Abstract

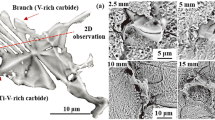

Oxide-dispersion-strengthened (ODS) ferritic steels of Fe–9Cr–0.3Y2O3 and Fe–9Cr–0.2Ti–0.3Y2O3 (in mass) incorporating nanoscale oxide particles, were produced by mechanical milling (MM) followed by hot pressing (HP). Microstructural evolution of these two types of ODS steels were structurally characterized at each step of the elaboration processes by means of scanning electron microscope (SEM), transmission electron microscope (TEM), X-ray diffraction (XRD), and optical microscope. The observations of structure of the mixed powders and the nanoscale oxide particles in both ODS steels after MM indicate that the initial powders, coupled with the original yttria powders, get fractured by severe plastic deformation and ultrafine bcc grains (~20 nm) of the matrix and Y2O3 nanocrystals with irregular edges are formed during MM. The addition of titanium (Ti) promotes the refinement of bcc grains, Y2O3 nanocrystals and the formation of amorphous phase of Y2O3 during MM. TEM observations of these two Oxide-dispersion-strengthened (ODS) steels exhibit a very fine structure of micrometer-scale grains in which large number of nanoscale oxide particles are distributed after HP process. The observation of some unreinforced domains without the nanoscale oxide particles indicates that there still exist inhomogeneous areas, although the size of those oxide particles reaches nanoscale. Threshold stress of the HPped Fe–9Cr–0.2Ti–0.3Y2O3 steel with the relatively homogeneous dispersion was carefully evaluated on the basis of higher magnified images of the nanoscale oxide particles. Different values of threshold stress were obtained due to the various dispersions of the nanoscale oxide particles within different areas. That may be the reason why the threshold stress cannot be clearly obtained by the results of creep tests.

Similar content being viewed by others

References

Noh S, Kasada R, Kimura A (2011) Acta Mater 59:3196

Hadraba H, Fournier B, Stratil L, Malaplate J, Rouffié A-L, Wident P, Ziolek L, Bchade J-L (2011) J Nucl Mater 411:112

Klimenkov M (2011) J Nucl Mater 411:160

Ukai S, Mizuta S, Fujiwara M, Okuda T, Kobayashi T (2002) J Nucl Sci Technol 39:778

Oksiuta Z, Lewandowska M, Unifantowicz P, Baluc N, Kurzydlowski KJ (2011) Fusion Eng Des 86:2417

Allen TR, Gan J, Cole JI, Miller MK, Busby JT, Shutthanandan S, Thevuthasan S (2008) J Nucl Mater 375:26

Hin C, Wirth BD (2010) J Nucl Mater 402:30

Lescoat M-L, Monnet I, Ribis J, Dubuisson P, de Carlan Y, Costantini J-M, Malaplate J (2011) J Nucl Mater 417:266

Lindau R, Möslang A, Schirra M, Schlossmacher P, Klimenkov M (2002) J Nucl Mater 307(311):769

Hsiung LL, Fluss MJ, Tumey SJ, Choi BW, Serruys Y, Willaime F, Kimura A (2010) Phys Rev B 82:184103

Ukai S, Mizuta S, Fujiwara M (2002) J Nucl Mater 307(311):749

Kishimoto H, Kasada R, Hashitomi O, Kimura A (2009) J Nucl Mater 386(388):533

Brocq M, Radiguet B, Breton JML, Cuvilly F, Pareige P, Legendre F (2010) Acta Mater 58:1806

Kimura Y, Takaki S, Suejima S, Uemor R, Tamehiro H (1999) ISIJ Int 39:176

Oksiuta Z, Baluc N (2009) Nucl Fusion 49:055003

Ukai S, Okuda T, Fujiwara M, Kobayashi T, Mizuta S, Nakashima H (2002) J Nucl Sci Technol 39:872

Brocq M, Radiguet B, Poissonnet S, Cuvilly F, Pareige P, Legendre F (2011) J Nucl Mater 409:80

Danilchenko SN, Kukharenko OG, Moseke C, Protsenko IY, Sukhodubi LF, Sulkio-Cleff B (2002) Cryst Res Technol 37:1234

Jiang HG, Rühle M, Lavernia EJ (1999) J Mater Res 14:549

Sakasegawa H, Tamura M, Ohtsuka S, Ukai S, Tanigawa H, Kohyama A, Fujiwara M (2008) J Alloy Compd 452:2

Tamura M, Sakasegawa H, Shiba K, Tanigawa H, Shinozuka K, Esaka H (2011) Metall Mater Trans A 42:2176

Zhang L, Ukai S, Hoshino T, Hayashi S, Qu X (2009) Acta Mater 57:3671

Okuda T, Fujiwara M (1995) J Mater Sci Lett 14:1600

Suryanarayana C (2001) Prog Mater Sci 46:1

Hsiung LL, Fluss MJ, Kimura A (2010) Mater Lett 64:1782

Hsiung LL, Fluss M, Kuntz J, El-Dasher B, Choi W, Tumey SJ, Kimura A (2010) TMS Annual Meeting Seattle, 14

Koyano T, Takizawa T, Fukunaga T, Mizutani U (1993) J Appl Phys 73:429

Morris DG, Morris MA (1991) Acta Metall Mater 39:1763

Suryanarayana C, Ivanov E, Boldyrev VV (2001) Mater Sci Eng A 304(306):151

Rahmanifard R, Farhangi H, Novinrooz AJ, Afshari N (2010) J Mater Sci 45:6498. doi:10.1007/s10853-010-4738-3

West MK (2006) PhD thesis, University of Tennessee, Knoxville

Koch CC, Scattergood RO, Youssef KM, Chan E, Zhu YT (2010) J Mater Sci 45:4725. doi:10.1007/s10853-010-4252-7

Alinger MJ (2004) PhD Thesis, University of California

Wang L, Xie G, Zhang J, Lou LH (2006) Scripta Mater 55:457

Yamasaki S, Bhadeshia HKDH (2003) Sci Technol 19:723

Takaki S, Kimura Y (1999) J Jpn Soc Powder Powder Metal 46:1235

Hotta S, Yamada K, Murakami T, Narushima T, Iguchi Y, Ouchi C (2006) ISIJ Int 46:129

Gao N, Baker TN (1998) ISIJ Int 38:744

Yamamoto M, Ukai S, Hayashi S, Kaito T, Ohtsuka S (2010) Mater Sci Eng A 527:4418

Foreman AJE, Makin MJ (1966) Philos Mag A 14:911

Ukai S, Ohtsuka S, Kaito T, Sakasegawa H, Chikata N, Hayashi S, Ohnuki S (2009) Mater Sci Eng A 510(511):115

Sakasegawa H, Chaffron L, Legendre F, Brocq M, Boulanger L, Poissonnet S, de Carlan Y, Bechade J, Cozzika T, Malaplate J (2009) J Nucl Mater 386(388):511

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China and Shanghai Baosteel Group Company (No. 50834011), National Natural Science Foundation of China (No. 50901049), and Natural Science Foundation of Tianjin City (No. 09JCYBJC15400) for grant and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, L., Liu, Y., Ma, Z. et al. Microstructural evolution of oxide-dispersion-strengthened Fe–Cr model steels during mechanical milling and subsequent hot pressing. J Mater Sci 48, 1826–1836 (2013). https://doi.org/10.1007/s10853-012-6948-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6948-3