Abstract

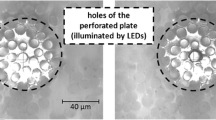

Two novel phenolic type thermosetting resin systems are investigated regarding the effectiveness of different toughness modifiers. These modifiers derive from different groups such as elastomers, thermoplastics, and core–shell polymers. Measurements are accomplished by mechanical, thermal, and microscopical studies. Toughness improvement is determined by increasing K Ic and G Ic values while glass transition temperature, flexural strength, and modulus must not suffer greatly. Suggestions on the mechanisms of toughness modification in the novel resins are made based on images from scanning electron microscopy.

Similar content being viewed by others

References

Agag T, Takeichi T (2002) High Perform Polym 14(2):115

Renner M, Altstädt V, Döring M, Merz T, Räckers B (2000) 32nd International SAMPE Technical Conference, vol 32, pp 619–632

Bucknall CB, Yoshii T (1978) Br Polym J 10(1):53

Yee AF, Pearson RA (1986) J Mater Sci 21:2462

Pearson RA, Yee AF (1986) J Mater Sci 21:2475

Pearson RA, Yee AF (1989) J Mater Sci 24:2571

Pearson RA, Yee AF (1991) J Mater Sci 26:3828

Sue HJ, Garcia-Meitin EI, Pickelmann DM, Yang PC (1993) In: Riew CK, Kinloch AJ (eds) Toughened plastics I. Science and engineering. Advances in Chemistry Series 233. ACS, Washington, DC, pp 259–291

New type of thermosetting resin: Benzoxazine, presentation of Shikoku Corporation, confidential

Noveon™ (B.F. Goodrich Company) (1998) Hycar® reactive liquid polymers: ATBN 1300x16, and CTBN 1300x13, Product data sheets

Kunz SC, Sayre JA, Assink RA (1982) Polymer 23:1897

Ishida H, Allen DJ (1996) J Polym Sci: Part B: Polym Phys 34:1019

Standard test method for flexural properties of unreinforced and reinforced plastics and electrical insulating materials, ASTM D 790-97

Standard test method for plane-strain fracture toughness and strain energy release rate of plastic materials, ASTM D 5045-96

Bucknall CB (1977) Toughened plastics. Applied Science Publishers Ltd

Hodgkin JH, Simon GP, Varley RJ, (1998) Polym Adv Technol 9(1):3

Shaw SJ (1994) In: Collyer AA (ed) Rubber toughened engineering plastics. Chapman & Hall, pp 165–209

Srawley JE (1976) Int J Fract Mech 12:475

Wu SJ, Tung NP, Lin TK, Shyu SS (2000) Polym Int 49(11):1452

Lange FF (1970) Philos Mag 22:983

Altstädt V (1991) Makromol Chem Macromol Symp 50:137

Ishida H, Lee Y-H (2001) Polymer 42:6971

Acknowledgements

The authors would like to thank Mr. Raymond S. Wong of Henkel Loctite Aerospace for providing laboratories in the R&D facilities as well as equipment and materials free of charge. Special thanks belong to Mr. Stanley L. Lehmann for sharing his invaluable experience and advice. The authors would like to thank numerous scientists at the Henkel Loctite Aerospace R&D center for technical assistance and illuminating discussions. The authors wish to thank Dipl.-Ing. (FH) Dietrich Sülthaus from the department of Polymer Engineering at Bayreuth University for his encouragement. Finally the authors wish to thank Miss Martha L. Gurtz for her assistance in reviewing the manuscript. This work was partially funded by the department of Polymer Engineering at Bayreuth University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dipl.-Ing. Gietl, T., Dr.-Ing. Lengsfeld, H. & Dr.-Ing. Altstädt, V. The efficiency of various toughening agents in novel phenolic type thermoset resin systems. J Mater Sci 41, 8226–8243 (2006). https://doi.org/10.1007/s10853-006-0879-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0879-9