Abstract

The structure and biocompatibility of anode materials significantly affect the performance of microbial fuel cells (MFCs). A biocompatible polyaniline–sodium alginate (PANI–SA) composite was prepared in situ oxidation polymerization on the 3D porous nitrogen-doped carbon nanotube/sponge (NCNT/S) to construct a high-performance microbial fuel cell in this investigation. The SEM showed that PANI–SA composite anode had a three-dimensional macroporous structure, and nitrogen-doped nanotubes were wound around the sponge skeleton, which had a large specific surface area, provided more places for the attachment and growth of microorganisms. A dual-chamber MFC equipped with a PANI–SA/NCNT/S bioanode to achieve a power density of 4380 mW m−3, which was much greater than the other MFCs. During the charge–discharge time of 60–90 min, the PANI–SA/NCNT/S bioanode had the highest total charge value of 26,617.86 C m−2, which was 3.23 times higher than that of NCNT/S (8231.87 C m−2). High-throughput sequencing results showed that the PANI–SA/NCNT/S bioanode exhibited high community diversity and selective enrichment of electrogenic bacteria. The excellent performance of the MFC equipped with PANI–SA/NCNT/S anode was attributed to the composite materials, which could be attributed to the large-pore network structure, better biocompatibility, large capacitance and high specific surface area.

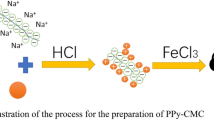

Graphic abstract

Illustration of the process for the preparation of PANI–SA

Similar content being viewed by others

References

Zhang D, Liao X, Liu Y, Zhong N, Xu Y (2018) Enhanced electricity generation performance and dye wastewater degradation of microbial fuel cell by using a petaline NiO@ polyaniline-carbon felt anode. Bioresour Technol 258:125–134

Yang W, Wang X, Rossi R, Logan BE (2020) Low-cost Fe–N–C catalyst derived from Fe (III)-chitosan hydrogel to enhance power production in microbial fuel cells. Chem Eng J 380:122522

Gong XB, You SJ, Yuan Y, Zhang JN, Sun K, Ren NQ (2015) Three-dimensional pseudocapacitive interface for enhanced power production in a microbial fuel cell. ChemElectroChem 2:1307–1313

Liang P, Zhang C, Jiang Y, Bian Y, Zhang H, Sun X, Yang X, Zhang X, Huang X (2017) Performance enhancement of microbial fuel cell by applying transient-state regulation. Appl Energy 185:582–588

Wang Y, Chen Y, Wen Q, Zheng H, Xu T, Qi L (2019) Electricity generation, energy storage, and microbial-community analysis in microbial fuel cells with multilayer capacitive anodes. Energy 189:116342

Deng Q, Li X, Zuo J, Ling A, Logan BE (2010) Power generation using an activated carbon fiber felt cathode in an upflow microbial fuel cell. J Power Sources 195:1130–1135

Xu H, Wang L, Wen Q, Chen Y, Qi L, Huang J, Tang Z (2019) A 3D porous NCNT sponge anode modified for high-performance microbial fuel cell. Bioelectrochemistry 129:144–153

Blanchet E, Erable B, Solan MD, Bergel A (2016) Two-dimensional carbon cloth and three-dimensional carbon felt perform similarly to form bioanode fed with food waste. Electrochem Commun 66:38–41

Yu F, Wang C, Ma J (2018) Capacitance-enhanced 3D graphene anode for microbial fuel cell with long-time electricity generation stability. Electrochim Acta 259:1059–1067

Duan T, Chen Y, Wen Q, Yin J, Wang Y (2016) Three-dimensional macroporous CNT–SnO2 composite monolith for electricity generation and energy storage in microbial fuel cells. RSC Adv 6:59610–59618

Xiao Q, Zhou X (2003) The study of multiwalled carbon nanotube deposited with conducting polymer for supercapacitor. Electrochim Acta 48:575–580

Peng C, Zhang S, Jewwell D, Chen GZ (2008) Carbon nanotube and conducting polymer composites for supercapacitors. Prog Polym Sci 18:777–788

Liang P, Wang HY, Xia X, Huang X, Mo Y, Cao X, Fan M (2011) Carbon nanotube powders as electrode modifier to enhance the activity of anodic biofilm in microbial fuel cells. Biosens Bioelectron 26:3000–3004

Delord B, Neri W, Bertaux K, Derre A, Ly I, Mano N, Poulin P (2017) Carbon nanotube fiber mats for microbial fuel cell electrodes. Bioresource Technol 243:1227–1231

Erbay C, Pu X (2015) Control of geometrical properties of carbon nanotube electrodes towards high-performance microbial fuel cells. J Power Sources 280:347–354

Zou Y, Xiang C, Yang L, Sun L, Xu F, Cao Z (2008) A mediatorless microbial fuel cell using polypyrrole coated carbon nanotubes composite as anode material. Int J Hydrogen Energy 33:4856–4862

Qiao Y, Li CM, Bao S, Bao Q (2007) Carbon nanotube/polyaniline composite as anode material for microbial fuel cells. J Power Sources 170:79–84

Cui HF, Lin D, Guo P, Zhu B, Luong JHT (2015) Controlled modification of carbon nanotubes and polyaniline on macroporous graphite felt for high performance microbial fuel cell anode. J Power Sources 283(1):46–53

Yang J, Xie Y, He W (2011) Research progress on chemical modification of alginate: A review. Carbohyd Polym 84:33–39

Li Y, Zhao X, Xu Q, Zhang Q, Chen D (2011) Facile preparation and enhanced capacitance of the polyaniline/sodium Alginate nanofiber network for supercapacitors. Langmuir 27:6458–6463

Wu W, Li Y, Yang L, Ma Y, Yan X (2014) Preparation and characterization of Coaxial multiwalled carbon nanotubes/polyaniline tubular nanocomposites for electrochemical energy storage in the presence of sodium alginate. Synthetic Met 193:48–57

Qi R, Guo J, Liu Y, Zhang R, Gan Z (2019) Effects of salt content on secondary structure of protein in sodium alginate/antarctic krill protein composite system and characterization of fiber properties. Dyes Pigments 171:107686

Huang HB, Zeng XP, Li W, Wang H, Wang Q, Yang Y (2014) Reinforced conducting hydrogels prepared from the in situ polymerization of aniline in an aqueous solution of sodium alginate. Journal Mater Chem A 2:16516–16522

Peng X, Yu H, Yu H, Wang X (2013) Lack of anodic capacitance causes power overshoot in microbial fuel cells. Bioresource Technol 138:353–358

Zhang C, Liang P, Jiang Y, Huang X (2015) Enhanced power generation of Microbial fuel cell using manganese dioxide-coated anode in flow-through mode. J Power Sources 273:580–583

Dewan A, Beyenal H, Lewandowski Z (2009) Intermittent Energy Harvesting Improves the Performance of Microbial Fuel Cells. Environ Sci Technol 43:4600–4605

Hatzell MC, Kim Y, Logan BE (2013) Powering microbial electrolyswas cells By capacitor circuits charged using microbial fuel cell. J Power Sources 229:198–202

Pant D, Bogaert GV, Diels L, Vanbroekhoven K (2010) A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresource Technol 101:1533–1543

Papaharalabos G, Greenman J, Stinchcombe A, Horsfield I, Melhuwash C, Ieropoulos I (2014) Dynamic electrical reconfiguration for improved capacitor charging in microbial fuel cell stacks. J Power Sources 272:34–38

Grondin F, Perrier M, Tartakovsky B (2012) Microbial fuel cell operation with intermittent connection of the electrical load. J Power Sources 208:18–23

Zhang B, Zhang J, Liu Y, Hao C, Tian C, Feng C, Lei Z, Huang W, Zhang Z (2013) Identification of removal principles and involed bacteria in microbial fuel cells for sulfide removal and electricity generation. Int J Hydrogen Energy 38:14348–14355

Dunaj SJ, Vallino JJ, Hines ME, Gay M, Kobyljanec C, Rooney-Varga JN (2012) Relationships between soil organic matter nutrients bacterial community structure, and the performance of microbial fuel cells. Environ Sci Technol 46:1914–1922

Acknowledgements

The project was supported by National Natural Science Foundation of China (21878060 and 21476053), Research Fund of State Key Laboratory for Marine Corrosion and Protection of Luoyang Ship Material Research Institute under the contract No. 6142901180401 and China Scholarship Council (201806685019), Research Project Fund of Harbin University of Commerce (2019DS082).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethics approval

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Zheng, H., Lin, C. et al. Development of a 3D porous sponge as a bioanode coated with polyaniline/sodium alginate/nitrogen-doped carbon nanotube composites for high-performance microbial fuel cells. J Appl Electrochem 50, 621–630 (2020). https://doi.org/10.1007/s10800-020-01410-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01410-7