Abstract

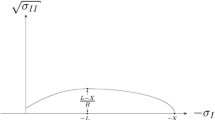

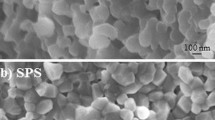

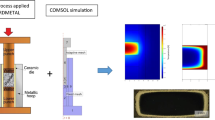

The powder compaction modeling of advanced sintering techniques such as spark plasma sintering is a crucial step in the conception of complex shape objects and the understanding of the process. The complete identification of common powder compaction models requires lengthy experimental investigations based on creep and compaction tests. In order to circumvent this problem, a semi-theoretical approach can be employed whereby the mechanical behavior of the powder material is determined theoretically and the temperature-dependent equivalent creep behavior of the material is determined experimentally. Extending the use of this approach to polymers, metals and ceramics is discussed and compared to other independent methods.

Similar content being viewed by others

References

Olevsky EA, Garcia-Cardona C, Bradbury WL et al (2012) Fundamental aspects of spark plasma sintering: II. Finite element analysis of scalability. J Am Ceram Soc 95:2414–2422. https://doi.org/10.1111/j.1551-2916.2012.05096.x

Olevsky EA (1998) Theory of sintering: from discrete to continuum. Mater Sci Eng R Rep 23:41–100. https://doi.org/10.1016/S0927-796X(98)00009-6

Guillon O, Gonzalez-Julian J, Dargatz B et al (2014) Field-assisted sintering technology/spark plasma sintering: mechanisms, materials, and technology developments. Adv Eng Mater 16:830–849. https://doi.org/10.1002/adem.201300409

Chaim R (2013) Electric field effects during spark plasma sintering of ceramic nanoparticles. J Mater Sci 48:502–510. https://doi.org/10.1007/s10853-012-6764-9

Rybakov KI, Olevsky EA, Semenov VE (2012) The microwave ponderomotive effect on ceramic sintering. Scr Mater 66:1049–1052. https://doi.org/10.1016/j.scriptamat.2012.02.043

Lee G, Olevsky EA, Manière C et al (2018) Effect of electric current on densification behavior of conductive ceramic powders consolidated by spark plasma sintering. Acta Mater 144:524–533. https://doi.org/10.1016/j.actamat.2017.11.010

Abouaf M, Chenot JL, Raisson G, Bauduin P (1988) Finite element simulation of hot isostatic pressing of metal powders. Int J Numer Methods Eng 25:191–212. https://doi.org/10.1002/nme.1620250116

Manière C, Kus U, Durand L et al (2016) Identification of the norton-green compaction model for the prediction of the Ti–6Al–4V densification during the spark plasma sintering process. Adv Eng Mater 18:1720–1727. https://doi.org/10.1002/adem.201600348

Martins D, Grumbach F, Manière C et al (2017) In-situ creep law determination for modeling Spark Plasma Sintering of TiAl 48-2-2 powder. Intermetallics 86:147–155. https://doi.org/10.1016/j.intermet.2017.03.006

Manière C, Olevsky EA (2017) Porosity dependence of powder compaction constitutive parameters: determination based on spark plasma sintering tests. Scr Mater 141:62–66. https://doi.org/10.1016/j.scriptamat.2017.07.026

Manière C, Durand L, Weibel A, Estournès C (2016) Spark-plasma-sintering and finite element method: from the identification of the sintering parameters of a submicronic α -alumina powder to the development of complex shapes. Acta Mater 102:169–175. https://doi.org/10.1016/j.actamat.2015.09.003

Li W, Olevsky EA, McKittrick J et al (2012) Densification mechanisms of spark plasma sintering: multi-step pressure dilatometry. J Mater Sci 47:7036–7046. https://doi.org/10.1007/s10853-012-6515-y

Skorohod V (1972) Rheological basis of the theory of sintering. Nauk Dumka, Kiev, p 72–250

Wang J, Raj R (1990) Estimate of the activation energies for boundary diffusion from rate-controlled sintering of pure alumina, and alumina doped with zirconia or titania. J Am Ceram Soc 73:1172–1175. https://doi.org/10.1111/j.1151-2916.1990.tb05175.x

Rahaman MN (2007) Sintering of ceramics. CRC Press, Boca Raton, p 1–100

Manière C, Durand L, Estournès C (2016) Powder/die friction in the spark plasma sintering process: modelling and experimental identification. Scr Mater 116:139–142. https://doi.org/10.1016/j.scriptamat.2016.01.040

Manière C, Durand L, Weibel A, Estournès C (2016) A predictive model to reflect the final stage of spark plasma sintering of submicronic α-alumina. Ceram Int 42:9274–9277. https://doi.org/10.1016/j.ceramint.2016.02.048

German RM (1996) Sintering theory and practice. Wiley, New York, p 80–82

Coble RL (1963) A model for boundary diffusion controlled creep in polycrystalline materials. J Appl Phys 34:1679–1682. https://doi.org/10.1063/1.1702656

Seltzer MS, Talty PK (1975) High-temperature creep of Y2O3-stabilized ZrO2. J Am Ceram Soc 58:124–130. https://doi.org/10.1111/j.1151-2916.1975.tb19574.x

Dimos D, Kohlstedt DL (1987) Diffusional creep and kinetic demixing in yttria-stabilized zirconia. J Am Ceram Soc 70:531–536. https://doi.org/10.1111/j.1151-2916.1987.tb05700.x

Bernard-Granger G, Guizard C (2007) Spark plasma sintering of a commercially available granulated zirconia powder: I. Sintering path and hypotheses about the mechanism(s) controlling densification. Acta Mater 55:3493–3504. https://doi.org/10.1016/j.actamat.2007.01.048

Ma ZY, Tjong SC (1999) The high-temperature creep behaviour of 2124 aluminium alloys with and without particulate and SiC-whisker reinforcement. Compos Sci Technol 59:737–747. https://doi.org/10.1016/S0266-3538(98)00113-4

Shi L, Wang Z-G, Zhang S-L (2015) Creep deformation of ductile cast iron cooling staves. Ironmak Steelmak 42:339–345. https://doi.org/10.1179/1743281214Y.0000000234

Crouch AG (1972) High-temperature deformation of polycrystalline Fe2O3. J Am Ceram Soc 55:558–563. https://doi.org/10.1111/j.1151-2916.1972.tb13436.x

Nicolle C (1999) Mise en forme de poudre de bore par compression isostatique à chaud: determination des propriétés rhéologiques et simulation numérique du procédé. Université de Bourgogne, France

Besson J (1990) Simulation numerique de la mise en forme des ceramiques application a la compaction isostatique a chaud. L’ecole nationale superieure des mines de Paris

Geindreau C, Bouvard D, Doremus P (1999) Constitutive behaviour of metal powder during hot forming.: Part II: unified viscoplastic modelling. Eur J Mech A Solids 18:597–615. https://doi.org/10.1016/S0997-7538(99)00101-1

Wolff C, Mercier S, Couque H et al (2016) Thermal-electrical-mechanical simulation of the nickel densification by Spark Plasma Sintering. Comparison with experiments. Mech Mater 100:126–147. https://doi.org/10.1016/j.mechmat.2016.06.012

Acknowledgements

C.M. and C.E. thank the French National Research Agency (ANR) for funding this study as part of the ANR09 MAPR-007 Impulsé project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manière, C., Durand, L., Chevallier, G. et al. A spark plasma sintering densification modeling approach: from polymer, metals to ceramics. J Mater Sci 53, 7869–7876 (2018). https://doi.org/10.1007/s10853-018-2096-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2096-8