Abstract

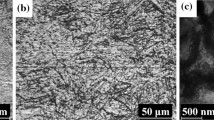

Silicon nitride (Si3N4) has been introduced clinically as an orthopedic biomaterial for interbody fusion devices and in joint replacements. However, the production of complex shapes through conventional mechanical machining is difficult and expensive and limits interesting applications. Thus, several electrically conductive reinforcements to the Si3N4 matrix, like TiN, have been proposed, generating composites suitable to be wrought by electrical discharge machining (EDM). In this study, Si3N4–TiN with high strength, low density, and good electric conductivity wrought by EDM was studied. The role of surface finishing was investigated comparing the interface generated during the EDM process to that resulting from further polishing. The different topographical features were assessed by electron microscopy, energy dispersive X-ray spectrometry, and profilometry. Surface wettability was also determined based on the measurement of the OCA of water and diiodomethane. The biological responses induced in MC3T3 cells, a widely diffused osteoblast model, were correlated with the surface pattern. The unpolished samples could promote better cell viability, with a more relevant effect on the cytoskeleton arrangement as highlighted by numerous cytoplasmic extensions and filopodia-like structures and the high number of focal adhesions, while MC3T3 cells grown on polished Si3N4–TiN specimens displayed a flat morphology. In addition, the unpolished Si3N4–TiN increased osteocalcin production and calcium deposition. Taken together, these data support the biocompatibility and in vitro osteogenic properties of the electroconductive Si3N4–TiN investigated. Further in vivo studies are required to explore the possible use of bone implants directly obtained by EDM.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Riley FL (2004) Silicon nitride and related materials. J Am Ceram Soc 83:245–265

Guicciardi S, Melandri C, Medri V et al (2003) Effects of testing temperature and thermal treatments on some mechanical properties of a Si3N4–TiN composite. Mater Sci Eng A 360:35–45

Bracisiewicz M, Medri V, Bellosi A (2002) Factors inducing degradation of properties after long term oxidation of Si3N4–TiN electroconductive composites. Appl Surf Sci 202:139–149

Medri V, Bracisiewicz M, Krnel K et al (2005) Degradation of mechanical and electrical properties after long-term oxidation and corrosion of non-oxide structural ceramic composites. J Eur Ceram Soc 25:1723–1731

McEntire BJ, Bal BS, Rahaman MN et al (2015) Ceramics and ceramic coatings in orthopaedics. J Eur Ceram Soc 35:4327–4369

Kersten RF, van Gaalen SM, Arts MP et al (2014) The SNAP trial: a double blind multi-center randomized controlled trial of a silicon nitride versus a PEEK cage in transforaminal lumbar interbody fusion in patients with symptomatic degenerative lumbar disc disorders: study protocol. BMC Musculoskelet Disord 15:57

Arts MP, Wolfs JFC, Corbin TP (2013) The CASCADE trial: effectiveness of ceramic versus PEEK cages for anterior cervical discectomy with interbody fusion; protocol of a blinded randomized controlled trial. BMC Musculoskelet Disord 14:244

Zhou Y (2001) Study on the friction properties of silicon nitride-silicon nitride as a material for hip prostheses. Chin J Biomed Eng 20:326–329 + 334

Bal BS, Khandkar A, Lakshminarayanan R et al (2009) Fabrication and testing of silicon nitride bearings in total hip arthroplasty. Winner of the 2007 ‘HAP’ PAUL Award. J Arthroplasty 24:110–116

Bal BS, Rahaman MN (2012) Orthopedic applications of silicon nitride ceramics. Acta Biomater 8:2889–2898

Roebben G, Sarbu C, Lube T et al (2004) Quantitative determination of the volume fraction of intergranular amorphous phase in sintered silicon nitride. Mater Sci Eng A 370:453–458

Becher PF, Sun EY, Plucknett KP et al (1998) Microstructural design of silicon nitride with improved fracture toughness: I, effects of grain shape and size. J Am Ceram Soc 81:2821–2830

Sun EY, Becher PF, Plucknett KP et al (1998) Microstructural design of silicon nitride with improved fracture toughness: II, effects of yttria and alumina additives. J Am Ceram Soc 81:2831–2840

Becher PF (1991) Microstructural design of toughened ceramics. J Am Ceram Soc 74:1551–2916

Neumann A, Reske T, Held M et al (2004) Comparative investigation of the biocompatibility of various silicon nitride ceramic qualities in vitro. J Mater Sci Mater Med 15:1135–1140

Guedes e Silva CC, Higa OZ, Bressiani JC (2004) Cytotoxic evaluation of silicon nitride-based ceramics. Mater Sci Eng C 24:643–646

Mazzocchi M, Bellosi A (2008) On the possibility of silicon nitride as a ceramic for structural orthopaedic implants. Part I: processing, microstructure, mechanical properties, cytotoxicity. J Mater Sci Mater Med 19:2881–2887

Mazzocchi M, Gardini D, Traverso PL et al (2008) On the possibility of silicon nitride as a ceramic for structural orthopaedic implants. Part II: chemical stability and wear resistance in body environment. J Mater Sci Mater Med 19:2889–2901

Santos C, Ribeiro S, Daguano JKMF et al (2007) Development and cytotoxicity evaluation of SiAlONs ceramics. Mater Sci Eng C 27:148–153

Cappi B, Neuss S, Salber J et al (2010) Cytocompatibility of high strength non-oxide ceramics. J Biomed Mater Res Part A 93:67–76

Howlett CR, McCartney E, Ching W (1989) The effect of silicon nitride ceramic on rabbit skeletal cells and tissue. Clin Orthop Relat Res 244:293–304

Neumann A, Kramps M, Ragoß C et al (2004) Histological and microradiographic appearances of silicon nitride and aluminum oxide in a rabbit femur implantation model. Materwiss Werksttech 35:569–573

Neumann A, Unkel C, Werry C et al (2006) Prototype of a silicon nitride ceramic-based miniplate osteofixation system for the midface. Otolaryngol Head Neck Surg 134:923–930

Rak K, Wasielewski N, Radeloff A et al (2011) Growth behavior of cochlear nucleus neuronal cells on semiconductor substrates. J Biomed Mater Res Part A 97A:158–166

Carter EA, Rayner BS, McLeod AI et al (2010) Silicon nitride as a versatile growth substrate for microspectroscopic imaging and mapping of individual cells. Mol BioSyst 6:1316–1322

Hirata I, Iwata H, Ismail ABM et al (2000) Surface modification of Si3N4-coated silicon plate for investigation of living cells. Jpn J Appl Phys Part 1 Regul Pap Short Notes Rev Pap 39:6441–6442

Guedes E, Silva CC, König B, Carbonari MJ et al (2008) Tissue response around silicon nitride implants in rabbits. J Biomed Mater Res Part A 84:337–343

Guedes e Silva CC, König B, Carbonari MJ et al (2008) Bone growth around silicon nitride implants—an evaluation by scanning electron microscopy. Mater Charact 59:1339–1341

Anderson MC, Olsen R (2010) Bone ingrowth into porous silicon nitride. J Biomed Mater Res Part A 92:1598–1605

Webster TJ, Patel AA, Rahaman MN et al (2012) Anti-infective and osteointegration properties of silicon nitride, poly(ether ether ketone), and titanium implants. Acta Biomater 8:4447–4454

Gorth DJ, Puckett S, Ercan B et al (2012) Decreased bacteria activity on Si3N4 surfaces compared with PEEK or titanium. Int J Nanomed 7:4829–4840

Herrmann M, Balzer B, Schubert C et al (1993) Densification, microstructure and properties of Si3N4Ti(C, N) composites. J Eur Ceram Soc 12:287–296

Bellosi A, Guicciardi S, Tampieri A (1992) Development and characterization of electroconductive Si3N4–TiN composites. J Eur Ceram Soc 9:83–93

Bucciotti F, Mazzocchi M, Bellosi A (2010) Perspectives of the Si3N4–TiN ceramic composite as a biomaterial and manufacturing of complex-shaped implantable devices by electrical discharge machining (EDM). J Appl Biomater Biomech 8:28–32

Martin C, Cales B, Vivier P et al (1989) Electrical discharge machinable ceramic composites. Mater Sci Eng A 109:351–356

Canullo L, Genova T, Tallarico M et al (2016) Plasma of argon affects the earliest biological response of different implant surfaces: an in vitro comparative study. J Dent Res 95:566–573

Ström G, Fredriksson M, Stenius P (1987) Contact angles, work of adhesion, and interfacial tensions at a dissolving hydrocarbon surface. J Colloid Interface Sci 119:352–361

Gould RF, Gould Robert F. Contact angle, wettability, and adhesion. Washington, D.C.: American Chemical Society. doi:10.1021/ba-1964-0043. (Epub ahead of print 1 January 1964)

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747

Mussano F, Lee KJ, Zuk P et al (2010) Differential effect of ionizing radiation exposure on multipotent and differentiation-restricted bone marrow mesenchymal stem cells. J Cell Biochem 111:322–332

Passeri G, Cacchioli A, Ravanetti F et al (2010) Adhesion pattern and growth of primary human osteoblastic cells on five commercially available titanium surfaces. Clin Oral Implants Res 21:756–765

Albrektsson T, Wennerberg A (2004) Oral implant surfaces: part 1—review focusing on topographic and chemical properties of different surfaces and in vivo responses to them. Int J Prosthodont 17:536–543

Bock RM, McEntire BJ, Bal BS et al (2015) Surface modulation of silicon nitride ceramics for orthopaedic applications. Acta Biomater 26:318–330

Gristina R, D’Aloia E, Senesi GS et al (2009) Increasing cell adhesion on plasma deposited fluorocarbon coatings by changing the surface topography. J Biomed Mater Res B Appl Biomater 88:139–149

Genova T, Munaron L, Carossa S et al (2016) Overcoming physical constraints in bone engineering: ‘the importance of being vascularized’. J Biomater Appl 30:940–951

Martin JY, Schwartz Z, Hummert TW et al (1995) Effect of titanium surface roughness on proliferation, differentiation, and protein synthesis of human osteoblast-like cells (MG63). J Biomed Mater Res 29:389–401

Geiger B, Bershadsky A, Pankov R et al (2001) Transmembrane extracellular matrix—cytoskeleton crosstalk. Nat Rev Mol Cell Biol 2:793–805

Anselme K (2000) Osteoblast adhesion on biomaterials. Biomaterials 21:667–681

Qu Z, Rausch-Fan X, Wieland M et al (2007) The initial attachment and subsequent behavior regulation of osteoblasts by dental implant surface modification. J Biomed Mater Res A 82:658–668

Zhao G, Raines AL, Wieland M et al (2007) Requirement for both micron- and submicron scale structure for synergistic responses of osteoblasts to substrate surface energy and topography. Biomaterials 28:2821–2829

Author information

Authors and Affiliations

Corresponding author

Additional information

F. Mussano and T. Genova contributed equally to the paper.

Rights and permissions

About this article

Cite this article

Mussano, F., Genova, T., Rivolo, P. et al. Role of surface finishing on the in vitro biological properties of a silicon nitride–titanium nitride (Si3N4–TiN) composite. J Mater Sci 52, 467–477 (2017). https://doi.org/10.1007/s10853-016-0346-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0346-1