Abstract

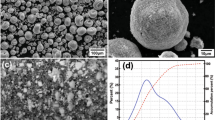

ZrB2-based composite coatings have broad application prospects in hypersonic aircraft, rockets, and re-entry spacecraft. However, poor toughness of the ZrB2 coating is an important problem to be solved urgently. This study designed and prepared ZrO2–B4C–Al precursor and nano-ZrB2-based composite coating were prepared in situ by reactive plasma spraying. The obtained toughness values of coating by plasma spraying ZrO2–B4C–Al powder increased by 241% in comparison with the coating by plasma spraying ZrB2–ZrC–Al2O3 powder. The coupling action of the toughening mechanism such as fine-grain strengthening, toughening crack deflection, and crack bridging greatly improved the toughness of the coating. This paper provides a novel idea for the preparation of high-properties nano-ZrB2 based composite coatings.

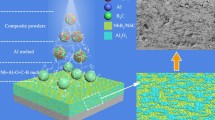

Graphical abstract

Similar content being viewed by others

References

Chen H, Wu ZH, Hai WX (2021) Tribo-oxidation and tribological behaviour of ZrB2–20%vol SiC composites coupled with WC and Al2O3 at high temperatures. Wear 464–465:203534

Padture NP (2016) Advanced structural ceramics in aerospace propulsion. Nat Mater 15:804–809

Kannan R, Rangaraj L (2020) Densification, mechanical, and tribological properties of ZrB2-ZrCx composites produced by reactive hot pressing. J Am Ceram Soc 103:6120–6135

Cui YH, Guo MY, Shao YX, Yang Y, Ma YD, Sun WW et al (2021) Effects of SiC on microstructure and properties of plasma sprayed ZrB2–ZrC composite coating. Ceram Int 47:12753–12761

Zhang L, Padture NP (2017) Inhomogeneous oxidation of ZrB2-SiC ultra-high-temperature ceramic particulate composites and its mitigation. Acta Mater 129:138–148

Huo CX, Zhou L, Guo LJ, Wang JC, Li YY, Sun J, Liu L (2019) Effect of the Al2O3 additive on the high temperature ablation behavior of the ZrC–ZrO2 coating for SiC-coated carbon/carbon composites. Ceram Int 45:23180–23195

Qing YC, Yao HY, Li Y, Luo F (2021) Plasma-sprayed ZrB2/Al2O3 ceramics with excellent high temperature electromagnetic interference shielding properties. J Eur Ceram Soc 41:1071–1075

Wang XM, La PQ, Wang BJ, Yang GL (2016) Toughening effect of ZrB2 in Al2O3-ZrB2 nanocomposite ceramics. Rare Metal Mat Eng 45(7):1714–1718

Xu JY, Zou BL, Fan XZ et al (2014) Reactive plasma spraying synthesis and characterization of TiB2–TiC–Al2O3/Al composite coatings on a magnesium alloy. J Alloys Compd 596:10–18

Zhao ZG, Li KZ, Li W (2021) Ablation behavior of ZrC-SiC-ZrB2 and ZrC-SiC inhibited carbon/carbon composites components under ultrahigh temperature conditions. Corros Sci 189:109598

Yeh CL, Wang YH (2021) Preparation of ZrB2–SiC–Al2O3 composites by SHS method with aluminothermic reduction. Ceram Int 47:11202–11208

Nayebi B, Parvin N, Mohandesi JA, Asl MS (2020) Densification and toughening mechanisms in spark plasma sintered ZrB2-based composites with zirconium and graphite additives. Ceram Int 46:13685–13694

Mishra SK, Rupa PKP, Das SK, Shcherbakov V (2007) Effect of titanium diluent on the fabrication of Al2O3–ZrB2 composite by SHS dynamic compaction. Compos Sci Technol 67:1734–1739

Nayebi B, Parvin N, Asl MS (2021) Nanostructural and nanoindentation characterization of ZrB2 ceramics toughened with in-situ synthesized ZrC. Int J Refract Met H 94:105391

Guo SQ, Kagawa Y (2004) Young’s moduli of zirconia top-coat and thermally grown oxide in a plasma-sprayed thermal barrier coating system. Scr Mater 50:1401–1406

Sun J, Fu QG, Huo CX, Li T (2018) Fracture toughness of thermally sprayed MoSi2 composite with different melting indices. Compos B Eng 150:242–247

Zhang RJ, Zhan X, Xing C, Hu L, Guo FW, Wang X, Zhao XF (2021) Preparation of long-lifetime thermal barrier coatings and toughening mechanism by using hierarchy structured zirconia-based microspheres. J Eur Ceram Soc 41(8):4625–4636

Zhou WY, Malzbender J, Zeng FL, Deibert W, Guillon O, Schwaiger R, Meulenberg WA (2020) Mechanical properties of BaCe0.65Zr0.2Y0.15O3-δ proton-conducting material determined using different nanoindentation methods. J Eur Ceram Soc 40(15):5653–5661

Garcia E, Garces HF, Turcer LR, Bale H, Padture NP, Sampath S (2021) Crystallization behavior of air-plasma-sprayed ytterbium-silicate-based environmental barrier coatings. J Eur Ceram Soc 41:3696–3705

Zhao ZM, Zhang L, Song YG, Wang WG, Wu J (2006) Microstructures and properties of rapidly solidified Y2O3 doped Al2O3/ZrO2 composites prepared by combustion synthesis. Scr Mater 55(9):819–822

Zhao ZM, Zhang L, Song YG, Wang WG (2008) Al2O3/ZrO2 (Y2O3) self-growing composites prepared by combustion synthesis under high gravity. Scr Mater 58(3):207–210

Zhao LY, Jia DC, Wang YJ, Rao JC, Yang ZH, Duan XM, Zhou Y (2010) ZrC–ZrB2 matrix composites with enhanced toughness prepared by reactive hot pressing. Scr Mater 163:887–890

Nayebia B, Parvina N, Aslb MS, Motallebzadehc A, Shokouhimehr M (2021) Nanostructural and nanoindentation characterization of ZrB2 ceramics toughened with in-situ synthesized ZrC. Int J Refract Met H 94:105391

Guo SQ (2014) Densification, microstructure, elastic and mechanical properties of reactive hot-pressed ZrB2–ZrC–Zr cermets. J Eur Ceram Soc 34:621–632

Asl MS, Nayebi B, Parvizi S, Ahmadi Z, Parvin N, Shokouhimehr M, Mohammadi M (2021) Toughening of ZrB2-based composites with in-situ synthesized ZrC from ZrO2 and graphite precursors. J Sci- Adv Mater Dev 6:42–48

Guo SQ (2019) In situ synthesis, physical and mechanical properties of ZrB2–ZrC–WB composites. J Eur Ceram Soc 39:3283–3291

Feng L, Fahrenholtz WG, Hilmas GE (2020) Effect of ZrB2 content on the densification, microstructure, and mechanical properties of ZrC-SiC ceramics. J Eur Ceram Soc 40:220–225

Guo QL, Li JG, Shen Q, Zhang LM (2012) Toughening of ZrB2-SiC ceramics with the microstructure ZrB2/Zr–Al–C fibrous monolith. Scr Mater 66:296–299

Zhang J, Su HJ, Song K, Liu L, Fu HZ (2011) Microstructure, growth mechanism and mechanical property of Al2O3-based eutectic ceramic in situ composites. J Eur Ceram Soc 31:1191–1198

Cheng EJ, Li Y, Sakamoto J, Han S, Sun HP, Noble J, Katsui H, Goto T (2017) Mechanical properties of individual phases of ZrB2-ZrC eutectic composite measured by nanoindentation. J Eur Ceram Soc 37(13):4223–4227

Fan ZQ, Zhao YT, Tan QY, Mo N, Zhang MX, Lu MY, Huang H (2019) Nanostructured Al2O3-YAG-ZrO2 ternary eutectic components prepared by laser engineered net shaping. Acta Mater 170:24–37

Xu CH (2005) Effects of particle size and matrix grain size and volume fraction of particles on the toughening of ceramic composite by thermal residual stress. Ceram Int 31:537–542

Dusza J, Csan´adi T, Medveˇd D, Sedl´ak R, Vojtko M, Ivor M, Ünsal H, Tatarko P, Tatarkov´a M, ˇSajgalík P (2021) Nanoindentation and tribology of a (Hf-Ta-Zr-Nb-Ti)C high-entropy carbide. J Eur Ceram Soc 41: 5417–5426.

Acknowledgements

The authors gratefully acknowledge the financial supports of the National Natural Science Foundation of China (52072110), the Natural Science Foundation of Hebei Province (E2018202034).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. No potential conflict of interest was reported by the authors.

Ethical approval

The authors confirm that the sources of all funding for the research work are listed. The authors confirm that this manuscript has not been previously published in any format, is not under consideration for publication elsewhere, that reuse permissions and appropriate citations have been included for all previously published material, and that the publication has been fully approved by all stakeholders. Results are presented clearly, honestly and without fabrication, falsification, or inappropriate data manipulation (including image manipulation). Authors confirm that they adhere to discipline-specific rules for acquiring, selecting. and processing data. And no data, text, or theories by others are presented as if they were the author’s own (“plagiarism”). Proper acknowledgments to other works are given (this includes material that is closely copied (near verbatim), summarized and/or paraphrased), quotation marks (to indicate words taken from another source) are used for verbatim copying of material, and permissions secured for material that is copyrighted.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cui, Yh., Jia, St., Yang, Y. et al. Toughening mechanism of in-situ synthesized ZrB2 based composite coating by plasma spraying. J Mater Sci 57, 4145–4152 (2022). https://doi.org/10.1007/s10853-021-06839-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06839-5