Abstract

Co3O4/graphene composites were synthesized and their high catalytic activity for the activation of peroxymonosulfate to remove the azo dye (Orange II) in aqueous solutions was found. As for the poor quality of rGO by the chemical process of graphene oxide, here, pristine graphite was exfoliated into graphene flakes through direct sonication with assistance of cetyltrimethyl ammonium bromide, which serves as a dispersant in the solvothermal procedure. The physical and chemical performance of Co3O4/graphene was characterised by X-ray diffraction, Fourier transform infrared spectroscopy, Raman spectroscopy, X-ray photoelectron spectroscopy, transmission electron microscopy, energy-dispersive X-ray spectroscopy and thermogravimetric analysis. The obtained Co3O4 nanocrystals were 15–25 nm in size and connected with each other to form the shape of sticks dispersing on graphene sheets. The Co3O4/graphene composites completely degraded Orange II solutions within 10 min, the catalyst can be reutilized, and the catalytic activity of the Co3O4/graphene dropped slightly after four successive runs. In addition, the mechanism for the formation of Co3O4/graphene nanostructures is also illustrated.

Similar content being viewed by others

1 Introduction

Azo dyes are widely used in textiles, paper, leather production, coating and the plastic industries, and can strongly damage the environment due to their non-biodegradability, toxicity and potential carcinogenic qualities [1, 2]. Orange II, as a representative of azo dyes, with a major presence in the textile sector, is drawing a lot of attention and research effort [1–3]. Various techniques are being studied to remove it such as physical adsorption, Fenton oxidation methods, biological treatment or photocatalysis [3–5]. Among these technologies, Fenton reaction is the most popular way where hydroxyl radicals (·OH) are usually generated as the main reactive and oxidizing species to degrade organic contaminants. However, the ·OH oxidation process has some drawbacks, such as the high cost of production, transport, storage of H2O2 and pH adjustments.

Presently, an available chemical, peroxymonosulfate (HSO5 −, PMS), has appeared as the producer of SO −·4 which is an inexpensive and environmentally-friendly oxidant that has been proven to be more effective and selective than ·OH for oxidation in several applications [6, 7]. The combination of transition metal ions and PMS promotes the generation of SO −·4 [8] and PMS coupled with Co2+ ions has demonstrated best performance [7]. Nevertheless, disadvantages also exist in the homogeneous system of Co2+/PMS due to the cobalt leachate being biologically toxic and harmful to human health and the environment [1, 5, 9]. Then, many approaches using different techniques to develop the activity and stability of Co2+/PMS heterogeneous systems have been reported. Wang et al. [10] found that Fe3O4/CS-supported Co3O4 nanoparticles exhibit a high activity of PMS activation. Liang et al. [11] used α-MnO2 as the support for Co3O4 nanoparticles, such that the compound produced a significant synergistic effect in PMS activation. Muhammad et al. [12] used coal fly-supported Co3O4 catalysts for phenol degradation using PMS and the catalyst showed higher activity. In our study, a support with excellent properties was chosen to improve the performance of Co2+/PMS heterogeneous system to remove Orange II [13].

An individual graphene sheet exhibits a series of distinct properties, including extremely high electrical conductivity, low thermal resistivity, large carrier mobility, high surface area and exceptional mechanical strength [14, 15]. During the past years, graphene based composites, such as Co3O4/graphene [16, 17], Co(OH)2/graphene [18], MoO2/graphene [19], and NiO/graphene [20], have been extensively explored and reported as the anode or supercapacitor. To the best of our knowledge, limited research on the catalytic reaction of Co3O4/graphene composites has been conducted for the heterogeneous activation of PMS. Chemically reduced graphene oxide (rGO) has widely served as the alternative for pristine graphene, resulting in low-cost, high-yield chemical reduction processes [21, 22]. However, rGO lacks some of the excellent properties of graphene because of several defects and functional groups which could lead to the aggregation of the nanoparticle catalyst on the surface. Recently, several approaches have showed that graphite could be exfoliated in certain solvents such as CTAB to yield a defect-free monolayer graphene [23–25] which results from using special solvents whose surface energy is so well-matched to that of graphene that exfoliation occurs freely [23]. A simple CTAB-assisted solvothermal method used to prepare Co3O4 nanoparticles has been explored as well [26, 27].

Here, we report on Co3O4/graphene composites, prepared through a CTAB-assisted solvothermal method, as efficient heterogeneous catalysts for Orange II degradation by activation of PMS. Physical and chemical characterizations of Co3O4/graphene composites were conducted, and the catalytic activity in heterogeneous reactions was assessed considering the influence of several primary variables (e.g., Orange II and PMS concentration, solution pH, and temperature). The Co3O4/graphene composites demonstrated high catalytic activity and excellent long-term stability for activation of PMS to remove Orange II. Moreover, the mechanism for synthesis of Co3O4/graphene nanostructure is described in this article.

2 Experimental

2.1 Materials

Natural graphite (300 mesh, 99.99 %) was purchased from Aladdin Industrial Corporation. PMS, available as a triple salt of sulfate commercially known as oxone (2KHSO5·KHSO4·K2SO4, 4.5–4.9 % active oxygen), was obtained from Shanghai Ansin Chemical Co. Ltd. and used as an oxidant. Other reagents including cobalt acetate [Co(CH3COO)2·4H2O], Methanol (CH3OH), urea [CO(NH2)2], sodium bicarbonate (NaHCO3), absolute ethanol (CH3CH2OH) and cetyltrimethylammonium bromide [CH3(CH2)15N(CH3)3Br, CTAB] were supplied by Sinopharm Chemical Reagent Co. Ltd. (China). All the other chemicals and reagents used in the experiments were of analytical grade and used without further purification. Deionized water was used throughout.

2.2 Synthesis of Co3O4/graphene composites

The graphene was prepared using a surfactant-assisted liquid-phase exfoliation [28]. First, 1.0 g of graphite was well dispersed in 50 mL of distilled water using 6 mmol (2.18676 g) CTAB by ultrasonication for 10 h. The resulting dispersion was left to stand for approximately 24 h to allow any unstable aggregates to form and then centrifuged for 20 min at 4000 rpm and the top 30 mL of the supernate was decanted by pipet and retained for use. Second, 5 mmol (1.2454 g) of cobalt acetate [Co(CH3COO)2·4H2O] was added into the foregoing supernate (about 0.15 g/L) under vigorous magnetic stirring for 1 h. And 10 mL urea (CO(NH2)2, 0.50 g/L) solution were added slowly to the above mixture, followed by 2 h stirring. After that, the solution was transferred into a Teflon liner, which was sealed in a steel autoclave [29]. The autoclave was maintained at 160 °C for 8 h and then was allowed to cool down to room temperature. The resulting precipitates were separated by filtration, washed with distilled water and absolute ethanol for several times, and then dried in a vacuum oven at 60 °C for 24 h. Finally, the sample was annealed at 500 °C in air for 3 h, Co3O4/graphene composites were successfully fabricated. For a comparison, bare graphene was prepared as the above procedure but without adding Co(CH3COO)2·4H2O. Additionally, Co3O4 was also synthesized with the same parameters by the absence of graphene.

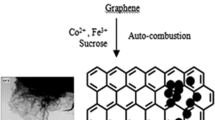

2.3 Mechanism for synthesis of Co3O4/graphene composites

CTAB plays an important role as a cationic surfactant in controlling the formation of micro- and nano-architectures [28, 30]. A graphene solution with a controllable concentration was obtained by controlling the sonication time and initial graphite concentration in the CTAB solution. In this study, 0.5 g of graphite was well-dispersed in 50 mL of distilled water using 6 mmol (2.18676 g) CTAB by sonication for 10 h, followed by centrifugation at 4000 rpm for 20 min to obtain the graphene solution [30]. Within the ultrasonic step, the surfactant cations (CTA+) are expected to be electrostatically adsorbed on the negatively charged surface of the graphene sheets. The resulting process of the surface energy of CTAB is so well-matched to that of graphene that exfoliation occurs freely [31]. The Co(CH3COO)2 and urea [CO(NH2)2] were added to the graphene solution while stirring. Afterward, the solution was transferred into a Teflon liner, which was sealed in a steel autoclave. In this procedure, urea served as a carbonate source because urea decomposes into carbon dioxide and ammonia in aqueous solutions at 160 °C [32]. The reaction between carbon dioxide and hydroxide generates carbonate ions, which reacts with cobalt ions to form cobalt carbonate [33]. The graphene sheets are homogenously and closely decorated with CoCO3 submicrometer crystals because of the existence of CTAB which serves as a dispersant. Afterward, the sample was milled and calcined at 500 °C for 3 h to remove CTAB and other impurities (the TGA curves of the prepared Co3O4/graphene composites was shown in Fig. S1). At the same time, the as-prepared CoCO3/graphene samples under air can be decomposed into Co3O4/graphene composites, carbon dioxide, and carbon monoxide. Therefore, the route for Co3O4/graphene composites based on direct liquid-phase exfoliation is feasible and homogenously produces large graphene sheets closely decorated with well-dispersed Co3O4 nanocrystals (Fig. 1).

2.4 Catalyst characterization

The structure of the Co3O4 and Co3O4/graphene were characterized on a powder X-ray diffraction (XRD) with a BRUKER-D8 X-ray diffractometer using Cu Kα (λ = 1.5418 Å) radiation at a voltage of 40 kV and a current of 40 mA with a scanning speed of 0.01°/s from 10° to 70° (2θ). The changes in the surface chemical bonding and surface composition were characterised by Fourier transform infrared (FT-IR) spectroscopy which was carried out on a SHIMADZU FTIR-8400S spectrometer with a resolution of 4 cm−1 in transmission mode at room temperature. The test samples were pressed into tablets with KBr. Raman measurements were carried out on a Raman spectrometer (LabRAM HR Evolution, Horiba) using the helium–neon laser at 532 nm. The atomic composition of the Co3O4/graphene composites was detected by X-ray photoelectron spectroscopy (XPS). The X-ray photoelectron spectroscopy (XPS) analysis was performed on a ESCALAB 250 photoelectron spectrometer (Thermo VG Scientific, USA) with Al Kα (1486.6 eV) as the X-ray source. The morphology and microstructure of samples were analyzed by transmission electron microscope (TEM). TEM/HRTEM images and selected area energy dispersive X-ray spectroscopy (EDS) were obtained using a JEM-2100 transmission electron microscope (TEM) equipped with a Link EDS detector operated at 200 kV. The sample was prepared by dispersing a small amount of dry powder in ethanol. The leached Co2+ ion was measured by inductively coupled plasma (ICP-PS3500DD, HITACHI) Solutions were obtained during the reactions, filtered, and mixed with 10 % nitric acid aqueous solution before analysis.

2.5 Catalyst performance

The 100 mL Orange II (0.2 mM) was carried out in a 250 mL glass vessel. The reactor was placed in a water-bathing constant-temperature oscillator with constantly stirring. Oxone (1 mM, which is necessary to release 2 mM PMS), as the oxidant, was added to the reactor and the pH of the reactive solution was adjusted to the suitable value by NaHCO3 (0.5 M). Later the catalyst (5 mg, 0.05 g/L) joined the above mixture to start the reaction. Aqueous phase samples (5.0 mL) were withdrawn at periodic intervals, joined immediately with an equal volume of methanol as quencher and then filtered (0.22 μm) to remove the catalyst samples. The concentration of Orange II without samples was analyzed by UV–Vis spectrophotometry (SHIMADZU UV-2550) at the maximum absorption band (486 nm). Co3O4/graphene, Co3O4, graphene were used for the degradation. The experiment was conducted at different pH from 4.0 to 10.0. Oxone was used at several dosages from 1.0 to 2.5 mM. Orange II was tested at three initial concentrations from 0.1 to 0.3 mM. The degradation rate under different catalyst dosage (0.025, 0.050 and 0.075 g/L) are also investigated. The reaction was detected at different temperatures (15, 25, 35 and 45 °C). For recycled catalyst tests, the catalyst was collected by centrifugation and thoroughly washed with distilled water and ethanol after each recycle. Then, the catalyst was dried in a vacuum oven overnight.

3 Results and discussion

3.1 Catalyst characterization

XRD is an effective way to investigate the crystalline properties of the synthesized material. XRD patterns of Co3O4/graphene composites, Co3O4 and the precursor of Co3O4 before calcining are shown in Fig. 2. As shown in Fig. 2a, all the characteristic peaks of the prepared Co3O4 samples are in good agreement with the crystalline Co3O4 (JCPDS: 43-1003) [16], indicating that the Co3O4 is well prepared. Furthermore, except a small and low broad diffraction peak appears around 26°, which attributed to the (002) reflection of graphene sheets [5], all of the other characteristic peaks can be indexed to the well-crystallized Co3O4 (JCPDS: 43-1003) [16]. The diffraction peaks at 2θ = 18.93°, 31.25°, 36.88°, 44.84° and 59.4° for Co3O4/graphene composites can be indexed to the (111), (220), (311), (400) and (511) reflections of Co3O4. These results demonstrate that the composites consist of homogeneously dispersed graphene sheets and well-crystallized Co3O4, and no impurities in the as-prepared Co3O4/graphene composites. Figure 2b shows the XRD spectra of the precursor of Co3O4 before calcining. All the peaks of the precursor of Co3O4 are in accordance with the characteristic peaks of CoCO3 (JCPDS: 11-0692). The result proves that urea generates carbonate ions, which reacts with cobalt ions to form cobalt carbonate in an autoclave.

The FT-IR spectra are used to analyze the obtained nanocrystals. Figure 3 shows the FT-IR spectra of Co3O4/graphene composites, two strong characteristic absorptions at 660 and 570 cm−1 are attributed to the formation of Co3O4. The peak at 1618 cm−1 (aromatic C=C) can be ascribed to skeletal vibrations of graphitic domains. The peak at 3424 cm−1 in the FT-IR spectrum of Co3O4/graphene composites was assigned as O–H stretching vibration relating to absorbed water on the surface that comes from the air [34]. In the FT-IR spectrum of Co3O4/graphene composites, the corresponding absorption peaks were shown, which confirmed that the composites were successfully produced. The results indicate that the number of functional groups that on the surface of as-prepared graphene are extremely less than the reduced graphene oxide (rGO) [4, 5].

Raman spectra of Co3O4/graphene composites were detected to distinguish the ordered and disordered crystal structure of carbon. As shown in Fig. 4, the characteristic G and 2D peaks at 1574 cm−1 (corresponding to sp 2-hybridized carbon) and 2700 cm−1 (originating from a double-resonance process) are rooted in the graphene sheets. The D to the G band intensity ratio (I D /I G ) indicates the disorder extent and crystallite size of the graphitic layers. A low D band appeared at 1346 cm−1 (corresponding to the breathing mode of the k-point phonons of A 1g symmetry), suggesting that the produced Co3O4/graphene lacks defects. Meanwhile, five characteristic peaks from the composite at 189, 454, 507, 606 and 675 cm−1 are consistent with T 2g , E g , F 12g , F 22g and A 1 g symmetrical mode of the crystalline Co3O4, respectively [28, 35]. These results further demonstrate the existence of both graphene and Co3O4 in the composites. In addition, the integral ratio of the 2D and G band demonstrates that the as-prepared graphene consists of mainly few-layer domains.

To confirm the chemical bonding states in Co3O4/graphene composites, XPS measurements were carried out. In the survey region (0–1100 eV), carbon, cobalt and oxygen were detected, displayed in Fig. 5a. Two peaks in the high-resolution Co 2p XPS spectra of the Co3O4/graphene composites in Fig. 4b are distinguished at 779.6 and 794.8 eV, in accordance with the Co 2p 3/2 and Co 2p 1/2 spin–orbit peaks of Co3O4, respectively [28, 36]. The result demonstrates the presence of Co species in the composites. The C 1s (284.6 eV) peak obtained is fitted to sp 2 C–C bonds of graphene, and another C 1s (285.8 eV) peak is related to the C–O/C–N bonds resulting from the CTAB and nitrogen in air via annealing (Fig. 5c). The O 1s XPS spectra (Fig. 5d) of the composite shows two peaks centered at 530.0 and 531.2 eV, corresponding to Co–O–C bond and Co–O–Co bond, respectively. This demonstrates that there are few functional groups on the surface of composites in contrast to the chemically reduced graphene oxide (rGO). The results are consistent with the XRD, FT-IR and Raman measurements which indicate the presence of Co3O4 and graphene in the as-prepared samples.

The morphology and microstructure of the graphene and Co3O4/graphene were studied by TEM. TEM images (Fig. 6a) of as-prepared graphene reveal that few-layer graphene flakes of high quality were observed, which is in good agreement with the Raman results. The TEM images can provide a better qualitative understanding of the internal structure and spatial distribution. It can be seen in Fig. 6b that Co3O4 nanocrystals have a size of 15–25 nm and are homogeneously anchored on the surface of graphene sheets [17, 18]. In addition, the Co3O4 nanocrystals connect with each other to form the shape of sticks (Fig. 6b, c). The high-resolution TEM image (Fig. 6d) distinctly indicate the well-textured of Co3O4 nanocrystals in the Co3O4/graphene composites and the lattice fringes of Co3O4 are about 0.244 nm, suggesting the (311) plane of a Co3O4 crystal as the main growth direction for the Co3O4 nanocrystals [18]. All the images prove that the method of direct liquid-phase exfoliation produces large graphene sheets homogenously and closely decorated with well-dispersed Co3O4 nanocrystals. The composition of the composites was confirmed by the EDS spectra as shown in Fig. 6d. The EDS curve of Co3O4/graphene further illustrates the presence of cobalt, carbon, and oxygen elements in the samples, which agrees very well with previous measurements [5, 6].

3.2 Catalyst performance

Apart from the experimental parameter, other factors were fixed: pH 7.0, [PMS] = 2 mM, [Orange II] = 0.2 mM, [Co3O4/graphene] = 0.05 g/L and T = 25 °C.

The pH of the solution is investigated in a range of 4.0–10.0, the degradation rate of Orange II accelerated with increasing pH (Fig. 7a) because of the formation of Co–OH on the surface of as-prepared Co3O4/graphene composites was enhanced at the higher pH value which consequently promoted heterogeneous PMS activation. The best catalytic activity was obtained at a pH value of 10, but there is a weak changes that the solution pH at 7.0, 8.5 and 10.0 [37–39]. The results are attributed to the fact that H+ captured and reacted with SO −·4 in an acidic solution to decrease the degradation date. The pH could be regarded as an important factor to control the degradation in Co2+/PMS heterogeneous system. Consequently, the suitable pH value is 7.0 because of the easier formation of SO −·4 at a neutral pH, which is also least harmful for life.

The effect of PMS on the degradation of Orange II is shown in Fig. 7b: with the increase of PMS dosage (1.0, 1.5, 2.0 and 2.5 mM), the catalytic efficiency rises due to more PMS, which provides a greater possibility for the generation of SO −·4 . However, the increase of degradation is inconspicuous that the dosage is 2.5 mM compared with 2.0 mM, over a large dosage of PMS will result in the high cost as well [5, 37, 39]. Therefore, 2.0 mM of PMS is the suitable dosage experimentally.

The concentration of Orange II is tested and shown in Fig. 7c. The dyes in solution was completely removed in the first 8, 10 and 16 min at the initial Orange II concentration of 0.1, 0.2 and 0.3 mM, respectively. The solution with a higher concentration demanded a longer time to reach complete degradation of Orange II when others parameters are uniform [40, 41]. Comprehensively, 0.2 mM of Orange II concentration is the appropriate index for the experiments.

Catalyst dosage plays an important role in the heterogeneous AOPs system. Figure 7d shows the degradation rate under different catalyst dosages (viz. 0.025, 0.050 and 0.075 g/L). The efficiency of the catalyst is enhanced with increase in the catalyst dosage, owing to the existence of more catalytic active sites to activate PMS and more SO −·4 were generated to degrade Orange II [7, 8]. Obviously, 65 % decomposition was reached 70 % within 2 min at the composites concentration of 0.050 and 0.075 g/L, but at 0.075 g/L catalyst dosage, the degradation rate of Orange II did not significantly increase. It may be because catalytic efficiency trends to be stable as increasing of the catalyst dosage. The result is the same as was achieved by Shi et al. [40] and Shukla et al. [7]. Meanwhile, the cost of wastewater treatment was increased with the enhanced catalyst dosage. In contrast, the catalyst dosage of 0.050 g/L satisfied the requirement.

Temperature is taken as an important means to manipulate the degradation of pollutants in the SO −·4 system. The degradation of Orange II over Co3O4/graphene/PMS was further investigated at varying temperature (15, 25, 35 and 45 °C), and the results are shown in Fig. 7e. Apparently, the Co3O4/graphene/PMS system exerted better degradation efficiency at elevated temperature, due to it being easy to activate PMS at higher temperatures [7, 8, 11]. High temperature is a dangerous element in industrial production and wastewater treatment; indeed, a degradation efficiency of 25 °C is sufficient to be applied to industrial wastewater disposal. Therefore, a temperature of 25 °C is applied in degradation.

The degradation curves of Orange II under different conditions are shown in Fig. 8a. The concentration of Orange II only decreased to around 90 % in the first few minutes and then reached an equilibrium, which indicates that Co3O4, graphene and Co3O4/graphene are able to absorb Orange II [5, 40]. Meanwhile, the physical adsorption on the Co3O4/graphene is better than the Co3O4 which leads to higher efficiency by heterogeneous catalytic reaction. For the Co3O4/graphene/PMS heterogeneous system, complete removal of Orange II was observed within 10 min. Furthermore, the catalytic efficiency of Co3O4 was much lower under the same situation that just 50 % of Orange II was removed in the first 10 min. The results indicate that graphene is catalytically active but it expressed the lowest catalytic activities, and there is 45 % dye remaining during first 30 min in the existence of PMS. The catalysis occurs because of a few chemical bonds on the surface of graphene, which fits the XPS result. Therefore, the Co3O4/graphene composites were used in the degradation of Orange II by AOPs based on SO −·4 is synergistic which is similar to that reported by Yun et al. [6]. In the Co3O4/graphene/PMS heterogeneous system, the hybrids catalyzed activation of PMS and degradation of Orange II is proposed as the following reactions:

In the presence of cobalt ions, PMS breaks up to generate active SO −·4 and SO −·5 , which consequently aid in the oxidation of pollutants. The efficiency of PMS may be enhanced by Co2+, producing SO −·4 according to the Eqs. (1)–(4) [42, 43]. SO −·4 can also undergo hydrolysis and leading to ·OH and SO4 2− as shown in Eq. (5). Both SO −·4 and ·OH can cause chain oxidative reactions of the oxidative degradation Orange II [Eqs. (6) and (7)], but SO −·4 are the dominant [44]. As an organics-selective-oxidant that differs from ·OH, SO −·4 would prefer to attack aromatic compounds first, thus benefiting the decomposition of both Orange II and its derivative aromatic fragments. Orange II can be oxidized by SO −·4 through abstraction of protons producing organic radicals (R·), which are highly reactive and can be further oxidized [45, 46].

The excellent catalytic activity of Co3O4/graphene has several contributing factors. First, the excellent electronic transmission performance of graphene increases the rate of ion transfer, promotes activation of PMS for SO −·4 production. Afterwards, graphene sheets provide a high specific surface area which leads to more active sites for adsorption of orange II. At the same time, the bare graphene expresses the degradation property (Fig. 8a) [42]. What is more, graphene as the support avoids the aggregation of the Co3O4 nanoparticles that improves the catalytic effect.

Figure 8b shows the UV–vis spectral variation for Orange II degradation with Co3O4/graphene/PMS system. The two absorption bonds at 484 nm and 309 nm are attributed to the n − π* transition, involving the lone pair on N atoms and the conjugated system extending over the two aromatic moieties, and encompassing the N–N group of the hydrazones form and the aromatic ring absorptions, respectively. However, the bond around 484 nm is predominant. The peak at 484 nm decreased with the increasing of degradation time, demonstrating that the excellent catalytic activities owe much to the damage of dye structure.

Cobalt leaching has drawing great attention as a result of the highly efficient generation of SO −·4 in Co2+/PMS system [11, 12]. The leached Co ion concentration in the reaction solution after filtration by microfiltration membrane (0.22 μm) was measured by ICP. There was hardly any leached Co ion in the Co2+/grapheme/PMS heterogeneous system (Fig. 9). While, the cobalt leachate is about 0.2 mg/L when Co3O4 activates PMS, and the final percentage of Co from the material is about 0.4 %. The ICP results indicate that the Co3O4 nanoparticles anchoring the graphene are obvious a stable cobalt source compared to pure Co3O4. The attendance of graphene support result in much higher stability and few metal leaching.

3.3 Stability of Co3O4/graphene in multiple runs

The stability of the Co3O4/graphene catalyst was evaluated by conducting five recycling runs of the composites as shown in Fig. 10. After every run of degradation, the catalyst was collected, washed with distilled water and absolute ethanol several times, and dried in a vacuum oven at 60 °C to be reused in next run [5, 47]. It was seen that the catalyst can be reutilized and catalytic activity of the Co3O4/graphene dropped slightly in five cycles. After four runs, complete removal of Orange II is achieved within 16 min. The results demonstrating that as-prepared Co3O4/graphene catalyst has an excellent catalytic activity and good long-term stability.

All of these results reveal that Co3O4/graphene composites are potential materials in a system for activation of PMS, used in the degradation of Orange II in water by AOPs based on SO −·4 .

4 Conclusions

In summary, the Co3O4/graphene composites were successfully prepared based on liquid-phase exfoliation with the assistance of CTAB. By direct aqueous-phase exfoliation of graphite in the presence of CTAB, the exfoliated few-layer graphene flakes with low defects were functionalized by CTAB simultaneously. The adsorbed CTAB on the surface of graphene flakes can be used very well for fabricated and immobilized Co3O4 nanoparticles. By using the in situ solvothermal method and calcination, the Co3O4/graphene composites with Co3O4 decorated on the surfaces of the graphene flakes were easily obtained. The size of the Co3O4 particles ranged from 15 to 25 nm and formed stick-shaped Co3O4 with lengths of 200–500 nm. The results demonstrated the Co3O4/graphene composites can act as excellent and efficient catalyst for the degradation of Orange II in water by AOPs based on SO −·4 that can completely degrade Orange II in aqueous solution within 10 min. Meantime, the composites also has an excellent long-term stability and recycling performance. After four runs, complete removal of Orange II can be achieved within 16 min. Hence, we believe that the method based on functional surfactant-assisted liquid-phase exfoliation can be more widely used for the fabrication of high-performance graphene-based composite catalyst.

References

B.R. Cabo, I.R. Palmeiro, R. Rodil, E. Rodil, A. Arce, A. Soto, J. Mater. Sci. 50, 3576 (2015)

J.F. Ma, K. Wang, L.Y. Li, T.L. Zhang, Y. Kong, S. Komarneni, Ceram. Int. 41, 2050 (2015)

F. Luo, D. Yang, Z.L. Chen, M. Megharaj, R. Naidu, J. Hazard. Mater. 296, 37 (2015)

A.T. Djowe, S. Laminsi, G.L. Noupeyi, E.M. Gaigneaux, Appl. Catal. B 176, 99 (2015)

P.H. Shi, R.J. Su, F.Z. Wan, M.C. Zhu, D.X. Li, S.H. Xu, Appl. Catal. B 123, 265 (2012)

Y.J. Yao, C. Xu, J.C. Qin, F.Y. Wei, M.N. Rao, S.B. Wang, Ind. Eng. Chem. Res. 52, 17341 (2013)

P.R. Shukla, S.B. Wang, H.Q. Sun, H.M. Ang, M. Tadé, Appl. Catal. B 100, 529 (2010)

L. Chen, X.Z. Peng, J.H. Liu, J.J. Li, F. Wu, Ind. Eng. Chem. Res. 51, 13632 (2012)

H.Q. Sun, H.Y. Tian, Y. Hardjono, C.E. Buckley, S.B. Wang, Catal. Today 186, 63 (2012)

Y.X. Wang, H.Q. Sun, H.M. Ang, M.O. Tadéand, S.B. Wang, Chem. Eng. J. 245, 1 (2014)

H.W. Liang, H.Q. Sun, A. Patel, P. Shukla, Z.H. Zhu, S.B. Wang, Appl. Catal. B 127, 330 (2012)

S. Muhammad, E. Saputra, H.Q. Sun, J.C. Izidoro, D.A. Fungaro, H.M. Ang, M.O. Tadé, S.B. Wang, RSC Adv. 2, 5645 (2012)

C.G. Hu, Z.Y. Mou, G.W. Lu, N. Chen, Z.L. Dong, M.J. Hu, L.T. Qu, Chem. Chem. Phys. 15, 13038 (2013)

M.A. Worsley, S.O. Kucheyev, H.E. Mason, M.D. Merrill, B.P. Mayer, J. Lewicki, C.A. Valdez, M.E. Suss, M. Stadermann, P.J. Pauzauskie, J.H. Satcher Jr, J. Biener, T.F. Baumann, Chem. Commun. 48, 8428 (2012)

S. Sattayasamitsathit, Y.G. Gu, K. Kaufmann, W.Z. Jia, X.Y. Xiao, M. Rodriguez, S. Minteer, J. Cha, D.B. Burckel, C.M. Wang, R. Polsky, J. Wang, J. Mater. Chem. A 1, 1639 (2013)

B.G. Choi, S.J. Chang, Y.B. Lee, J.S. Bae, H.J. Kim, Y.S. Huh, J. Mater. Chem. 22, 17278 (2012)

Y.G. Liu, Z.Y. Cheng, H.Y. Sun, H. Arandiyan, J.P. Li, M. Ahmad, J. Power Sources 273, 878 (2015)

S. Chen, J.W. Zhu, X. Wang, J. Phys. Chem. C 114, 11829 (2010)

K. Palanisamy, Y. Kim, H. Kim, J.M. Kim, W.S. Yoon, J. Power Sources 275, 351 (2015)

Q. Wang, C.Y. Zhang, W.F. Shan, L.L. Xing, X.Y. Xue, Mater. Lett. 118, 66 (2014)

L.J. Xie, J.F. Wu, C.M. Chen, C.M. Zhang, L. Wan, J.L. Wang, Q.Q. Kong, C.X. Lv, K.X. Li, G.H. Sun, J. Power Sources 242, 148 (2013)

H.T. Sun, X. Sun, T. Hu, M.P. Yu, F.Y. Lu, J. Lian, J. Phys. Chem. C 118, 2263 (2014)

S.M. Notley, Langmuir 28, 14110 (2012)

J.J. Li, D.D. Miao, R. Yang, L.B. Qu, P.B. Harrington, Electrochim. Acta 125, 1 (2014)

Y. Lin, J. Jin, O. Kusmartsevab, M. Song, J. Phys. Chem. C 117, 17237 (2013)

K. Deori, S.K. Ujjain, R.K. Sharma, S. Deka, A.C.S. Appl, Mater. Interfaces 5, 10665 (2013)

G.M. Bai, H.X. Dai, J.G. Deng, Y.X. Liu, F. Wang, Z.X. Zhao, W.G. Qiu, C.T. Au, Appl. Catal. A 450, 42 (2013)

M. Lotya, Y. Hernandez, P.J. King, R.J. Smith, V. Nicolosi, L.S. Karlsson, F.M. Blighe, S. De, Z.M. Wang, I.T. McGovern, G.S. Duesberg, J.N. Coleman, J. Am. Chem. Soc. 131, 3611 (2009)

Y.Y. Liang, Y.G. Li, H.L. Wang, J.G. Zhou, J. Wang, T. Regier, H.J. Dai, Nat. Mater. 10, 780 (2011)

Y.F. Fan, Y.S. Liu, Q. Cai, Y.Z. Liu, J.M. Zhang, Synth. Met. 162, 1815 (2012)

J.L. Wang, Z.X. Shi, Y. Ge, Y. Wang, J.C. Fan, J. Yin, Mater. Chem. Phys. 136, 43 (2012)

D. Ghosh, S. Giri, C.K. Das, Chem. Eng. 1, 1135 (2013)

Z.S. Wu, Y. Sun, Y.Z. Tan, S.B. Yang, X.L. Feng, K. Müllen, J. Am. Chem. Soc. 134, 19532 (2012)

N. Yan, L. Hu, Y. Li, Y. Wang, H. Zhong, X.Y. Hu, X.K. Kong, Q.W. Chen, J. Phys. Chem. C 116, 7227 (2012)

X.C. Dong, H. Xu, X.W. Wang, Y.X. Huang, M.B. Chan-Park, H. Zhang, L.H. Wang, W. Huang, P. Chen, ACS Nano 4, 3206 (2012)

Z.S. Wu, W.C. Ren, L. Wen, L.B. Gao, J.P. Zhao, Z.P. Cjem, G.M. Zhou, F. Li, H.M. Cheng, ACS Nano 6, 3187 (2013)

P. Bautista, A.F. Mohedano, J.A. Casas, J.A. Zazo, J.J. Rodriguez, J. Chem. Technol. Biotechnol. 83, 1323 (2008)

H.Y. Li, Y.H. Gong, Q.Q. Huang, H. Zhang, Ind. Eng. Chem. Res. 52, 15560 (2013)

Y.J. Yao, C. Xu, S.M. Yu, D.W. Zhang, S.B. Wang, Ind. Eng. Chem. Res. 52, 3637 (2013)

P.H. Shi, X.F. Dai, H.A. Zheng, D.X. Li, W.F. Yao, C.Y. Hu, Chem. Eng. J. 240, 264 (2014)

H.Q. Sun, S.Z. Liu, G.L. Zhou, H.M. Ang, M.O. Tadé, S.B. Wang, Interfaces 4, 5466 (2012)

P.H. Shi, R.J. Su, S.B. Zhu, M.C. Zhu, D.X. Li, S.H. Xu, J. Hazard. Mater. 229–230, 331 (2012)

G.P. Anipsitakis, D.D. Dionysiou, Environ. Sci. Technol. 37, 4790 (2003)

Y.X. Wang, S. Indrawirawan, X.G. Duan, H.Q. Sun, H.M. Ang, M.O. Tadé, S.B. Wang, Chem. Eng. J. 266, 12 (2015)

W.H.M. Abdelraheem, X.X. He, X.D. Duan, D.D. Dionysiou, J. Hazard. Mater. 282, 233 (2015)

X.X. He, A.A. de la Cruz, K.E. O’Shea, D.D. Dionysiou, Water Res. 63, 168 (2014)

M.Y. Nassar, I.S. Ahmed, Polyhedron 30, 2431 (2011)

Acknowledgments

The study was supported by National Natural Science Foundation of China (Nos. 21507081, 21271010), Shanghai Municipal Natural Science Foundation (Nos. 15ZR1417800, 14DZ2261000), “Dawn” Program of Shanghai Education Commission (No. 11SG52), Shanghai Key Project for Fundamental Research (No. 13JC1402800), and Scientific Research Foundation of Shanghai University of Electric Power (No. K2014–015).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhou, X.J., Shi, P.H., Qin, Y.F. et al. Synthesis of Co3O4/graphene composite catalysts through CTAB-assisted method for Orange II degradation by activation of peroxymonosulfate. J Mater Sci: Mater Electron 27, 1020–1030 (2016). https://doi.org/10.1007/s10854-015-3847-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3847-9