Abstract

Disconnections were recently shown to play a role in the mechanism of grain boundary motion in general grain boundaries in SrTiO3. In this work, we demonstrate the existence of disconnections in the viewing direction along the projected thickness of transmission electron microscopy samples and characterize possible aspects of the structure of these disconnections. We show that the presence of steps along the viewing direction may result in the appearance of a disordered region at the boundary, while it is actually composed of ordered crystalline material. We discuss the subsequent complications in analysis of transmission electron microscopy data and strict meaning of the term “edge-on” for grain boundaries.

Similar content being viewed by others

Introduction

Modern high-resolution transmission electron microscopy (HRTEM) is important when characterizing structural defects due to its ability to achieve real space sub-Angstrom resolution with reduced contrast delocalization for relatively straightforward interpretation of image contrast at extended defects. The latter can be achieved using negative spherical aberration (Cs) imaging conditions combined with exit wave reconstruction [1].

Negative Cs conditions provide a bright intensity in HRTEM micrographs directly correlated with the position of atomic columns, in addition to minimization of the contrast delocalization [1, 2]. Exit wave reconstruction recovers the complex wave function at the exit plane of the sample, offering additional advantages for quantitative analysis. These advantages include an enhanced signal-to-noise ratio compared to single micrographs, the removal of residual contrast delocalization, the measurement of residual aberrations a posteriori, and the removal of nonlinear imaging artifacts. In addition, no information is lost due to null contrast at specific spatial frequencies, which is intrinsic to a single experimental micrograph due to the form of the phase-contrast transfer function [3,4,5,6,7].

As a result, structural information can be recovered at resolutions beyond those achieved using conventional imaging (which are limited by the temporal and spatial coherence of the incident wave). The required data sets needed for exit wave reconstruction are either a defocus series of HRTEM micrographs or a tilted illumination series of HRTEM micrographs. Exit wave reconstruction performed using a focal series is resolution limited by the coherence of the incident wave, whereas using a tilt series, the resolution can be further extended [8, 9]. Since exit wave reconstruction restores the complex wave function, free of the objective lens aberration, a comparison between simulated and experimental wave functions requires only one unknown parameter (the thickness), in contrast to a number of unknown variables involved when analyzing conventional HRTEM micrographs [5, 8,9,10,11,12].

Exit wave reconstruction can be conducted using linear filters, such as the Wiener filter [5, 7] or nonlinear iterative methods [13,14,15]. In this work, we used the focal and tilt series restoration (FTSR) software [16] for general grain boundaries. As described elsewhere [17, 18], FTSR initially uses a phase correlation function to find the relative defocus values between images in a focus series and the image registration vectors, and subsequently a phase contrast index function to determine the absolute astigmatism and defocus. Finally, a linear Wiener filter is used to restore the exit wave function [19].

Recently, general high-angle grain boundaries in SrTiO3 were shown to be composed of steps and microscopic segments of grain boundary planes, creating overall macroscopic (vicinal) grain boundary planes [20]. It was shown that in samples annealed under a relatively high oxygen partial pressure, the grain boundary and step planes were aligned mainly parallel to {001} and {110} crystallographic planes. These steps include a dislocation character creating overall disconnections [20].

In the present work, we have characterized the structure of these disconnections at general grain boundaries in SrTiO3 annealed under a relatively high oxygen partial pressure, focusing on the structure of the macroscopic grain boundary planes along the viewing direction of the TEM samples, using aberration-corrected TEM and exit wave reconstruction. General grain boundaries have been studied in either polycrystalline SrTiO3 samples or as boundaries between a single crystal of SrTiO3 of a predefined orientation diffusion-bonded to polycrystalline SrTiO3.

The kinetic behavior of the characterized grain boundaries was studied by Rheinheimer et al. who showed that a significant change in the grain boundary mobility appeared in a temperature range of 1350–1425 °C in both polycrystalline SrTiO3 and diffusion-bonded samples annealed under a relatively high oxygen partial pressure [21, 22]. Thus, the present work will focus on samples annealed within this temperature range.

Experimental methods

SrTiO3 samples

Two different sample types were used in the present study; standard polycrystalline samples and single crystals which were diffusion-bonded to a polycrystal. For the polycrystals, stoichiometric ceramic powder was prepared by a mixed oxide/carbonate route based on high-purity raw materials (SrCO3 and TiO2, purity of 99.95% and 99.995%, Sigma-Aldrich Chemie GmbH, Taufkirchen, Germany). Details of the synthesis are published elsewhere [23]. The green bodies were pre-sintered at 1425 °C for 1 h in oxygen to obtain a relative density of 99.5 ± 0.2%. After pre-sintering, polycrystalline samples were heated at 20 K/min to 1350 °C and 1550 °C in oxygen or air. For all heat treatments in this study, a tube furnace was used (Carbolite Gero GmbH & Co. KG, Neuhausen, Germany). After different heating times, samples were either furnace-cooled, air-quenched or water-quenched. For air quenching, the samples were removed from the hot zone of the furnace without changing the atmosphere yielding a cooling rate of more than 200 K/min. For water quenching, samples were dropped into liquid water without changing the atmosphere. Cooling below 100 °C was estimated to occur within 3 s [20].

For the joining of diffusion-bonded samples, pre-sintered polycrystals were cut into disks and polished (diamond slurry, 0.25 µm). The SrTiO3 single crystals (impurity content: < 10 ppm Si, < 2 ppm Ba, < 1 ppm Ca, SurfaceNet GmbH, Rheine, Germany) were chemical–mechanical polished and placed between two polished and intentionally scratched polycrystalline disks. Stacks were joined at 1430 °C for 20 min in air with a compressive load of 1 MPa. More details of this procedure can be found elsewhere [20, 22, 24].

In a similar manner to the polycrystals, the diffusion-bonded samples were heated to temperatures between 1350 and 1425 °C in oxygen. All diffusion-bonded samples were water-quenched as described above.

Characterization methods

TEM samples were prepared using the following methods:

-

(a)

The conventional method based on slicing, mechanical thinning, dimpling and ion milling with Ar at 2–5 kV was used for polycrystalline samples.

-

(b)

The lift-out technique using a dual beam focused ion beam (FIB; FEI Strata 400s) was used for selecting and preparing TEM samples from the diffusion-bonded samples, focusing on boundaries between the single crystal and a grain from the polycrystalline side [25].

The samples were characterized using an aberration-corrected TEM (FEI Titan 80–300 keV S/TEM) operated at 300 keV with minimum and maximum high-angle annular dark field (HAADF)-scanning transmission electron (STEM) detector angles of 1.9–200 mrad. Each boundary was tilted to the edge-on condition, such that the electron beam was parallel to the macroscopic grain boundary plane.

Results

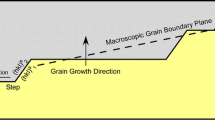

Recently, the existence of steps along edge-on general grain boundaries in SrTiO3 was demonstrated using HRTEM [20]. For a boundary oriented to the edge-on condition, both the step and the grain boundary planes are parallel to the electron beam direction across the entire projected thickness of the sample (Fig. 1a). At the same time, steps in the viewing direction of the TEM samples (in the direction of the projected thickness) are also expected to exist. Such steps in the viewing direction would shift the position of sections of the edge-on grain boundary plane in the viewing direction (Fig. 1b). The steps in the viewing direction (the direction of the projected thickness of the sample) are defined here as “inclined steps” since they are inclined to the viewing direction (the electron beam direction) to differentiate them from “edge-on steps” which are parallel to the viewing direction. The existence of steps in the viewing direction of the TEM sample results in small changes in the position of the edge-on macroscopic grain boundary plane (which is composed of edge-on steps and grain boundary planes) in the viewing direction of the sample, as demonstrated schematically in Fig. 1c. As such, the majority of the boundary is edge-on and the inclined steps are the only section of the macroscopic grain boundary plane which is tilted from the viewing direction.

A schematic drawing of the definitions used in this manuscript. a Edge-on steps and grain boundary planes are present along the boundary. b Steps inclined to the electron beam direction are present along the boundary. The grain boundary plane in this case is parallel to the electron beam direction. c Inclined steps intersecting with edge-on step and grain boundary planes. Below each schematic drawing of a boundary, an expected representation of a TEM micrograph is shown

In constructing Fig. 1b and c, we have assumed that in the majority of cases the segments of the grain boundary plane in the viewing direction are aligned parallel to the electron beam direction and the steps in the viewing direction are inclined. This assumption is consistent with our experimental data (as will be discussed below) since the artifacts resulting from the disconnections in the viewing direction are rather narrow and can be related to the shorter sections of the macroscopic grain boundary plane, meaning the steps. These cause small shifts in the position of sections of the grain boundary plane in the viewing direction, resulting in the projection of such inclined steps in the TEM micrograph to appear as narrow regions of indeterminate contrast. If the grain boundary plane was not parallel to the viewing direction (and the steps in the viewing direction were edge-on), the grain boundary plane in the viewing direction would be tilted and its projection would appear as wide regions of indeterminate contrast. As such, throughout the paper, we adopt the geometry of inclined steps rather than inclined grain boundary plane segments. It should, however, be considered that both possibilities can occur depending on the local curvature of the grain boundary and the one adopted here is that experimentally identified. In cases where the grain boundary and step planes are of similar length, this description would no longer be valid.

Noting the anisotropic nature of the edge-on steps and grain boundary planes in samples annealed under similar conditions [20], we expect the step and grain boundary planes in the viewing direction to be parallel to the same crystallographic planes. This assumption will be subsequently supported using simulations and experimental data. The description of the boundaries shown previously [20] represents the projections of samples with several inclined steps along the sample projected thickness, since the step and grain boundary planes are significantly smaller than the thickness of the samples.

As a result of inclined steps, the position of the edge-on step and grain boundary planes in Fig. 1c is shifted by a certain distance normal to the edge-on step plane, normal to the edge-on grain boundary plane and in the direction of the electron beam. The distance of the resulting shift in the direction normal to the edge-on step and grain boundary planes is a projection of the length of the inclined step in these directions. In the direction of the electron beam, this distance is a projection of the length of the inclined step along the electron beam direction.

The presence of inclined steps is demonstrated in Figs. 2, 3, 4 and 5. It should be taken into account that given that the complete 3D structure of general grain boundaries cannot be determined, as described in detail in [26], an inherent uncertainty lies in determination of the position of inclined steps based on the resulting artifacts. As such, in this work the goal is to indicate their presence in addition to some examples of possible positions, rather than their exact position, which cannot be determined. As such, the grain boundary and step planes were identified by the bright contrast in the HRTEM micrographs, even though the exact atomic arrangement cannot be determined (as described in detail in [26]). To distinguish between edge-on grain boundary and step planes and inclined steps, the edge-on planes were identified by bright contrast in the boundary region with a small decrease in intensity compared to the bulk. Inclined steps were thus identified by weaker contrast along the boundary region.

HRTEM micrograph of an edge-on grain boundary. The lower grain is oriented close to a [110] zone axis. The upper grain is close to a [210] zone axis. Nanometer length-scale steps are visible along the boundary. The micrograph was acquired using an accelerating voltage of 300 kV, Cs = − 7.0 μm, and Wiener filtered to remove noise. (Reproduced with permission from [20]. The difference in the overlaid markings results from dividing between edge-on and inclined steps in this work.)

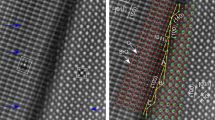

HAADF-STEM micrographs of the grain boundary presented in Fig. 2. The micrographs were acquired using an accelerating voltage of 300 kV

HRTEM micrograph of an edge-on grain boundary. The lower grain is oriented close to a [111] zone axis. Nanometer length-scale steps are visible along the boundary. The micrograph was acquired using an accelerating voltage of 300 kV, Cs = − 7.0 μm, and Wiener filtered to remove noise. (Reproduced with permission from [20]. The difference in the overlaid markings results from dividing between edge-on and inclined steps in this work.)

HRTEM micrograph of an edge-on general grain boundary. The upper grain is oriented close to a [001] zone axis. Nanometer length-scale steps are visible along the boundary (marked in yellow). The lower grain is close to a [331] zone axis. The micrograph was acquired using an accelerating voltage of 300 kV, Cs = − 5.69 μm, and Wiener filtered to remove noise (reproduced with permission from [20])

In the region of the micrograph showing inclined steps (or grain boundary planes), the lattice of one grain overlaps with that of the second grain, and a superimposed lattice pattern of the two grains must then form. For example, Fig. 2 presents a HRTEM micrograph of a polycrystalline sample, annealed at 1350 °C for 10 h in oxygen and quenched in gas, and then annealed at 1350 °C in air and quenched in water. The dashed yellow lines indicate an area in the upper grain which is superimposed with the lower grain, presumably due to inclined steps. The inclined steps in this case would be perpendicular to the incident beam direction. As a result, the shifts between the positions of segments of grain boundary planes in the viewing direction are the inclined step height (or an integer multiple). As can be seen in Fig. 2, these shifts match the length of an edge-on step. In addition, it is apparent that possible positions of grain boundary planes and steps indicated by the dashed lines lay parallel to the yellow lines representing edge-on grain boundary and step planes. These findings support the assumption that the segments of the grain boundary plane in the viewing direction are parallel to the edge-on grain boundary planes and that the inclined steps are perpendicular to the edge-on grain boundary and step planes, such that the edge-on step and grain boundary planes and those in the viewing direction run parallel to the same family of crystallographic planes (are of the same nature).

In HAADF-STEM micrographs from the same boundary (Fig. 3), a decrease in intensity (compared to the bulk of the lower grain) is evident at the last planes of atoms which show the same periodicity as the lower grain. These planes are marked by the dashed yellow lines and are parallel to the edge-on step and grain boundary planes along the boundary marked by the yellow lines. In HAADF-STEM micrographs, the contrast is dependent on the atomic number of the atoms in projection. Since the entire sample is composed of SrTiO3, the decrease in intensity in the last planes of the lower grain must be correlated with a local decrease in the relative thickness of this grain in the sample. Since the overall thickness of the sample is relatively uniform (which was confirmed by electron energy loss thickness maps), the decrease in thickness of the lower grain is due to the presence of inclined steps. As mentioned above for Fig. 2, the shifts in the position of segments of grain boundary planes (distances between parallel yellow lines and dashed yellow lines) equal the length of an edge-on step. This, in addition to the dashed yellow lines being parallel to the edge-on step and grain boundary planes, supports the presence of inclined steps, which are of the same nature as the edge-on steps. The appearance of contrast resulting from inclined steps in HAADF-STEM micrographs is consistent with the contrast observed in HRTEM micrographs and the presence of inclined steps.

The dashed lines in Figs. 2, 3, 4 and 5 indicate regions with a relatively high density of inclined steps. Thus, in HRTEM micrographs the superimposed lattice structure from the two grains is imaged. In areas with a lower density of inclined steps, marked by arrows in Figs. 4 and 5, only small parts that show this contrast are visible. Figure 4 presents a HRTEM micrograph of another boundary from the same sample from which Fig. 2 was acquired. Figure 5 presents a HRTEM micrograph of a polycrystalline sample that was annealed at 1350 °C for 10 h in oxygen and furnace-cooled. In this case, a weak pattern of single or multiple spots which should not appear in the absence of inclined steps is apparent. In Fig. 4, these spots appear with the same periodicity as the lower grain “inside” the area related to the upper grain. These spots appear in the form of triangular patterns indicated by the dashed lines in Fig. 5. These features result from local changes in the relative thickness of each of the grains due to the presence of inclined steps. As such, the lattice contrast changes locally and the expected bulk fourfold symmetry is distorted to a triangular shape. In the HAADF-STEM micrographs (Fig. 3), no triangular features were observed. This is due to the contrast in HAADF-STEM being less sensitive to small changes in effective thickness of each of the grains (varying due to inclined steps) than phase-contrast HRTEM imaging. This further supports our hypothesis that the appearance of triangular-shaped features is due to inclined steps rather than actual changes in the atomistic structure or strain. In these cases, due to the presence of inclined steps, there is no abrupt change in the contrast from one grain to the other. The periodicity of both types of artifacts (marked by dashed lines and arrows) indicates that the inclined steps are of the same nature as the edge-on step and grain boundary planes.

In order to detect grain boundary steps, the grain boundary must be aligned such that the majority of the boundary is edge-on, and the inclined steps are the only planes along the macroscopic grain boundary plane which are not edge-on. When the boundary is not aligned in such a manner, the projection of the boundary area is characterized by a relatively wide boundary region having a combination of moiré contrast, superimposed lattice patterns from the two grains and interference lines resulting from extinction distance. This will be subsequently defined as a “tilted boundary” in this work. In Fig. 6, a HRTEM micrograph from a tilted boundary is presented, acquired from a polycrystalline SrTiO3 sample that was annealed at 1350 °C for 10 h in oxygen, and quenched in gas at a cooling rate of ~ 200 °C/min, then annealed again at the same temperature in air for an hour and finally quenched in water. Two lines of dark contrast appear along the boundary, apparently resulting from interference lines correlated with the extinction distance, since when the boundary is tilted, the electron beam travels through varying distances in each of the grains in this region. The gradual change in the relative thickness of both grains can be described using the extinction distance, resulting in the appearance of dark and bright fringes [27]. The spacing between the dark lines is ~ 2.5 nm. The fact that these dark lines are not straight supports our model for steps at the boundary. In Fig. 6, an angle of ~ 137° was measured between the yellow lines. The yellow lines represent estimated planes for edge-on grain boundary and step planes (which would appear as edge-on planes after tilting the boundary such that the majority of the boundary is edge-on). One of these planes is the (011) plane in the upper grain. Based on a previous study [20], assuming that the second plane is the (\( 00\overline{1} \)) plane in the upper grain, an angle of 135° is expected. A moiré pattern appears along the black lines (marked by red lines in Fig. 6) with a measured periodicity of 0.87 nm matching the calculated spacing of the moiré pattern resulting from the (011) periodicities in each of the grains [27]. The direction of the expected moiré pattern resulting from the (011) planes of both grains is marked by a purple line in Fig. 6. This line is in a similar direction to the red lines in the micrograph which indicate the moiré pattern. Between the black lines, superimposed lattice patterns from the two grains are evident. The appearance of step and grain boundary planes in a tilted boundary was noted in each of the studied boundaries before they were aligned such that the majority of the boundary was edge-on, regardless of the annealing temperature, quenching rate and the orientation of the grains creating the boundary.

HRTEM micrograph of a tilted boundary. The red lines indicate a moiré pattern. The white and orange lines indicate the periodicity of the (011) planes of the upper and lower grains, respectively. The purple line indicates the moiré pattern resulting from the white and orange lines. The yellow lines indicate estimated grain boundary and step planes. The micrograph was acquired using an accelerating voltage of 300 kV, Cs = − 7.6 μm, and Wiener filtered to remove noise

To further confirm that inclined steps are present in the studied boundaries, their influence on single micrographs and on a focal series was studied by comparing experimental data and simulations. For these calculations, simulated random grain boundaries were constructed by defining two crystals where at least one was oriented along a low index zone axis. The step and grain boundary planes were defined as parallel to {100} and {110} planes following experimental observations [20].

For each simulated grain boundary, the sample was sectioned into thin slices and the dynamically scattered electron wave was calculated using the multi-slice approach within the EMS software package [28,29,30,31,32]. For simulated focal series, defocus values of − 20 nm up to 20 nm were selected (at defocus steps of 2 nm), whereas for simulated micrographs under negative Cs conditions, Cs = − 7 μm and defocus = 4 nm were used (accelerating voltage of 300 kV). The defocus series was subsequently used to reconstruct a theoretical exit wave function using the FTSR software [16].

The influence of two inclined steps on a single micrograph is shown in Figs. 7 and 8. The grain on the left was oriented in the [010] zone axis, and the grain on the right was randomly oriented. The segments of grain boundary plane in the viewing direction were oriented parallel to {100} planes, and inclined steps were introduced parallel to {110} planes (Fig. 7e, f). One example, in which the inclined steps were parallel to two different types of planes (both {100} and {110} planes), was also studied (Fig. 7c), even though this case has not been observed experimentally [20]. A boundary without inclined steps is also shown for comparison (Fig. 7a). In all cases, strain was not introduced in either of the grains at the boundary region. As noted in the negative Cs simulated images (Fig. 8), instead of a clear transition between the crystal in the [010] zone axis and the randomly selected grain, an apparently partially disordered transition area with complex contrast appears along the boundary, although no disordered material was introduced into the simulation. This transition area is the result of inclined steps, which change the local symmetries in the viewing direction in the vicinity of the boundary. These simulated inclined steps cause a shift in the position of segments of the grain boundary plane along the viewing direction, which is visible in the simulated images, and is similar to the contrast seen in the experimental TEM micrographs (the previously mentioned artifacts). Along the area in which the inclined steps are present, triangular-shaped features appear in the simulated micrographs (marked by the dashed lines in Fig. 8b), similar to those observed experimentally (Fig. 5).

Boundary models with and without inclined steps. In a, c, e, f, the grain on the left is oriented along [001] zone axis. b, d were constructed by tilting the boundaries in a, c by 90°, respectively. a–f were used to create the simulated images in Fig. 8. a, b A flat grain boundary without steps. c, d A grain boundary with two steps along {001} and {110} planes. e A grain boundary with two steps, both along {110} planes. TiO-Sr terminations were selected along {110} planes. f A grain boundary with two steps, both along {110} planes. O–O terminations were selected along {110} planes. The electron beam direction is marked in red in all diagrams. Green circles represent Sr, red circles represent O, and blue circles represent Ti

Simulated HRTEM images of boundaries where the majority of the boundary is edge-on under negative Cs imaging conditions (Cs = − 7 μm, defocus = 4 nm, accelerating voltage of 300 kV). The images were simulated based on the boundary models presented in Fig. 7. The grain on the left is oriented along [010] zone axis. a A flat edge-on grain boundary without steps (Fig. 7a, b). b A grain boundary with two inclined steps along {001} and {110} planes (Fig. 7c, d). c A grain boundary with two inclined steps, both along {110} planes. TiO-Sr terminations were selected along {110} planes (Fig. 7e). d A grain boundary with two inclined steps, both along {110} planes. O–O terminations are along {110} planes (Fig. 7f)

Increasing the number of inclined steps in a model of a boundary with higher symmetry, composed of a grain oriented in a [010] zone axis and a grain in a [\( 11\overline{2} \)] zone axis, resulted in a similar transition contrast at the grain boundary (Figs. 9 and 10). For simplicity, both the grain boundary and the step planes along the viewing direction were set parallel to {100} planes of the grain on the left. In this case, due to the presence of more changes between the symmetries of the delimiting grains in the beam direction, this area appears less ordered and triangular-shaped patterns appear in the image in the region where the inclined steps are present.

a Boundary model with 21 inclined steps. The grain on the left is oriented along [001] zone axis, and the grain on the right is oriented along [111] zone axis. b The boundary after rotating (a) by 90° to the orientation used to simulate the image in Fig. 10. The electron beam direction is marked in red. Green circles represent Sr, red circles represent O, and blue circles represent Ti

Simulated HRTEM image of an edge-on grain boundary (Fig. 9b) under negative Cs imaging conditions with inclined steps (Cs = − 7 μm, defocus = 4 nm, accelerating voltage of 300 kV). The left grain is oriented along [010] zone axis and the right grain along [\( 11\overline{2} \)] zone axis

A focal series from the boundary presented in Fig. 5 was also acquired and was used to reconstruct the exit wave function using the FTSR software [16]. The phase of the exit wave function from the boundary from Fig. 5 is shown in Fig. 11. Nanometer length-scale steps and a partially disordered layer appear along the boundary. This area is assumed to be related to inclined steps, consistent with our data from single images. It should be noted that the disordered region at the boundary, resulting from the inclined steps, is more pronounced in the exit wave function (Fig. 11) than in the single micrograph (Fig. 5). To highlight this, the Fourier transform of the phase presented in Fig. 11 was filtered in Fourier space to remove the periodic reflections and inverse transformed. The result is presented in Fig. 12, enhancing regions in which non-periodic scattering is significant. From Fig. 12, it can be seen that non-periodic scattering is dominant at the boundary region, due to the inclined steps.

Experimentally recovered phase of the exit wave function of the grain boundary presented in Fig. 5. Nanometer length-scale steps are visible along the boundary, and a partially disordered layer is evident

An inverse transform of a filtered Fourier transform of the phase presented in Fig. 11, highlighting regions in which non-periodic scattering is dominant

The appearance of inclined steps was more pronounced in the exit wave function. To further confirm this, a focal series of a simulated boundary was calculated (using the boundary model in Fig. 9b) and the amplitude and phase of the simulated exit wave function are presented in Fig. 13. As in the experimental data, the inclined steps are more pronounced in the exit wave function rather than in a single micrograph in the simulated results (assuming negative Cs conditions as in Fig. 8). It should be noted that the simulated contrast in the bulk of the grains deviates from what would be expected for an ideally thin sample (weak phase object) due to the thickness of the simulated structure.

a Amplitude and b phase of the exit wave function of the boundary presented in Fig. 9b

Discussion

Grain boundaries are usually studied using HRTEM assuming that the grain boundary is flat in the electron beam direction. Recently, grain boundaries in SrTiO3 were found to have disconnections along macroscopic grain boundary planes [20]. The results presented here indicate that disconnections are also present within the thickness of TEM specimens. Here, we refer only to the step character of disconnections in the viewing direction (along the projected thickness of the TEM sample), since the dislocation component of the disconnections cannot be determined in this direction.

The presence of inclined steps in the viewing direction can appear as a “disordered” contrast at the boundary due to each inclined step resulting in the superposition of atoms from both grains in the viewing direction. This is an imaging artifact which does not exist for extremely thin edge-on grain boundaries without inclined steps. Due to the short length of the inclined steps (as expected from the experimental results involving edge-on steps reported previously [20]) and the thickness of TEM samples, it is not likely that a TEM sample without inclined steps can be produced.

Since a small number of inclined steps cause only slight changes in the contrast of TEM micrographs, this effect is not significant. Consequently, a lack of contrast resulting from inclined steps does not necessarily indicate their absence. The density of steps and the length of grain boundary planes are related to the curvature of a boundary, the orientation of the macroscopic grain boundary plane and the orientation of the grains defining the boundary [20, 26]. In addition to variations in sample thickness, the varying density of steps and lengths of grain boundary planes also affect the ratio between regions which appear ordered or disordered.

From Fig. 8, slight deviations in the intensity of the step and grain boundary planes in the viewing direction are expected to appear in the boundary region when changing the orientation of the inclined steps (Fig. 8b, c) or the chemical composition of the last plane of atoms (Fig. 8c, d). In the case of experimental micrographs for which the quantity, chemistry and structure of the inclined steps are unknown, it is not possible to distinguish between such cases from image contrast alone. Throughout this manuscript, we assume that the disconnections in the viewing direction are of a similar nature to those previously characterized along the boundary in SrTiO3 [20], which was verified by simulations and experimental results. Hence, we further assume that the case presented in Figs. 7c, d and 8b, which considers two types of inclined steps, does not occur.

The presence of inclined steps causes changes in the local effective thickness at each of the grains in the vicinity of the boundary. As a result, the contrast in HRTEM micrographs is changed, which may lead to changes in the apparent periodicity expected from bulk grains in the vicinity of the boundary. Such changes in contrast were noted in HRTEM simulations in which no distortions in the atomic structure of the grains were introduced at the boundary. In addition, in HAADF-STEM micrographs, which are less sensitive to local changes in effective thickness, the atomic structure of the bulk continued to the vicinity of the boundary where inclined steps were detected.

Summary and conclusions

Disconnections along the viewing direction of TEM samples were found to cause an apparently disordered contrast at the grain boundary region in HRTEM micrographs. While less-ordered boundaries are possible, it was shown using image simulations that this can be an artifact, resulting entirely from inclined steps along the boundary plane which cause an overlap between the two boundary forming grains. In addition, the position of the grain boundary plane in the viewing direction can be shifted along the projected thickness of the sample by inclined steps.

Using image simulations, it was shown that the density, chemistry of the last plane of atoms, and exact orientation of the inclined steps cannot be determined from the experimental data. In the work reported here, it is assumed that the grain boundary and step planes in the viewing direction are of the same nature as the edge-on grain boundary and step planes along the boundary. This assumption was supported by simulations and experimental data. The resulting artifacts were found to be more pronounced in the exit wave function than in single micrographs. The appearance of inclined steps in HAADF-STEM micrographs indicated an absence of structural changes at the boundary region. Therefore, changes in the local lattice structure in HRTEM micrographs at the vicinity of the boundary are caused by the presence of inclined steps and thus do not necessarily indicate the presence of strain.

References

Lentzen M, Jahnen B, Jia CL, Thust A, Tillmann K, Urban K (2002) High-resolution imaging with an aberration-corrected transmission electron microscope. Ultramicroscopy 92:233–242. https://doi.org/10.1016/s0304-3991(02)00139-0

Urban KW (2008) Studying atomic structures by aberration-corrected transmission electron microscopy. Science 321:506–510. https://doi.org/10.1126/science.1152800

Tillmann K, Houben L, Thust A, Urban K (2006) Spherical-aberration correction in tandem with the restoration of the exit-plane wavefunction: synergetic tools for the imaging of lattice imperfections in crystalline solids at atomic resolution. J Mater Sci 41:4420–4433. https://doi.org/10.1007/s10853-006-0154-0

Houben L (2006) Aberration-corrected HRTEM of defects in strained La2CuO4 thin films grown on SrTiO3. J Mater Sci 41:4413–4419. https://doi.org/10.1007/s10853-006-0151-3

Kirkland AI, Meyer RR (2004) “Indirect” high-resolution transmission electron microscopy: aberration measurement and wavefunction reconstruction. Microsc Microanal 10:401–413. https://doi.org/10.1017/S1431927604040437

Allen LJ, McBride W, O’Leary NL, Oxley MP (2004) Exit wave reconstruction at atomic resolution. Ultramicroscopy 100:91–104. https://doi.org/10.1016/j.ultramic.2004.01.012

Haigh S, Kirkland A (2012) High resolution exit wave restoration. In: Vogt T, Dahmen W, Binev P (eds) Modeling nanoscale imaging in electron microscopy. Springer, Berlin, pp 41–72

Haigh SJ, Sawada H, Takayanagi K, Kirkland AI (2010) Exceeding conventional resolution limits in high-resolution transmission electron microscopy using tilted illumination and exit-wave restoration. Microsc Microanal 16:409–415. https://doi.org/10.1017/S1431927610093359

Kirkland AI, Saxton WO, Chau KL, Tsuno K, Kawasaki M (1995) Super-resolution by aperture synthesis: tilt series reconstruction in CTEM. Ultramicroscopy 57:355–374. https://doi.org/10.1016/0304-3991(94)00191-O

Kirkland AI, Saxton WO, Chand G (1997) Multiple beam tilt microscopy for super resolved imaging. J Electron Microsc 46:11–22

Haigh SJ, Sawada H, Kirkland AI (2009) Optimal tilt magnitude determination for aberration-corrected super resolution exit wave function reconstruction. Philos Trans R Soc A Math Phys Eng Sci 367:3755–3771. https://doi.org/10.1098/rsta.2009.0124

Chang L-Y, Kirkland AI (2006) Comparisons of linear and nonlinear image restoration. Microsc Microanal 12:469–475. https://doi.org/10.1017/S1431927606060582

Kirkland EJ (1982) Nonlinear high resolution image processing of conventional transmission electron micrographs. Ultramicroscopy 9:45–64. https://doi.org/10.1016/0304-3991(82)90228-5

Kirkland EJ (1984) Improved high resolution image processing of bright field electron micrographs. Ultramicroscopy 15:151–172. https://doi.org/10.1016/0304-3991(84)90037-8

Coene WMJ, Thust A, de Beeck MO, Van Dyck D (1996) Maximum-likelihood method for focus-variation image reconstruction in high resolution transmission electron microscopy. Ultramicroscopy 64:109–135. https://doi.org/10.1016/0304-3991(96)00010-1

Meyer RR, Kirkland AI, Saxton WO (2002) A new method for the determination of the wave aberration function for high resolution TEM: 1. Measurement of the symmetric aberrations. Ultramicroscopy 92:89–109. https://doi.org/10.1016/S0304-3991(02)00071-2

Meyer RR, Kirkland AI, Saxton WO (2004) A new method for the determination of the wave aberration function for high-resolution TEM.: 2. Measurement of the antisymmetric aberrations. Ultramicroscopy 99:115–123. https://doi.org/10.1016/j.ultramic.2003.11.001

Kirkland AI, Chang SL-Y, Hutchison JL (2007) Atomic resolution transmission electron microscopy. In: Hawkes PW, Spence JCH (eds) Science of microscopy. Springer, New York, pp 3–64

Sternlicht H, Rheinheimer W, Hoffmann MJ, Kaplan WD (2016) The mechanism of grain boundary motion in SrTiO3. J Mater Sci 51:467–475. https://doi.org/10.1007/s10853-015-9058-1

Rheinheimer W, Hoffmann MJ (2015) Non-arrhenius behavior of grain growth in strontium titanate: new evidence for a structural transition of grain boundaries. Scr Mater 101:68–71. https://doi.org/10.1016/j.scriptamat.2015.01.021

Rheinheimer W, Bäurer M, Handwerker CA, Blendell JE, Hoffmann MJ (2015) Growth of single crystalline seeds into polycrystalline strontium titanate: anisotropy of the mobility, intrinsic drag effects and kinetic shape of grain boundaries. Acta Mater 95:111–123. https://doi.org/10.1016/j.actamat.2015.05.019

Baurer M, Kungl H, Hoffmann MJ (2009) Influence of Sr/Ti stoichiometry on the densification behavior of strontium titanate. J Am Ceram Soc 92:601–606. https://doi.org/10.1111/j.1551-2916.2008.02920.x

Rheinheimer W, Bäurer M, Chien H, Rohrer GS, Handwerker CA, Blendell JE, Hoffmann MJ (2015) The equilibrium crystal shape of strontium titanate and its relationship to the grain boundary plane distribution. Acta Mater 82:32–40. https://doi.org/10.1016/j.actamat.2014.08.065

Baram M, Kaplan WD (2008) Quantitative HRTEM analysis of FIB prepared specimens. J Microsc 232:395–405. https://doi.org/10.1111/j.1365-2818.2008.02134.x

Sternlicht H, Rheinheimer W, Dunin-Borkowski RE, Hoffmann MJ, Kaplan WD (2018) Characterization of grain boundary disconnections in SrTiO3 Part I: the dislocation component of grain boundary disconnections. J Mater Sci. https://doi.org/10.1007/s10853-018-3096-4

Williams DB, Carter CB (2009) Transmission electron microscopy. Springer, New York

Cowley JM, Moodie AF (1957) Fourier images: I—the point source. Proc Phys Soc Sect B 70:486–496

Cowley JM, Moodie AF (1957) Fourier images: II—the out-of-focus patterns. Proc Phys Soc Sect B 70:497–504

Cowley JM, Moodie AF (1957) Fourier images: III—finite sources. Proc Phys Soc Sect B 70:505–513

Cowley JM, Moodie AF (1960) Fourier images IV: the phase grating. Proc Phys Soc 76:378–384

Stadelmann PA (1987) EMS—a software package for electron-diffraction analysis and HREM image simulation in materials science. Ultramicroscopy 21:131–145. https://doi.org/10.1016/0304-3991(87)90080-5

Acknowledgements

This work was partially supported via a German-Israel Fund (GIF) Grant No. I-1276-401.10/2014. The authors acknowledge the British Council for funding a visit by HS to the UK. AIK acknowledges the European Union under the Seventh Framework Programme under a contract for an Integrated Infrastructure Initiative Reference 312483-ESTEEM2. Financial support from EPSRC (Platform Grant EP/K032518/1) is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Hadas Sternlicht: Conducted when the author was at Department of Materials Science and Engineering, Technion – Israel Institute of Technology, Haifa, Israel.

Wolfgang Rheinheimer: Conducted when the author was at Karlsruhe Institute of Technology, Institute of Applied Materials, Karlsruhe, Germany.

Rights and permissions

About this article

Cite this article

Sternlicht, H., Rheinheimer, W., Kim, J. et al. Characterization of grain boundary disconnections in SrTiO3 Part II: the influence of superimposed disconnections on image analysis. J Mater Sci 54, 3710–3725 (2019). https://doi.org/10.1007/s10853-018-3095-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-3095-5