Abstract

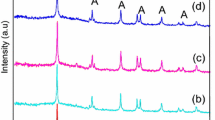

The lanthanum-doped TiO2 (La3+-TiO2) photocatalysts were prepared by coprecipitation and sol–gel methods. Rhodamine B was used as a model chemical in this work to evaluate the photocatalytic activity of the catalyst samples. The optimum catalyst samples were characterized by XRD, N2 adsorption–desorption measurement, SEM and electron probe microanalyses to find their differences in physical and chemical properties. The experimental results showed that the La3+-TiO2 catalysts prepared by coprecipitation exhibited obviously higher photocatalytic activities as compared with that prepared by the conventional sol–gel process. The optimum photocatalysts prepared by the coprecipitation and sol–gel process have similar adsorption equilibrium constants in Rhodamine B solution and particle size distribution in water medium although there are larger differences in their surface area, morphology and pore size distribution. The pores in the sol-gel prepared catalysts are in the range of mesopores (2–50 nm), whereas the pores in the coprecipitation prepared catalysts consist of bigger mesopores and macropores (>50 nm). The morphology of the primary particles and agglomerates of the La3+-TiO2 catalyst powders was affected by doping processes. The inhibition effect of lanthanum doping on the phase transformation is greater in the coprecipitation process than in the sol–gel process, which could be related with the different amount of Ti–O–La bonds in the precursors. This finding could be used for preparing the anatase La3+-TiO2 catalysts with more regular crystal structure through a higher heat treatment temperature. The optimum amount of lanthanum doping is ca. 1.0 wt.% and the surface atomic ratio of [O]/[Ti] is ca. 2.49 for 1.0 wt.% La3+-TiO2 catalysts prepared by the two processes. The obviously higher photocatalytic activity of the La3+-TiO2 samples prepared by the coprecipitation could be mainly attributed to their more regular anatase structure and more proper surface chemical state of Ti3+ species. The optimum preparation conditions are 1.0 wt.% doping amount of lanthanum ions, calcination temperature 800 °C and calcination time 2 h using the coprecipitation process. As compared with the sol-gel process, the coprecipitation process used relatively cheap inorganic raw materials and a simple process without organic solvents. Therefore, the coprecipitation method provides a potential alternative in realizing large scale production.

Similar content being viewed by others

References

Noorjahan M, Durga KV, Subrahmanyam M, Boule P (2004) Appl Catal B: Environ 3:209

Lee JH, Kang M, Choung SJ (2004) Water Res 3:713

Ohno S, Sato D, Kon M (2003) Thin Solid Films 2:207

Kawahara T, Ozawa T, Iwasaki M, Tada H (2003) J Colloid Interface Sci 2:377

Kwon CH, Kim JH, Jung IS, Shin H (2003) Ceramics Int 8:851

Kominami H, Kumamoto H, Kera Y (2003) J Photochem Photobiol A: Chem 1/2:99

Nakashima T, Ohko Y, Kubota Y, Fujishima A (2003) J Photochem Photobiol A: Chem 1/2:115

Villacres R, Ikeda S, Torimoto T, Ohtani B (2003) J Photochem Photobiol A: Chem 1/2:121

Ohno T, Tokieda K, Higashida S, Matsumura M (2003) Appl Catal A: Gen. 2:383

Watson S, Beydoun D, Amal R (2002) J Photochem Photobiol A: Chem 1–3:303

Yin S, Li RX, He QL, Sato T (2002) Mater Chem Phys 1–3:76

Jung KY, Park SB, Ihm SK (2002) Appl Catal A: Gen 1/2:229

Jin S, Shiraishi F (2004) Chem Eng J 2/3:203

Di P, Agatino GL, Elisa MG (2004) Appl Catal B: Environ 3:223

Yamashita H, Harada M, Misaka J (2003) Catal Today 3/4:191

Sugiyama K, Ogawa T, Saito N (2003) Surf Coat Technol 174–175:882

Takeuchi M, Onozaki Y, Matsumura Y (2003) Nucl Instrum Methods Phys Res Section B. 206:259

Rampaul A, Parkin IP, O’Neill SA, Souza JD, Mills A (2003) Polyhedron 1:35

Yan PF, Zhou DR, Wang JQ (2002) Chem J Chinese U 12:2317 (in Chinese)

Liu HY, Gao L (2004) J Am Ceramic Soc 8:1582

Wu SX, Ma Z, Qin YN (2004) Acta Phys Chim Sin 2:138

Ihara T, Miyoshi M, Iriyama Y, Matsumoto O, Sugihara S (2003) Appl Catal B: Environ 4:403

Dana D, Vlasta B, Milan M, Malati MA (2002) Appl Catal B: Environ 2:91

Di PA, Garcıa LE, Ikeda S (2002) Catal Today 1–4:87

Hu C, Tang YC, Tang HX (2004) Catal Today 3/4:325

Ranjit KT, Willner I, Bossmann SH, Braun AM (2001) Environ Sci Technol 7:1544

Ranjit KT, Cohen H, Willner I, Bossmann S, Braun AM (1999) J Mater Sci 34:5273

Ranjit KT, Willner I, Bossmann SH, Braun AM (2001) J Catal 204:305

Xu AW, Gao Y, Liu HQ (2002) J Catal 2:151

Matsuo S, Sakaguchi N, Yamada K, Matsuo T, Wakita H (2004) Appl Surf Sci 1–4:233

Li FB, Li XZ, Hou MF (2004) Appl Catal B: Environ 48:185

Xie YB, Yuan CW, Li XZ (2005) Mater Sci Eng B3:325

Kimura T, Yoshikawa N, Matsumura N, Kawase Y (2004) J Environ Sci Health Part A 11–12:2867

Qian SW, Wang ZY, Wang MQ (2003) J Mater Sci Eng 1:48 (in Chinese)

Overstone J, Yanagisawa K (1999) Chem Mater 11:2770

Yu JG, Yu JC, Leung MKP, Ho WK, Cheng B, Zhao XJ, Zhao JC (2003) J Catal 217:69

Huang W, Tang X, Wang Y, Koltypin Y, Gendanken A (2000) Chem Commun 1415

Yu JG, Zhou MH, Cheng B, Yu HG, Zhao XJ (2005) J Mol Catal A: Chem 227:75

Mills A, Morris S (1993) J Photochem Photobiol A: Chem 71:75

Acknowledgements

This research is supported by the fundamental research projects of Chongqing Institute of Technology and Chongqing Science and Technology Commission.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quan, X., Tan, H., Zhao, Q. et al. Preparation of lanthanum-doped TiO2 photocatalysts by coprecipitation. J Mater Sci 42, 6287–6296 (2007). https://doi.org/10.1007/s10853-006-1022-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1022-7