Abstract

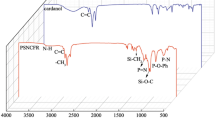

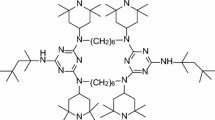

A novel phosphorus-containing cardanol (PCC) derived from cardanol—a renewable meta-substituted phenol and harmful by-product of the cashew industry—in combination with 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) was used to produce bio-based phenolic foams (PFs). The properties of the PFs were then characterized in detail. The PCC was fully characterized by using Fourier transform infrared spectroscopy (FTIR) and proton nuclear magnetic resonance (1H NMR), while the thermal degradation was studied and monitored by thermogravimetry coupled to FTIR (TGA/FTIR) and TGA coupled with mass spectrometry (TGA/MS). It was found that PCC exhibited high thermal stability. The total heat release, peak heat release rate and mean heat release rate of PF containing 4% PCC decreased by 13.55, 33.43 and 13.42%, respectively, in comparison with pristine PF. The enhanced flame-retardant behavior was attributed to the free radicals PO· produced during combustion, which captured free radicals in the gas phase; moreover, the phosphaphenanthrene group may create a char residue barrier against the further combustion of the polymer. Meanwhile, bio-based PFs showed excellent mechanical properties, as the compressive and flexural strength of PF with 4% PCC increased by 79.59 and 20.98%, respectively, in comparison with pristine PF. The pulverization ratio of bio-based PFs was reduced with the increase in PCC content. The findings in this study demonstrate that PCC could be used as a phenol substitute in the synthesis of PFs to overcome their intrinsic brittleness and high flammability.

Similar content being viewed by others

References

Hu XM, Wang DM, Cheng WM, Zhou G (2014) Effect of polyethylene glycol on the mechanical property, microstructure, thermal stability, and flame resistance of phenol–urea–formaldehyde foams. J Mater Sci 49:1556–1565. https://doi.org/10.1007/s10853-013-7838-z

Bo C, Wei S, Hu L, Jia P, Liang B, Zhou J, Zhou Y (2016) Synthesis of a cardanol-based phosphorus-containing polyurethane prepolymer and its application in phenolic foams. RSC Adv 6:62999–63005

Shang L, Zhang X, Zhang M, Jin L, Liu L, Xiao L, Li M, Ao Y (2017) A highly active bio-based epoxy resin with multi-functional group: synthesis, characterization, curing and properties. J Mater Sci 53(7):5402–5417. https://doi.org/10.1007/s10853-017-1797-8

Perdriau S, Harder S, Heeres HJ, de Vries JG (2012) Selective conversion of polyenes to monoenes by RuCl(3)-catalyzed transfer hydrogenation: the case of cashew nutshell liquid. Chemsuschem 5:2427–2434

Puchot L, Verge P, Fouquet T, Vancaeyzeele C, Vidal F, Habibi Y (2016) Breaking the symmetry of dibenzoxazines: a paradigm to tailor the design of bio-based thermosets. Green Chem 18:3346–3353

Ma HX, Li JJ, Qiu JJ, Liu Y, Liu CM (2017) Renewable cardanol-based star-shaped prepolymer containing a phosphazene core as a potential biobased green fire-retardant coating. ACS Sustain Chem Eng 5:350–359

Cal E, Maffezzoli A, Mele G, Martina F, Mazzetto SE, Tarzia A, Stifani C (2007) Synthesis of a novel cardanol-based benzoxazine monomer and environmentally sustainable production of polymers and bio-composites. Green Chem 9:754–759

Srivastava R, Srivastava D (2015) Mechanical, chemical, and curing characteristics of cardanol–furfural-based novolac resin for application in green coatings. J Coat Technol Res 12:303–311

Chiverton JP, Ige O, Barnett SJ, Parry T (2017) Multiscale shannon’s entropy modeling of orientation and distance in steel fiber micro-tomography data. IEEE Trans Image Process 26:5284–5297

Liang B, Li X, Hu L, Bo C, Zhou J, Zhou Y (2016) Foaming resol resin modified with polyhydroxylated cardanol and its application to phenolic foams. Ind Crops Prod 80:194–196

Haddadi M, Agoudjil B, Benmansour N, Boudenne A, Garnier B (2017) Experimental and modeling study of effective thermal conductivity of polymer filled with date palm fibers. Polym Compos 38:1712–1719

Wang S, Ma S, Xu C, Liu Y, Dai J, Wang Z, Liu X, Chen J, Shen X, Wei J, Zhu J (2017) Vanillin-derived high-performance flame retardant epoxy resins: facile synthesis and properties. Macromolecules 50:1892–1901

Illy N, Fache M, Ménard R, Negrell C, Caillol S, David G (2015) Phosphorylation of bio-based compounds: the state of the art. Polym. Chem. 6:6257–6291

Xiao F, Wang K, Zhan MS (2012) Atomic oxygen resistant phosphorus-containing polyimides for LEO environment. J Mater Sci 47:4904–4913. https://doi.org/10.1007/s10853-012-6363-9

Choi SW, Sholl DS, Nair S, Moore JS, Liu YJ, Dixit RS, Pendergast JG (2017) Modeling and process simulation of hollow fiber membrane reactor systems for propane dehydrogenation. AIChE J 63:4519–4531

de Sousa Rios MA, Mazzetto SE (2012) Effect of organophosphate antioxidant on the thermo-oxidative degradation of a mineral oil. J Therm Anal Calorim 111:553–559

de Sousa Rios MA, Nascimento TL, Santiago SN, Mazzetto SE (2009) Cashew nut shell liquid: a versatile raw material utilized for syntheses of phosphorus compounds. Energy Fuels 23:5432–5437

Wang X, Zhou S, Guo W, Wang P, Xing W, Song L, Hu Y (2017) Renewable cardanol-based phosphate as a flame retardant toughening agent for epoxy resins. ACS Sustain Chem Eng 5:3409–3416

Bo C, Hu L, Jia P, Liang B, Zhou J, Zhou Y (2015) Structure and thermal properties of phosphorus-containing polyol synthesized from cardanol. RSC Adv 5:106651–106660

Liu Z, Chen J, Knothe G, Nie X, Jiang J (2016) Synthesis of epoxidized cardanol and its antioxidative properties for vegetable oils and biodiesel. ACS Sustain Chem Eng 4:901–906

Zhang M, Luo Z, Zhang J, Chen S, Zhou Y (2015) Effects of a novel phosphorus–nitrogen flame retardant on rosin-based rigid polyurethane foams. Polym Degrad Stab 120:427–434

Riosfacanha M, Mazzetto S, Beserracarioca J, Debarros G (2007) Evaluation of antioxidant properties of a phosphorated cardanol compound on mineral oils (NH10 and NH20). Fuel 86:2416–2421

Wang X, Hu Y, Song L, Xing W, Lu H (2011) Thermal degradation mechanism of flame retarded epoxy resins with a DOPO-substitued organophosphorus oligomer by TG-FTIR and DP-MS. J Anal Appl Pyrol 92:164–170

Jia P, Zhang M, Hu L, Bo C, Zhou Y (2015) Thermal degradation and flame retardant mechanism of poly(vinyl chloride) plasticized with a novel chlorinated phosphate based on soybean oil. Thermochim Acta 613:113–120

Liu Z, Huo J, Yu Y (2017) Water absorption behavior and thermal-mechanical properties of epoxy resins cured with cardanol-based novolac resins and their esterified ramifications. Mater Today Commun 10:80–94

Yen WP, Chen KL, Yeh MY, Uramaru N, Lin HY, Wong FF (2016) Investigation of soluble PEG-imidazoles as the thermal latency catalysts for epoxy-phenolic resins. J Taiwan Inst Chem Eng 59:98–105

Wang F, Huang Z, Liu Y, Li Y (2016) Novel cardanol-containing boron-modified phenolic resin composites. High Perform Polym 29:279–288

van Rijn SP, Srivastava S, Wessels MA, van Soolingen D, Alffenaar JWC, Gumbo T (2017) Sterilizing effect of ertapenem-clavulanate in a hollow-fiber model of tuberculosis and implications on clinical dosing. Antimicrob Agents Chemother 61:e2039–e2116

Gong R, Xu Q, Chu Y, Gu X, Ma J, Li R (2015) A simple preparation method and characterization of epoxy reinforced microporous phenolic open-cell sound absorbent foam. RSC Adv 5:68003–68013

Song SA, Chung YS, Kim SS (2014) The mechanical and thermal characteristics of phenolic foams reinforced with carbon nanoparticles. Composites Sci Technol 103:85–93

Zhou J, Yao Z, Chen Y, Wei D, Xu T (2014) Fabrication and mechanical properties of phenolic foam reinforced with graphene oxide. Polym Compos 35:581–586

Lacoste C, Basso MC, Pizzi A, Laborie MP, Celzard A, Fierro V (2013) Pine tannin-based rigid foams: mechanical and thermal properties. Ind Crops Prod 43:245–250

Jia DW, Shi HJ, Cheng L (2017) Multiscale thermomechanical modeling of short fiber-reinforced composites. Sci Eng Composite Mater 24:765–772

Li Q, Chen L, Li X, Zhang J, Zhang X, Zheng K, Fang F, Zhou H, Tian X (2016) Effect of multi-walled carbon nanotubes on mechanical, thermal and electrical properties of phenolic foam via in situ polymerization. Compos A Appl Sci Manuf 82:214–225

Liu Y, Zhao X, Ye L (2016) A novel elastic urea–melamine–formaldehyde foam: structure and properties. Ind Eng Chem Res 55:8743–8750

Paimushin VN, Firsov VA, Shishkin VM (2017) Modeling the dynamic response of a carbon-fiber-reinforced plate at resonant vibrations considering the internal friction in the material and the external aerodynamic damping. Mech Compos Mater 53:425–440

Fu YG, Li JB (2017) Exact stationary-wave solutions in the standard model of the kerr-nonlinear optical fiber with the bragg grating. J Appl Anal Comput 7:1177–1184

Schartel B, Hull TR (2007) Development of fire-retarded materials—Interpretation of cone calorimeter data. Fire Mater 31:327–354

Xing W, Yang W, Yang W, Hu Q, Si J, Lu H, Yang B, Song L, Hu Y, Yuen RK (2016) Functionalized carbon nanotubes with phosphorus- and nitrogen-containing agents: effective reinforcer for thermal, mechanical, and flame-retardant properties of polystyrene nanocomposites. ACS Appl Mater Interfaces 8:26266–26274

Savas LA, Deniz TK, Tayfun U, Dogan M (2017) Effect of microcapsulated red phosphorus on flame retardant, thermal and mechanical properties of thermoplastic polyurethane composites filled with huntite&hydromagnesite mineral. Polym Degrad Stab 135:121–129

Long L, Chang Q, He W, Xiang Y, Qin S, Yin J, Yu J (2017) Effects of bridged DOPO derivatives on the thermal stability and flame retardant properties of poly(lactic acid). Polym Degrad Stab 139:55–66

Wang X, Hu Y, Song L, Xing W, Lu H, Lv P, Jie G (2010) Flame retardancy and thermal degradation mechanism of epoxy resin composites based on a DOPO substituted organophosphorus oligomer. Polymer 51:2435–2445

Cao Y, Wang XL, Zhang WQ, Yin XW, Shi YQ, Wang YZ (2017) Bi-DOPO structure flame retardants with or without reactive group: their effects on thermal stability and flammability of unsaturated polyester. Ind Eng Chem Res 56:5913–5924

Acknowledgements

The authors are grateful to the financial support by supported by the Fundamental Research Funds for the Central Non-profit Research Institution of CAF (No. CAFYBB2018MA001) and National Natural Science Foundation of China (Nos. 31470613, 31670577, 31670578).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bo, C., Hu, L., Chen, Y. et al. Synthesis of a novel cardanol-based compound and environmentally sustainable production of phenolic foam. J Mater Sci 53, 10784–10797 (2018). https://doi.org/10.1007/s10853-018-2362-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2362-9