Abstract

A stress-state dependent cyclic cohesive model, which accounts for accumulation of plasticity, during both tensile as well as compressive deformations, and incorporates accumulation of irreversible damage due to macroscopic plasticity as well as microstructural mechanisms, is formulated. The model is implemented in mode-I plane strain fatigue crack growth simulations. The model is validated by reproducing the effect of retardation in crack growth rates after different combinations of tensile and compressive overloads. We show accurate description of the elastic–plastic behaviour of the process zone is vital, in particular for negative stress ratios subsequent to a tensile over-load, as considerable plasticity occurs in compression at the crack-tip, significantly reducing retardation effects.

Similar content being viewed by others

References

Anvari M, Scheider I, Thaulow C (2006) Simulation of dynamic ductile crack growth using strain-rate and triaxiality-dependent cohesive elements. Eng Fract Mech 73:2210–28

Banerjee A, Manivasagam R (2009) Triaxiality dependent cohesive zone model. Eng Fract Mech 76:1761–70

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space 46:81–98

Barsoum I, Faleskog J (2007) Rupture mechanisms in combined tension and shear-Experiments. Int J Solids Struct 44:1768–86

Beden SM, Abdullah S, Ariffin AK (2009) Review of fatigue crack propagation models for metallic components. vol. 28

Bouvard JL, Chaboche JL, Feyel F, Gallerneau F (2009) A cohesive zone model for fatigue and creep-fatigue crack growth in single crystal superalloys. Int J Fatigue 31:868–79

Danas K, Ponte Castañeda P (2012) Influence of the Lode parameter and the stress triaxiality on the failure of elasto-plastic porous materials. Int J Solids Struct 49:1325–42

De-Andrés A, Pérez JL, Ortiz M (1999) Elastoplastic finite element analysis of three-dimensional fatigue crack growth in aluminum shafts subjected to axial loading. Int J Solids Struct 36:2231–58

Elber W (1971) The Significance of Fatigue Crack Closure. ASTM Spec Tech Publ 230–42

Hancock JW, Brown DK (1983) On the role of strain and stress state in ductile failure. J Mech Phys Solids 31:1–24

Hancock JW, Mackenzie AC (1976) On the mechanisms of ductile failure in high-strength steels subjected to multi-axial stress-states. J Mech Phys Solids 24:147–60

Horstemeyer MF, Farkas D, Kim S, Tang T, Potirniche G (2010) Nanostructurally small cracks (NSC): a review on atomistic modeling of fatigue. Int J Fatigue 32:1473–502

Hutař P, Seitl S, Knésl Z (2006) Effect of constraint on fatigue crack propagation near threshold in medium carbon steel. Comput Mater Sci 37:51–7

Jha D, Banerjee A (2012) A cohesive model for fatigue failure in complex stress-states. Int J Fatigue 36:155–62

Jiang H, Gao X, Srivatsan TS (2009) Predicting the influence of overload and loading mode on fatigue crack growth : a numerical approach using irreversible cohesive elements. Finite Elem Anal Des 45:675–85

Lemaitre J (2012) A course on damage mechanics. Springer, New York

Li H, Li C, Yuan H (2017) Prediction of fatigue crack growth retardation using a cyclic cohesive zone model. Arch Appl Mech 87:1061–75

Li H, Yuan H (2013) Cohesive zone modelling of low cycle fatigue cracks in cracked and notched specimens. Fatigue Fract Eng Mater Struct 36:1246–57

Liu J, Xiang C, Yuan H (2009) Prediction of 3D small fatigue crack propagation in shot-peened specimens. Comput Mater Sci 46:566–71

Miarka P, Cruces AS, Seitl S, Malíková L, Lopez-Crespo P (2020) Influence of the constraint effect on the fatigue crack growth rate in S355 J2 steel using digital image correlation. Fatigue Fract Eng Mater Struct 1703–18

Needleman A (1992) Micromechanical modelling of interfacial decohesion. Ultramicroscopy 40:203–14

Newman JC (1984) A crack opening stress equation for fatigue crack growth. Int J Fract 24:131–5

Nijin IS, Banerjee A (2020) Mesoscopic mechanisms in fatigue crack initiation in an aluminium alloy. Fatigue Fract Eng Mater Struct 43(5):893–906

Nijin IS, Shravan Kumar R, Banerjee A (2019) Role of stress-state on initiation and growth of a fatigue crack. Int J Fatigue 118:298–306

Nguyen O, Repetto EA, Ortiz M, Radovitzky RA (2001) A cohesive model of fatigue crack growth 351–69

Pandey VB, Singh IV, Mishra BK, Ahmad S, Venugopal Rao A, Kumar V (2019) A new framework based on continuum damage mechanics and XFEM for high cycle fatigue crack growth simulations. Eng Fract Mech 206:172–200

Park K, Paulino GH (2011) Cohesive zone models: a critical review of traction-separation relationships across fracture surfaces. Appl Mech Rev 64:1

Peerlings RHJ, Brekelmans WAM, De Borst R, Geers MGD (2000) Gradient-enhanced damage modelling of high-cycle fatigue. Int J Numer Methods Eng 49:1547–69

Qian Z, Takezono S, Tao K (1996) A nonlocal damage mechanics approach to high temperature fatigue crack growth. Eng Fract Mech 53:535–43

Rashid FM, Banerjee A (2013) Implementation and validation of a triaxiality dependent cohesive model: experiments and simulations. Int J Fract 181:227–39

Rashid FM, Banerjee A (2017) Simulation of fracture in a low ductility aluminum alloy using a triaxiality dependent cohesive model. Eng Fract Mech 179:1–12

Roe KL, Siegmund T (2003) An irreversible cohesive zone model for interface fatigue crack growth simulation. Eng Fract Mech 70:209–32

Roth S, Kuna M (2017) Prediction of size-dependent fatigue failure modes by means of a cyclic cohesive zone model. Int J Fatigue 100:58–67

Segurado J, LLorca J (2004) A new three-dimensional interface finite element to simulate fracture in composites. Int J Solids Struct 41:2977–93

Shlyannikov VN, Zakharov AP (2014) Multiaxial crack growth rate under variable T-stress. Eng Fract Mech 123:86–99

Siegmund T (2004) A numerical study of transient fatigue crack growth by use of an irreversible cohesive zone model. Int J Fatigue 26:929–39

Siegmund T, Brocks W (1999) Prediction of the Work of Separation and Implications to Modeling. Int J Fract 99:97–116

Siegmund T, Brocks W (2000) Numerical study on the correlation between the work of separation and the dissipation rate in ductile fracture. Eng Fract Mech 67:139–54

Skorupa M (1999) Load interaction effects during fatigue crack growth under variable amplitude loading—a literature review. Part II: qualitative interpretation. Fatigue Fract Eng Mater Struct 21:905–26

Stephens RI, Chen DK, Horn BW (1976) Fatigue Crack Growth with Negative Stress Ratio Following Single Overloads in 2024-T3 and 7075-T6 Aluminum Alloys. Vol 595. American Society for Testing and Materials

Sunder R (2012) Unraveling the science of variable amplitude fatigue. J ASTM Int 9:20–64

Tong J (2002) T-stress and its implications for crack growth. Eng Fract Mech 69:1325–37

Ural A, Krishnan VR, Papoulia KD (2009) International Journal of Solids and Structures A cohesive zone model for fatigue crack growth allowing for crack retardation q. Int J Solids Struct 46:2453–62

Voorwald HJC, Torres MAS, Pinto Júnior CCE (1991) Modelling of fatigue crack growth following overloads. Int J Fatigue 13:423–7

Xu Y, Yuan H (2009) On damage accumulations in the cyclic cohesive zone model for XFEM analysis of mixed-mode fatigue crack growth. Comput Mater Sci 46:579–85

Yuan H, Li X (2018) Critical remarks to cohesive zone modeling for three-dimensional elastoplastic fatigue crack propagation. Eng Fract Mech 202:311–31

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Summary of the traction–separation behaviour.

Consistent tangent operator

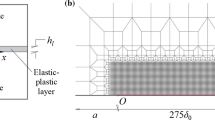

The incremental form of the stress-state dependent traction separation behaviour for the cohesive elements is shown in Eq. 3. The associated tangent modulus, K, is then defined as

and is implemented into FEM as per (Segurado and LLorca 2004). From Eqs. 8 and 11, \(\frac{\partial {\hat{\delta }}_{n}^p}{\partial {\hat{\delta }}_{n}}\) and \(\frac{\partial D}{\partial {\hat{\delta }}_{n}}\) are determined to be of the form

where \(\frac{\partial \lambda }{\partial {\hat{\delta }}_{n}}\) is found by enforcing consistency condition to the triaxiality dependent one dimensional yield surface formulated, earlier in Eq. 15, so that during yielding traction remains on the yield surface. From consistency condition of the damage coupled yield surface, \({\dot{\varPhi }}\) = 0, \(\frac{\partial \lambda }{\partial {\hat{\delta }}_{n}}\) is found and takes the form

Rights and permissions

About this article

Cite this article

Nijin, I.S., Banerjee, A. An incremental elastic–plastic triaxiality dependent fatigue model. Int J Fract 227, 39–55 (2021). https://doi.org/10.1007/s10704-020-00494-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-020-00494-8