Abstract

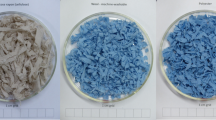

Increasing environmental concern has put forward the use of flax fibers instead of glass fibers in composite materials. However, durability performances of these bio-fibers remain one of their main issues. This study focuses on the hydrothermal aging of flax fibers. Flax tows were immersed in distilled water at a temperature of 80 °C for different durations. The effect of the hydrothermal aging on mechanical properties of flax tows was evaluated. Results showed a strong decrease in the maximal strength and the stiffness by 31% and 49%, respectively, until one week of aging. Multi-scale analyses were realized to explain these evolutions. Morphological characterization highlighted a washing of fiber surfaces during the hydrothermal aging, extracting amorphous components as pectins, lignins and amorphous hemicelluloses from cortical tissues. We showed that this morphological evolution impacted the fiber crystallinity. Based on a mechanical analysis, we showed that amorphous components extraction may be at the origin of the material softening. Moreover, the amorphous phase in particular the natural binder pectin would play a major role in the fiber stiffness but does not modify the flaws at the origin of failure.

adapted from Moothoo et al. [15]; a cross-sectional view, b longitudinal view

Similar content being viewed by others

References

Baley C, Goudenhooft C, Gibaud M, Bourmaud A (2018) Flax stems: from a specific architecture to an instructive model for bioinspired composite structures. Bioinspir Biomim 13:026007. https://doi.org/10.1088/1748-3190/aaa6b7

Baley C, Gomina M, Breard J et al (2019) Specific features of flax fibres used to manufacture composite materials. Int J Mater Form 12:1023–1052. https://doi.org/10.1007/s12289-018-1455-y

Baley C, Gomina M, Breard J et al (2020) Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind Crops Prod 145:111984. https://doi.org/10.1016/j.indcrop.2019.111984

Baley C, Le Duigou A, Morvan C, Bourmaud A (2018) 8—Tensile properties of flax fibers. In: Bunsell AR (ed) Handbook of properties of textile and technical fibres, 2nd edn. Woodhead Publishing, Cambridge, pp 275–300

Dittenber DB, GangaRao HVS (2012) Critical review of recent publications on use of natural composites in infrastructure. Compos Part A Appl Sci Manuf 43:1419–1429. https://doi.org/10.1016/j.compositesa.2011.11.019

Cicala G, Cristaldi G, Recca G, Latteri A (2010) Composites based on natural fibre fabrics. Woven fabric engineering. Sciyo, Rijeka

Baley C (2002) Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos Part A Appl Sci Manuf 33:939–948. https://doi.org/10.1016/S1359-835X(02)00040-4

Lefeuvre A, Le DA, Bourmaud A et al (2015) Analysis of the role of the main constitutive polysaccharides in the flax fibre mechanical behaviour. Ind Crops Prod 76:1039–1048. https://doi.org/10.1016/j.indcrop.2015.07.062

Gorshkova T, Brutch N, Chabbert B et al (2012) Plant fiber formation: state of the art, recent and expected progress, and open questions. CRC Crit Rev Plant Sci 31:201–228. https://doi.org/10.1080/07352689.2011.616096

Lefeuvre A, Bourmaud A, Morvan C, Baley C (2014) Elementary flax fibre tensile properties: correlation between stress–strain behaviour and fibre composition. Ind Crops Prod 52:762–769. https://doi.org/10.1016/j.indcrop.2013.11.043

Alix S, Colasse L, Morvan C et al (2014) Pressure impact of autoclave treatment on water sorption and pectin composition of flax cellulosic-fibres. Carbohydr Polym 102:21–29. https://doi.org/10.1016/j.carbpol.2013.10.092

Lamon J, R’Mili M, Reveron H (2016) Investigation of statistical distributions of fracture strengths for flax fibre using the tow-based approach. J Mater Sci 51:8687–8698. https://doi.org/10.1007/s10853-016-0128-9

Baley C, Bourmaud A (2014) Average tensile properties of French elementary flax fibers. Mater Lett 122:159–161. https://doi.org/10.1016/j.matlet.2014.02.030

Stamboulis A, Baillie CA, Peijs T (2001) Effects of environmental conditions on mechanical and physical properties of flax fibers. Compos Part A Appl Sci Manuf 32:1105–1115. https://doi.org/10.1016/S1359-835X(01)00032-X

Moothoo J, Allaoui S, Ouagne P, Soulat D (2014) A study of the tensile behaviour of flax tows and their potential for composite processing. Mater Des 55:764–772. https://doi.org/10.1016/j.matdes.2013.10.048

Bos HL (2004) The potential of flax fibres as reinforcement for composite materials. Technische Universiteit Eindhoven, Eindhoven

Beakou A, Charlet K (2013) Mechanical properties of interfaces within a flax bundle—part II: numerical analysis. Int J Adhes Adhes 43:54–59. https://doi.org/10.1016/j.ijadhadh.2013.01.013

Charlet K, Béakou A (2011) Mechanical properties of interfaces within a flax bundle—part I: experimental analysis. Int J Adhes Adhes 31:875–881. https://doi.org/10.1016/j.ijadhadh.2011.08.008

Romhány G, Karger-Kocsis J, Czigány T (2003) Tensile fracture and failure behavior of technical flax fibers. J Appl Polym Sci 90:3638–3645. https://doi.org/10.1002/app.13110

Griffith AA, Taylor GI (1921) VI. The phenomena of rupture and flow in solids. Philos Trans R Soc Lond Ser A Contain Pap a Math or Phys Character 221:163–198. https://doi.org/10.1098/rsta.1921.0006

Griffith AA (1924) Proceedings of the first international congress of applied mechanics, Delft, pp 56–63

Shah SP, McGarry F (1971) Griffith fracture criterion and concrete. ASCE J Eng Mech Div 97:1663–1676

Xiao ZM, Chen BJ (2001) Stress analysis for a Zener-Stroh crack interacting with a coated inclusion. Int J Solids Struct 38:5007–5018. https://doi.org/10.1016/S0020-7683(00)00335-8

Lazarus V (2017) Fracture spacing in tensile brittle layers adhering to a rigid substrate. EPL (Europhys Lett) 117:24002. https://doi.org/10.1209/0295-5075/117/24002

Rice JR (1968) A path independent integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech 35:379–386. https://doi.org/10.1115/1.3601206

Rice JD (1968) Mathematical analysis in the mechanics of fracture. Math Fundam 2:191–311

Dubois F, Chazal C, Petit C (2002) Viscoelastic crack growth process in wood timbers: an approach by the finite element method for mode I fracture. Int J Fract 113:367–388. https://doi.org/10.1023/A:1014203405764

Mokhothu TH, John MJ (2015) Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr Polym 131:337–354. https://doi.org/10.1016/j.carbpol.2015.06.027

Célino A, Fréour S, Jacquemin F, Casari P (2014) The hygroscopic behavior of plant fibers: a review. Front Chem 1:43. https://doi.org/10.3389/fchem.2013.00043

Célino A, Gonçalves O, Jacquemin F, Fréour S (2014) Qualitative and quantitative assessment of water sorption in natural fibres using ATR-FTIR spectroscopy. Carbohydr Polym 101:163–170. https://doi.org/10.1016/j.carbpol.2013.09.023

Thuault A, Eve S, Blond D et al (2014) Effects of the hygrothermal environment on the mechanical properties of flax fibres. J Compos Mater 48:1699–1707. https://doi.org/10.1177/0021998313490217

Le Duigou A, Bourmaud A, Davies P (2011) Etude des mécanismes d’adhérence entre une fibre de lin et le PLLA- Influence d’un traitement faiblement impactant à l’eau Study of adherence mechanism between flax fibre and PLLA matrix- Influence of low environmental impact water treatment. Science 80:1–9

Bourmaud A, Morvan C, Baley C (2010) Importance of fiber preparation to optimize the surface and mechanical properties of unitary flax fiber. Ind Crops Prod 32:662–667. https://doi.org/10.1016/j.indcrop.2010.08.002

Tserki V, Zafeiropoulos NE, Simon F, Panayiotou C (2005) A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos Part A Appl Sci Manuf 36:1110–1118. https://doi.org/10.1016/j.compositesa.2005.01.004

Hill CAS, Norton A, Newman G (2009) The water vapor sorption behavior of natural fibers. J Appl Polym Sci 112:1524–1537. https://doi.org/10.1002/app.29725

Moine C (2005) Extraction, caractérisation structurale et valorisation d’une famille d’hémicelluloses du bois: obtention de matériaux plastiques par modification des xylanes. Université de Limoges, Limoges

Lu Y, Miller JD (2002) Carboxyl stretching vibrations of spontaneously adsorbed and LB-transferred calcium carboxylates as determined by FTIR internal reflection spectroscopy. J Colloid Interface Sci 256:41–52. https://doi.org/10.1006/jcis.2001.8112

Irwin GR (1957) Analysis of stresses and strains near the end of a crack transversing a plate. Trans ASME Ser E J Appl Mech 24:361–364

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The flax fibers used in these studies had the following composition.

Cellulose wt% | Hemicellulose wt% | Pectin wt% | Lignin wt% | Waxes wt% | Water wt% |

|---|---|---|---|---|---|

83.8 | 2.5 | 4.2 | 2.3 | 4.8 | 7 |

Rights and permissions

About this article

Cite this article

Van Schoors, L., Beauzieres, N., Cadu, T. et al. Relationship between physicochemical evolution and the failure process of flax fibers aged in water. J Mater Sci 56, 10664–10675 (2021). https://doi.org/10.1007/s10853-021-05908-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05908-z