Abstract

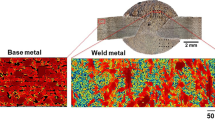

The morphology of austenite (fcc) precipitates in a duplex stainless steel (DSS) is dominated by rods distributed in a ferrite (bcc) matrix. Minority of austenite precipitates also exhibits a lath shape, a common morphology in fcc to bcc transformations rather than a bcc to fcc transformation in a DSS. While the rod-shaped austenite precipitates in a DSS have been interpreted in previous investigations, precipitates with a lath shape were not well understood. This study focused on the lath-shaped austenite by using transmission electron microscopy. The habit plane of lath-shaped austenite was observed to be free of dislocations, but one array of dislocations was observed in the major side facet with a spacing of 9.6 nm and Burgers vector of [110]f/2|[010]b. These observations of crystallographic features were interpreted consistently by an O-line and good matching site analysis. Different morphologies in a DSS and similar morphologies in fcc to bcc and bcc to fcc transformations are compared and discussed.

Similar content being viewed by others

Notes

The morphology of precipitates in fcc/bcc systems was mainly distinguished by the cross-sectional shape. The aspect ratio (width to thickness) of lath shape is around 2–4, while the aspect ratio for rod shape is around 1.

References

Luo CP, Weatherly GC (1987) The invariant line and precipitation in a Ni-45 wt% Cr alloy. Acta Metall 35(8):1963–1972

Luo CP, Weatherly GC (1988) The interphase boundary structure of precipitates in a Ni–Cr alloy. Philos Mag A 58(3):445–462

Chen JK, Chen G, Reynolds WT Jr (1998) Interfacial structure and growth mechanisms of lath-shaped precipitates in Ni-45 wt% Cr. Philos Mag A 78(2):405–422

Furuhara T, Wada K, Maki T (1995) Atomic structure of interphase boundary enclosing bcc precipitate formed in fcc matrix in a Ni-Cr alloy. Metall Mater Trans A 26(8):1971–1978

Hall MG, Aaronson HI, Kinsma KR (1972) The structure of nearly coherent fcc: bcc boundaries in a Cu–Cr alloy. Surf Sci 31:257–274

Luo CP, Dahmen U, Westmacott KH (1994) Morphology and crystallography of Cr precipitates in a Cu-0.33 wt% Cr alloy. Acta Metall Mater 42(6):1923–1932

Luo CP, Dahmen U (1998) Interface structure of faceted lath-shaped Cr precipitates in a Cu–0.33 wt% Cr alloy. Acta Mater 46(6):2063–2081

Dahmen U, Ferguson P, Westmacott K (1984) Invariant line strain and needle-precipitate growth directions in Fe–Cu. Acta Metall 32(5):803–810

Fujii T, Mori T, Kato M (1992) Crystallography and morphology of needle-like α-Fe precipitate particles in a Cu matrix. Acta Metall Mater 40(12):3413–3420

Forwood CT, Clarebrough LM (1989) The dislocation structure of f.c.c-b.c.c. interfaces in a Cu-Fe alloy. Philos Mag B 59(6):637–665

Ameyama K, Weatherly GC, Aust KT (1992) A study of grain boundary nucleated widmanstätten precipitates in a two-phase stainless steel. Acta Metall Mater 40(8):1835–1846

Jiao H, Aindow M, Pond RC (2003) Precipitate orientation relationships and interfacial structures in duplex stainless steel Zeron-100. Philos Mag 83(16):1867–1887

Qiu D, Zhang W-Z (2007) A TEM study of the crystallography of austenite precipitates in a duplex stainless steel. Acta Mater 55(20):6754–6764

Rigsbee JM, Aaronson HI (1979) A computer modeling study of partially coherent FCC: BCC boundaries. Acta Metall 27(3):351–363

Bollmann W (1974) O-Lattice calculation of an FCC–BCC interface. Phys Status Solidi A 21(2):543–550

Bollmann W (1970) Crystal defects and crystalline interfaces. Springer Science & Business Media, Berlin

Hall MG, Aaronson HI (1986) The fine structure fcc/bcc boundaries in a Cu-0.3% Cr alloy. Acta Metall 34(7):1409–1418

Hall MG, Rigsbee JM, Aaronson HI (1986) Application of the “0” lattice calculation to fcc/bcc interfaces. Acta Metall 34(7):1419–1431

Dahmen U (1981) The role of the invariant line in the search for an optimum interphase boundary by O-lattice theory. Scr Metall 15(1):77–81

Dahmen U (1982) Orientation relationships in precipitation systems. Acta Metall 30(1):63–73

Xiao SQ, Howe JM (2000) Analysis of a two-dimensional invariant line interface for the case of a general transformation strain and application to thin-film interfaces. Acta Mater 48(12):3253–3260

Qiu D, Zhang W-Z (2003) A systematic study of irrational precipitation crystallography in fcc–bcc systems with an analytical O-line method. Philos Mag 83(27):3093–3116

Zhang W-Z, Purdy GR (1993) O-lattice analyses of interfacial misfit. II. Systems containing invariant lines. Philos Mag A 68(2):291–303

Liang Q, Reynolds W Jr (1998) Determining interphase boundary orientations from near-coincidence sites. Metall Mater Trans A 29(8):2059–2072

Kurdjumow G, Sachs G (1930) Über den mechanismus der stahlhärtung. Zeitschrift für Physik 64(5–6):325–343

Tsai WT, Tsai KM, Lin CJ, Fu Y (2003) Selective corrosion in duplex stainless steel. Electrochemistry 9(2):170–176

Zhang M-X (1997) Crystallography of phase transformations in steels. University of Queensland, Brisbane

Meng Y, Gu L, Zhang W-Z (2010) Precise determination of the irrational preferred interface orientation by TEM. Acta Metall Sin 46(4):411–417

Zhang W-Z, Weatherly GC (2005) On the crystallography of precipitation. Prog Mater Sci 50(2):181–292

Dai F-Z, Zhang W-Z (2013) A systematic study on the interfacial energy of O-line interfaces in fcc/bcc systems. Modell Simul Mater Sci Eng 21(7):075002

Yang X-P, Zhang W-Z (2012) A systematic analysis of good matching sites between two lattices. Sci China Technol Sci 55:1343–1352

Qiu D, Zhang W-Z (2008) An extended near-coincidence-sites method and the interfacial structure of austenite precipitates in a duplex stainless steel. Acta Mater 56(9):2003–2014

Knowles KM, Smith DA (1982) The application of surface dislocation theory to the fcc-bcc interface. Acta Crystallogr A 38(1):34–40

Kalman D (1996) A singularly valuable decomposition: the SVD of a matrix. College Math J 27(1):2–23

Gu X-F, Zhang W-Z, Qiu D (2011) A systematic investigation of the development of the orientation relationship in an fcc/bcc system. Acta Mater 59:4944–4956

Acknowledgements

Supports from National Natural Science Foundation of China (No. 51471097 and No. 51671111) and helpful discussions from Dr. Dong Qiu are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The experimentally measured orientation matrix b M f was determined by the two pairs of parallel direction in Eq. 1 as

In the O-line condition with the minimum interfacial energy of O-line interfaces, the transformation matrix A and displacement matrix T were determined as

and

where I is a unit matrix. The orientation matrix M is related to A by

where C is the Bain correspondence matrix. The column vectors of C are given by [110], \( [\overline{1}10] \) and [001] corresponding to the OR in Eq. 3.

Rights and permissions

About this article

Cite this article

Du, J., Mompiou, F. & Zhang, WZ. A TEM study of the crystallography of lath-shaped austenite precipitates in a duplex stainless steel. J Mater Sci 52, 11688–11700 (2017). https://doi.org/10.1007/s10853-017-1324-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1324-y