Abstract

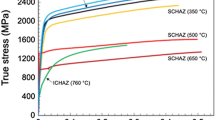

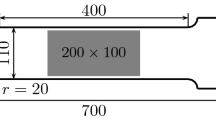

Ductile plug failure of resistance spot welded shear-lab specimens is studied by full 3D finite element analysis, using an elastic-viscoplastic constitutive relation that accounts for nucleation and growth of microvoids to coalescence (The Gurson model). Tensile properties and damage parameters are based on uni-axial tensile testing of the basis material, while the modelled tensile response of the shear-lab specimens is compared to experimental results for the case of a ductile failure near the heat affected zone (HAZ). A parametric study for a range of weld diameters is carried out, which makes it possible to numerically relate the weld diameter to the tensile shear force (TSF) and the associated displacement, u TSF , respectively. Main focus in the paper is on modelling the localization of plastic flow and the corresponding damage development in the vicinity of the spot weld, near the HAZ. For decreasing weld diameter, localization of plastic flow may be observed to occur in the weld nugget, introducing significant shearing. Due to these competing mechanisms a critical transition radius of the weld may be found. However, due to the limitation of the Gurson model in describing ductile failure at very low stress triaxiality, further analysis of the shear failure is omitted.

Similar content being viewed by others

References

Ahmad E, Tanvir M, Kanwar Liaqat A, Akhter JI (2000) Effect of microvoid formation on the tensile properties of dual-phase steel. J Mater Eng Perform 9: 306–310

Anastassiou M, Babbit M, Lebrun JL (1990) Residual stresses and microstructure distribution in spot-welded steel sheets: relation with fatigue behaviour. Mater Sci Eng A 125: 141–156

AWS (2000) Recommended practices for resistance welding. AWS—American Welding Society, C1.1M/C1.1:2000

Budiansky B (1964) Remarks on theories of solid and structural mechanics. Harvard University, SIAM, pp 77–83

Chu CC, Needleman A (1980) Void nucleation effects in biaxially stretched sheets. J Eng Mater Technol 102: 249–256

Ferrasse S, Verrier P, Meesemaecker F (1998) Resistance spot weldability of high strength steels for use in car industry. Weld World 41: 177–195

Gologanu M, Leblond JB, Perrin G, Devaux J (1997) Recent extensions of Gurson’s model for porous ductile metals. In: Continuum micromechanics. Springer-Verlag, Berlin, pp 61–106

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth. I. Yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99: 2–15

Hasanbaşoğlu A, Kaçar R (2006) Microstructure and property relationships in resistance spot weld between 7114 interstitial free steel and 304 austenitic stainless steel. J Mater Sci Technol 22: 375–381

Hoon H, Seok-Bong K, Jung-Han S, Ji-Ho L (2008) Dynamic tensile characteristics of TRIP-type and DP-type steel sheets for an auto-body. Mech Sci 50: 918–931

Hutchinson J (1973) Finite strain analysis of elastic-plastic solids and structures, vol 6. Harvard University, AMD, pp 17–29

Kahraman N (2007) The influence of welding parameters on the joint strength of resistance spot welded titanium sheets. Society of Automotive Engineering, Inc., 810352, vol 28, Warrendale, PA, pp 420–427

Lassance D, Fabrègue D, Delannay F, Pardoen T (2007) Micromechanics of room and high temperature fracture in 6xxx Al alloys. Prog Mater Sci 52: 62–129

Long X, Khanna SK (2007) Fatigue properties and failure characterization of spot welded high strength steel sheet. Int J Fatigue 29: 879–886

Marashi P, Pouranvari M, Amirabdollahian S, Abedi A, Goodarzi M (2008) Microstructure and failure behavior of dissimilar resistance spot welds between low carbon galvanized and austenitic stainless steels. Mater Sci Eng A 480: 175–180

Markiewicz E, Ducrocq P, Drazetic P, Haugou G, Fourmentraux T, Berard JY (2001) Material behaviour law identification for the various zones of the spot-weld under quasi-static loadings. Int J Mater Product Technol 16: 484–509

Marya M, Gayden XQ (2005) Development of requirements for resistance spot welding dual-phase (DP600) steels. Part 1: The causes of interfacial fracture. Weld J 84(11): 172–182

Marya M, Wang K, Hector LG, Gayden X (2006) Tensile-shear forces and fracture modes in single and multiple weld specimens in dual-phase steels. J Manufac Sci Eng 128: 287–298

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. Eur J Mech 27: 1–17

Needleman A, Tvergaard V (1999) A micromechanical analysis of ductile-brittle transition at a weld. Eng Frac Mech 62: 317–338

Nielsen KL (2008) Ductile damage development in Friction Stir Welded Aluminum (AA2024) joints. Eng Frac Mech 75: 2795–2811

Nielsen KL, Tvergaard V (2008) Effect of a shear modified Gurson Model on damage development in a FSW tensile specimen. Int J Solids Struct. doi:10.1016/j.ijSOLSTR.2008.09.011

Okazawa S, Usami T, Noguchi H, Fujii F (2002) Three-dimensional necking bifurcation in tensile steel specimens. J Eng Mech 128(4): 479–486

Pardoen T, Hutchinson JW (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48: 2467–2512

Pedersen KR , Harthøj A (2008) Analysis and modelling of microstructure and hardness in resistance welded steel (in Danish). Bachelor project at IPL - DTU, Supervised by Prof. N. Bay., Prof. M.A.J. Somers, Ph.D. W. Zhang and M.Sc. K.L. Fris., No. MM08.02

Peirce D, Shih CF, Needleman A (1984) A tangent modulus method for rate dependent solids. Comput Struct 118: 875–887

Pouranvari M, Asgari HR, Mosavizadch M, Marashi PH, Goodarzi M (2007) Effect of weld nugget size on overload failure mode of resistance spot welds. Sci Technol Weld Join 12: 217–225

Ranjbar IN, Serajzadeh S, Kokabi AH (2008) Simulation of welding residual stresses in resistance spot welding, FE modeling and X-ray verification. J Mater Proces Technol 205: 60–69

Sarwar M, Priestner R (1996) Influence of ferrite-martensite microstructural morphology on tensile properties of dual-phase steel. J Mater Sci 31: 2091–2095

Sawhill JM Jr, Furr ST (1981) Spot weldability tests for high-strength steels. Society of Automotive Engineering, Inc., 810352, Warrendale, PA

Smith RA (1980) Sizing of spot welds by elastic/plastic analysis. In: Proceedings of the 3rd Colloquium of fracture, ECF 3, pp 49–56

Song Q, Zhang W, Bay N (2005) An experimental study determines the electrical contact resistance in resistance welding. Weld J 84: 73–76

Sun X, Stephens EV, Khaleel MA (2008) Effects of fusion zone size and failure mode on peak load and energy absorption of advanced high strength steel spot welds under lap shear loading conditions. Eng Fail Anal 15: 356–367

Tong W, Tao H, Jaing X, Zhang N, Marya MP, Hector LG Jr, Gayden XQ (2005) Deformation and fracture of miniature tensile bars with resistance-spot-weld microstructures. Metal Mater Trans A 36: 2651–2669

Tvergaard V (1982a) Influence of void nucleation on ductile shear fracture at a free surface. J Mech Phys Solids 30: 399–425

Tvergaard V (1982b) On localization in ductile materials containing spherical voids. Int J Fract 18: 237–252

Tvergaard V (1990) Material failure by void growth to coalescence. Adv Appl Mech 27: 83–151

Tvergaard V (1993) Necking in tensile bars with rectangular cross-section. Comput Methods Appl Mech Eng 103: 273–290

Tvergaard V, Needleman A (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17: 389–407

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Mater 32: 157–169

Tvergaard V, Needleman A (2004) 3D analyses of the effect of weld orientation in Charpy specimens. Eng Fract Mech 71: 2179–2195

Uijl ND, Smith S (2006) Resistance spot welding of advanced high strength steels for the automotive industry. In: Proceedings of the 4th international seminar on advances in resistance welding, pp 30–60

Vanden Bossche DJ (1977) Ultimate strength and failure mode of spot welds in high strength steels. Society of Automotive Engineering, Inc., 770214, Warrendale, PA, pp 1–12

Wung P, Walsh T, Ourchane A, Stewart W, Jie M (2001) Failure of spot welds under in-plane static loading. Exp Mech 41: 100–106

Zhang W, Jensen HH, Bay N (1997) Finite element modeling of spot welding similar and dissimilar metals. In: Seventh international conference on computer technology in welding, pp 364–373

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nielsen, K.L. 3D modelling of plug failure in resistance spot welded shear-lab specimens (DP600-steel). Int J Fract 153, 125–139 (2008). https://doi.org/10.1007/s10704-008-9305-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-008-9305-4