Abstract

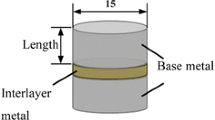

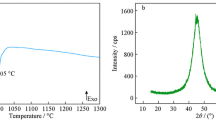

Tensile behavior at different deformation temperature of a transient liquid-phase (TLP) bonded joint of γ′-strengthened Co-based superalloy was investigated. A temperature dependence phenomenon of the joint’s fracture position was found, which transferred from the base metal to the bonding area with increase in the temperature, and this is related to the deformation mechanism. At room temperature, dislocation shearing the γ′ phases in different areas of the joint domains the deformation and makes it heterogeneous, and more deformation has occurred at the BM because of lower content of γ′ phase, which makes the failure occurred at the BM. The deformation mechanism gradually transferred from dislocation shearing to bypassing the γ′ with increasing the temperature, making the deformation become diffused, and this can lead to the fracture of the joint’s brittle borides, and the coalescence of the boride-induced cracks makes the fracture occur at the diffusion affect zone at 600 °C~ 900 °C. As the secondary-γ′ in the joint’s isothermal solidification zone dissolves at 1000 °C, more deformation occurs there and the accumulation of micro-voids induced by the dislocation climbing leads to the fracture.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Sato J, Omori T, Oikawa K, Ohnuma I, Kainuma R, Ishida K (2006) Cobalt-base high-temperature alloys. Science 312(5770):90–91

Xue F, Zenk CH, Freund LP, Hoelzel M, Neumeier S, Goken M (2018) Double minimum creep in the rafting regime of a single-crystal Co-base superalloy. Scripta Mater 142:129–132

Lu S, Antonov S, Li L, Liu C, Feng Q (2020) Atomic structure and elemental segregation behavior of creep defects in a Co-Al-W-based single crystal superalloys under high temperature and low stress. Acta Mater 190:16–28

Freund LP, Messe OM, Barnard JS, Goken M, Neumeier S, Rae CMF (2017) Segregation assisted microtwinning during creep of a polycrystalline L1(2)-hardened Co-base superalloy. Acta Mater 123:295–304

Wen MY, Sun Y, Yu JJ, Meng J, Wang SY, Dong ZG, Niu JT, Sun XF, Zhou YZ (2021) Enhancement of multi-pass weld-crack resistance of Co-based superalloys by B-doping 182:111527

Mattheij JHG (1985) Role of brazing in repair of superalloy components advantages and limitations. Mater Sci Tech-Lond 1(8):608–612

Pouranvari M (2009) Diffusion brazing of a precipitation hardened nickel based superalloy, metal 2009, conference proceedings, pp 574–579

Duvall DS, Owczarski WA, Paulonis DF (1974) TLP bonding: a new method for joining heat resistant alloys. Welding J 20(4):203–213

Pouranvari M (2009) Solidification behavior during diffusion brazing of a nickel based superalloy, metal 2009, conference proceedings, pp 580–583

Pouranvari M, Ekrami A, Kokabi AH (2013) Solidification and solid state phenomena during TLP bonding of IN718 superalloy using Ni-Si-B ternary filler alloy. J Alloy Compd 563:143–149

Binesh B, Gharehbagh AJ (2016) Transient liquid phase bonding of IN738LC/MBF-15/IN738LC: solidification behavior and mechanical properties. J Mater Sci Technol 32(11):1137–1151

Wang GL, Sun Y, Wang XG, Liu JD, Liu JL, Li JG, Yu JJ, Zhou YZ, Jin T, Sun XD, Sun XF (2017) Microstructure evolution and mechanical behavior of Ni-based single crystal superalloy joint brazed with mixed powder at elevated temperature. J Mater Sci Technol 33(10):1219–1226

Arhami F, Mirsalehi SE (2018) Microstructural evolution and mechanical properties evaluation of IN-939 bonds made by isothermal solidification of a liquated Ni–Cr–B interlayer. Metall Mater Trans A 49a(12):6197–6214

Doroudi A, Shamsipur A, Omidvar H, Vatanara M (2019) Effect of transient liquid phase bonding time on the microstructure, isothermal solidification completion and the mechanical properties during bonding of Inconel 625 superalloy using Cr-Si-B-Ni filler metal. J Manuf Process 38:235–243

Wang SY, Sun Y, Hou XY, Cui CY, Sun XF, Zhou YZ (2019) Borides of preferred orientation formed in the transient liquid phase joint of γ′-strengthened Co-base single crystal superalloy. Mater Lett 246:190–194

Hu XB, Zhu YL, Shao XH, Niu HY, Zhou LZ, Ma XL (2015) Atomic configurations of various kinds of structural intergrowth in the polytypic M2B-type boride precipitated in the Ni-based superalloy. Acta Mater 100:64–72

Zhang BQ, Sheng GM, Jiao YJ, Gao ZH, Gong XF, Fan H, Zhong J (2017) Precipitation and evolution of boride in diffusion affected zone of TLP joint of Mar-M247 superalloy. J Alloy Compd 695:3202–3210

Arhami F, Mirsalehi SE, Sadeghian A (2019) Effect of bonding time on microstructure and mechanical properties of diffusion brazed IN-939. J Mater Process Tech 265:219–229

Doroudi A, Pilehrood AE, Mohebinia M, Dastgheib A, Omidvar H (2020) Effect of the isothermal solidification completion on the mechanical properties of Inconel 625 transient liquid phase bond by changing bonding temperature. J Market Res 9(5):10355–10365

Amiri D, Sajjadi SA, Bakhtiari R, Kamyabi-Gol A (2018) The role of TLP process variables in improvement of microstructure and mechanical properties in TLP joints of GTD-111/Ni-Cr-Fe-B-Si/GTD-111 system. J Manuf Process 32(APR.):644–655

Phillips AL (1957) Welding handbook, welding handbook

Wang SY, Sun Y, Hou XY, Cui CY, Sun XF, Zhou YZ (2020) Investigation on microstructure and mechanical properties of a vacuum brazed joint of γ′-strengthened Co-based single crystal superalloy before and after the post-bond heat treatment. Vacuum 177:109413

Shi L, Yu JJ, Cui CY, Sun XF (2015) Effect of Ta additions on microstructure and mechanical properties of a single-crystal Co-Al-W-base alloy. Mater Lett 149:58–61

Shi L, Yu JJ, Cui CY, Sun XF (2015) Temperature dependence of deformation behavior in a Co-Al-W-base single crystal superalloy. Mat Sci Eng A Struct 620:36–43

Milligan WW, Antolovich SD (1991) The mechanisms and temperature dependence of superlattice stacking fault formation in the single-crystal superalloy PWA 1480. Metall Trans A 22:2309–2318

Wang XG, Liu JL, Jin T, Sun XF, Zhou YZ, Hu ZQ, Do JH, Choi BG, Kim IS, Jo CY (2015) Deformation mechanisms of a nickel-based single-crystal superalloy during low-cycle fatigue at different temperatures. Scripta Mater 99:57–60

Zhang JX, Harada H, Koizumi Y, Kobayashi T (2010) Dislocation motion in the early stages of high-temperature low-stress creep in a single-crystal superalloy with a small lattice misfit. J Mater Sci 45(2):523–532

Meyers M (2009) Mechanical behavior of materials (2nd edn), vol 81, no 2. Aircraft Eng & Aerospace Tech

Yuan Y, Zhu B, Song RH, Yang GX, Shen L (2017) Tensile deformation mechanisms at various temperatures in a new directionally solidified Ni-base superalloy. J Alloys Comp Interdisc J Mater Sci Solid State Chem Phys 694:502–509

Titus MS, Eggeler YM, Suzuki A, Pollock TM (2015) Creep-induced planar defects in L12-containing Co- and CoNi-base single-crystal superalloys. Acta Mater 82:530–539

Feller-Kniepmeier M, Link T, Poschmann I (1996) Temperature dependence of deformation mechanisms in a single crystal nickel-base alloy with high volume fraction of γ′ phase. Acta Mater 44(6):2397–2407

Reppich B (1982) Some new aspects concerning particle hardening mechanisms in γ’ precipitating Ni-base alloys—I. Theoretical concept. Acta Metall Mater 30(1):87–94

Kruml T, Viguier B, Bonneville J, Martin JL (1997) Temperature dependence of dislocation microstructure in Ni3(Al, Hf). Mater Sci Eng, A 234–236:755–757

Okamoto NL (2011) Plastic deformation of polycrystals of Co3(Al, W) with the L12 structure. Phil Mag 91(28):3667–3684

Zhang P, Yuan Y, Shen SC, Li B, Zhu RH, Yang GX, Song XL (2017) Tensile deformation mechanisms at various temperatures in a new directionally solidified Ni-base superalloy. J Alloy Compd 694:502–509

Grant B, Francis EM, Fonseca J, Daymond MR, Preuss M (2012) Deformation behaviour of an advanced nickel-based superalloy studied by neutron diffraction and electron microscopy. Acta Mater 60(19):6829–6841

Yuan Y, Gu YF, Osada T, Zhong ZH, Yokokawa T, Harada H (2012) Deformation mechanisms in a new disc superalloy at low and intermediate temperatures. Scripta Mater 67(2):137–140

Tan XP, Liu JL, Jin T, Hu ZQ, Hong HU, Choi BG, Kim IS, Jo CY, Mangelinck D (2013) Effect of Ru additions on very high temperature creep properties of a single crystal Ni-based superalloy. Mater Sci Eng A Struct Mater Prop Microstruct Process 580(10):21–35

Field RD, Pollock TM, Murphy WH (1992) The development of γ/γ' interfacial dislocation networks during creep in Ni-base Superalloy. Superalloys 557–566

Wang SY, Sun Y, Hou XY, Cui CY, Sun XF, Zhou YZ (2020) Fracture mechanism of transient liquid phase bonding joint of γ’-strengthened Co-based single crystal superalloy. Mater Lett 258:126730

Wang SY, Sun Y, Cui CY, Sun XF, Zhou YZ, Ma YM, An HL (2021) Effect of post-bond heat treatment on the microstructure and high temperature mechanical property of a TLP bonded γ′-strengthened Co-based single crystal superalloy. J Mater Sci Technol 80(4):244–258

Danesh A, Ata K-G, Seyed Abdolkarim S (2022) Standard heat treatment effects on TLP bonded IN-738LC superalloy using BNi-9 filler: an approach to make an ideal joint. Trans Nonferr Metals Soc China 32(01):192–205

Sun W, Li X, Chen M, Ding R, Qiao Z, Wang Z, Liu C, Liu Y (2022) Effect of post bonding heat treatment on the local strain evolution of transient liquid phase bonded RAFM steel. Mater Sci Eng, A 840(04):143008

Acknowledgements

This research was funded by the National Key R&D Program of China under Grant No.2021YFB3700401 and Key Specialized Research and Development Breakthrough—unveiling and commanding the special project program in Liaoning province under Grant No. 2021JH15.

Funding

National Natural Science Foundation of China, 2021YFB3700401, Y. H. Yang, Key Specialized Research and Development Breakthrough–unveiling and commanding the special project program in Liaoning province, 2021JH15, Yuan Sun.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S.Y., Hou, X.Y., Cheng, Y. et al. Effect of temperature on the tensile deformation behavior and fracture mechanism of a transient liquid-phase bonding joint of γ′-strengthened Co-based single-crystal superalloy. J Mater Sci 57, 12012–12033 (2022). https://doi.org/10.1007/s10853-022-07351-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07351-0