Abstract

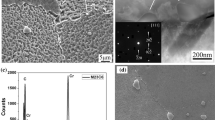

After isothermal aging at 850 °C for different hours, the microstructures as well as creep-rupture properties of a novel directionally solidified Ni-based superalloy M4706 are studied under the condition of 980 °C and 180 MPa. We found that the mean edge length of γ′ particles only increases up to 484 ± 99 nm after the aging treatment of 850 °C/5000 h, and the corner of the γ′ particle becomes more and more rounded with particle size, whereas the γ′ volume fraction remains unchanged with time. At grain boundaries, the carbide film, which is consisted of MC and M23C6 carbides, is produced after thermal exposure for 1000 h, and its content increases with time. Creep-rupture tests reveal that the creep-rupture life is reduced only from 180 ± 15 to 106 ± 15 h, and the elongation to fracture decreases from 32 ± 2% to 21 ± 1% after isothermal aging for 5000 h. Microstructural observations disclose that creep deformation is achieved mainly by dislocation climb, although shearing of γ′ particles by pairs of a/2 < 011 > dislocations also takes place occasionally. Based on the experimental results, the relationship between the creep-rupture properties and microstructures together with the creep deformation mechanisms is discussed.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Pollock TM (2016) Alloy design for aircraft engines. Nature Mater 15(8):809–815

Cailletaud G, Cormier J, Eggeler G, Maurel V, Nazé L (2022) Nickel base single crystals across length scales. Elsevier

Jackson MP, Reed RC (1999) Heat treatment of UDIMET 720Li: the effect of microstructure on properties. Mater Sci Eng A 259:85–97

Sluytman JSV, Pollock TM (2012) Optimal precipitate shapes in nickel-base γ–γ′ alloys. Acta Mater 60:1771–1783

Tian C, Han G, Cui C, Sun X (2014) Effects of stacking fault energy on the creep behaviors of Ni-base superalloy. Mater Des 64:316–323

Grant BMB, Francis EM, Quinta da Fonseca J, Daymond MR, Preuss M (2012) Deformation behaviour of an advanced nickel-based superalloy studied by neutron diffraction and electron microscopy. Acta Mater 60:6829–6841

Wang J, Zhou L, Sheng L, Guo J (2012) The microstructure evolution and its effect on the mechanical properties of a hot-corrosion resistant Ni-based superalloy during long-term thermal exposure. Mater Des 39:55–62

Zhang P, Yuan Y, Zhong L et al (2021) Microstructural stability and tensile properties of a new γ′-hardened Ni-Fe-base superalloy. Materialia 16:101061

Jianting G (2010) The current situation of application and development of superalloys in the fileds of energy industry. Acta Metall Sin 46:513–527

Zhang P, Li J, Gong XF, Yuan Y, Gu YF, Wang JC, Yan JB, Yin HF (2019) Creep behavior and deformation mechanisms of a novel directionally solidified Ni-base superalloy at 900 °C. Mater Charact 148:201–207

Zhang P, Yuan Y, Shen SC, Li B, Zhu RH, Yang GX, Song XL (2017) Tensile deformation mechanisms at various temperatures in a new directionally solidified Ni-base superalloy. J Alloys Compds 694:502–509

Zhang P, Yuan Y, Li B, Guo SW, Yang GX, Song XL (2016) Tensile deformation behavior of a new Ni-base superalloy at room temperature. Mater Sci Eng A 655:152–159

Zhang P, Yuan Y, Li J, Xu YF, Song X, Yang G (2017) Tensile deformation mechanisms in a new directionally solidified Ni-base superalloy containing coarse γ′ precipitates at 650 °C. Mater Sci Eng A 702:343–349

CS Press, GB/T 14999.T-2010, Test methods for grain sizes, primary dendrite spacing and microshrinkage of superalloy castings. China Standard Press, Beijing, China, 2010.

Roskosz S, Adamiec J (2009) Methodology of quantitative evaluation of porosity, dendrite arm spacing and grain size in directionally solidified blades made of CMSX-6 nickel alloy. Mater Charact 60:1120–1126

Shao C, Liu H, Li JT, Ma ZL, Zhao M (2012) Applications of hot isostatic pressing on cast superalloy. Mater Rev 26:121–135

Kozar RW, Suzuki A, Milligan WW, Schirra JJ, Savage MF, Pollock TM (2009) Strengthening mechanisms in polycrystalline multimodal nickel-base superalloys. Metall Mater Trans A 40:1588–1603

Zhang P, Yuan Y, Gao ZH, Gu YF, Lu JT (2020) Strain-rate insensitive yield strength and deformation mechanisms of Ni-base superalloy CM247LC at 600 °C. J Alloys Compds 45:158478

Lvov G, Levit VI, Kaufman MJ (2004) Mechanism of primary MC carbide decomposition in Ni-base superalloys. Metall Mater Trans A 35:1669–1679

Qin XZ, Guo JT, Yuan C, Chen CL, Ye HQ (2007) Effects of long-term thermal exposure on the microstructure and properties of a cast Ni-base superalloy. Metall Mater Trans A 38:3014–3022

Hou JS, Guo JT, Yang GX, Zhou LZ, Qin XZ, Ye HQ (2008) The microstructural instability of a hot corrosion resistant superalloy during long-term exposure. Mater Sci Eng A 498:349–358

Wang T, Sheng G, Liu ZK, Chen LQ (2008) Coarsening kinetics of γ′ precipitates in the Ni-Al-Mo system. Acta Mater 56:5544–5551

Philippe T, Voorhees PW (2013) Ostwald ripening in multicomponent alloys. Acta Mater 61:4237–4244

Martens V, Nembach E (1975) Strengthening of the nimonic alloy PE 16 by ordered particles of Ni3(Al, Ti). Acta Metall 23:149–153

Zhang P, Yuan Y, Yan JB, Wang JC, Song XL, Yang GX (2018) Morphological evolution of γ′ precipitates in superalloy M4706 during thermal aging. Mater Letts 211:107–109

Zhang P, Ma L, Yang G, Song X (2016) Extraordinary plastic behaviour of the γ′ precipitate in a directionally solidified nickel-based superalloy. Phil Mag Letts 96:19–26

Li L, Gong X, Wang C et al (2021) Correlation between phase stability and tensile properties of the Ni-based superalloy MAR-M247. Acta Metall Sin 34:872–884

Lifshitz IM, Slyozov VV (1961) The kinetics of precipitation from supersaturated solid solutions. J Phys Chem Solids 19:35–50

Wagner C (1961) Theorie der Alterung von Niederschägen durch Umlösen (Ostwald-Reifung). Z Metall 65:581–591

Moshtaghin RS, Asgari S (2003) Growth kinetics of γ′ precipitates in superalloy IN-738LC during long term aging. Mater Des 24:325–330

Jiang XW, Wang D, Xie G, Li H, Lou LH, Zhang J (2014) The effect of long-term thermal exposure on the microstructure and stress rupture property of a directionally solidified Ni-based superalloy. Metall Mater Trans A 45:6016–6026

Ardell AJ, Nicholson R (1966) On the modulated structure of aged Ni-Al alloys. Acta Metall 14:1295–1309

Fährmann M, Fratzl P, Paris O, Fährmann E, Johnson WC (1995) Influence of coherency stress on microstructural evolution in model Ni-Al-Mo alloys. Acta Metall Mater 43:1007–1022

Fährmann M, Wolf JG, Pollock TM (1996) The influence of microstructure on the measurement of γ-γ′ lattice mismatch in single-crystal Ni-base superalloys. Mater Sci Eng A 210:8–15

Xia PC, Yu JJ, Sun XF, Guan HR, Hu ZQ (2007) The influence of thermal exposure on the microstructure and stress rupture property of DZ951 nickel-base alloy. J Alloys Compds 443:125–131

Zhang JX, Wang JC, Harada H, Koizumi Y (2005) The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep. Acta Mater 53:4623–4633

Zhang JX, Harada H, Koizumi Y, Kobayashi T (2010) Dislocation motion in the early stages of high-temperature low-stress creep in a single-crystal superalloy with a small lattice misfit. J Mater Sci 45:523–532. https://doi.org/10.1007/s10853-009-3970-1

Tang Y, Huang M, Xiong J, Li J, Zhu J (2017) Evolution of superdislocation structures during tertiary creep of a nickel-based single-crystal superalloy at high temperature and low stress. Acta Mater 126:336–345

Pollock TM, Argon AS (1992) Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall Mater 40:1–30

Carry C, Strudel JL (1977) Apparent and effective creep parameters in single crystals of a nickel base superalloy-I Incubation period. Acta Metall 25:767–777

Carry C, Strudel JL (1978) Apparent and effective creep parameters in single crystals of a nickel base superalloy-II. Secondary creep Acta Metall 26:859–870

Blum W, Reppich B (1985) Creep of particle-strengthened alloys. In: Wilshire B, Evans RW (eds) Creep behavior of crystalline solids. Pineridge Press, pp 83–135

Link T, Feller-Kniepmeier M (1992) Shear mechanisms of the γ′ phase in single-crystal superalloys and their relation to creep. Metall Trans A 23:99–105

Wang C, Guo Y, Guo J, Zhou L (2016) Microstructural changes and their effect on tensile properties of a Ni-Fe based alloy during long-term thermal exposure. Mater Sci Eng A 670:178–187

Pollock TM, Argon AS (1994) Directional coarsening in nickel-base single crystals with high volume fractions of coherent precipitates. Acta Metall Mater 42:1859–1874

Nabarro FRN (1996) Rafting in Superalloys. Metall Mater Trans A 27:513–530

Guo JT, Yuan C, Yang HC, Lupinc V, Maldini M (2001) Creep-rupture behavior of a directionally solidified nickel-base superalloy. Metall Mater Trans A 32:1103–1110

Monkman FC, Grant NJ (1956) An empirical relationship between rupture life and minimum creep rate in creep-rupture tests. Rroc. ASTM: 595–603.

Reppich B, Schepp P, Wehner G (1982) Some new aspects concerning particle hardening mechanisms in γ’ precipitating nickel-base alloys-II. Experiments Acta Metallu 30:95–104

Ardell AJ (1995) Intermetallics compounds as precipitates and dispersoids in high-strength alloys. In: Westbrook JH, Fleischer RL (eds) in: IntermetallicCompounds. John Wiley and Sons, pp 257–286

Heilmaier M, Leetz U, Reppich B (2001) Order strengthening in the cast nickel-based superalloy IN 100 at room temperature. Mater Sci Eng A 319–321:375–378

Feller-Kniepmeier M, Link T, Poschmann I, Scheunemann-Frerker G, Schulze C (1996) Temperature dependence of deformation mechanisms in a single crystal nickel-base alloy with high volume fraction of γ′ phase. Acta Mater 44:2397–2407

Acknowledgements

This work was financially supported by Natural Science Basic Research Plan in Shaanxi Province of China (grant number 2022JQ-314, 2022JQ-460), Research and Development Funds of Xi’an Thermal Power Research Institute Co., Ltd. (grant number TA-20-TYK03), Young Elite Scientists Sponsorship Program by CSEE (grant number JLB-2020-165), Sichuan Science and Technology Program (grant number 2019ZDZX0022), the Science & Technology Foundation of Huaneng Group Co, Ltd. (grant number HNKJ20-H41).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, P., Yuan, Y., Niu, Q. et al. Correlation microstructural evolution with creep-rupture properties of a novel directionally solidified Ni-based superalloy M4706. J Mater Sci 57, 17812–17827 (2022). https://doi.org/10.1007/s10853-022-07735-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07735-2