Abstract

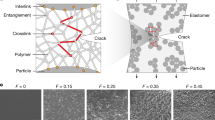

Rubber toughened epoxies are used in a wide range of applications including adhesives when toughness is a crucial property. It is well known that the cavitation of the rubber particles is an important process to optimise the toughness of such materials. This article describes the development of a predictive model to describe the dependence of rubber particle cavitation on particle size. The model is developed using a combination of experimental observations and finite element simulations. Predictions have been obtained for both uniaxial loading conditions and the triaxial loading conditions expected ahead of a crack. The model has been extended to consider the cavitation of nano-sized ‘rubber’ particles.

Similar content being viewed by others

References

Jeong HY, Pan J (1995) Int J Solids Struct 32:3669. doi:10.1016/0020-7683(95)00009-Y

Jeong HY, Pan J (1996) Polym Eng Sci 36:2306. doi:10.1002/pen.10629

Bagheri R, Marouf BT, Pearson RA (2009) Polym Rev 49:201. doi:10.1080/15583720903048227

Hsieh TH, Kinloch AJ, Masania K, Sohn Lee J, Taylor AC, Sprenger S (2010) J Mater Sci 45:1193. doi:10.1007/s10853-009-4064-9

Kinloch AJ (2003) MRS Bull 28:445

Sue H-J, Yee AF (1996) Polym Eng Sci 36:2320. doi:10.1002/pen.10630

Guild FJ, Kinloch AJ (1994) J Mater Sci Lett 13:629. doi:10.1007/BF00271216

Guild FJ, Kinloch AJ (1995) J Mater Sci 30:1689. doi:10.1007/BF00351597

Gehant S, Fond C, Schirrer R (2003) Int J Fract 122:161. doi:10.1023/B:FRAC.0000005790.35684.1d

Huang Y, Kinloch AJ (1992) J Mater Sci 27:2753. doi:10.1007/BF00540702

Pearson RA, Yee AF (1986) J Mater Sci 21:2475. doi:10.1007/BF01114294

Yee AF, Pearson RA (1986) J Mater Sci 21:2462. doi:10.1007/BF01114293

Pearson RA, Yee AF (1991) J Mater Sci 26:3828. doi:10.1007/BF01184979

Fond C (2001) J Polym Sci B 39:2081. doi:10.1002/polb.1183

Dompas D, Groeninckx G, Isogawa M, Hasegawa T, Kadokura M (1994) Polymer 35:4750. doi:10.1016/0032-3861(94)90728-5

Lazzeri A, Bucknall CB (1995) Polymer 36:2895. doi:10.1016/0032-3861(95)94338

Liu J, Sue HJ, Thompson ZJ, Bates FS, Dettloff M, Jacob G, Verghese N, Pham H (2008) Macromolecules 41:7616. doi:10.1021/ma801037q

Kunz SC, Beaumont PWR (1981) J Mater Sci 16:3141. doi:10.1007/BF00540323

Hibbitt, Karlsson, Sorensen (2002) ABAQUS/standard user manual: version 6.3

Yasmin A, Daniel IM (2004) Polymer 45:8211. doi:10.1016/j.polymer.2004.09.054

Mamlouk MS, Witczak MW, Kaloush KE, Hasan NJ (2005) Test Eval 33:118. doi:10.1520/JTE12592

Oba T (1999) PhD thesis. Imperial College London

Kinloch AJ, Shaw SJ, Tod DA, Hunston DL (1983) Polymer 24:1341. doi:10.1016/0032-3861(83)

Duncan B, Dean GD (2003) Int J Adhes Adhes 23:141. doi:10.1016/S0143-7469(03)00006-X

Huang Y, Kinloch AJ (1992) J Mater Sci Lett 11:484. doi:10.1007/BF00731112

Guild FJ, Kinloch AJ, Taylor AC. A predictive model for the toughness of rubber toughened epoxies (in preparation)

Levy N, Marcel PV, Ostergren WJ, Rice JR (1971) Int J Fract 7:143. doi:10.1007/BF00183802

Rice JR (1968) J Appl Mech 35:379

Davy PJ, Guild FJ (1988) Proc R Soc A 418:95. doi:10.1098/rspa.1988.0075

Bucknall CB, Karpodinis A, Zhang XC (1994) J Mater Sci 29:3377. doi:10.1007/BF00352036

Lake GJ, Thomas AG (1967) Proc R Soc A 300:108. doi:10.1098/rspa.1967.0160

Almer CJ, Pocius AV (1980) In: Proceedings of the SAMPE technical conference, Seattle, USA

Gent AN (1990) Rubber Chem Technol 63:49

Bucknall CB, Paul DR (2009) Polymer 50:5539. doi:10.1016/j.polymer.2009.09.059

Smit RJM, Brekelmans WAM, Meijer HEH (2000) J Mater Sci 35:2869. doi:10.1023/A:1004763606229

Kim DS, Cho K, Kim JK, Park CE (1996) Polym Eng Sci 36:755. doi:10.1002/pen.10463

Day RJ, Lovell PA, Wazzan AA (2001) Polym Int 50:849. doi:10.1002/pi.690

Acknowledgements

This project was jointly funded by the Engineering and Physical Sciences Research Council, UK, and the Defence Science and Technology Laboratory, UK. We gratefully acknowledge the contributions to the Finite Element simulations from Dr Xiaowei Wang and Dr Nadia Balhi, University of Bristol, UK. We thank Dr Bernt Johnsen and Spyros Spyridoulias, Imperial College London, UK, and Dr G. D. Dean, National Physical Laboratory, UK, for providing experimental results. We thank Dr D. L. Hunston, National Institute of Standards and Technology, USA, and Professor J. G. Williams, Imperial College London, UK, for valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guild, F.J., Kinloch, A.J. & Taylor, A.C. Particle cavitation in rubber toughened epoxies: the role of particle size. J Mater Sci 45, 3882–3894 (2010). https://doi.org/10.1007/s10853-010-4447-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4447-y