Abstract

Microalgae are potential plant biostimulants and biocontrol agents. A major hurdle towards their commercialization is the production of large volumes of biomass at the correct time of year. Secondary metabolites are unstable and the “shelf-life” of bioactive microalgal biomass needs to be investigated. The aim of the study was to investigate the effects of storage conditions on freeze-dried microalgae to determine how long the biomass retained its growth promoting and bioactive properties under various temperature and light conditions. Chlorella vulgaris biomass was stored in the dark at − 70 °C, 10 °C, and 25 °C and in the light at 25 °C. Samples were tested every 3–4 months for 15 months. Storage time significantly influenced the rate of change in the bioactivity in the C. vulgaris biomass with storage temperature also having some effect. Rooting activity decreased in the mungbean rooting assay over time up to 12 months and then increased slightly. Antimicrobial activity increased against Staphylococcus aureus and Escherichia coli for up to 12 months and then declined. Antioxidant activity measured in the DPPH assay remained relatively stable for up to 12 months and then significantly decreased with longer storage. The change in bioactivity over time was attributed to the gradual breakdown of the rigid cell wall of C. vulgaris, thereby improving extraction efficiency but exposing the secondary metabolites to oxygen, thus quickening their degradation. Biomass produced for commercial purposes requires preliminary validation as the results of the present study showed that bioactive compounds are susceptible to degradation over time.

Similar content being viewed by others

Introduction

Current agricultural research is focused on ways to achieve sustainable food security amidst an ever-increasing global population and negative impacts of climate change, pollution, and deteriorating soil due to overuse of agrochemicals. New agricultural technologies need to combine ways of increasing agricultural productivity with reduced environmental impacts and promoting environmental regeneration (Garcia-Gonzalez and Sommerfeld 2016; Alvarez et al. 2021). Natural, renewable plant biostimulants such as microalgae meet these criteria and are a promising avenue of research. Microalgal biomass has useful agricultural properties such as improving soil fertility, promoting plant growth, and providing protection against pests and pathogens. This is due to traits such as microalgae containing plant-growth-promoting compounds (e.g., phytohormones, polysaccharides, amino acids, polyamines, and fatty acids), synthesizing secondary metabolites with bioactive properties (e.g., antimicrobial, antiviral, and antioxidant compounds), producing stress tolerance metabolites, and the production of exopolysaccharides which improve soil aggregation and stability (reviewed in Renuka et al. 2018 and in Alvarez et al. 2021).

Microalgal-derived biostimulants elicit many beneficial effects on growth, metabolite content, and yield in a diverse range of cereal and vegetable crops (Renuka et al. 2018; Alvarez et al. 2021). Modes of application include cell suspension or extracts (lysates) of dried microalgal biomass or living cultures applied as soil inoculum or in hydroponic systems. Growth experiments have mainly been conducted in pot trials in greenhouses with fewer field trials. Plants responded to the biostimulants in a dose-dependent manner with optimum dosage rates varying between crops and mode and time of application. For example, in greenhouse trials, freeze-dried Chlorella sorokiniana improved wheat germination and seedling growth when applied at 2 g L−1 DW (Kholssi et al. 2019); hydrolysates made from 100 g L−1 DW Arthrospira platensis and 10 g L−1 DW Scenedesmus almeriensis applied 5 × after transplanting increased plant growth of Petunia x hybrida (Plaza et al. 2018); when hydrolysate of Acutodesmus dimorphus extracted using 150 g L−1 DW was applied as a foliar spray to tomato seedlings, 50% (3.75 g mL−1) or higher concentrations elicited beneficial effects (Garcia-Gonzalez and Sommerfeld 2016). In a field trial, a single foliar application of freeze-dried Nostoc piscinale suspension (1 g L−1 DW) applied at 400 L ha−1 to maize (Zea mays) elicited faster growth and a higher grain yield (Ördög et al. 2021), meaning that 400 g DW microalgal biomass was required per ha. Similarly, an increase in yield parameters of winter wheat was achieved with foliar application of freeze-dried N. piscinale suspension. Two concentrations (0.3 g L−1 DW and 1.0 g L−1 DW) were applied at 400 L ha−1 once (at tillering) or twice (at tillering and ear emergence). The most effective treatment was 0.3 g L−1 suspension applied twice so that 120 g DW ha−1 was required for each application (Takács et al. 2019).

The time of application to the crop is also critical, and application at the wrong phenological phase may reduce the effectiveness of the biostimulants or have negative effects on plant growth. For example, 50 g and 100 g DW of A. dimorphus applied as a biofertilizer to the soil around tomato seedlings were significantly more effective when applied 22 days prior to transplanting compared to being applied at the time of transplanting (Garcia-Gonzalez and Sommerfeld 2016). Thus, there is a specific and limited timeframe within the crop’s life-cycle when the microalgal fertilizer and biostimulant can be effectively applied.

Phytopathogenic bacteria can cause severe economic loses in crop production, reducing yields and quality. With current legislation restricting the use of agrochemicals and antibiotics, good agricultural practices are encouraging the use of alternative, natural ways to manage bacterial diseases (Ambrico et al. 2020). Many microalgae and cyanobacteria synthesize compounds which exhibit antimicrobial activity against Gram-positive and Gram-negative phytopathogenic bacteria, making them potential biocontrol agents for crop protection (Ördög et al. 2004; Costa et al. 2019).

A major hurdle towards the commercialization of microalgal biostimulants is the production of large volumes of suitable microalgal biomass at the correct time of year. Biomass would need to be generated throughout the year and stored until the appropriate season for application to the crop. Secondary metabolites are unstable and their degradation can be triggered by light, high temperature, and the presence of oxygen (Gouveia and Empis 2003). The “shelf-life” of microalgal biomass needs to be investigated as physical conditions during storage and transportation of the biomass may impact on its effectiveness as a plant biostimulant and biocontrol agent (Alvarez et al. 2021). The aim of the present study was to investigate the effects of storage conditions on freeze-dried microalgal biomass to determine how long the biomass retains its growth promoting and bioactive properties (antimicrobial and antioxidant activity) under various temperature and light conditions.

Materials and methods

Biomass generation

An axenic agar culture of Chlorella vulgaris MACC-1 was inoculated into 2 flasks containing 250 mL Zehnder-8 nutrient medium (Staub 1961). These were grown at 25 ± 2 °C in a 12:12 h light:dark photoperiod and illuminated from below with 130 μmol photons m−2 s−1 light intensity. Cultures were aerated with 20 L h−1 sterile air enriched with 1.5% CO2 for 10 h during the light period. After 7 days, these cultures were used as inoculum to generate the biomass under the same growth conditions at the Széchenyi István University, Hungary. The suspension cultures were used to inoculate 48 flasks each containing 250 mL Zehnder-8 medium, giving a total cultivation volume of 12 L. The starting biomass was 10 mg L−1 DW and the cultivation time was 8 days. The culture suspensions of 16 flasks were combined to give 3 samples at harvest. These were centrifuged (2 150 × g for 15 min at room temperature; SIGMS 6K15) and the supernatant free biomass freeze-dried (Christ Gamma 1–20, Germany). The dried biomass was stored at − 70 °C. This process was repeated eight times over 8 weeks (October–November 2019) in order to generate sufficient biomass for the experiment (Online resource 1).

The microalgal biomass was combined to give a total of 151.78 g DW. This was couriered (9 December 2019) in an airtight container to the Research Centre for Plant Growth and Development, South Africa, taking 6 days in transit. On arrival, the biomass was immediately placed at − 70 °C in the dark until the experiment commenced 8 weeks later.

Storage conditions

At the start of the experiment, the biomass was divided into 2 samples and each sample was further divided into 4 portions. These were placed in (i) − 70 °C in the dark; (ii) 10 °C in the dark; (iii) 25 °C in the dark; and (iv) 25 °C in continuous light (130 µmol photons m−2 s−1) provided by fluorescent and incandescent lights. A portion of the biomass was immediately analyzed (time 0; T0), and thereafter biomass from each of the two replicate samples stored in the various conditions was sampled after 4, 6, 9, 12, and 15 months (T4, T6, T9, T12, and T15) for analysis. The T3 sampling was delayed by 1 month due to COVID-19 restrictions.

Mungbean rooting bioassay

The mungbean rooting assay (Crouch and van Staden 1991) was used to measure the plant biostimulating activity of the microalgal biomass. Briefly, mungbeans (Vigna radiata) were germinated in vermiculite at 26 ± 1 °C in 16:8 h light:dark photoperiod and 120 µmol photons m−2 s−1 light intensity. On day 9, 420 mg DW microalgal biomass from each replicate sample was suspended in 42 mL distilled water (10 mg mL−1), shaken at 80 rpm for 3 h at 25 °C, and then left overnight at 25 °C. The following day, the extracts were diluted to 1, 2, 3, and 4 mg mL−1 with distilled water. Uniform 10-day-old mungbean cuttings (12-cm stem length) with two leaves were placed in the prepared microalgal solutions for 6 h, then rinsed and transferred to clean vials containing water. There were five cuttings per vial and two vials per sample solution at each concentration (10 cuttings in total per extract concentration and two replicate samples = 20 cuttings per concentration). Distilled water and indole-3-butyric acid (IBA) at 10−8–10−3 M were included for comparative purposes. The cuttings were placed in the growth conditions described above and the number of roots recorded 10 days after the pulse treatment.

Antimicrobial activity

Microalgae biomass (500 mg DW) in 25 mL methanol (MeOH) was sonicated in an ice-bath for 20 min, shaken at 80 rpm for 2 h, left overnight at 25 °C, and then shaken for a further 30 min. The extracts were double filtered using Whatman No. 1 filter paper and dried in a flow of air. The resulting residue was weighed and resuspended in 50% MeOH at 50 mg mL−1. Antimicrobial activity was evaluated using a Gram-positive (Staphylococcus aureus ATCC 12600) and a Gram-negative (Escherichia coli ATCC 11775) bacteria using a microdilution assay as previously described (Aremu et al. 2010) from which the minimum inhibitory concentration (MIC) was determined. There were 3–6 technical replicates per sample. Neomycin (100 µg mL−1) was included as a positive control.

Antioxidant activity

Dichloromethane extracts were prepared from the biomass (450 mg DW extracted in 25 mL dichloromethane) using the same protocol as for the antimicrobial extracts. The resulting dried residue was weighed to determine the yield (w/w) and then suspended at 10 mg mL−1 MeOH. Antioxidant activity was quantified using the diphenylpicrylhydrazyl (DPPH) free radical scavenging assay as previously described (Moyo et al. 2010). Ascorbic acid (AA) and butylated hydroxytoluene (BHT) were used as positive controls. The extracts were tested in a range of concentrations (final concentration from 0.2 to 0.5 mg mL−1). The % free radical scavenging activity (% RSA) was determined by the decolouration of the DPPH solution over 30 min in the dark and used to calculate the IC50 using linear regression analysis.

Pigment extraction

Two technical replicates (5–8 mg DW) per sample were extracted in acetone using a bead mill and absorbance measured at 470, 645, and 662 nm as previously described (Stirk et al. 2019). Chlorophyll a (chl a), chl b, and total carotenoids were calculated based on equations of Lichtenhaler (1987).

Statistical analysis

Mean and standard error (SE) or range were calculated for each parameter. A general analysis of variance was performed to determine the effects of storage time and conditions (temperature and light) and their interactions on each measured parameter. Results were considered significantly different at p < 0.05. Duncan’s multiple range test was also used to evaluate differences between storage times and storage conditions. Statistical analysis was carried out using GenStat (18th edition).

Results

Mungbean rooting bioassay

There was a dose-dependent rooting response in the mungbean cuttings with increasing concentrations of C. vulgaris suspension used as a pulse treatment increasing the number of roots initiated. The best rooting responses were obtained with 3–4 mg mL−1 DW suspensions (Fig. 1a–d). A dose-dependent response was also elicited with the IBA standard (Fig. 1e).

Root promoting activity measured in the mungbean assay of water suspensions made from C. vulgaris biomass stored for up to 15 months under four temperature and light regimes. Results are shown as mean ± SE where 20 cuttings (10 cuttings per replicate sample, n = 2) were treated at each concentration

Using data from the 4 mg L−1 DW suspension, storage time had a significant effect on the rooting response elicited by the C. vulgaris biomass (Table 1). There was an initial increase in the rooting response obtained with biomass stored in all conditions (from T0 to T4). This was followed by a gradual decrease in the root stimulating ability of the microalgal suspension with the lowest or no rooting activity recorded in the mungbean cuttings treated with T9 biomass from all the storage treatments. Thereafter, there was an increase in the rooting activity of the microalgal suspension (T12–T15; similar to that obtained with 0.5–2 mg L−1 IBA) although this was lower than the T4 rooting activity (similar to 2–20 mg L−1 IBA; Fig. 1). Storage conditions (temperature and light) did not have a significant effect on the rooting activity of the biomass (Table 1) although by T15, biomass stored at 25 °C in continuous light elicited the lowest rooting response (Fig. 1).

Antimicrobial activity

Methanol extracts obtained from C. vulgaris were more active against the Gram-positive S. aureus compared to the Gram-negative E. coli. Antimicrobial activity was moderate against S. aureus with MIC values less than 4.7 mg mL−1 and low against E. coli with MIC values of 12.5 mg mL−1 or higher (Table 2). Storage time had a significant effect on the antimicrobial activity (Table 1). Low antimicrobial activity was measured in the T0 sample against S. aureus. Activity of the microalgal biomass steadily increased with length of storage time with the most significantly active extracts against S. aureus obtained from the T12 samples. Antimicrobial activity significantly decreased with longer storage (T15). Storage temperature also had a significant effect on the antimicrobial activity against S. aureus (Table 1) with the significantly higher activity measured in the biomass stored in the dark at 10 °C and 25 °C at T9 and T12 compared to those stored at − 70 °C and in the light (Table 2). There was no significant change in activity against E. coli apart for the T12 sample stored at 25 °C in the light (Table 2).

Yield of dichloromethane extracts

Compound yield (w/w) from the C. vulgaris biomass extracted with dichloromethane and subjected to 20 min-sonication followed by gentle shaking ranged from 1.1 to 3.3% (Table 3). Yields increased significantly over time (Table 1) with the highest yields generally obtained from T9–T15 samples. Storage conditions had no significant effect on yield (Table 3).

Antioxidant activity

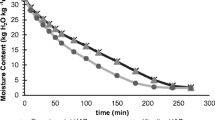

Storage time and storage conditions (temperature and light) had a significant effect on the antioxidant activity measured in the DPPH assay with all interactions being significant (Table 1). Between 90 and 97% antioxidant activity was recorded for the AA and BHT controls tested at 0.2–0.5 mg mL−1. Antioxidant activity in the dichloromethane extracts made from the T0 samples had an IC50 of 0.198 mg mL−1. IC50 values remained relatively constant in the T4 and T6 biomass. There was a gradual decrease in antioxidant activity with longer storage up to T12 (Fig. 2) with a sharp decrease in activity in the T15 extracts. The biomass stored at − 70 °C retained the most antioxidant activity with IC50 values only doubling after 15 months with larger losses in antioxidant activity when the biomass was stored at higher temperatures. The largest loss of antioxidant activity occurred in the biomass stored at 25 °C in the light where IC50 values had quadrupled by T15 (Fig. 2).

Pigment content

Storage time and conditions (temperature and light) had a significant effect on the pigment content (Chl a and carotenoids) in the C. vulgaris biomass (Table 1). Longer storage, higher temperatures, and light caused a significant decrease in the Chl a content with all factors and interactions being significant (Fig. 3a). The Chl b content was only significantly affected by increasing temperature (Fig. 3b). The carotenoid content significantly decreased with storage time and higher temperatures causing significant changes (Fig. 3c).

Discussion

The growth-promoting effects of microalgal biomass are, in part, attributed to secondary metabolites such as plant hormones and polyamines that are synthesized by microalgae (Renuka et al. 2018; Alvarez et al. 2021). The mungbean rooting assay was selected for the present study to monitor the growth-promoting activity of the C. vulgaris suspensions over time. This assay has previously been used to measure the activity of microalgal suspensions, including Chlorella strains (Stirk et al. 2020) as well as activity of other natural plant biostimulants such as seaweed-derived extracts (Stirk and van Staden 1997), eckol (a phlorotannin) in the seaweed Ecklonia maxima (Rengasamy et al. 2015), and karrikinolide — a smoke-derived butenolide (Jain et al. 2008). In the present study, the initial rooting activity (T0 and T4) achieved with the microalgal suspension prepared by gentle shaking can be attributed to the release of low molecular weight and water soluble compounds through the cell membranes that were damaged by freeze-drying. Previous experiments with two Chlorella and a Scenedesmus strain showed that freeze-drying did not disrupt the cell walls but damaged the cell membranes, increasing the membrane permeability compared to living cells (Stirk et al. 2020). Rooting activity of the C. vulgaris biomass significantly declined over time with storage up to T9 (Fig. 1), suggesting degradation of the active metabolites. Highest rooting was previously achieved in the mungbean bioassay using freeze-dried Chlorella biomass compared to sonicated or ball milled biomass which caused more extensive disruption to the cell walls (Stirk et al. 2020). This was attributed to faster oxidation and degradation of the active compounds in the more extensively damaged cells (Stirk et al. 2020).

Biomass stored for longer periods (T12–T15) had increased rooting activity in the mungbean assay although not as high as T0–T4 biomass (Fig. 1). This can be attributed to the slow breakdown of the C. vulgaris cell walls over an extended time, enabling more intracellular-bound compounds to be released into the water suspension. This is corroborated by the significant increase in % yield over time with the highest yields obtained for the dichloromethane extracts following 20-min sonication at T15 (Table 3). One important selection criterion for mass culture is that the microalgae species has a robust cell wall in order to withstand the sheer stresses due to mixing. However, a thick cell wall impedes extraction of intracellular compounds (Kim et al. 2016) and extraction of compounds is improved if cells are disrupted (Lee et al. 2012). Chlorella species have a highly resistant, rigid cell wall composed mainly of cellulose (Alhattab et al. 2019). The long storage time in the present experiment may have caused a slow degradation of the cell wall, so that more active components were released from the T12–T15 samples into the water suspension, leading to higher rooting activity in the mungbean bioassay. Storage conditions (temperature and light) had no effect on the rooting activity of the C. vulgaris biomass (Table 1). Additional experiments are required to assess the effects of storage on biological activity of (partially) intact cells (freeze-dried cells) compared to cells where the cell wall has been more extensively disrupted prior to storage.

Microalgae synthesize many bioactive metabolites with diverse chemical structures. The polarity of the extraction solvent has a large influence on the suite of compounds extracted from the biomass (Goiris et al. 2012; Iglesias et al. 2019). A previous bioactivity study of three Chlorella strains showed that dichloromethane extracts had higher antioxidant activity in both the DPPH and β-carotene-linoleic acid assays compared to methanol extracts while methanol extracts had higher antimicrobial activity against two Gram-positive and three Gram-negative bacterial strains (Aremu et al. 2016). Based on these results, antimicrobial activity was measured in methanol extracts using S. aureus and E. coli and antioxidant activity of dichloromethane extracts of C. vulgaris biomass was monitored using the DPPH assay in the present study.

Apart from being plant biostimulants, microalgae are also potential biocontrol agents able to provide protection to crops (Ördög et al. 2004; Costa et al. 2019). Thus, the effect of storage time and conditions on the antimicrobial activity of the C. vulgaris biomass were monitored in the present study. Gram-positive bacteria are generally more susceptible than Gram-negative bacteria to inhibitory activity of extracts due to the structure of their cell walls as was the case in the present study where C. vulgaris extracts were more effective at inhibiting S. aureus than E. coli (Table 2). Similar moderate-to-low/no antimicrobial activity occurs in other microalgae species (Ambrico et al. 2020). Secondary metabolites synthesized by microalgae with antibacterial activity include lipids, long chain polyunsaturated fatty acids, phenolic compounds, polyphenols, tocopherols, carbohydrates, and peptides (Costa et al. 2019; Iglesias et al. 2019).

Antimicrobial activity of the C. vulgaris biomass significantly increased against S. aureus with storage time up to T12 and decreased thereafter (Table 2). Storage temperature also had a significant effect on the antimicrobial activity against S. aureus (Table 1) with the highest activity in the biomass stored at 10 °C and 25 °C in the dark at T12 (Table 2). The biomass was extracted by 20-min sonication in methanol. Prolonged storage may have contributed to the slow degradation of the cell wall, thus allowing more efficient extraction of the antimicrobial compounds by sonication even after only 6 months storage. These results suggest that any detrimental effects to the active antimicrobial compounds caused by prolonged storage were offset by improved extraction efficiency due to weakened cell walls up to T12. Active antimicrobial compounds were degraded with longer storage times (T15).

Antioxidant activity in microalgae is related to secondary metabolites such as carotenoids (e.g., lutein, β-carotene, zeaxanthin, and astaxanthin), phenolic compounds as well as polyunsaturated fatty acids, polysaccharides, amino acids, and peptides (Goiris et al. 2012; Choochote et al. 2014; Jerez-Martel et al. 2017). In the present study, antioxidant activity measured in the DPPH assay was relatively constant up to T6, decreased slowly with longer storage up till T12, and then decreased more sharply by T15. The antioxidant activity also significantly decreased with higher storage temperatures and light (Fig. 2 and Table 1). This may be related to the pigment content which was similarly affected by temperature (Chl a, Chl b, and carotenoids) and light (Chl a; Table 1 and Fig. 3). Antioxidant compounds act as radical scavengers and prevent lipid oxidation. Natural antioxidant compounds have preservation properties which, when incorporated into food products, can enhance their shelf-life (Goiris et al. 2012; Ortiz et al. 2014). They may have played a similar preservation role in the C. vulgaris biomass in the present study with a link between a sharp decreased antioxidant activity and antimicrobial activity at T15 (Fig. 2 and Table 2). When liquid extracts made from three seaweeds (Durvillaea antarctica, Ulva lactuca, and Pyropia columbina) were used as a preservative, they delayed the deterioration of canned salmon by reducing lipid peroxidation. This was attributed to the antioxidant properties of the seaweed extracts (Ortiz et al. 2014).

While the effects of storage time and conditions have been reported for macromolecules in microalgal biomass, this is the first report on the effects of storage on the stability and bioactivity of secondary metabolites. Storage conditions influenced the rate of change in the bioactivity in the C. vulgaris biomass with time, followed by temperature having the largest effects. The changes (both increases and decreases) in bioactivity over time can be explained by the gradual breakdown of the rigid cell wall of C. vulgaris, thereby improving extraction efficiency but exposing the secondary metabolites to oxygen, thus quickening their degradation. This is a similar trend to that found in other microalgae with regard to the effect of storage on the macromolecule content. For example, when Isochrysis galbana, Nannochloropsis gaditana, and Scenedesmus almeriensis were stored at three temperatures in the dark (− 20 °C; 6 °C; 25 °C) and at 25 °C in the light, there was no change in the lipid and fatty acid content with storage up to 15 months. There was a gradual (but not significant) decrease in protein content over time with a slightly faster decline in protein content at 25 °C dark and light storage conditions. The carotenoid content was stable for 6 months storage and then significantly decreased with longer storage with the largest decrease measured at 25 °C in both dark and light conditions. The stability of the biomass was attributed to the high antioxidant content preventing biomolecule degradation. The faster degradation of protein was due to natural antioxidant compounds being themselves degraded faster at the higher temperature and by light (Camacho-Rodríguez et al. 2018). When I. galbana biomass was freeze-dried or frozen and stored at − 76 °C, protein content was unchanged after 7 days but decreased after 3 months in both the freeze-dried and frozen biomass. There was no loss in the carbohydrate content in the frozen biomass but carbohydrates decreased after 7 days and 3 months in the freeze-dried biomass. The lipid content was unchanged in all the biomass. The different freezing methods cause different amounts of cell damage due to the rate of ice crystal formation inside and around the cells as a function of the rate of cooling. The extent of the damage caused to the cells affected the long-term storage (Babarro et al. 2001). Freeze-dried and frozen (− 20 °C) Acutodesmus obliquus biomass had a higher methane yield compared to cooled (4 °C) biomass due to the damaged caused to the cell walls during freezing. However, longer storage times (4 months) led to a loss in available organic matter, resulting in lower methane levels (Gruber-Brunhumer et al. 2015). Similarly, storage conditions had no effect on the protein, lipid, carbohydrate, and ash content of freeze-dried and frozen Chlorella sp. and Scenedesmus sp. biomass. However, there was a higher hydrolysis constant and methane yield in the freeze-dried and frozen biomass compared to fresh biomass. Methane yield increased after 10 days storage at 4 °C, suggesting damage to the cells increased with storage time at 4 °C, improving the extraction efficiency (Barreiro-Vescovo et al. 2018). The present results suggest that the bioactive secondary metabolites are more susceptible to degradation compared to primary macromolecules but this requires more extensive investigation.

Owing to the costs of producing large volumes of microalgal biomass, multiple uses for the biomass need to be combined to make the process more economically feasible. Algal residue remaining after extraction of primary metabolites (lipids, proteins, and carbohydrates) still contains bioactive compounds, including macro- and micro-elements, so that the microalgal residue would be an inexpensive source of agricultural biofertilizer (Renuka et al. 2018). However, the present study has shown that bioactive compounds are prone to degradation. The rate of degradation would most likely increase if these compounds were exposed to air as would occur in biomass with cell wall disruption required for efficient macromolecule extraction. For example, there was a gradual decrease in the carotenoid content in Chlorella vulgaris and Haematococcus pluvialis dried biomass and acetone extracts when stored for up to 18 months in different temperature and light conditions, under vacuum or in a nitrogen-rich atmosphere. The carotenoid content of the dried biomass only began to decline after 1 month storage and was most affected by light and oxygen with temperature having the least influence. When stored under vacuum in the dark, there was only 6% loss after 18 months storage. The carotenoid content in the stored acetone extracts was much less stable with 50% loss after 1 month. The carotenoid content in H. pluvialis was more stable than in C. vulgaris due to the thicker cell wall of H. pluvialis (Gouveia and Empis 2003).

In conclusion, this is the first report on the effects of long-term storage conditions on the shelf-life of microalgal biomass with regard to secondary metabolites and their bioactivities. The time of storage and, in some instances, temperature followed by light had a significant effect on root stimulating, antimicrobial and antioxidant activity of the C. vulgaris biomass. Initially, degradation of the bioactive metabolites was probably offset by the more efficient extraction due to the gradual breakdown of the rigid cell wall (T0-T12). There was a loss in antimicrobial and antioxidant activity after the 12 months period. Use of residual microalgal feedstock following macromolecule extraction could potentially provide an inexpensive source of agricultural fertilizer with biostimulant properties. However, valorisation of such biomass requires further investigation as the results from the current experiment show that bioactive compounds are susceptible to degradation with storage. These detrimental effects could be reduced if the microalgal biomass preserves its antioxidant activity and this should be a selection criterion when screening for suitable microalgae strains for a multiple use scenario.

Data availability

The data generated during this study are available from the corresponding author on reasonable request.

References

Alhattab M, Kermanshahi-Pour A, Brooks MS-L (2019) Microalgae disruption techniques for product recovery: influence of cell wall composition. J Appl Phycol 31:61–88

Alvarez AL, Weyers SL, Goemann HM, Peyton BM, Gardner RD (2021) Microalgae, soil and plants: a critical review of microalgae as renewable resources for agriculture. Algal Res 54:102200

Ambrico A, Trupo M, Magarelli R, Balducchi R, Ferraro A, Hrisstoforou E, Marino T, Musmarra D, Casella P, Molino A (2020) Effectiveness of Dunaliella salina extracts against Bacillus subtilis and bacterial plant pathogens. Pathogens 9:613

Aremu AO, Ndhlala AR, Fawole OA, Light ME, Finnie JF, van Staden J (2010) In vitro pharmacological evaluation and phenolic content of ten South African medicinal plants used as anthelminthics. S Afr J Bot 76:558–566

Aremu AO, Masondo NA, Molnár Z, Stirk WA, Ördög V, van Staden J (2016) Changes in phytochemical content and pharmacological activities of three Chlorella strains grown in different nitrogen conditions. J Appl Phycol 28:149–159

Babarro JMF, Fernández Reiriz MJ, Labarta U (2001) Influence of preservation techniques and freezing storage time on biochemical composition and spectrum of fatty acids of Isochrysis galbana clone T-ISO. Aquacult Res 2001:565–572

Barreiro-Vescovo S, de Godos I, Tomás-Pejó E, Ballesteros M, Gonzále-Fernández C (2018) Effect of microalgae storage conditions on methane yields. Environ Sci Pollut Res 25:14263–14270

Camacho-Rodríguez J, Macías-Sáchez MD, Cerón-García MC, Alarcón FJ, Molína-Grima E (2018) Microalgae as a potential ingredient for partial fish meal replacement in aquafeeds: nutrient stability under different storage conditions. J Appl Phycol 30:1049–1059

Choochote W, Suklampoo L, Ochaikul D (2014) Evaluation of antioxidant capacities of green microalgae. J Appl Phycol 26:43–48

Costa JAV, Freitas BCB, Cruz CG, Silveira J, Morais MG (2019) Potential of microalgae as biopesticides to contribute to sustainable agriculture and environmental development. J Environ Sci Health B 54:366–375

Crouch IJ, van Staden J (1991) Evidence for rooting factors in a seaweed concentrate prepared from Ecklonia maxima. J Plant Physiol 137:319–322

Garcia-Gonzalez J, Sommerfeld M (2016) Biofertilizer and biostimulants properties of the microalga Acutodesmus dimorphus. J Appl Phycol 28:1051–1061

Goiris K, Muylaert K, Fraeye I, Foubert I, De Brabanter J, De Cooman L (2012) Antioxidant potential of microalgae in relation to their phenolic and carotenoid content. J Appl Phycol 24:1477–1486

Gouveia L, Empis J (2003) Relative stabilities of microalgal carotenoids in microalgae extracts, biomass and fish feed: effect of storage conditions. Innov Food Sci Emerg Technol 4:227–233

Gruber-Brunhumer MR, Jerney J, Zohar E, Nussbaumer M, Hieger C, Bochmann G, Schagerl M, Obbard JP, Fuchs W, Drosg B (2015) Acutodesmus obliquus as a benchmark strain for evaluating methane production from microalgae: influence of different storage and pretreatment methods on biogas yield. Algal Res 12:230–238

Iglesias MJ, Soengas R, Probert I, Guilloud E, Gourvil P, Mehiri M, López Y, Cepas V, Gutiérrez-del-Río I, Redondo-Blanco S, Villar CJ, Lombó F, Soto S, Ortiz FL (2019) NMR characterization and evaluation of antibacterial and antibiofilm activity of organic extracts from stationary phase batch cultures of five marine microalgae (Dunaliella sp., D. salina, Chaetoceros calcitrans, C. gracilis and Tisochrysis lutea). Phytochemistry 164:192–205

Jain N, Stirk WA, van Staden J (2008) Cytokinin- and auxin-like activity of a butanolide isolated from plant-derived smoke. S Afr J Bot 74:327–331

Jerez-Martel I, Garcia-Poza S, Rodrigues-Martel G, Rico M, Afonso-Olivares C, Gómez-Pinchetti JL (2017) Phenolic profile and antioxidant activity of crude extracts from microalgae and cyanobacteria strains. J Food Qual 2017:2924508

Kholssi R, Marks EAN, Miñón J, Montero O, Debdoubi A, Rad C (2019) Biofertilizing effect of Chlorella sorokiniana suspension on wheat growth. J Plant Grow Regul 38:644–649

Kim D-Y, Vijayan D, Praveenkumar R, Han J-I, Lee K, Park J-Y, Chang W-S, Lee J-S, Oh Y-K (2016) Cell-wall disruption and lipid/astaxanthin extraction from microalgae: Chlorella and Haematococcus. Bioresour Technol 199:300–310

Lee AK, Lewis DM, Ashman PJ (2012) Disruption of microalgal cells for the extraction of lipids for biofuels: processes and specific energy requirements. Biomass Bioenergy 46:89–101

Lichtenhaler HK (1987) Chlorophylls and carotenoids. Pigments of photosynthetic biomembranes. In: Packer L, Douce R (eds) Methods in enzymology, vol 148. Academic Press, New York, pp 350–382

Moyo M, Ndhlala AR, Finnie JF, van Staden J (2010) Phenolic composition, antioxidant and acetylcholinesterase inhibitory activities of Sclerocarya birrea and Harpephyllum caffrum (Anacardiaceae) extracts. Food Chem 123:69–76

Ördög V, Stirk WA, Lenobel R, Bancířová M, Strnad M, van Staden J, Szigeti J, Németh L (2004) Screening microalgae for some potentially useful agricultural and pharmaceutical secondary metabolites. J Appl Phycol 16:309–314

Ördög V, Stirk WA, Takács G, Pöthe P, Illés A, Bojtor C, Széles A, Tóth B, van Staden J, Nagy J (2021) Plant biostimulating effects of the cyanobacterium Nostoc piscinale on maize (Zea mays L.) in field experiments. S Afr J Bot 140:153–160

Ortiz J, Vivanco JP, Aubourg SP (2014) Lipid and sensory quality of canned Atlantic salmon (Salmo salar): effect of the use of different seaweed extracts as covering liquids. Eur J Lipid Sci Technol 116:596–605

Plaza BM, Gómez-Serrano C, Acién-Fernández FG, Jimenez-Becker S (2018) Effect of microalgae hydrolysate foliar application (Arthrospira platensis and Scenedesmus sp.) on Petunia x hybrida growth. J Appl Phycol 30:2359–2365

Rengasamy KRR, Kulkarni MG, Stirk WA, van Staden J (2015) Eckol – a new plant growth stimulant from the brown seaweed Ecklonia maxima. J Appl Phycol 27:581–587

Renuka N, Guldhe A, Prasanna R, Singh P, Bux F (2018) Microalgae as multi-functional options in modern agriculture: current trends, prospects and challenges. Biotechnol Adv 36:1255–1273

Staub R (1961) Ernährungsphysiologisch-autökologische untersuchungen an der planktischen blaualge Oscillatoria rubescens DC. Schweiz Zr Hydrol 23:82–198

Stirk WA, van Staden J (1997) Comparison of cytokinin- and auxin-like activity in some commercially used seaweed extracts. J Appl Phycol 8:503–508

Stirk WA, Tarkowská D, Gruz J, Strnad M, Ördög V, van Staden J (2019) Effect of gibberellins on growth and biochemical constituents in Chlorella minutissima (Trebouxiophyceae). S Afr J Bot 126:92–98

Stirk WA, Bálint P, Vambe M, Lovász C, Molnár Z, van Staden J, Ördög V (2020) Effect of cell disruption methods on the extraction of bioactive metabolites from microalgal biomass. J Biotechnol 307:35–43

Takács G, Stirk WA, Gergely I, Molnár Z, van Staden J, Ördög V (2019) Biostimulating effects of the cyanobacterium Nostoc piscinale on winter wheat in field experiments. S Afr J Bot 126:99–106

Funding

The research was funded by the project SABANA (grant number 727874) from the European Union Horizon 2020 Research and Innovation Program and by the EFOP-3.6.3-VEKOP-16–2017-00008 project co-funded by the European Union and European Social Fund. The University of KwaZulu-Natal is thanked for financial support.

Author information

Authors and Affiliations

Contributions

WAS helped conceptualize and design the experiment; conducted the mungbean bioassay, DPPH assay, and pigment extraction; and wrote the manuscript; PB ran the growth experiments to generate the biomass; MV conducted the antimicrobial assay; MGK did the statistical analysis; JvS edited the manuscript; VÖ conceptualized and designed the experiment and edited the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Stirk, W.A., Bálint, P., Vambe, M. et al. Effect of storage on plant biostimulant and bioactive properties of freeze-dried Chlorella vulgaris biomass. J Appl Phycol 33, 3797–3806 (2021). https://doi.org/10.1007/s10811-021-02596-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-021-02596-9