Abstract

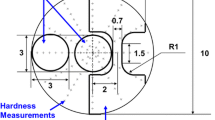

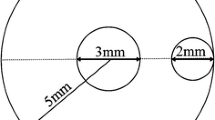

A commercial age-hardenable Al-7136 alloy was successfully processed by high-pressure torsion (HPT) at room temperature through 1/8 to 4 turns. Microhardness measurements showed significant hardening even after 1/8 turn with the average hardness value reaching a maximum after 1 turn and then slowly decreasing. Higher hardness values were attained by processing the alloy through one pass of equal-channel angular pressing in a supersaturated condition at room temperature and then applying HPT for 1 or 2 turns. Microstructural observations revealed the possibility of achieving true nanometer grain sizes of <100 nm after processing at room temperature. There were variations in hardness with imposed strain due to the fragmentation and subsequent growth of precipitates during processing.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881

Zhilyaev AP, Langdon TG (2008) Prog Mater Sci 53:893

Sergueeva AV, Stolyarov VV, Valiev RZ, Mukherjee AK (2001) Scripta Mater 45:747

Valiev RZ, Sergueeva AV, Mukherjee AK (2003) Scripta Mater 49:669

Wei Q, Zhang HT, Schuster BE, Ramesh KT, Valiev RZ, Kecskes LJ, Dowding RJ, Magness L, Cho K (2006) Acta Mater 54:4079

Lugo N, Llorca N, Cabrera JM, Horita Z (2008) Mater Sci Eng A477:366

Murashkin MYu, Kil′mametov AR, Valiev RZ (2008) Phys Met Metal 106:90

Zhilyaev AP, Nurislamova GV, Kim BK, Baró MD, Szpunar JA, Langdon TG (2003) Acta Mater 51:753

Vorhauer A, Pippan R (2004) Scripta Mater 51:921

Zhilyaev AP, Oh-ishi K, Langdon TG, McNelley TR (2005) Mater Sci Eng A410–411:277

Pippan R, Vorhauer A, Wetscher F, Faleschini M, Hafok M, Sabirov I (2006) Mater Sci Forum 503–504:407

Xu C, Horita Z, Langdon TG (2007) Acta Mater 55:203

Zhilyaev AP, McNelley TR, Langdon TG (2007) J Mater Sci 42:1517. doi:10.1007/s10853-006-0628-0

Xu C, Horita Z, Langdon TG (2008) Acta Mater 56:5168

Kawasaki M, Langdon TG (2008) Mater Sci Eng A498:341

Xu C, Horita Z, Langdon TG (2008) J Mater Sci 43:7286. doi:10.1007/s10853-008-2624-z

Xu C, Langdon TG (2009) Mater Sci Eng A503:71

Kawasaki M, Ahn B, Langdon TG (2010) Acta Mater 58:91

Xu C, Horita Z, Langdon TG (2010) Mater Trans 51:2

Pippan R, Wetscher F, Hafok M, Vorhauer A, Sabirov S (2006) Adv Eng Mater 8:1046

Estrin Y, Molotnikov A, Davies CHJ, Lapovok R (2008) J Mech Phys Solids 56:1186

Molotnikov A (2008) Mater Sci Forum 584–586:1051

Sha G, Wang YB, Liao XZ, Duan ZC, Ringer SP, Langdon TG (2009) Acta Mater 57:3123

Sha G, Ringer SP, Duan ZC, Langdon TG (2009) Intl J Mater Res 100:1674

Figueiredo RB, Duan Z, Kawasaki M, Langdon TG (2010) Mater Sci Forum 633–634:341

Duan ZC, Chinh NQ, Xu C, Langdon TG (2010) Metall Mater Trans A 41A:802

Chinh NQ, Gubicza J, Czeppe T, Lendvai J, Xu C, Valiev RZ, Langdon TG (2009) Mater Sci Eng A516:248

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Scripta Mater 35:143

Xu C, Langdon TG (2007) J Mater Sci 42:1542. doi:10.1007/s10853-006-0899-5

Xu C, Furukawa M, Horita Z, Langdon TG (2003) Acta Mater 51:6139

Kawasaki M, Horita Z, Langdon TG (2009) Mater Sci Eng A524:143

Edalati K, Fujioka T, Horita Z (2008) Mater Sci Eng A497:169

Ito Y, Horita Z (2009) Mater Sci Eng A503:32

Edalati K, Fujioka T, Horita Z (2009) Mater Trans 50:44

Harai Y, Ito Y, Horita Z (2008) Scripta Mater 58:469

Edalati K, Horita Z (2009) Mater Trans 50:92

Zhilyaev AP, Kim BK, Szpunar JA, Baró MD, Langdon TG (2005) Mater Sci Eng A391:377

Zhilyaev AP, Gimazov AA, Raab GI, Langdon TG (2008) Mater Sci Eng A486:123

Zhilyaev AP, Gimazov AA, Soshnikova EP, Révész Á, Langdon TG (2008) Mater Sci Eng A489:207

Hohenwarter A, Bachmaier A, Gludovatz B, Scheriau S, Pippan R (2009) Int J Mater Res 100:1653

Ungár T, Schafler E, Hanák P, Bernstorff S, Zehetbauer M (2005) Z Metallkd 96:578

Zehetbauer M, Schafler E, Ungár T (2005) Z Metallkd 96:1044

Sauvage X, Wetscher F, Pareige P (2005) Acta Mater 53:2127

Acknowledgement

This study was supported by the National Science Foundation of the United States under Grant No. DMR-0855009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, Z.C., Liao, X.Z., Kawasaki, M. et al. Influence of high-pressure torsion on microstructural evolution in an Al–Zn–Mg–Cu alloy. J Mater Sci 45, 4621–4630 (2010). https://doi.org/10.1007/s10853-010-4400-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4400-0