Abstract

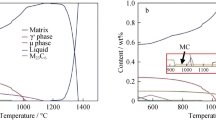

This study investigates the influence of alloy composition on γ′ precipitation in Ni–8Al–8Cr and Ni–10Al–10Cr at.% during continuous cooling from a supersolvus temperature. When subjected to the same cooling rate, Ni–8Al–8Cr develops a monomodal population, whereas Ni–10Al–10Cr develops a multimodal (primarily bimodal) population of γ′ precipitates. The bimodal γ′ precipitate size distribution in Ni–10Al–10Cr alloy can be attributed to two successive nucleation bursts during continuous cooling while the monomodal γ′ size distribution in Ni–8Al–8Cr results from a single nucleation burst followed by a longer time—wider temperature window for nucleation resulting in a larger number density of precipitates. Three-dimensional atom probe investigations reveal that while local equilibrium is achieved across the γ/γ′ interface, far-field γ compositions still retain an excess of Al and a depletion of Cr with respect to equilibrium, thus giving direct experimental evidence of the driving force for subsequent nucleation bursts during continuous cooling in case of Ni–10Al–10Cr. Contrastingly, in case of the Ni–8Al–8Cr alloy, while the γ phase retains an excess of Al and a depletion of Cr with respect to equilibrium after continuous cooling to room temperature, the additional driving force is consumed during subsequent isothermal annealing by growth of the large number of γ′ precipitates without any new nucleation.

Similar content being viewed by others

References

Hwang JY, Nag S, Singh ARP, Srinivasan R, Tiley J, Fraser HL, Banerjee R (2009) Scripta Mater 61:92

Hwang JY, Nag S, Singh ARP, Srinivasan R, Tiley R, Viswanathen GB, Fraser HL, Banerjee R (2009) Metall Mater Trans A 40A:3059

Hong YM, Mishima Y, Suzuki T (1989) Mater Res Soc Symp Proc 133:429

Caron P (2000) Superalloys 2000. TMS, Warrendale, PA, p 737–746

Porter DA, Easterling KE (2004) Phase transformations in metal and alloys, 2nd edn. Taylor & Francis, London

Booth-Morrison C, Eninger JW, Sudbrack CK, Mao Z, Noebe R, Seidman DN (2008) Acta Mater 56:3422

Singh ARP, Nag S, Hwang JY, Viswanathen GB, Tiley J, Srinivasan R, Fraser HL, Banerjee R (2011) Mater Charact 62:878

Sarosi PM, Wang B, Simmons P, Wang Y, Mills MJ (2007) Scripta Mater 57:767

Radis R, Schaffer M, Albu M, Kothleitner G, Polt P, Kozeschnik E (2009) Acta Mater 57:5739

Wen YH, Simmons JP, Shen C, Woodward C, Wang Y (2003) Acta Mater 51:1123

Wen YH, Wang B, Simmons JP, Wang Y (2006) Acta Mater 54:2087

Payton EJ, Phillips PJ, Mills MJ (2010) Mater Sci Eng A 527:2684

Babu SS, Miller MK, Vitak JM, David SA (2001) Acta Mater 49:4149

Miller MK (2001) Micron 32:757

Blavette D, Cadela E, Deconihout B (2000) Material Charact 44:133

Ardell AJ, Ozolins V (2005) Nat Mater 4:309

Hellman OC, Vandenbroucke JA, Rusing J, Isheim D, Seidman DN (2000) Microsc Microanal 6:437

Saunders N (1996) In: Kissinger RD et al (eds) Superalloys 1996. TMS, Warrendale, p 101

Dupin N, Ansara I, Sundman B (2001) CALPHAD 25:279

Acknowledgements

This study was supported by the U.S. Air Force Research Laboratory (AFRL ISES Contract, contract number FA8650-08-C-5226). In addition, the authors also gratefully acknowledge the Center for Advanced Research and Technology (CART) at the University of North Texas for access to the experimental facilities used for this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rojhirunsakool, T., Meher, S., Hwang, J.Y. et al. Influence of composition on monomodal versus multimodal γ′ precipitation in Ni–Al–Cr alloys. J Mater Sci 48, 825–831 (2013). https://doi.org/10.1007/s10853-012-6802-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6802-7