Abstract

Herein, we investigate the suitability of hen egg-white lysozyme (HEWL) as a protein matrix for dispersal of various hydrophobic dyes. Moreover, we investigate the use of a mixer mill for grinding operation as an alternative to hand grinding by mortar and pestle. HEWL and various dyes are mixed by mechanochemistry, and the resulting composite material is dissolved in aqueous acid. The samples are then exposed to conditions promoting self-assembly of HEWL into protein nanofibrils (PNFs). The effect of PNF formation on dye photophysics is investigated by spectroscopic examination by absorption and luminescence spectroscopy, and product morphology is examined by scanning electron microscopy. The self-assembly process results in protein nanofibrils functionalized with luminescent dyes. Such structures may find future applications in various devices for light emission. In addition, we demonstrate that the anticancer drug camptothecin can be incorporated into protein nanofibrils giving materials that can find application as drug delivery agents.

Similar content being viewed by others

Introduction

Mechanochemistry has been used since prehistoric times, and it continues to be important in both everyday life (e.g., in cooking procedures) and industrial settings [1, 2]. In contrast, most research chemists will be highly suspicious of processes not involving solvent/liquids and may thus not even consider the option of employing mechanochemical processes (perhaps with the exception of preparing samples for IR spectroscopy) [3]. However, recent years have seen rapid developments in mechanochemistry both regarding inorganic and organic systems, including enzymes [2,3,4,5,6,7,8,9]. Mechanochemistry may, for example, enable organic reactions to be carried out without solvent, thereby minimizing the environmental impact of synthetic procedures. In addition, mechanochemistry can be employed for the formation of composite materials, e.g., nanofillers, in a polymer matrix [10]. It should not be overlooked that mechanochemistry may allow formation of novel metastable materials not accessible by solution processing [5]. In conjunction with such processes, it should thus be possible to use mechanochemistry to prepare starting materials that can be employed to carry out further unique chemistry, regardless if occurring in solvent or not. Such chemistry could be termed mechanochemically assisted chemistry. Herein, we investigate an example of such a process, where mechanochemistry is employed to prepare a metastable starting material for a liquid-phase self-assembly process. In short (see below for a more detailed description), a protein, capable of self-assembly in aqueous phase, is co-grinded with a hydrophobic dye molecule/material. Upon addition of water, the protein dissolves, at the same time helping to disperse the finely ground dye in water. The protein is then exposed to conditions inducing protein self-assembly. As a result of structural changes in the protein, the dye molecules obtain new degrees of freedom, and accordingly, both protein and dye form novel structures. As both mechanochemical processing of biopolymers [11,12,13] and self-assembly processes having a huge number of possibilities regarding both applicable materials and exact milling conditions, such processes should enable facile preparation of novel materials for a wide range of applications. Self-assembly of proteins is an efficient process enabling preparation of materials with potential applications ranging from food science to light-emitting diodes and organic dye lasers [14,15,16,17,18]. A very important self-assembly process is the conversion of proteins into fibrillar aggregates, known as amyloid fibrils [19,20,21]. Such fibrils are associated with a range of diseases including Alzheimer’s and Parkinson’s [20]. However, in recent years a range of amyloid structures have been discovered, where organisms employ amyloid for functional purposes [22]. Both in the case of pathological amyloid and functional amyloid, the amyloid material consists of protein nanofibrils. The discovery of functional amyloid hints that assembly of proteins into nanofibrils can be used to form novel nanomaterials [23]. Hereafter, we will abbreviate such protein nanofibrils as PNFs. For PNF formation, typically water-soluble globular proteins are employed that upon appropriate stimuli (typically heating to 65–90 °C in combination with acidic pH) self-assembles into fibrillar objects with typical diameters of 5–10 nm and lengths in the μm range [19, 20]. For many applications, it is desirable to functionalize such structures with additional materials [24]. For example, by addition of luminescent dyes PNFs can be prepared suitable for applications related to light emission [25,26,27,28]; in addition, interesting nonlinear optical effects have been observed in dye-doped PNF systems [29]. Moreover, dye-doped PNFs may be valuable as, e.g., labeled proteins for amyloidosis studies. Alternatively, addition of drug molecules enables use of PNFs as drug delivery systems [30]. There exist a large number of readily available luminescent dyes that are highly hydrophobic. When using traditional functionalization approaches, this creates problems as the employed proteins have a high solubility in water, whereas dyes are completely insoluble in water. Standard approaches to functionalize such structures would be to attach hydrophilic moieties to the hydrophobic dye; conjugate the hydrophobic dye to the protein, or in the case of relatively polar hydrophobic dyes employ an organic co-solvent miscible with water. We recently reported a novel method for protein functionalization utilizing a preliminary mechanochemical mixing step [31,32,33,34,35,36]. By co-grinding the hydrophobic dye and the protein, a composite material is formed that can be dissolved in water. Due to the hydrophobic effect, the dye and the protein will stay associated in the aqueous environment, meaning that the dye will be carried along into whatever protein structures are formed. This means that functionalized protein materials can be prepared, avoiding time-consuming synthetic procedures involving covalent bond formation. An overview of the process is shown in Fig. 1. The main point of the mechanochemical treatment is to finely divide and disperse the hydrophobic material within the water-soluble material. If during the mechanochemical treatment fine division is not achieved, upon addition of water a turbid dispersion is obtained. Hydrophobic dyes typically contain a large fraction of aromatic units and a relatively low degree of polar groups. The main interactions between dye molecules are thus of van der Waals type and pi–pi interactions. The most efficient way of dispersing such dyes within a polymer/protein matrix is to expose the mixture to shear forces. During the mechanochemical treatment of dyes within the protein matrix, relatively weak van der Waals interactions may be broken and the dye dispersed in the protein matrix. Impact forces should lead to division of dye particles but is expected to be less efficient than shear at tearing of thin layers of dye molecules. With the above point in mind, grinding with mortar and pestle should be an efficient technique for dispersing dyes in a protein matrix, and we have utilized this method in several publications, where the protein bovine insulin has been mixed with a variety of hydrophobic dyes/materials [31,32,33,34,35,36]. However, mechanochemistry by hand grinding with mortar and pestle suffers from some drawbacks. As exact grinding conditions may be difficult to reproduce, there may be undesired variations between different sample preparations; for example, it is challenging to control variations in force and grinding motions. In contrast, the use of a shaker mill allows for systematic variations of grinding parameters as well as enhancing repeatability between different sample preparations. In addition, in our previous studies the employed protein (bovine insulin) is relatively expensive, and it would be desirable to investigate lower cost alternatives. Hen egg-white lysozyme (HEWL) is a relatively low-cost alternative that is well studied with regard to PNF formation [37]. Herein, we investigate the suitability of HEWL as a protein matrix for dispersal of hydrophobic dyes 1–5 (Fig. 2); in addition, we investigate the use of a shaker mill for grinding operation as an alternative to hand grinding by mortar and pestle. HEWL and various dyes are mixed by mechanochemistry, and the resulting composite material is dissolved in aqueous acid. The samples are then exposed to conditions promoting self-assembly of HEWL PNFs. The effect of PNF formation on dye photophysics is investigated by spectroscopic examination by absorption and luminescence spectroscopy, and product morphology is examined by SEM.

Experimental

Materials

Hen egg-white lysozyme, pyrene, Nile red and (S)-(+)-camptothecin were obtained from Sigma-Aldrich. α-sexithiophene and α-octithiophene were obtained from TCl. All chemicals were used as received without further purification.

Preparation of HEWL-dye composites

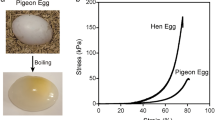

The grinding was done with a shaker mill (Mixer Mill MM 400, Retsch, Germany). The milling operation was carried out in a stainless steel milling jar with a volume of 1.5 mL using grinding balls of the same material of 3 mm in diameter. Fifty milligrams of HEWL was ground with 0.5, 1, 1.5, 2 or 3 mg of 6T. The HEWL and 6T mixture put into the grinding jar with 1, 10, 20 or 30 balls. Shaking time was 1, 5, 10, 20 or 30 min, and frequency was 10, 20 or 30 Hz. For other hydrophobic dye–HEWL composites, typically, 50 mg of HEWL was ground with 1 mg of hydrophobic dye by shaking the grinding jar with 20 balls at 30 Hz for 10 min. For comparison, 50 mg of HEWL was ground with 1 mg of hydrophobic dye by a mortar and a pestle. The grinding carried out at intervals for a total of 10 min.

Self-assembly of hydrophobic dyes:HEWL composites

The composite material (prepared by grinding) was dissolved in 5 mL 25 mM hydrochloric acid followed by filtration through a 0.2-μm PES filter. The resulting dispersion was heated at 80 °C with magnetic stirring at 1000 rpm for 24 h to obtain hydrophobic dyes@HEWL fibrils.

Determination of concentration of 6T in 6T:HEWL composites

Fifty milligrams of HEWL was ground with different amounts of 6T (0.5, 0.75, 1, 1.25 mg) employing the shaker mill, shaking the grinding jar at 30 Hz for 10 min with 20 balls (3 mm diameter). The resulting composite materials were dissolved in 5 mL 25 mM hydrochloric acid to obtain solutions containing 0.01, 0.015, 0.02, 0.025 and 0.03 mg mL−1 of 6T, respectively.

Uv–Vis spectroscopy

Absorption data were obtained using a PerkinElmer Lambda 950 UV–Vis spectrometer. Samples measured were diluted 20 times from the reaction mixture concentration.

Fluorescence spectroscopy

Fluorescence spectra were collected using a Horiba Jobin–Yvon Fluoromax-4 spectra fluorometer. Samples prior to measuring were diluted 20 times from the reaction mixture concentration.

Atomic force microscopy

AFM measurements were taken using a digital instruments dimension 3100 atomic force microscope. Samples were diluted 100 times from the reaction solution prior to applying to silica substrates and left to dry for 1 min. Excess fluid was removed by applying a nitrogen gas flow.

Scanning electron microscopy

SEM images were recorded on a Philips XL30 FEG SEM microscope. Small amount of samples powder were attached to metal substrates by double adhesive carbon tape. The stock solution samples were incubated for 1 min prior to drop casting on Si substrates. Excess fluid was removed by applying a nitrogen gas flow. All samples were sputter-coated with a thin layer of Pt under argon in a sputter coater (Leica EM SCD 500).

Results and discussion

Investigation of milling conditions for 6T:HEWL

A variety of parameters will influence the efficiency of the milling process. We investigated the effect of number of grinding balls, grinding time and frequency. The experiments were performed using a Retsch mixer mill MM400. The milling process was performed in stainless steel jars with an interior volume of 1.5 mL employing stainless steel grinding balls with a diameter of 3 mm. For this study, we focused on combinations of 6T and HEWL. A typical particle size after milling is 5 μm (information from the Retsch Company Web site). However, in the present material system, the hydrophobic dye (6T) is milled in a large excess of HEWL. It can therefore be expected that 6T will be diluted in the form of smaller particles in the HEWL matrix. As stated earlier, 6T is insoluble in water, whereas HEWL readily dissolves in water. As a consequence, the particle size of HEWL upon milling is of low importance. In contrast, an inefficient milling process, resulting in the presence of large 6T particles within the HEWL matrix, will result in a dispersion of large-sized particles that will scatter light, resulting in a turbid sample. This effect is readily apparent, as can be seen in Fig. 3a, b, where photographs are shown in different samples, dispersed in 25 mM HCl and obtained under different milling conditions (number of grinding balls being 1, 10, 20 and 30). The sample ground with one ball is turbid, and upon filtration through a 0.2-μm membrane, the majority of 6T is removed (Fig. 3a). In contrast, for samples ground with several balls all the samples look transparent. However, when analyzed by UV–Vis spectroscopy, after filtration through a membrane it can be seen that 20 grinding balls give the most efficient result. Ten and 30 grinding balls lead to less 6T being incorporated (Fig. 3b). We also tested the effect of frequency and found that 30 Hz (the highest frequency available) is more efficient than 20 or 10 Hz (Fig. 3d). We also investigated the milling process at different time points. For this test, we employed 20 grinding balls in combination with a frequency of 30 Hz. The milling operation was stopped after the allotted time, the grinding jar was opened and a small amount of sample powder was collected. This was then dispersed in 25 mM HCl, filtered through a 0.2-μm membrane and analyzed for 6T content (Fig. 3c). After 1-min milling, a small amount of 6T is dispersed, but after 6 min there is an significant increase in the amount of dispersed 6T. Finally, after 10 min only small changes are observed upon increasing the milling time (for up to 30 min). It is also interesting to compare SEM images of the composite material, either as prepared or as drop casted (after treatment with 25 mM HCl) (Fig. 4). In order to investigate the as-prepared milled powder, small amounts of the sample were attached to metal substrates by double adhesive carbon tape. The resulting SEM images, obtained for powders exposed to different milling conditions, are shown in Fig. 4. It is difficult to see any clear difference in particle size between different samples (Fig. 4 left section). However, when zooming in on individual particles, interesting differences in morphology can be observed as a function of milling parameters (Fig. 4 middle section). For the sample with one grinding ball, the majority of examined particles have relatively cleanly cleaved surfaces. On the other hand, for samples where multiple grinding balls are employed, the majority of particles are of a more irregular shape, containing components with a “flake-like” shape. This is true both for samples consisting of ground pure HEWL and for co-ground of 6T and HEWL. In contrast, when examining samples with SEM after treatment with 25 mM HCl, the observable particles have a smaller size (Fig. 4, right section). These results indicate that the particles as prepared after milling consist of mixtures of 6T and HEWL, where upon addition of 25 mM HCl the HEWL is dissolved, and the remaining observable particles consist of 6T. The sample corresponding to 20 grinding balls (Fig. 4i) shows the least amount of particles, which matches the result from the absorption spectroscopy of the corresponding filtered sample (Fig. 3b). For comparison, SEM images of powders obtained by grinding HEWL and 6T by hand with mortar and pestle are shown in Fig. S1. There is a large variety of particles sizes (see Fig. S1a), and when zooming in an individual particle (Fig. S1b), the surface of the particle shows flaky shapes, similar to the particle shown in Fig. 4h. However, after addition of 25 mM HCl and deposition on the substrate, the hand ground sample contains large particles of a size up to 2 μm, in contrast to the samples ground by the shaker mill (c.f. Fig. 4i and Fig. S1c). This result indicates that the grinding with mortar and pestle gives a more heterogenous sample than the sample ground by the shaker mill. We also tested combinations of different amounts of 6T in combination with a constant amount of HEWL (Fig. 5). Fifty milligrams of HEWL was combined with 0.5, 1.0, 1.5, 2.0 and 3.0 mg of 6T, respectively. The weight ratio of HEWL:6T that gives the highest amount of 6T dispersed in water after filtration is 50:1. Increasing the amount of 6T does not lead to a higher concentration of 6T in the liquid phase. Instead, it was found that a higher 6T ratio leads to less efficient dispersion of 6T. When inspecting the 50:2 and 50:3 ratio samples dispersed in 25 mM HCl, it is readily apparent that large 6T particles are present, resulting in turbid samples. Consequently, upon filtration through a 0.2-μm membrane, it is apparent that the concentrations of 6T in these samples are lower than in the sample with a 50:1 ratio. In order to quantify the amount of 6T dispersed in the liquid phase after filtration, we prepared a calibration curve in the following manner: Samples were prepared by co-grinding HEWL and 6T in ratios of 50:0.5, 50:0.75, 50:1.0 and 50:1.25. The resulting composite materials were dissolved in 25 mM HCl and were inspected to make certain that no non-dissolved material remained. The 6T absorption maximum is located at 412 nm. The absorbance at 412 nm versus the concentration of 6T was then plotted, and a calibration curve was constructed (Fig. S2). This curve can then be used to calculate the concentration of 6T in the aqueous phase. Three independent samples were prepared by grinding HEWL:6T (with 20 grinding balls at a 30 Hz frequency) in a 50:1 mg ratio (dissolved in 5 mL 25 mM HCl). According to the calibration curve, the concentration of 6T is 0.168 ± 0.008 mg mL−1 in the 6T:HEWL samples (with the maximum possible amount being 0.2 mg mL−1). This shows good reproducibility of the shaker mill grinding method.

SEM images of 6T:HEWL composites powder after milling with different numbers of grinding balls: 1 ball (a, b); 10 balls (d, e); 20 balls (g, h); 30 balls (j, k). SEM images of the resulting composites dissolved by 25 mM HCl and then drop casted onto substrates: 1 ball (c); 10 balls (f); 20 balls (i); 30 balls (l)

When comparing results from grinding with one and many grinding balls, we see that one grinding ball gives poor incorporation of 6T. In fact, grinding with one ball gives a poorer result than hand grinding by mortar and pestle. These results indicate that shear forces are very important in order to efficiently disperse 6T in the protein matrix. The organic dyes contain strong intramolecular covalent bonds. In contrast, intermolecular bonds are much weaker and we assume that such intermolecular bonds are readily cleaved upon exposure to shear forces, leading to mixing of protein and dye. However, it should be noted that after grinding the majority of dye molecules are present in aggregates (not as individual molecules) as judged by absorption and fluorescence spectroscopy. However, during/after fiber formation (see below, the next section), the dyes are able to redistribute within the PNF matrix, resulting in isolated molecules dispersed within the protein fibrils.

Self-assembly of HEWL:thiophene composites

Whereas 6T can be viewed as the “fruit fly” of organic electronics, the corresponding compound containing two additional thiophene moieties is much more rarely used. A large reason is the low solubility of these compounds. Already 6T is hard to dissolve in organic solvents, and with 8T, the solubility limit is reached. Accordingly, spectral data for 8T in solution phase are rare. It would be desirable to have a processable form of 8T available, and we tested whether preparation of such materials could be assisted by mechanochemistry. We compared both grinding by mortar and pestle and milling by shaker mill with 20 grinding balls at 30 Hz for 10 min. Both methods work well, and dispersions processable from aqueous solvent can be obtained (Fig. S3 0 h and Fig. S4a 0 h). However, it should be noted that the absorption spectrum of 6T ground with HEWL is narrower when ground with the shaker mill compared to the hand ground sample, indicating a more homogenous sample when ground with the shaker mill. We then investigated whether the 6T:HEWL and 8T:HEWL composites were capable of self-assembly into protein fibrils. We have earlier reported that composite materials between bovine insulin and hydrophobic dyes can form PNFs [32]. Oligothiophenes are convenient compounds to study as the absorption and emission spectra of oligothiophenes are sensitive to the packing of thiophene molecules [32, 38,39,40,41,42]. Typically, 6T or 8T in an aggregated state will give rise to a redshift of emission with a low intensity. Conversely, 6T or 8T in a monomeric state will give rise to a blueshifted emission of high intensity. Moreover, there will be corresponding changes in absorption spectra. This means that the development of structural change can be monitored through variations in emission and absorption spectra. When 6T:HEWL and 8T:HEWL composites (prepared by a shaker mill with 20 grinding balls at 30 Hz for 10 min) are exposed to heating in acidic water (80 °C for 24 h with stirring in 25 mM HCl), and spectral changes are monitored, we observe typical changes as observed earlier in the 6T:insulin system [32]. For 6T, we observe strong emission with a maximum at 508 nm and a typical vibronic structure (Fig. 6a). For 8T, we observe strong emission with a maximum at 548 nm and a typical vibronic structure (Fig. 6b). Conversely, in the 0 h samples, emission is weak and typical of aggregated oligothiophenes. Moreover, when samples are observed by SEM or AFM after the fibrillation process, typical fibrillar object can be observed, confirming the presence of PNFs (Fig. 6c, d). We also observed similar results when fibrillated 6T and 8T samples were observed by AFM (Fig. S7). For comparison, samples prepared by grinding with mortar and pestle give similar result for both 6T and 8T (Figs. S4 and S6).

Fluorescence spectroscopy spectra at 25 mM HCl for samples of 6T:HEWL composites (excited at 465 nm) (a) and 8T:HEWL composites (excited at 495 nm) (b) before (0 h) and after fibril formation (24 h); SEM image of HEWL ground with 6T (c) and 8T (d) after fibrils formation (24 h of heating and stirring)

Other dye:HEWL materials

We investigated three other dyes in combination with HEWL: Nile red (3), pyrene (4) and campthotecin (5). Nile red is a famous dye molecule with applications as a laser dye as well as an optical probe for sensing applications [29]. For example, Nile red has been applied as a probe for the presence of amyloid fibrils [35, 43]. We tested co-grinding of HEWL and Nile red and exposed the resulting composite materials to fibrillation conditions (80 °C for 24 h with stirring in 25 mM HCl). When comparing samples before fibrillation (0 h) and after fibrillation (24 h), it can be seen there is a large increase in fluorescence intensity after 24 h, with a maximum at 620 nm. The high fluorescence intensity in the 24-h sample is typical of the presence of PNFs (Fig. 7a). In addition, fibrillar objects can be observed by SEM in the 24-h sample (Fig. 7b). For comparison, samples prepared by grinding with mortar and pestle give similar result (Fig. S9).

Pyrene is polyaromatic hydrocarbon that can pack efficiently into crystals. The pyrene molecule can be excited by UV light and fluoresces in the blue region of the spectrum. Due to the tight packing, the pyrene crystal should be relatively challenging to fragment by milling. This is readily observed when mixing pyrene with HEWL. When pyrene is co-ground with HEWL, a white-colored composite material is obtained. Upon addition of aqueous 25 mM HCl, a turbid white-colored dispersion is obtained, demonstrating the presence insoluble pyrene particles (Fig. S10a). Still the resulting dispersion can be filtered, and the sample retains a strong absorption from pyrene (Fig. S10b, c). Pyrene photophysics is sensitive to the concentration of pyrene molecules [44, 45]. It is known that pyrene readily forms excimers (an excited state dimer) which show a redshifted emission without vibronic fine structure. In contrast, the monomer shows vibronic structure and a relatively blueshifted emission. Spectral properties were compared for as-prepared (0-h) and fibrillated (24-h) samples (Fig. 8a). The 0- and 24-h samples show markedly different spectral properties. Before formation of PNFs, the emission spectrum is dominated by a broad peak typical of excimer emission with a maximum at 465 nm. This indicates that before fiber formation pyrene molecules are tightly packed together. In contrast, upon PNF formation the emission spectrum shows typical characteristics of monomer emission, with and emission maxima at 375 and 395 nm and featuring vibronic structure. In addition, when the 24-h sample is examined by SEM, fibrillar objects can be observed, confirming PNF formation (Fig. 8b). As the emission spectra are typical of monomer emission, this indicates that in the fibrillated sample the pyrene molecules are relatively spread out within the fibril. For comparison, samples prepared by grinding with mortar and pestle gave similar result; however, less pyrene is incorporated into PNFs using hand grinding compared to use of a mixer mill (c.f. Fig. S10c and Fig. S11a). Interestingly, pyrene fluorescence is known to be sensitive to the polarity of the environment. Pyrene fluorescence has been measured in organic solvents of varying polarity, and it has been found that the ratio of the intensity of the I to III emission bands varies from ~ 0.6 in hydrocarbon media to ~ 2 in DMSO. In our sample, the I peak occurs at 375 nm and the III peak occurs at 395 nm. For our samples prepared with a shaker mill (Fig. 8a), the III/I ratio is 1.038. For our sample prepared by hand grinding (Fig. S11b), the III/I ratio is 1.097. These results indicate that the pyrene molecules in PNFs are located in hydrophobic domains [45, 46].

Camptothecine is a fluorescent natural product with anticancer activity [47]. It has been demonstrated that PNFs can act as drug delivery agents [30]; it is thus of interest to test whether the mechanochemistry approach can be used to prepare protein–drug complexes. Camptothecine has dye-like properties and is fluorescent, which enables convenient monitoring of the dye by spectroscopy [48]. However, in contrast to the other dyes used herein, camptothecin emission does not appear to be sensitive toward the presence of PNFs, as both as-prepared (0-h) and fibrillated (24-h) samples show the same spectral features, typical of camptothecine at low pH (Fig. 9a) [48]. Investigation of the 24-h sample by SEM clearly shows fibrillar objects confirming PNF formation (Fig. 9b). For camptothecin, it appears that grinding with mortar and pestle somewhat more efficient than grinding by the shaker mill, as hand ground samples give higher absorption than samples prepared by shaker milling (c.f. Figs. S12, S13 and 9a).

Herein, we have ground HEWL with various dyes. Co-grinding of dyes with other powder materials is a well-known technique for dispersion of dyes. For example, mechanical dry milling of organic pigments (aggregate of dye molecules) has been performed in the presence of silica nanoparticles, resulting in efficient dispersion [49]. Such organic pigments can be dispersed in a liquid and solid solutions and employed as inks, coatings and plastics. Dynamic processes of dyes in polymer matrices are known. For example, in so-called latent pigment technology a soluble pigment precursor is employed, that upon chemical or physical treatment is converted to the (insoluble) pigment in situ [50]. In contrast, in the approach reported herein, the mechanochemical step results in composite material consisting mostly of small dye molecule aggregates dispersed in a HEWL matrix. However, the HEWL matrix is under appropriate conditions capable of self-assembly resulting in PNFs and these structures are in turn able to promote disruption of dye aggregates into monomeric species. These effects are clear for a variety of dyes (6T, 8T, Nile red, pyrene) employed herein.

Conclusions

We have shown that a shaker mill can be used for materials preparation, in addition to hand grinding by mortar and pestle. The shaker mill shows better efficiency and reproducibility than hand grinding. The samples ground by shaker mill shows a more homogenous particle distribution as judged by SEM images. Moreover, the absorption spectrum of 6T ground with HEWL is narrower when ground with the shaker mill, again indicating a more homogenous sample. In addition, we report that HEWL can be employed for preparation of functionalized PNFs. Moreover, as one of the components is insoluble in the solvent, a cohesive force is generated by the solvent rather than any specific favorable interactions between the reagents. To the best of our knowledge, this novel approach has a possibility for creativity from both the mechanochemistry and self-assembly sides. For example, by variations in mechanochemical conditions it may be possible to prepare different metastable materials that may evolve into different structures in a sequential self-assembly step. Depending on the selected functionalization agent (dye), materials can be prepared aiming toward various applications, for example light-emitting diodes (for luminescent molecules) or drug delivery systems (for drug molecules).

Supplementary information

Calibration of 6T concentration by absorbance spectra; absorbance spectra for samples of HEWL ground with 6T, 8T, Nile red, pyrene and camptothecin by shaking mixer mill and absorbance and fluorescence spectroscopy spectra for samples prior to grinding by hand grinding with mortar and pestle before and after fibril formation; AFM images of 6T:HEWL and 8T:HEWL fibrils.

References

Takacs L (2013) The historical development of mechanochemistry. Chem Soc Rev 42:7649–7659

Balaz P, Achimovicova M, Balaz M, Billik P, Cherkezova-Zheleva Z, Criado JM, Delogu F, Dutkova E, Gaffet E, Gotor FJ, Kumar R, Mitov I, Rojac T, Senna M, Streletskii A, Wieczorek-Ciurowa K (2013) Hallmarks of mechanochemistry: from nanoparticles to technology. Chem Soc Rev 42:7571–7637

Tan D, Friscic T (2018) Mechanochemistry for organic chemists: an update. Eur J Org Chem 2018:18–33

Boldyrev VV (2006) Mechanochemistry and mechanical activation of solids. Usp Khim 75(3):203–216

Boldyreva E (2013) Mechanochemistry of inorganic and organic systems: what is similar, what is different? Chem Soc Rev 42:7719–7738

Hernandez JG, Bolm C (2017) Altering product selectivity by mechanochemistry. J Org Chem 82:4007–4019

James SL, Adams CJ, Bolm C, Braga D, Collier P, Friscic T, Grepioni F, Harris KD, Hyett G, Jones W, Krebs A, Mack J, Maini L, Orpen AG, Parkin IP, Shearouse WC, Steed JW, Waddell DC (2012) Mechanochemistry: opportunities for new and cleaner synthesis. Chem Soc Rev 41:413–447

Hernández JG, Frings M, Bolm C (2016) Mechanochemical enzymatic kinetic resolution of secondary alcohols under ball-milling conditions. ChemCatChem 8:1769–1772

Dreizin EL, Schoenitz M (2017) Mechanochemically prepared reactive and energetic materials: a review. J Mater Sci 52:11789–11809.

Gorrasi G, Sorrentino A (2015) Mechanical milling as a technology to produce structural and functional bio-nanocomposites. Green Chem 17:2610–2625

Pazesh S, Grasjo J, Berggren J, Alderborn G (2017) Comminution-amorphisation relationships during ball milling of lactose at different milling conditions. Int J Pharm 528:215–227

Liu B, Wang H, Hu T, Zhang P, Zhang Z, Pan S, Hu H (2017) Ball-milling changed the physicochemical properties of SPI and its cold-set gels. J Food Eng 195:158–165

Sun C, Liu R, Wu T, Liang B, Shi C, Zhang M (2015) Effect of superfine grinding on the structural and physicochemical properties of whey protein and applications for microparticulated proteins. Food Sci Biotechnol 24:1637–1643

Luo Q, Hou C, Bai Y, Wang R, Liu J (2016) Protein assembly: versatile approaches to construct highly ordered nanostructures. Chem Rev 116:13571–13632

Tao H, Kaplan DL, Omenetto FG (2012) Silk materials—a road to sustainable high technology. Adv Mater 24:2824–2837

Wei G, Su Z, Reynolds NP, Arosio P, Hamley IW, Gazit E, Mezzenga R (2017) Self-assembling peptide and protein amyloids: from structure to tailored function in nanotechnology. Chem Soc Rev 46:4661–4708

Fresta E, Fernández-Luna V, Coto PB, Costa RD (2018) Merging biology and solid-state lighting: recent advances in light-emitting diodes based on biological materials. Adv Funct Mater. https://doi.org/10.1002/adfm.201707011

Mysliwiec J, Cyprych K, Sznitko L, Miniewicz A (2017) Biomaterials in light amplification. J Opt 19:31

Chiti F, Dobson CM (2017) Protein misfolding, amyloid formation, and human disease: a summary of progress over the last decade. Annu Rev Biochem 86:27–68

Otzen DE (2013) Amyloid fibrils and prefibrillar aggregates: molecular and biological properties. Wiley, Weinheim

Knowles TP, Vendruscolo M, Dobson CM (2014) The amyloid state and its association with protein misfolding diseases. Nat Rev Mol Cell Biol 15:384–396

Li C, Qin R, Liu R, Miao S, Yang P (2018) Functional amyloid materials at surfaces/interfaces. Biomater Sci 6:462–472

Knowles TP, Mezzenga R (2016) Amyloid fibrils as building blocks for natural and artificial functional materials. Adv Mater 28(31):6546–6561.

Woolfson DN, Mahmoud ZN (2010) More than just bare scaffolds: towards multi-component and decorated fibrous biomaterials. Chem Soc Rev 39:3464–3479

Rizzo A, Solin N, Lindgren LJ, Andersson MR, Inganas O (2010) White light with phosphorescent protein fibrils in OLEDs. Nano Lett 10:2225–2230

Solin N, Inganäs O (2012) Protein nanofibrils balance colours in organic white-light-emitting diodes. Isr J Chem 52:529–539

Sznitko L, Hanczyc P, Mysliwiec J, Samoc M (2015) Low-threshold stimulated emission from lysozyme amyloid fibrils doped with a blue laser dye. Appl Phys Lett 106:023702

Hanczyc P, Sznitko L, Zhong CM, Heeger AJ (2015) Stimulated emission from rhodamine 6G aggregates self-assembled on amyloid protein fibrils. ACS Photonics 2:1755–1762

Hanczyc P, Justyniarski A, Gedefaw DA, Andersson MR, Samoc M, Muller C (2015) Two-photon absorption of polyfluorene aggregates stabilized by insulin amyloid fibrils. RSC Adv 5:49363–49368

Mains J, Lamprou DA, McIntosh L, Oswald ID, Urquhart AJ (2013) Beta-adrenoceptor antagonists affect amyloid nanostructure; amyloid hydrogels as drug delivery vehicles. Chem Commun 49:5082–5084

Rizzo A, Inganas O, Solin N (2010) Preparation of phosphorescent amyloid-like protein fibrils. Chemistry 16:4190–4195

Bäcklund FG, Wigenius J, Westerlund F, Inganäs O, Solin N (2014) Amyloid fibrils as dispersing agents for oligothiophenes: control of photophysical properties through nanoscale templating and flow induced fibril alignment. J Mater Chem C 2:7811

Bäcklund FG, Solin N (2015) Tuning the aqueous self-assembly process of insulin by a hydrophobic additive. RSC Adv 5:92254–92262

Bäcklund FG, Pallbo J, Solin N (2016) Controlling amyloid fibril formation by partial stirring. Biopolymers 105:249–259

Bäcklund FG, Solin N (2014) Development and application of methodology for rapid screening of potential amyloid probes. ACS Comb Sci 16:721–729

Andersson BV, Skoglund C, Uvdal K, Solin N (2012) Preparation of amyloid-like fibrils containing magnetic iron oxide nanoparticles: effect of protein aggregation on proton relaxivity. Biochem Biophys Res Commun 419:682–686

Mishra R, Sorgjerd K, Nystrom S, Nordigarden A, Yu YC, Hammarstrom P (2007) Lysozyme amyloidogenesis is accelerated by specific nicking and fragmentation but decelerated by intact protein binding and conversion. J Mol Biol 366:1029–1044

Becker RS, deMelo JS, Macanita AL, Elisei F (1996) Comprehensive evaluation of the absorption, photophysical, energy transfer, structural, and theoretical properties of alpha-oligothiophenes with one to seven rings. J Phys Chem 100:18683–18695

Leclere P, Surin M, Viville P, Lazzaroni R, Kilbinger AFM, Henze O, Feast WJ, Cavallini M, Biscarini F, Schenning A, Meijer EW (2004) About oligothiophene self-assembly: from aggregation in solution to solid-state nanostructures. Chem Mat 16:4452–4466

Loi MA, da Como E, Dinelli F, Murgia M, Zamboni R, Biscarini F, Muccini M (2004) Supramolecular organization in ultra-thin films of α-sexithiophene on silicon dioxide. Nat Mater 4:81–85

Da Como E, Loi MA, Murgia M, Zamboni R, Muccini M (2006) J-aggregation in alpha-sexithiophene submonolayer films on silicon dioxide. J Am Chem Soc 128:4277–4281

Fichou D, Teulade-Fichou MP, Horowitz G, Demanze F (1997) Thermal and optical characterization of high purity alpha-octithiophene. Adv Mater 9:75–80

Mishra R, Sjolander D, Hammarstrom P (2011) Spectroscopic characterization of diverse amyloid fibrils in vitro by the fluorescent dye Nile red. Mol BioSyst 7:1232–1240

Winnik FM (1993) Photophysics of preassociated pyrenes in aqueous polymer solutions and in other organized media. Chem Rev 93:587–614

Valeur B, Berberan-Santos MN (2012) Molecular fluorescence: principles and applications, 2nd edn. Wiley, Weinheim

Kalyanasundaram K, Thomas JK (1977) Environmental effects on vibronic band intensities in pyrene monomer fluorescence and their application in studies of micellar systems. J Am Chem Soc 99:2039–2044

Li QY, Zu YG, Shi RZ, Yao LP (2006) Review camptothecin: current perspectives. Curr Med Chem 13:2021–2039

di Nunzio MR, Cohen B, Douhal A (2011) Structural photodynamics of camptothecin, an anticancer drug in aqueous solutions. J Phys Chem A 115:5094–5104

Hayashi K, Morii H, Iwasaki K, Horie S, Horiishi N, Ichimura K (2007) Uniformed nano-downsizing of organic pigments through core–shell structuring. J Mater Chem 17:527–530

Zambounis JS, Hao Z, Iqbal A (1997) Latent pigments activated by heat. Nature 388:131–132

Acknowledgements

L. W. acknowledges financial support from the China Scholarship Council. We acknowledge financial support from the Swedish Government Strategic Research Area in Materials Science on Functional Materials at Linköping University (Faculty Grant SFO-Mat-Liu # 2009-00971).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wang, L., Solin, N. Preparation of functionalized protein materials assisted by mechanochemistry. J Mater Sci 53, 13719–13732 (2018). https://doi.org/10.1007/s10853-018-2461-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2461-7