 (2012)

M. Bouaicha, N. Ghrairi, Nanoscale Res. Lett. 7, 357 (2012)

A.I. Martinez, et al., J. Phys. 16(22), S2335–S2344 (2004)

R. Mariappan, V. Ponnuswamy, et al., Mater. Sci. Semicond. Process. 16, 1328–1335 (2013)

L. Wei, O. Caiwen, P. Huang, et al., Int. J. Electrochem. Sci. 8, 8213–8226 (2013)

I. Oja, A. Mere, M. Krunks, et al., Thin Solid Film 515, 674–677 (2006)

F.D. Duminica, F. Maury, et al., Thin Solid Film 515, 7732–7739 (2007)

H. Zabova, V. Cirkva, J. Chem. Technol. Biotechnol. 84, 1624–1630 (2009)

W. Niu, G. Wang, et al., Int. J. Electrochem. Sci. 10, 2613–2620 (2015)

B.D. Cullity, Elements of X-ray Diffraction, 2nd edn. (Addison-Wesley Publishing Company Inc, Toronto, 1978)

S.K. Joung, T. Amemiya, et al., Chem. Eur. J. 12, 5526–5534 (2006)

M.A. Martynez, C. Guillen, J. Herrero, J. Appl. Surf. Sci. 136, 8 (1998)

D. Mardare, M. Tasca, M. Delibas, et al, J. Appl. Surf. Sci. 156, 200–206 (2000)

N.M. Ganesan, T.S. Senthil, et al., Int. J. Chem. Tech. Res. 6(5), 3078–3082 (2014)

K.Y. Rajpure, C.D. Lokhande, et al., Mater. Res. Bull. 34, 1079–1087 (1999)

A.A. Haidrya, J. Puskelova, et al., Appl. Surf. Sci. 259, 270–275 (2012)

C.H. Han, D.W. Hong, et al., Sens Actuators B Chem. 128, 320–325 (2007)

L.A. Patil, D.N. Suryawanshi, et al., Bull. Mater. Sci. 37(3), 425–432 (2014)

C. Garzella, E. Comini, et al., Sens Actuators B Chem. 68, 189–196 (2000)

P. Shailesh, C. Manik, et al., J. Sensor Technol. 1, 9–16 (2011)

M.R. Vaezi, S.K. Sadrnezhaad, Mater. Sci. Eng. B 140, 73–80 (2007)

H. Windichamann, P. Mark, J. Electrochem. Soc. 126(4), 627–633 (1979)

J. Mizsei, Sens Actuators B Chem. 23, 173–176 (1995)

Acknowledgements

One of the authors (V. Gopala Krishnan) gratefully acknowledges to Dr. T. Shripathi, Dr. U. P. Deshpande and Er. Mohan Gangrade from the UGC—DAE CSR, Indore Centre, Khandwa Road, India for their scientific advice and for providing the necessary laboratory facilities such XPS and AFM measurements for carry out this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krishnan, V.G., Purushothaman, A. & Elango, P. Effect of thickness on the physical properties and gas sensing application: anatase titanium dioxide nanofilms by automated nebulizer spray pyrolysis (ANSP). J Mater Sci: Mater Electron 28, 11473–11481 (2017). https://doi.org/10.1007/s10854-017-6943-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6943-1