Abstract

Quality in a manufacturing process implies that the performance characteristics of the product and the process itself are designed to meet specific objectives. Thus, accurate quality prediction plays a principal role in delivering high-quality products to further enhance competitiveness. In tubing extrusion, measuring of the inner and outer diameters is typically performed either manually or with ultrasonic or laser scanners. This paper shows how regression models can result useful to estimate both those physical quality indices in a tube extrusion process. A real-life data set obtained from a Mexican extrusion manufacturing company is used for the empirical analysis. Experimental results demonstrate that k nearest-neighbor and support vector regression methods (with a linear kernel and with a radial basis function) are especially suitable for predicting the inner and outer diameters of an extruded tube based on the evaluation of 15 extrusion and pulling process parameters.

Similar content being viewed by others

References

Adly, F., Alhussein, O., Yoo, P. D., Al-Hammadi, Y., Taha, K., Muhaidat, S., et al. (2015). Simplified subspaced regression network for identification of defect patterns in semiconductor wafer maps. IEEE Transactions on Industrial Informatics, 11(6), 1267–1276.

Batista, G. E. A. P. A., & Silva, D. F. (2009). How k-nearest neighbor parameters affect its performance. In Argentine symposium on artificial intelligence, Mar de Plata, Argentina (pp. 1–12).

Biau, G., Devroye, L., Dujmović, V., & Krzyzak, A. (2012). An affine invariant k-nearest neighbor regression estimate. Journal of Multivariate Analysis, 112, 24–34.

Buza, K., Nanopoulos, A., & Nagy, G. (2015). Nearest neighbor regression in the presence of bad hubs. Knowledge-Based Systems, 86, 250–260.

Carrano, E. G., Coelho, D. G., Gaspar-Cunha, A., Wanner, E. F., & Takahashi, R. H. (2015). Feedback-control operators for improved Pareto-set description: Application to a polymer extrusion process. Engineering Applications of Artificial Intelligence, 38, 147–167.

Caruana, R., & Niculescu-Mizil, A. (2004). Data mining in metric space: An empirical analysis of supervised learning performance criteria. In Proceedings of the 10th ACM SIGKDD international conference on knowledge discovery and data mining, New York, NY (pp. 69–78).

Charaniya, S., Le, H., Rangwala, H., Mills, K., Johnson, K., Karypis, G., et al. (2010). Mining manufacturing data for discovery of high productivity process characteristics. Journal of Biotechnology, 147(3–4), 186–197.

Chevanan, N., Muthukumarappan, K., & Rosentrater, K. A. (2007). Neural network and regression modeling of extrusion processing parameters and properties of extrudates containing DDGS. Transactions of the American Society of Agricultural and Biological Engineers, 50(5), 1765–1778.

Chien, C. F., Wang, W. C., & Cheng, J. C. (2007). Data mining for yield enhancement in semiconductor manufacturing and an empirical study. Expert Systems with Applications, 33(1), 192–198.

Chondronasios, A., Popov, I., & Jordanov, I. (2016). Feature selection for surface defect classification of extruded aluminum profiles. The International Journal of Advanced Manufacturing Technology, 83(1), 33–41.

Chou, J. S., Ngo, N. T., & Chong, W. K. (2017). The use of artificial intelligence combiners for modeling steel pitting risk and corrosion rate. Engineering Applications of Artificial Intelligence, 65, 471–483.

Choudhary, A. K., Harding, J. A., & Tiwari, M. K. (2008). Data mining in manufacturing: A review based on the kind of knowledge. Journal of Intelligent Manufacturing, 20(5), 501–521.

Dhafr, N., Ahmad, M., Burgess, B., & Canagassababady, S. (2006). Improvement of quality performance in manufacturing organizations by minimization of production defects. Robotics and Computer-Integrated Manufacturing, 22(5–6), 536–542.

Draper, N. R., & Smith, H. (1998). Applied regression analysis. Hoboken, NJ: Wiley.

Dudani, S. A. (1976). The distance-weighted k-nearest-neighbor rule. IEEE Transactions on Systems, Man, and Cybernetics, 6(4), 325–327.

Erzurumlu, T., & Oktem, H. (2007). Comparison of response surface model with neural network in determining the surface quality of moulded parts. Materials & Design, 28(2), 459–465.

Ghorai, S., Mukherjee, A., Gangadaran, M., & Dutta, P. K. (2013). Automatic defect detection on hot-rolled flat steel products. IEEE Transactions on Instrumentation and Measurement, 62(3), 612–621.

González Marcos, A., Pernía Espinoza, A. V., Alba Elías, F., & García Forcada, A. (2007). A neural network-based approach for optimising rubber extrusion lines. International Journal of Computer Integrated Manufacturing, 20(8), 828–837.

Guyader, A., & Hengartner, N. (2013). On the mutual nearest neighbors estimate in regression. The Journal of Machine Learning Research, 14, 2361–2376.

Hall, M., Frank, E., & Holmes, G. (2009). The WEKA data mining software: An update. SIGKDD Explorations, 11(1), 10–18.

Harding, J. A., Shahbaz, M., Srinivas, S., & Kusiak, A. (2006). Data mining in manufacturing: A review. Journal of Manufacturing Science and Engineering, 128(4), 969–976.

Hsiang, S. H., Lin, Y. W., & Lai, J. W. (2012). Application of fuzzy-based Taguchi method to the optimization of extrusion of magnesium alloy bicycle carriers. Journal of Intelligent Manufacturing, 23(3), 629–638.

Hu, C., Jain, G., Zhang, P., Schmidt, C., Gomadam, P., & Gorka, T. (2014). Data-driven method based on particle swarm optimization and k-nearest neighbor regression for estimating capacity of lithium-ion battery. Applied Energy, 129, 49–55.

Jiang, H., Yan, Z., & Liu, X. (2013). Melt index prediction using optimized least squares support vector machines based on hybrid particle swarm optimization algorithm. Neurocomputing, 119, 469–477.

Khan, J. G., Dalu, R. S., & Gadekar, S. S. (2014). Defects in extrusion process and their impact on product quality. International Journal of Mechanical Engineering and Robotics Research, 3(3), 10–18.

Kohlert, M., & König, A. (2015). Large, high-dimensional, heterogeneous multi-sensor data analysis approach for process yield optimization in polymer film industry. Neural Computing and Applications, 26(3), 581–588.

Köksal, G., Batmaz, I., & Testik, M. C. (2011). A review of data mining applications for quality improvement in manufacturing industry. Expert Systems with Applications, 38(10), 13,448–13,467.

Kramer, O. (2011). Unsupervised K-nearest neighbor regression. ArXiv e-prints arXiv:1107.3600.

Krömer, P., Snášel, V., Platoš, J., & Abraham, A. (2010). Evolving fuzzy classifier for data mining—An information retrieval approach. In Proceedings of the 3rd international conference on computational intelligence in security for information systems, León, Spain (pp. 25–32).

Kusiak, A. (2006). Data mining: Manufacturing and service applications. International Journal of Production Research, 44(18–19), 4175–4191.

Kusiak, A., & Kurasek, C. (2001). Data mining of printed-circuit board defects. IEEE Transactions on Robotics and Automation, 17(2), 191–196.

Lee, S. K., Kang, P., & Cho, S. (2014). Probabilistic local reconstruction for k-nn regression and its application to virtual metrology in semiconductor manufacturing. Neurocomputing, 131, 427–439.

Li, H. J., Qi, L. H., Han, H. M., & Guo, L. J. (2004). Neural network modeling and optimization of semi-solid extrusion for aluminum matrix composites. Journal of Materials Processing Technology, 151(1–3), 126–132.

Liukkonen, M., Hiltunen, T., Havia, E., Leinonen, H., & Hiltunen, Y. (2009). Modeling of soldering quality by using artificial neural networks. IEEE Transactions on Electronics Packaging Manufacturing, 32(2), 89–96.

Ma, J., Theiler, J., & Perkins, S. (2003). Accurate on-line support vector regression. Neural Computation, 15(11), 2683–2703.

Meiabadi, M. S., Vafaeesefat, A., & Sharifi, F. (2013). Optimization of plastic injection molding process by combination of artificial neural network and genetic algorithm. Journal of Optimization in Industrial Engineering, 6(13), 49–54.

Oberg, E., Jones, F., Horton, H., Ryffel, H., & McCauley, C. (2012). Machinery’s handbook. New York, NY: Industrial Press.

Oke, S. A., Johnson, A. O., Charles-Owaba, O. E., Oyawale, F. A., & Popoola, I. O. (2006). A neuro-fuzzy linguistic approach in optimizing the flow rate of a plastic extruder process. International Journal of Science & Technology, 1(2), 115–123.

Pratihar, D. K. (2015). Expert systems in manufacturing processes using soft computing. The International Journal of Advanced Manufacturing Technology, 81(5), 887–896.

Ramana, E. V., & Reddy, P. R. (2013). Data mining based knowledge discovery for quality prediction and control of extrusion blow molding process. The International Journal of Advanced Manufacturing Technology, 6(2), 703–713.

Ribeiro, B. (2005). Support vector machines for quality monitoring in a plastic injection molding process. IEEE Transactions on Systems, Man, and Cybernetics, Part C, 35(3), 401–410.

Sadeghi, B. H. M. (2000). A BP-neural network predictor model for plastic injection molding process. Journal of Materials Processing Technology, 103(3), 411–416.

Sharma, R. S., Upadhyay, V., & Raj, K. H. (2009). Neuro-fuzzy modeling of hot extrusion process. Indian Journal of Engineering and Materials Sciences, 16, 86–92.

Smola, A., & Schlkopf, B. (2004). A tutorial on support vector regression. Statistics and Computing, 14(3), 199–222.

Tan, S. C., Watada, J., Ibrahim, Z., & Khalid, M. (2015). Evolutionary fuzzy ARTMAP neural networks for classification of semiconductor defects. IEEE Transactions on Neural Networks and Learning Systems, 26(5), 933–950.

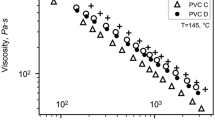

Urraca Valle, R., Sodupe Ortega, E., Antoñanzas Torres, J., Alonso García, E., Sanz García, A., & Martínez de Pisón Ascacíbar, F. J. (2013). Comparative methodology of non-linear models for predicting rheological properties of rubber mixtures in industrial lines. In Proceedings of the 17th international congress on project management and engineering, Logroño, Spain (pp. 1346–1357)

Wang, J., Ma, Y., Zhang, L., Gao, R. X., & Wu, D. (2018). Deep learning for smart manufacturing: Methods and applications. Journal of Manufacturing Systems,. https://doi.org/10.1016/j.jmsy.2018.01.003.

Witten, I. H., Frank, E., & Hall, M. A. (2011). Data mining: Practical machine learning tools and techniques. Burlington, MA: Morgan Kaufmann Publishers.

Wu, C. Y., & Hsu, Y. C. (2002). Optimal shape design of an extrusion die using polynomial networks and genetic algorithms. The International Journal of Advanced Manufacturing Technology, 19(2), 79–87.

Wu, D., Jennings, C., Terpenny, J., Gao, R. X., & Kumara, S. (2017). A comparative study on machine learning algorithms for smart manufacturing: Tool wear prediction using random forests. Journal of Manufacturing Science and Engineering, 139(7), 071,018–071,026.

Xu, Y., Zhang, Q., Zhang, W., & Zhang, P. (2015). Optimization of injection molding process parameters to improve the mechanical performance of polymer product against impact. The International Journal of Advanced Manufacturing Technology, 76(9), 2199–2208.

Yang, C. C., & Shieh, M. D. (2010). A support vector regression based prediction model of affective responses for product form design. Computers & Industrial Engineering, 59(4), 682–689.

Yin, S., Li, X., Gao, H., & Kaynak, O. (2015). Data-based techniques focused on modern industry: An overview. IEEE Transactions on Industrial Electronics, 62(1), 657–667.

Yu, J. C., Chen, X. X., Hung, T. R., & Thibault, F. (2004). Optimization of extrusion blow molding processes using soft computing and Taguchi’s method. Journal of Intelligent Manufacturing, 15(5), 625–634.

Zhang, Z., Wang, T., & Liu, X. (2014). Melt index prediction by aggregated RBF neural networks trained with chaotic theory. Neurocomputing, 131, 368–376.

Zhao, G., Chen, H., Zhang, C., & Guan, Y. (2013). Multiobjective optimization design of porthole extrusion die using pareto-based genetic algorithm. The International Journal of Advanced Manufacturing Technology, 69(5), 1547–1556.

Acknowledgements

The authors would like to acknowledge the financial support from the Spanish Ministry of Economy, Industry and Competitiveness [TIN2013-46522-P], and the Generalitat Valenciana [PROMETEOII/2014/062].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

García, V., Sánchez, J.S., Rodríguez-Picón, L.A. et al. Using regression models for predicting the product quality in a tubing extrusion process. J Intell Manuf 30, 2535–2544 (2019). https://doi.org/10.1007/s10845-018-1418-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-018-1418-7