Abstract

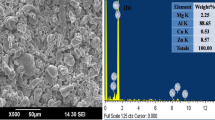

The reliability and integrity of diamond cutting tools depend on the properties of diamond–metal joints as created by a brazing process. Block-shaped monocrystalline diamonds were brazed onto a steel substrate (X2CrNiMo 18-14-3), using silver–copper based Cusil-ABA™ (Ag–35wt%Cu–1.75wt%Ti) filler alloy. The experimental procedure includes a thorough microstructural investigation of the filler alloy, the determination of the induced residual stresses by Raman spectroscopy as well as the joint’s shear strength utilizing a special shear device. The brazing processes were carried out at 850, 880 and 910 °C for dwell durations of 10 and 30 min, respectively. At the steel interface two interlayers develop. The layers grow with extended dwell duration and higher brazing temperature. The residual stresses only slightly depend on the brazing parameters and exhibit a maximum value of −400 MPa. Unlike the residual stresses, the shear strength strongly depends on the brazing parameters and thus on the microstructure. Three failure modes could be identified; a ductile fracture in the filler alloy, a brittle fracture in the interlayers and a partly shattering of the diamond.

Similar content being viewed by others

References

Burkhard G, Rehsteiner F (2002) CIRP Ann Manuf Technol 51:271

Fu YC, Xiao B, Xu JH, Xu HJ (2004) Key Eng Mater 259-2:73

Sung CM (1999) Diamond Relat Mater 8:1540

Sung JC, Sung M (2009) Int J Refract Met Hard Mater 27:382

Klotz UE, Liu CL, Khalid FA, Elsener HR (2008) Mater Sci Eng A 495:265

Liu CL (2007) Characterisation and modelling of interface reactions between diamond and active brazing alloys. Diss. ETH No. 17469, ETH Zurich, Switzerland

Paiva OC, Barbosa MA (2008) Mater Sci Eng A 480:306

De Wolf I (2003) Spectrosc Eur 15:6

Knight DS, White WB (1989) J Mater Res 4:385

Olson JM, Dawes MJ (1996) J Mater Res 11:1765

Aleksandrov IV, Goncharov AF, Stishov SM (1986) JETP Lett 44:611

Aleksandrov IV, Goncharov AP, Makarenko IN, Zisman AN, Jakovenko EV, Stishov SM (1989) High Press Res 1:333

Boppart H, Van Straaten J, Silvera IF (1985) Phys Rev B 32:1423

Grimsditch MH, Anastassakis E, Cardona M (1978) Phys Rev B 18:901

Hanfland M, Syassen K, Fahy S, Louie SG, Cohen ML (1985) Phys Rev B 31:6896

Mitra SS, Brafman O, Daniels WB, Crawford RK (1969) Phys Rev 186:942

Tardieu A, Cansell F, Petitet JP (1990) J Appl Phys 68:3243

Whalley E, Lavergne A, Wong PTT (1976) Rev Sci Instrum 47:845

Occelli F, Loubeyre P, Letoullec R (2003) Nat Mater 2:151

Kunc K, Loa I, Syassen K (2003) Phys Rev B 68:094107

Nielsen OH (1986) Physica B 139 & 140:202

Nielsen OH (1986) Phys Rev B 34:5808

Klocke F, Merbecks T (2001) Characterization of vitrified cBN grinding wheels. 4th int mach grind conf, Society of Manufacturing Engineers, Michigan

Dos Santos SI, Balzaretti NM, Da Jornada JAH (2006) Diamond Relat Mater 15:1457

Siegmann S, Dvorak M, Gruetzner H, Nassenstein K, Walter A (2005) Proc Int Therm Spray Conf 2005:823

Mizuhara H, Huebel E, Oyama T (1989) Am Ceram Soc Bull 68:1591

ElementSix-website (2009) Isle of Man, United Kingdom. http://www.e6.com. Accessed 9 Oct 2009

Wegst C, Wegst M (2007) Nachschlagewerk Stahlschüssel. Verlag Stahlschüssel Wegst GmbH, Marbach

Field JE (1979) The properties of diamond. Academic Press, London

Ikawa N, Shimada S, Ono T (1976) Technol Rep Osaka Univ 26:245

Ganesan S, Maradudin AA, Oitmaa J (1970) Ann Phys 56:556

Anastassakis E, Pinczuk A, Burstein E, Pollak FH, Cardona M (1970) Solid State Commun 8:133

Englert T, Abstreiter G, Pontcharra J (1980) Solid-State Electron 23:31

Klocek P (1991) Handbook of infrared optical materials. Marcel Dekker, Inc., New York

Cousins CSG (2003) Phys Rev B 67:024107-1-13

Chen KH, Lai YL, Lin JC, Song KJ, Chen LC, Huang CY (1995) Diamond Relat Mater 4:460

Loechelt GH, Cave NG, Menendez J (1999) J Appl Phys 86:6164

Feng JC, Li YL, He P, Liu HJ, Yan JC (2005) Mater Sci Technol 21:255

Kar A, Ghosh M, Ray AK, Ray AK (2008) Mater Sci Eng A 498:283

Duhaj P, Sebo P, Svec P, Janickovic D (1999) Mater Sci Eng A 271:181

Groegler T, Zeiler E, Hoerner A, Rosiwal SM, Singer RF (1998) Surf Coat Technol 98:1079

Scardi P, Leoni M, Cappuccio G, Sessa V, Terranova ML (1997) Diamond Relat Mater 6:807

Fu YQ, Du HJ, Sun CQ (2003) Thin Solid Films 424:107

Fan QH, Gracio J, Pereira E, Teixeira V, Tavares CJ (2001) Thin Solid Films 398:265

Ralchenko VG, Obraztsova ED, Korotushenko KG, Smolin AA, Pimenov SM, Pereverzev VG (1995) Mechanical behaviour of diamond and other forms of carbon, Mater Res Soc Symp Proc, Materials Research Society, Pittsburgh, PA ,vol 383, pp 153–158

Kohzaki M, Higuchi K, Noda S, Uchida K (1993) Diamond Relat Mater 2:612

Qin YQ, Feng JC (2007) Mater Sci Eng A 454:322

Sun FL, Feng JC, Li D (2001) J Mater Process Technol 115:333

Acknowledgements

The authors would like to thank the Swiss National Science Foundation for the financial support under the number 200021-117847. S.B. is grateful to Dr. H.-R. Elsener (Laboratory for Joining and Interface Technology, Empa, Duebendorf) for his support in brazing and Dr. T. Wermelinger (Laboratory for Nanometallurgy, ETH, Zurich) for fruitful discussions about Raman spectroscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buhl, S., Leinenbach, C., Spolenak, R. et al. Influence of the brazing parameters on microstructure, residual stresses and shear strength of diamond–metal joints. J Mater Sci 45, 4358–4368 (2010). https://doi.org/10.1007/s10853-010-4260-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4260-7