Abstract

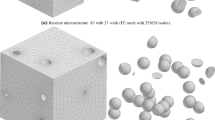

Large-scale direct numerical simulations of void growth and coalescence from 3-dimensional distributions of void nucleating particles are used to investigate the effect of material strain hardening and strain rate sensitivity on spall response. The computational model spans multiple particle spacings in the in-plane directions, and several finite elements span the initial particle diameters in the mixed-zone Arbitrary Lagrange–Eulerian (ALE) simulations. The matrix material is represented by traditional plasticity models in which material failure is not permitted. The 1000\(+\) particles are represented by the same material model as the surrounding matrix except the particles have low tensile strength to permit fracture, which is used to simulate particle cracking or decohesion. Voids grow and coalesce naturally in the ALE framework, and the simulations produce dimpled failure surfaces similar to those observed experimentally in spalled samples. The strain hardening and strain rate sensitivity of the matrix material are altered to explore their influence on the void growth and coalescence processes and on the simulated free surface velocity. The details available from the computational model permit association of the longitudinal stress evolution with features on the free surface velocity profile.

Similar content being viewed by others

Notes

While applicable at this size scale, crystal placity is neglected.

References

Antoun T, Seaman L, Curran DR, Kanel IG, Razorenov SV, Utkin AV (2003) Spall fracture. Springer, New York

Barbee T, Seaman L, Crewdson R (1969) Model for spall damage in ductile metals. Bull Am Phys Soc 14(12):1171

Becker R, LeBlanc MM, Cazamias JU (2007) Characterization of recompressed spall in copper gas gun targets. J Appl Phys 102(9):093512-1–093512-8. doi:10.1063/1.2802589

Benzerga AA, Leblond JB (2014) Effective yield criterion accounting for microvoid coalescence. J Appl Mech Trans ASME. doi:10.1115/1.4024908

Bringa EM, Traiviratana S, Meyers MA (2010) Void initiation in fcc metals: effect of loading orientation and nanocrystalline effects. Acta Mater 58(13):4458–4477. doi:10.1016/j.actamat.2010.04.043

Davison L, Stevens AL, Kipp ME (1977) Theroy of spall damage accumulation in ductile metals. J Mech Phys Solids 25(1):11–28. doi:10.1016/0022-5096(77)90017-5

Escobedo JP, Dennis-Koller D, Ceretta EK, Patterson BM, Bronkhorst CA, Hanson BL, Tonks D, Lebensohn RA (2011) Effects of grain size and boundary structure on the dynamic tensile response of copper. J Appl Phys 110(3):033513-1–033513-13. doi:10.1063/1.342000

Grady DE (2015) Unifying role of dissipative action in the dynamic failure of solids. J Appl Phys 117(16):165905-1–165905-15. doi:10.1063/1.4918603

Grüneisen E (1926) Zustand des festen Körpers. Handbuch der Physik, vol 10. Springer, Berlin, pp 1–59

Jacques N, Mercier S, Molinari A (2012) Void coalescence in a porous solid under dynamic loading conditions. Int J Fract. doi:10.1007/s10704-012-9683-5

Jacques N, Czarnota C, Mercier S, Molinari A (2015) A micromechanical constitutive model for dynamic damage and fracture of ductile materials. Int J Fract 162:159–175. doi:10.1007/s10704-009-9436-2

Johnson JN (1981) Dynamic fracture and spallation in ductile solids. J Appl Phys 52(4):2812–2825. doi:10.1063/1.329011

Johnson JN, Addessio FL (1988) Tensile plasticity and ductile fracture. J Appl Phys 64(12):6699–6712. doi:10.1063/1.342000

Knowles JK, Jakub MT (1965) Finite dynamic deformations of an incompressible elastic medium containing a spherical cavity. Arch Ration Mech Anal 18(5):367–378. doi:10.1007/BF00281326

Krasnikov VS, Mayer AE (2015) Plasticity driven growth of nanovoids and strength of aluminum at high rate tension: molecular dynamics simulations and continuum modeling. Int J Plast 74(1):75–91. doi:10.1016/j.ijplas.2015.06.007

Lou SN, Germann TC, Tonks DL (2009) Spall damage of copper under supported and decaying shock loading. J Appl Phys 106(12):123518-1–123518-7. doi:10.1063/1.3271414

Molinari A, Jacques N, Mercier S, Leblond JB, Benzerga AA (2015) A micromechanical model for the dynamic behavior of porous media in the void coalescence stage. Int J Solids Struct 71:1–18. doi:10.1016/j.ijsolstr.2015.05.003

Moninari A, Wright TW (2005) A physical model for nucleation and early growth of voids in ductile materials under dynamic loading. J Mech Phys Solids 53:1476–1504. doi:10.1016/j.jmps.2005.02.010

Morin L, Leblond JB, Benzerga AA (2015) Coalescence of voids by internal necking: theoretical estimates and numerical results. J Mech Phys Solids 75:140–158. doi:10.1016/j.jmps.2014.11.009

Nichols AL (2015) ALE3D. An arbitrary Lagrange/Eulerian 2D and 3D code system. Lawrence Livermore National Laboratory, V4.26 edn, LLNL-SM-681737

Noh WF, Woodward P (1976) SLIC (Simple Line Interface Calculation). In: van de Vooren AI, Zandbergen PJ (eds) Proceedings of the fifth international conference on numerical methods in fluid dynamics June 28–July 2, 1976 Twente University, Enschede, Springer, Berlin, pp 330–340. doi:10.1007/3-540-08004-X_336

Romanchenko VI, Stepanov GV (1980) Dependence of the critical stress on the loading time parameters during spall in copper, aluminum and steel. J Appl Mech Tech Phys 21(4):555–561. doi:10.1007/BF00916495

Seaman L, Curran DR, Shockey DA (1976) Computational models for ductile and brittle fracture. J Appl Phys 47(11):4814–4826. doi:10.1063/1.322523

Seppälä ET, Belak J, Rudd RE (2004) Effect of stress triaxiality on the void growth in dynamics fracture of metals: a molecular dynamics study. Phys Rev B 69(13):134101-1–134101-19. doi:10.1103/PhysRevB.69.134101

Steinberg DJ, Cochran SG, Guinan MW (1980) A constitutive model for metals applicable at high-strain rate. J Appl Phys 51(3):1498–1504. doi:10.1063/1.327799

Wang Y, He H, Wang L (2013) Critical damage evolution model for spall failure of ductile metals. Mech Mater 56:131–141

Wilkerson JW, Ramesh KT (2016) A closed-form criterion for dislocation emission in nano-porous materials under arbitrary thermomechanical loading. J Mech Phys Solids 86(1):94–116. doi:10.1016/j.jmps.2015.10.005

Zurek AK, Thissell WR, Johnson JN, Tonks DL, Hixson R (1996) Micromechanics of spall and damage in tantalum. J Mater Proc Technol 60(1–4):261–267. doi:10.1016/0924-0136(96)02340-0

Acknowledgements

The author is grateful for the support US Army Research Laboratory. The findings in this report are not to be construed as an official Department of the Army position unless so designated by other authorized documents. Approved for public release; distribution is unlimited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Becker, R. Direct numerical simulation of ductile spall failure. Int J Fract 208, 5–26 (2017). https://doi.org/10.1007/s10704-017-0198-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-017-0198-y