Abstract

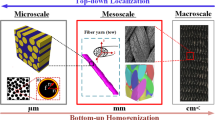

Three-dimensional viscoelastic properties of four-step three-dimensionally (3D) braided composites are studied in this paper. Based on the three-cell division scheme, a multi-scale model for 3D braided composites is proposed. A periodic boundary condition is applied to characterize the periodic structure of 3D braided composites and yarns. Given the viscoelastic parameters of resin matrix and the elastic constants of fibers, the viscoelastic properties of yarns are obtained by the finite element method and Prony Series fitting. The three-dimensional viscoelastic constitutive relationship of interior cells is derived based upon the viscoelastic properties of yarns and resin matrix. Moreover, the viscoelasticity of 3D braided composites is studied by creep experiment. The viscoelastic deformation obtained from the multi-scale method agrees well with the experimental results. The influence of the two independent micro-structural parameters, braiding angles, and fiber volume fractions, on the viscoelastic properties of 3D braided composites is investigated in detail.

Similar content being viewed by others

References

Ko FK, Pastore CM (1985) In: Vinson JR, Taya M (eds) Recent advances in composites in the United States and Japan. American Society for Testing Material, Philadelphia, p 428

Yang JM, Ma CL, Chou TW (1986) J Compos Mater 20:472

Wu DL (1996) Compos Sci Technol 56:225

Chen L, Tao XM, Choy CL (1999) Compos Sci Technol 59:2383

Ma CL, Yang JM, Chou TW (1986) In: Composite materials: testing and design (seventh conference), ASTM STP 893 p 404

Byun JH, Du GW, Chou TW (1991) In: High-tech fibrous materials (ACS symposium series 457) p 22

Sun HY, Qiao X (1997) Compos Sci Technol 57:623

Sun BZ, Gu BH (2007) J Mater Sci 42:2463. doi:10.1007/s10853-006-1295-x

Tang ZX, Postle R (2001) Compos Struct 51:451

Sun HY, Di SL, Zhang N, Pan N, Wu CC (2003) Comput Struct 81:2021

Zeng T, Fang DN, Ma L, Guo LC (2004) Mater Lett 58:3237

Xu K, Xu XW (2008) Mater Sci Eng, A 487:499

Chen ZR, Zhu DC, Meng L, Lin Y (1999) Compos Struct 47:477

Feng ML, Wu CC (2001) Compos Sci Technol 61:1889

Yu XG, Cui JZ (2007) Compos Sci Technol 67:471

Dong JW, Feng ML (2010) Compos Struct 92:873

Brinson LC, Knauss WG (1991) J Mech Phys Solids 39:859

Koishi M, Shiratori M, Miyoshi T, Kabe K (1997) JSME Int J, Ser A 40:306

Chung PW, Tamma KK, Namburu RR (2000) Compos Sci Technol 60:2233

Seifert OE, Schumacher SC, Hansen AC (2003) Compos B 34:571

Lévesque M, Derrien K, Mishnaevski L Jr, Baptiste D, Gilchrist MD (2004) Compos A 35:905

Liu JY, Chen L, Li DS, Li JL (2004) J Tianjin Poly Univ 23:13

Li DS, Li JL, Chen L, Lu ZX (2006) J Aero Mater 26:76

Chen L, Tao XM, Choy CL (1999) Compos Sci Technol 59:391

Xia ZH, Zhang YF, Fernand E (2003) Int J Solids Struct 40:1907

Chang CY, Liu ST, Wang CG (2006) Chin J Comput Mech 23:414

Zhou CW, Zhang YX (2007) Acta Mater Compos Sini 24:125

Acknowledgements

This research was supported by National Natural Science Foundation of China (10972101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, Y., Sun, H. Prediction on viscoelastic properties of three-dimensionally braided composites by multi-scale model. J Mater Sci 48, 6499–6508 (2013). https://doi.org/10.1007/s10853-013-7524-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7524-1