Abstract

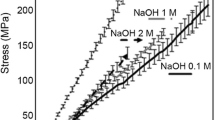

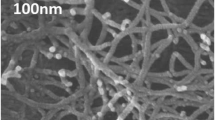

Biomass composition on cellulose, hemicelluloses and lignin determinates its behavior in torrefaction (200–350 °C, default-oxygen atmosphere). Up to now, commercial microcrystalline cellulose was typically used to represent cellulose behavior in biomass torrefaction models based on macromolecular components. The objective of this work is to evaluate the impact of cellulose properties on its behavior in torrefaction, so as to identify the most suitable cellulose sample for modelling. To do this, five extracted celluloses from woody and agricultural biomass, commercial microcrystalline cellulose (Avicel) and four cotton linters tailored to different degrees of polymerization (DP) were considered. Cellulosic samples were deeply characterized in terms of fiber analysis, molar mass distribution (MMD), hydrodynamic behavior (SEC-RALS) and allomorphic structure. Cellulosic samples were torrefied in a thermogravimetric analysis up to two temperatures, leading to partial (300 °C) and total (350 °C) cellulose degradation. Extracted celluloses and Avicel cellulose degradation profiles showed strong differences at 300 °C. Polymer MMD, dispersity and the presence of residual hemicellulose sugars, especially xylose, strongly impacted cellulose degradation through torrefaction. Extracted celluloses presented high purity, narrow MMD and high DP, but a cellulose II structure due to mercerization. This cellulosic allomorph was shown to be more reactive, but it led to an identical final solid mass loss. The observed hydrodynamic behavior and the probable preservation of cellulose amorphous areas from native cellulose may also influence polymer structural behavior in torrefaction. Finally, at least one-order-of-magnitude DP variation was shown to be required to see an impact in cellulose degradation profile through torrefaction.

Similar content being viewed by others

References

Agrawal RK (1988a) Kinetics of reactions involved in pyrolysis of cellulose I. The three reaction model. Can J Chem Eng 66:403–412. https://doi.org/10.1002/cjce.5450660309

Agrawal RK (1988b) Kinetics of reactions involved in pvrolvsis of cellulose II. The modified kilzer-bioid model. Can J Chem Eng 66:413–418. https://doi.org/10.1002/cjce.5450660310

Arseneau DF (1971) Competitive reactions in the thermal decomposition of cellulose. Can J Chem 49:632–638. https://doi.org/10.1139/v71-101

Berggren R, Berthold F, Sjöholm E, Lindström M (2003) Improved methods for evaluating the molar mass distributions of cellulose in kraft pulp. J Appl Polym Sci 88:1170–1179. https://doi.org/10.1002/app.11767

Biagini E, Barontini F, Tognotti L (2006) Devolatilization of biomass fuels and biomass components studied by TG/FTIR technique. Ind Eng Chem Res 45:4486–4493. https://doi.org/10.1021/ie0514049

Bradbury AGW, Sakai Y, Shafizadeh F (1979) A kinetic model for pyrolysis of cellulose. J Appl Polym Sci 23:3271–3280. https://doi.org/10.1002/app.1979.070231112

Broido A, Nelson MA (1975) Char yield on pyrolysis of cellulose. Combust Flame 24:263–268. https://doi.org/10.1016/0010-2180(75)90156-X

Broström M, Nordin A, Pommer L et al (2012) Influence of torrefaction on the devolatilization and oxidation kinetics of wood. J Anal Appl Pyrol 96:100–109. https://doi.org/10.1016/j.jaap.2012.03.011

Chen W-H, Kuo P-C (2011a) Torrefaction and co-torrefaction characterization of hemicellulose, cellulose and lignin as well as torrefaction of some basic constituents in biomass. Energy 36:803–811. https://doi.org/10.1016/j.energy.2010.12.036

Chen W-H, Kuo P-C (2011b) Isothermal torrefaction kinetics of hemicellulose, cellulose, lignin and xylan using thermogravimetric analysis. Energy 36:6451–6460. https://doi.org/10.1016/j.energy.2011.09.022

Chen W-H, Peng J, Bi XT (2015) A state-of-the-art review of biomass torrefaction, densification and applications. Renew Sustain Energy Rev 44:847–866. https://doi.org/10.1016/j.rser.2014.12.039

Chen D, Gao A, Cen K et al (2018) Investigation of biomass torrefaction based on three major components: Hemicellulose, cellulose, and lignin. Energy Convers Manage 169:228–237. https://doi.org/10.1016/j.enconman.2018.05.063

Cheng K, Winter WT, Stipanovic AJ (2012) A modulated-TGA approach to the kinetics of lignocellulosic biomass pyrolysis/combustion. Polym Degrad Stab 97:1606–1615. https://doi.org/10.1016/j.polymdegradstab.2012.06.027

Detcheberry M, Destrac P, Massebeuf S et al (2016) Thermodynamic modeling of the condensable fraction of a gaseous effluent from lignocellulosic biomass torrefaction. Fluid Phase Equilib 409:242–255. https://doi.org/10.1016/j.fluid.2015.09.025

Giudicianni P, Cardone G, Ragucci R (2013) Cellulose, hemicellulose and lignin slow steam pyrolysis: Thermal decomposition of biomass components mixtures. J Anal Appl Pyrol 100:213–222. https://doi.org/10.1016/j.jaap.2012.12.026

Gomez LD, Steele-King CG, McQueen-Mason SJ (2008) Sustainable liquid biofuels from biomass: the writing’s on the walls. New Phytol 178:473–485. https://doi.org/10.1111/j.1469-8137.2008.02422.x

González Martínez M, Dupont C, Thiery S et al (2016) Characteristic time analysis of biomass torrefaction phenomena—application to thermogravimetric analysis device. Chem Eng Trans 50:61–66. https://doi.org/10.3303/CET1650011

González Martínez M, Ohra-aho T, da Silva PD et al (2019) Influence of step duration in fractionated Py-GC/MS of lignocellulosic biomass. J Anal Appl Pyrol 137:195–202. https://doi.org/10.1016/j.jaap.2018.11.026

González Martínez M, Dupont C, da Silva PD et al (2020) Understanding the torrefaction of woody and agricultural biomasses through their extracted macromolecular components. Part 1: experimental thermogravimetric solid mass loss. Energy 205:118067. https://doi.org/10.1016/j.energy.2020.118067

Harmsen PFH, Huijgen WJJ, Bermúdez López LM, Bakker RRC (2010) Literature review of physical and chemical pretreatment processes for lignocellulosic biomass. Energy Research Centre of the Netherlands, Petten

Hosoya T, Kawamoto H, Saka S (2007) Cellulose–hemicellulose and cellulose–lignin interactions in wood pyrolysis at gasification temperature. J Anal Appl Pyrol 80:118–125. https://doi.org/10.1016/j.jaap.2007.01.006

Hunt ML, Newman S, Scheraga HA, Flory PJ (1956) Dimensions and hydrodynamic properties of cellulose trinitrate molecules in dilute solution. J Phys Chem 60:1278–1290. https://doi.org/10.1021/j150543a031

Ioelovich M, Leykin A (2009) Accesibility and supermolecular structure of cellulose. Cellul Chem Technol 43:379–385

Katō K, Komorita H (1968) Pyrolysis of cellulose. Agric Biol Chem 32:21–26. https://doi.org/10.1080/00021369.1968.10859016

Kleen M, Gellerstedt G (1991) Characterization of chemical and mechanical pulps by pyrolysis—gas chromatography/mass spectrometry. J Anal Appl Pyrol 19:139–152. https://doi.org/10.1016/0165-2370(91)80040-F

Kolpak FJ, Blackwell J (1976) Determination of the structure of cellulose II. Macromolecules 9:273–278. https://doi.org/10.1021/ma60050a019

Krässig HA (1993) Cellulose, structure, accessibility and reactivity. Gordon and Breach Publishers, London

Leng E, Zhang Y, Peng Y et al (2018) In situ structural changes of crystalline and amorphous cellulose during slow pyrolysis at low temperatures. Fuel 216:313–321. https://doi.org/10.1016/j.fuel.2017.11.083

Luo W, Liao C (2004) Mechanism study of cellulose rapid pyrolysis. Ind Eng Chem Res 43:5605–5610. https://doi.org/10.1021/ie030774z

Mamleev V, Bourbigot S, Yvon J (2007) Kinetic analysis of the thermal decomposition of cellulose: the main step of mass loss. J Anal Appl Pyrol 80:151–165. https://doi.org/10.1016/j.jaap.2007.01.013

Nocquet T, Dupont C, Commandre J-M et al (2014) Volatile species release during torrefaction of biomass and its macromolecular constituents: part 2—modeling study. Energy 72:188–194. https://doi.org/10.1016/j.energy.2014.05.023

Nomura S, Kugo Y, Erata T (2020) 13C NMR and XRD studies on the enhancement of cellulose II crystallinity with low concentration NaOH post-treatments. Cellulose 27:3553–3563. https://doi.org/10.1007/s10570-020-03036-6

Pasangulapati V, Ramachandriya KD, Kumar A et al (2012) Effects of cellulose, hemicellulose and lignin on thermochemical conversion characteristics of the selected biomass. Biores Technol 114:663–669. https://doi.org/10.1016/j.biortech.2012.03.036

Pastorova I, Botto RE, Arisz PW, Boon JJ (1994) Cellulose char structure: a combined analytical Py-GC-MS, FTIR, and NMR study. Carbohyd Res 262:27–47. https://doi.org/10.1016/0008-6215(94)84003-2

Paulsen AD, Mettler MS, Dauenhauer PJ (2013) The role of sample dimension and temperature in cellulose pyrolysis. Energy Fuels 27:2126–2134. https://doi.org/10.1021/ef302117j

Pena CA, Soto A, King AWT, Rodríguez H (2019) Improved reactivity of cellulose via its crystallinity reduction by nondissolving pretreatment with an ionic liquid. ACS Sustainable Chem Eng 7:9164–9171. https://doi.org/10.1021/acssuschemeng.8b06357

Pisupati SV, Tchapda AH (2015) Chapter 15: thermochemical processing of biomass. In: Advances in bioprocess technology. Pogaku Ravindra, Switzerland

Prins MJ, Ptasinski KJ, Janssen FJJG (2006) Torrefaction of wood: part 1. Weight loss kinetics. J Anal Appl Pyrol 77:28–34. https://doi.org/10.1016/j.jaap.2006.01.002

Ramiah MV (1970) Thermogravimetric and differential thermal analysis of cellulose, hemicellulose, and lignin. J Appl Polym Sci 14:1323–1337. https://doi.org/10.1002/app.1970.070140518

Scheller HV, Ulvskov P (2010) Hemicelluloses. Annu Rev Plant Biol 61:263–289. https://doi.org/10.1146/annurev-arplant-042809-112315

Sczostak A (2010) Cotton Linters: An Alternative cellulosic raw material. Macromol Symp 294:151–151. https://doi.org/10.1002/masy.201050606

Shen DK, Gu S (2009) The mechanism for thermal decomposition of cellulose and its main products. Biores Technol 100:6496–6504. https://doi.org/10.1016/j.biortech.2009.06.095

Shen DK, Gu S, Bridgwater AV (2010) The thermal performance of the polysaccharides extracted from hardwood: cellulose and hemicellulose. Carbohyd Polym 82:39–45. https://doi.org/10.1016/j.carbpol.2010.04.018

Sixta H (2008) Pulp Purification. In: Handbook of pulp. Wiley, pp 933–965

Sjöström E (1993) Wood chemistry: fundamentals and applications, 2nd edn. Academic Press, Cambridge

European Commission (2014) State of play on the sustainability of solid and gaseous biomass used for electricity, heating and cooling in the EU

Stefanidis SD, Kalogiannis KG, Iliopoulou EF et al (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrol 105:143–150. https://doi.org/10.1016/j.jaap.2013.10.013

Vea EB, Romeo D, Thomsen M (2018) Biowaste valorisation in a future circular bioeconomy. Procedia CIRP 69:591–596. https://doi.org/10.1016/j.procir.2017.11.062

Wang S, Guo X, Liang T et al (2012) Mechanism research on cellulose pyrolysis by Py-GC/MS and subsequent density functional theory studies. Biores Technol 104:722–728. https://doi.org/10.1016/j.biortech.2011.10.078

Wang Z, McDonald AG, Westerhof RJM et al (2013) Effect of cellulose crystallinity on the formation of a liquid intermediate and on product distribution during pyrolysis. J Anal Appl Pyrol 100:56–66. https://doi.org/10.1016/j.jaap.2012.11.017

Williams PT, Besler S (1996) The influence of temperature and heating rate on the slow pyrolysis of biomass. Renew Energy 7:233–250. https://doi.org/10.1016/0960-1481(96)00006-7

Wooten JB, Seeman JI, Hajaligol MR (2004) Observation and characterization of cellulose pyrolysis intermediates by 13C CPMAS NMR. New Mech Model Energy Fuels 18:1–15. https://doi.org/10.1021/ef0300601

Yang H, Yan R, Chen H et al (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Acknowledgments

LGP2-Grenoble INP, CEA-LITEN and FCBA (Grenoble, France) are acknowledged for the support of this work. Céline Boachon and Véronique Nallet from RAPSODEE (Albi, France) are acknowledged for their support in TGA and XRD tests, respectively.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No 637020 − MOBILE FLIP.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

González Martínez, M., Marlin, N., Da Silva Perez, D. et al. Impact of cellulose properties on its behavior in torrefaction: commercial microcrystalline cellulose versus cotton linters and celluloses extracted from woody and agricultural biomass. Cellulose 28, 4761–4779 (2021). https://doi.org/10.1007/s10570-021-03812-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03812-y