Abstract

Microgel particles have recently emerged as an alternative route to emulsion stabilisation. Classed as soft colloidal particles, their ability to swell to differing degrees in certain solvents and to rearrange once attached to an interface makes them highly suitable for systems requiring long-term stabilization, such as formulations in the food, agricultural, cosmetic and pharmaceutical industries. Microgels made with biocompatible polymers such as proteins and polysaccharides in particular offer an environmental advantage and currently form a very active area of research. Cellulose, being a natural, biodegradable polymer, is an attractive ingredient for gels and microgels. However, its use as a functional material is often somewhat hindered by its insolubility in water and most other organic solvents. Furthermore, the surface activity of cellulose has proven difficult to harness and therefore its ability to act as an emulsion stabiliser has been almost exclusively applied to oil-in-water (O/W) emulsions, with very few reports on its water in oil (W/O) activity. This review aims to summarise some of the recent progress made in the microgel field including their ability to act as emulsion stabilisers, with a focus on cellulose microgels (CMGs). A brief overview of cellulose processing is also given, describing the dissolution and reprecipitation routes used to functionalise cellulose without covalent modification and the potential for cellulose particles and CMGs to act as O/W and W/O emulsion stabilisers.

Graphic abstract

Similar content being viewed by others

Microgel particles

Microgel particles (also referred to as “microgels”) are a class of soft colloidal species which are receiving increasing interest in the area of emulsion stabilisation (Dickinson 2015). Originally, the term microgel was introduced in 1949, with the word “micro” referring to the gel particle size and “gel” meaning the ability of the particles to swell in organic solvents (Baker 1949; Pelton and Hoare 2011). They are often now referred to as “colloidal dispersions of gel-like particles”, in which each individual microgel exists as a long-lived, kinetically stable particle (Dickinson 2015). Microgels are made up of a covalently, or strong physically cross-linked polymer network that must be dispersed in and swollen by the solvent. Their swelling ‘state’ is to an extent governed by the cross-link density, polymer/solvent compatibility and the presence (or not) of electrical charges (Pelton and Hoare 2011). In some cases, thermodynamic parameters such as temperature and pH can be used to control their degree of swelling (DOS) and such microgels are often referred to as “intelligent” or “responsive,” since they may shrink and expand in response to an external stimulus (Fig. 1a) (Schmitt and Ravaine 2013). Unlike surfactant micelles and other self-assembling molecular aggregates, they have a static composition. Although they may aggregate to different extents in ‘solution,’ the polymer network remains stable.

(a) Illustration of “intelligent” microgels experiencing contraction and swelling in response to an external stimulus (on and off, respectively); (b) different methods of microgel synthesis discussed in “Microgel Synthesis” section: (i) from monomer; (ii) from polymer; (iii) from macrogel

Altering the synthetic method and conditions of formation allows one to access to a broad range of gel particles with specific morphologies, sizes and microstructures, depending on the desired application. This is reflected by the huge potential impact of microgels in a wide variety of industries, such as food (Murray 2019a), cosmetics (Boularas et al. 2018), medicine (Agrawal and Agrawal 2018), and agriculture (Abd El-Rehim 2005).

Microgel synthesis

Three general approaches to microgel synthesis, as defined by Pelton et al., are given in Fig. 1b: (i) from monomer; (ii) from polymer; (iii) from macrogel (Pelton and Hoare 2011). It is important to distinguish between the terms “macrogel” and “microgel” at this stage: macrogel refers to a large, cross-linked structure or “a bowl of jelly,” whilst microgels are discrete particles (illustrated in Fig. 1b) (Thorne et al. 2011). The former routes (i and ii) are often referred to as “bottom-up” and the latter (iii) as “top-down” approaches (Torres et al. 2016). Different approaches may be preferred depending on the level of control required during synthesis and the nature of the polymeric material but, generally, a specific distribution of a functional groups, a narrow microgel size distribution and high colloidal stability are desired (Pelton and Hoare 2011; Agrawal and Agrawal 2018). Some examples of microgel synthesis will be briefly described below, however we refer readers to comprehensive reviews for a more detailed discussion of these aspects (Saunders and Vincent 1999; Ballauff and Lu 2007; Burey et al. 2008; Dendukuri and Doyle 2009; Pich and Richtering 2010).

“Bottom-up” approaches

Microgel “bottom-up” preparation methods can be further classified into those formed by homogeneous nucleation, emulsification and complex formation (Pelton and Hoare 2011), each of which will be briefly discussed below.

Homogeneous nucleation, emulsion polymerisation and precipitation polymerisation

Homogeneous nucleation describes the polymerisation of a monomer from a homogenous (or nearly homogeneous) solution, usually employing an initiator or cross-linking agent. Microgel size distribution can be controlled in many different ways depending on the monomer- and polymer-type, for example by changing the solvent composition, temperature and initiator concentration (Pelton 2000). Homogeneous nucleation is further characterised into two forms of emulsion polymerisation, (distinct from the emulsification method described in the sub-section below): conventional emulsion polymerization (EP) and surfactant-free emulsion polymerisation (SFEP). EP uses a surfactant, giving some control over microgel particle size through colloidal stabilisation (McPhee et al. 1993; Zhang et al. 2004). Generally, a higher concentration of surfactant leads to formation of microgel particles with a lower hydrodynamic radius and lower polydispersity (Saunders et al. 2009; Haider et al. 2014). SFEP has the advantage of mitigating surfactant contamination and has been used to fabricate temperature sensitive poly-N-isopropylacrylamide poly-(NIPAM) microgels since the 1980s (Pelton and Chibante 1986). Higher reaction temperatures are conventionally employed to produce smaller particle sizes (Dowding et al. 2000), however, generally the preparation of very small particles is complicated by the higher surface area to volume ratio and the limited number of charges available (Zhang et al. 2004). Finally, precipitation polymerisation has been used as a facile route to prepare poly-(NIPAM) (PNIPAM) microgels where the monomer is soluble but the polymer is not (Schmitt and Ravaine 2013). Growing polymer chains therefore collapse once a critical length is reached, leading to relatively monodisperse microgel particle sizes (Grinberg et al. 2020). This type of microgel preparation is referred to as “batch synthesis” and has been reported to yield heterogeneous core–shell microgel structures, since the cross-linking agent is consumed at a faster rate than the NIPAM monomers (Kyrey et al. 2019). Therefore, the formation of a highly dense core and a loose corona is commonly observed (Gavrilov et al. 2020).

Emulsification

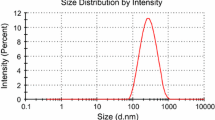

The emulsification strategy involves the formation of a W/O emulsion, made up of an oil/brine continuous phase and a monomer or polymer aqueous solution discontinuous phase, often referred to as a “pre-gel.” The monomer/polymer located within the droplets is subsequently gelled through a cross-linking or nucleation reaction (Dowding et al. 2000; Ikkai et al. 2005; Burey et al. 2008; MacHado et al. 2012). Preparation of polysaccharide microgels have been reported using the emulsification technique, using alginate dissolved in the aqueous phase and Ca2+ ions injected into the emulsion as bridging/gelling agent (MacHado et al. 2012). Alternatively, it has been demonstrated that mixing of two aqueous phases containing alginate and calcium ions under highly turbulent conditions produces microgel particles which are ca. 100 nm in size (Pravinata et al. 2016).

Gelation is most commonly induced by the application of heat or through a low-temperature redox reaction, depending on the type of polymer and monomer (Schosseler et al. 1991; Takata et al. 1999). On the other hand, photo-polymerisation is mostly used for continuous flow reactors (Gokmen and Du Prez 2012): for example, UV-induced gelation has been coupled with microchannel emulsification to produce microgel particles of low size polydispersity (Ikkai et al. 2005). Microfluidics have also been applied to alginate microgel particles, where the size of droplets displayed an indirect dependence on the concentration of reagents (aqueous alginate and CaCl2) and flow rate, which in turn affected the time for an alginate-structured solution to form and the time for microgel particles to form, respectively (Amici et al. 2008).

Complex formation

In complex formation, two oppositely charged polyelectrolytes are mixed to form microgel suspensions or coacervate particles (Azarikia et al. 2015). One of the species must be present in excess to avoid charge neutralisation (Pelton and Hoare 2011) as evidenced in the phase diagram of carboxymethyl cellulose ± polyvinylamine (PVAm) (anionic and cationic, respectively), where mixtures containing an excess of one polyelectrolyte give stable colloidal complexes whilst a stoichiometric mixture yields a macrogel or macroscopic precipitates (Feng et al. 2007). Although complexation is a very simple method for microgel preparation, it can be challenging to prepare monodisperse particles. Monodispersity has been improved by first synthesising a microgel based on one polymer, then adding the second polyelectrolyte later. For example, anionic PNIPAM microgels, whose composition and size distribution can be carefully controlled, have been subsequently complexed with cationic PVAm to give a stable, colloidal suspension of monodisperse spheres (Wen et al. 2012). Gelatin-OSA starch hydrogel particles have also been fabricated by simply mixing aqueous solutions and acidifying the mixture to pH 5, where it was shown again that the cation:anion ratio has an effect on particle size and polydispersity. In this instance, adjusting the pH varied the electrostatic interactions between the two polyelectrolytes and therefore provided a means of controlling the strength of complex formation (Wu and McClements 2015).

“Top-down” approaches

“Top-down” processing to produce microgels simply involves formation of a macrogel followed by mechanical comminution to produce particles of micron size, or less. Generally, this type of approach yields highly polydisperse microgel dispersions with particles of irregular morphologies and as a result, somewhat fewer reports are available in the literature (Pelton and Hoare 2011). However, sizes < 90 nm have been achieved via mechanical shearing of heat-set gels (Sarkar et al. 2016). Furthermore, the top-down approach may offer some level of control over the microgel particle properties by fine-tuning the macrogel structure, since at least some characteristics of the microgel are expected to be inherited from the initial macrogel, e.g. the internal cross-link density in the microgel (Murray 2019a). Thus specific “gel recipes” can be designed in order to produce macrogels with a certain desired microscopic structure: for example, more brittle, highly porous heterogenous gels break down more easily to give microgels with a narrower and smaller size distribution compared to gels which are elastic and homogenous (Saavedra Isusi et al. 2019). Microgel size dispersity is also affected by the concentration (and type) of salt, for gel systems where inorganic ions act the bridging agents (Matsumiya and Murray 2016). The effect of pH is particularly important for protein-based microgels, where significant particle aggregation can occur at their isoelectric point (Jiao et al. 2018; Zhang et al. 2020). Polymer properties such as the distribution of functional groups, molecular weight and branching versus linearity will also have an influence on gel properties (Fraeye et al. 2009). For example, a decrease in degree of polymerisation (DP) has been correlated with the formation of more brittle gels (Fraeye et al. 2010) which are more easily broken down to form microgel particles.

The type of stress (e.g. compressive, tensile or shear) and its magnitude applied during top-down processing also affects how a gel breaks down (Saavedra Isusi et al. 2019). Processing may deform and alter the gel network structure, often leading to a more open structure in the microgel particles (Murray 2019a). It has been reported that pectin-based microgels are more easily broken down when conditions favouring extensional forces were employed, for example laminar flow in a rotor–stator device, since the tensile strength of the gels was lower than the compressive strength (Saavedra Isusi et al. 2019). Smaller microgels are usually produced, up to a limit, by higher energy processing methods: for example, a mixture of blending and high-pressure homogenisation (HPH) was shown to produce smaller soybean-protein-isolate microgel particles compared to blending and ultrasonication or blending alone (Matsumiya and Murray 2016). Similarly, peanut-protein-isolate microgel particles prepared using a rotor–stator homogeniser followed by HPH gave an average diameter range of 200–300 nm (Jiao et al. 2018). However, to our knowledge, few attempts have been made to relate directly the properties manifested in the microgel particles to the initial macrogel from which they were formed.

Cellulose microgels (CMGs)

Gels made up of cellulose can be broken down using mechanical force such as HPH, producing CMGs via a top-down approach (Fig. 2). As discussed previously (“Top-Down Approaches” section), like other polymer microgels the nature and morphology is highly dependent on the properties of the macrogel, which in turn is affected by the amount of cellulose dissolved and the method and conditions of coagulation (applied shear force, temperature, anti-solvent, etc.) (Li et al. 2009; Fan et al. 2017; Rajeev and Basavaraj 2019).

Cellulose-based gels can be fabricated via dissolution of cellulose followed by re-coagulation of the polymer molecules so that they spontaneously form a network structure, or by chemical reactions that form cross-links between polymer molecules. In the former approach, the regions of reassociation of the cellulose molecules via H-bonds form the cross-links, or junction zones of the gel (Kadokawa et al. 2008; Takada and Kadokawa 2015) whilst in the latter, active groups on derivatized cellulose interact to from the cross-links (Kang et al. 2016). Many covalently cross-linked cellulose gels have been fabricated for various applications, with derivatization of the cellulose commonly being the first step in their synthesis (Lu et al. 2000; Sannino et al. 2005; Demitri et al. 2008; Butun et al. 2011). However, we focus herein on reviewing physically cross-linked cellulose gels, in the interest of functionalising cellulose in its natural state, which can be formed via H-bonding, hydrophobic, ionic and host–guest interactions (Shang et al. 2008; Kang et al. 2016).

Preparation of cellulose particles and cellulose microgel particles

Solubilisation of cellulose

Acid hydrolysis

Cellulose is found naturally in wood and cotton fibres, along with lignin and hemicellulose (see Fig. 3), which are broken down into their components using acid hydrolysis to yield cellulose crystals and monomeric sugars (Rånby 1949; Zhao et al. 2007). The treated cellulose retains the same crystalline structure as the original material (Mukherjee et al. 1952) and various forms of crystalline cellulose can be obtained depending on the source, treatment temperatures and times (Habibi et al. 2010). Acid hydrolysis is a well-established method for the production of cellulose nanoparticles (CNPs) or cellulose nanocrystals (CNCs), which have impressive mechanical properties (Zhao et al. 2007), as well as microcrystalline cellulose (MCC), which has now been used for over 50 years in the pharmaceutical industry (Battista and Smith 1962; Thoorens et al. 2014). Since acid hydrolysis generally yields fragments of cellulose, it might be argued that this is not true solubilisation; in the following we concentrate on solvent systems that result in 'true', complete, molecular solubilisation.

Cellulose solvents

Crystalline cellulose obtained via acid hydrolysis, however, is often still insoluble in water and most other organic solvents and therefore further modification is often required through dissolution in a particular solvent system. A summary of various cellulose solvents and their discovery is given in the timeline below (Fig. 4). Aqueous alkali/urea solvent systems have been developed (Zhou and Zhang 2000; Cai and Zhang 2005; Qi et al. 2011), in which the urea is proposed to aid dissolution by interacting with the hydrophobic part of cellulose through its nitrogen atoms (Xiong et al. 2014; Medronho et al. 2015). Other additives such as thiourea and polyethylene glycol have shown success in dissolving cellulose when combined with an alkali and are believed to play a similar role to urea (Cai and Zhang 2005; Yan and Gao 2008; Xiong et al. 2014; Kang et al. 2016).

N-Methylmorpholine-N-oxide (NMMO) has also been widely used as a non-derivatizing solvent for cellulose since it was first patented in 1969 (Johnson 1969). A mixture of NMMO and water is used, (50–60% and 20–30% respectively), with the remaining optimum amount of cellulose depending on the cellulose source (Gagnaire et al. 1980; Rosenau et al. 2001). Finally, we focus in more detail on ionic liquids (ILs) as cellulose solvents.

Ionic liquids

“Liquified quaternary ammonium salts” were first patented at the start of the 20th century, providing a route for cellulose dissolution and derivatization (Graenacher 1934). However, a molten solution of N-alkylpyridinium chloride was used and because the melting point was greater than 100 °C, the process was deemed to be “of little practical value” and no further interest was reported for some time. Almost 70 years later, salts made up of a large, organic cation and a variety of anions, now described as ILs, were shown to be liquid over a wide temperature range (Huddleston et al. 2001). In 2002, Swatloski et al. demonstrated that imidazolium-based ILs with melting points < 100 °C, often now referred to as “room temperature ionic liquids”, were suitable solvents for cellulose (Swatloski et al. 2002). Since then, a number of ILs have been successfully applied for cellulose dissolution: 1-butyl-3-methylimidazolium chloride (BmimCl), 1-allyl-3-methylimidazolium chloride (AmimCl) and 1-ethyl-3-methylimidazolium acetate (EmimAc) (Zhang et al. 2017), as well as ammonium-, morpholium- and cholinium-based cations paired with carboxylate (formate, acetate) and chloride anions (Zhang et al. 2005; Ignatyev et al. 2010; Chen et al. 2011; Tang et al. 2012; Meenatchi et al. 2017). ILs are promising due to their high thermal and chemical stability, ease of handling, non-flammability and low vapour pressure, amongst other things (Zhang et al. 2017). They are also often described as “green” solvents due to their recyclability and mild operating temperatures.

As with NMMO systems, microwave assistance can be applied during IL-cellulose dissolution which results in highly efficient heating. However, in general, dissolution temperatures of < 120 °C are used in order to prevent thermal degradation of cellulose to increase the quality of the resulting material (Swatloski et al. 2002; Zhu et al. 2006; Wang et al. 2012; Olsson and Westman 2013). Whilst most conventional ILs have an onset temperature (Ton) of over 170 °C in their pure form (and therefore won’t decompose until they reach very high temperatures), the addition of cellulose decreases Ton and notably increases the degree of heat release and therefore the potential for cellulose degradation. Consequently, slower dissolution times at lower temperatures may be more suitable for industrial scaleup (Wendler et al. 2012). Milder conditions have also been shown to limit unwanted by-product formation, maintaining the ability of the IL to act as a non-derivatizing solvent (Clough et al. 2015).

Different conditions, co-solvents and dissolution times have been employed to obtain different cellulose microstructures, as well as the design of so-called “task specific” ILs (TSILs), fabricated for highly specific applications (Gericke et al. 2012). TSILs have a functional group tethered covalently to the anion or cation (or both), which can be a reagent or a catalyst in a chemical reaction or simply act as part of the reaction medium. A comprehensive review was published in 2011 on the synthesis and role of TSILs in organic reactions (Yue et al. 2011), which focuses on ILs and their use as non-derivatizing cellulose solvents (Table 1).

Deep eutectic solvents (DESs)

A more recently developed class of “advanced ionic liquids” or DESs may offer a relatively cheap and more practical route for cellulose dissolution compared to conventional ILs, which are generally much more air-sensitive due to their hygroscopicity (Brinchi et al. 2013; Van Osch et al. 2017; Satlewal et al. 2018; Verma et al. 2019). DESs were first reported in 2001 (Abbott et al. 2001) and are comprised of a hydrogen bond donor and a halide salt or hydrogen bond acceptor: for example urea, carboxylic acids, polyols and metal chlorides (Zhang et al. 2017). The resulting mixtures have a much lower melting temperature compared to their anion and cation components, due to the formation of hydrogen bonding between the two (Van Osch et al. 2017). Numerous reports of DESs displaying good cellulose dissolving capacity at impressive rates can be found in the literature (Wang et al. 2006; Zhang et al. 2012; Li et al. 2017; Ling et al. 2019; Sirviö 2019). Ma et al. used a hydrated choline chloride/oxalic acid dihydrate DES to prepare CNCs, reporting that their solvent dissolving capability is further improved by the addition of water. It should also be mentioned that such solvents clearly comply with the green chemistry principles and therefore have high potential for scale-up (Ma et al. 2019). However, currently DESs display inferior cellulose dissolution capacities and rates compared to conventional ILs (Chen et al. 2019) and further work is required to fully understand their thermal stabilities and toxicities.

ILs from renewable feedstocks

Finally, many ILs prepared from renewable feedstocks have been reported (Halder et al. 2019), further improving their case as “green,” environmentally friendly solvents. ILs made up of cholinium- or choline-based cations, choline being a water-soluble nutrient, have received attention due to their biodegradability and biocompatibility (Abbott et al. 2006; Bisht and Venkatesu 2017; Depoorter et al. 2019). Choline-chloride + oxalic acid and choline chloride + urea have both been shown to be effective pre-treatments for biomass (Satlewal et al. 2018), whilst choline butyrate was used to dissolve MCC and produce a cellulose aerogel (Xu et al. 2018). Furthermore, amino-acids which are cost-effective and natural have been used as IL precursors (Jiang et al. 2018). A mini-review on amino-acid ILs provides a useful summary on how the structure relates to the properties of ILs fabricated from raw materials (Ossowicz et al. 2019). Alternative bio-based ILs fabricated from proteins, (Bao et al. 2003) polysaccharides, (Handy et al. 2003) lignin, (Socha et al. 2014) and terpenes (Nageshwar et al. 2009) have also been reported, offering the potential for a “closed-loop” biorefinery (Hulsbosch et al. 2016).

A comprehensive overview of ILs and the temperatures, conditions and dissolution times required to solubilise different concentrations of cellulose has been compiled by Van Osch et al., which also provides a comparison of the particle sizes of the cellulose regenerated from different sources (Van Osch et al. 2017). Given the impressive cellulose dissolution capacities that have been achieved (up to 25 wt.%), the mild conditions required (relative to conventional methods) and the potential for recycling the solvent, ILs offer a convenient route for cellulose processing and whole biomass treatment (Hossain et al. 2019). However, it must be highlighted that plenty of understanding is still required regarding their recyclability on an industrial scale and any potential toxicity.

Cellulose reprecipitation

Cellulose particles

Once cellulose has been dissolved, it is generally reprecipitated, or coagulated, by addition of an “anti-solvent”, which competes with the cellulose for bonding to the solvent and initiates phase separation. This method of regeneration can be used for the NaOH-based aqueous systems (Qi et al. 2011), NMMO (Ilyin et al. 2018) and ILs/DESs described above (Hedlund et al. 2019; Sirviö 2019), but in this review we focus herein on cellulose processed from ILs.

A good anti-solvent forms stronger H-bonds with the IL than cellulose, resulting in the reaggregation of cellulose chains via H-bonds. The use of different anti-solvents during the regeneration of cellulose from ILs allows access to a wide range of morphologies (Brinchi et al. 2013). Most commonly water, ethanol or acetone are added as anti-solvent, each yielding cellulose with differing levels of crystalline structure. The concentration of cellulose in solution and the physical conditions of coagulation also affect the properties of the precipitated cellulose. It has been widely observed that the use of water as a coagulant produces cellulose II (from feedstocks high in cellulose I, e.g. MCC), whilst addition of alcohols leads to a larger decrease in crystallinity and an increase in amorphous cellulose (Xu et al. 2008; Lan et al. 2011; Östlund et al. 2013; Sun et al. 2015; Zhang et al. 2018). For example, cellulose dissolved in EmimAc was regenerated separately in water and ethanol, giving degrees of crystallinity of 43.33% and 13.45% respectively (Tan et al. 2019), whilst similar observations were made for CNPs regenerated in water, methanol, ethanol and n-propanol (43.9%, 26.9%, 20.3% and 12.5% respectively) (Fan et al. 2018). In all of these examples, the coagulated material consisted of cellulose particles.

Different flow conditions (e.g. extrusion, stirring) during coagulation have also been employed and introduce an additional level of tunability. Thus if water is added to a stirred solution of MCC dissolved in 1-butyl-3-methylimidazolium hydrogen sulfate (BmimHSO4) and the mixture then sonicated, washed and centrifuged, highly crystalline nanocellulose crystals can be obtained (Man et al. 2011). Cellulose films with an impressive tensile strength of 138 MPa have been fabricated by Zhang et al. using AmimCl or EmimAc with regeneration in water (Zhang et al. 2005), whilst rods and fibres can be prepared via direct extrusion into water (Swatloski et al. 2002). Cellulose membranes have also been produced by pouring cellulose/EmimAc solutions onto a glass plate followed by immersion in a coagulation bath of water/alcohol at room temperature (Fryczkowska et al. 2018).

Cellulose gels

Cellulose gels can also be fabricated from cellulose solutions using anti-solvents through the reformation of hydrophobic interactions and H-bonds (Isobe et al. 2012), if the coagulation medium is not stirred during regeneration. As with cellulose particles, the type of medium dictates the properties of the gel obtained, such as “thickness”, transparency and tensile strength (Saito et al. 2003). However, the regeneration mechanism differs to that of cellulose particles and therefore varying the coagulation conditions will have a different effect on the gel properties. For example, cellulose gels and CNPs regenerated using the same four anti-solvents displayed the opposite trend in crystallinity. As described above (Fan et al. 2018), the crystallinity of the CNPs decreases as the polarity of the anti-solvent decreases, but crystallinity decreased in the following order for cellulose gels: n-propanol > ethanol > methanol > water (Fan et al. 2017). Such a different result is believed to be governed by the diffusion coefficient (D) of the various anti-solvent molecules. Regeneration in water without stirring results in the water molecules, that have the highest D (27.39 ± 1.68 × 10−6 cm2 s−1), precipitating the cellulose at a much faster rate than n-propanol (D = 2.03 ± 0.47 × 10−6 cm2 s−1), which therefore “fixes” the cellulose chains before they can realign to form crystalline structures. On the other hand, regeneration with high enough stirring generates cellulose particles in which the anti-solvent H-bonding properties dictate the crystallinity of the regenerated cellulose. Thus two competitive mechanisms can take place during regeneration (Fan et al. 2018). It is also important to mention that cellulose gels will only form when the concentration of dissolved cellulose is sufficiently high, in order for the reprecipitating material to be able to form a network structure.

In general, cellulose gels fabricated via the dissolution-regeneration route are aqueous-based, made up of cellulose networks trapping large amounts of water in the pores and are therefore usually termed cellulose hydrogels. The coagulation step usually involves water as the anti-solvent or some other water-compatible polar solvent such as an alcohol, the latter generally sequentially exchanged for water in the final gel washing step, in order to ensure complete removal of the original cellulose solvent (Östlund et al. 2013). The type of anti-solvent and/or anti-solvent sequence affects both the gel porosity and crystallinity (Östlund et al. 2013). Cellulose concentration and the cellulose DP also have an effect on the strength of the coagulated hydrogel (de Oliveira and Glasser 1996), whilst the amount of anti-solvent used in the coagulation bath can be varied to alter the hydrogel properties (Östlund et al. 2009). A summary of cellulose hydrogels and their formation from a wide variety of solvents can be found in several reviews (Sannino et al. 2009; Chang and Zhang 2011; Kabir et al. 2018; Fu et al. 2019).

In order for CMGs to be produced via a top-down approach, the cellulose gel must be brittle enough to be broken down into small particle sizes, however the cellulose concentration must be sufficiently high to form a gel during regeneration. Therefore, controlling the gel cross-link density is important, whilst the coagulation medium and conditions can also be altered in order to produce a gel most suitable for breaking down to a CMG-dispersion. It is important to understand the form of the cellulose in its dissolved state in order to manipulate the properties of the cellulose gel in its precipitated state.

Microgels as stabilisers for emulsions

Emulsion systems

Conventionally, low molecular weight surfactants (LMWS) and high molecular weight surfactants (HMWS), such as proteins, have been used as stabilisers of emulsions. The stabiliser lowers the interfacial tension and provides steric and also electrostatic (if the stabiliser is charged) colloidal stability to the system, preventing coalescence and thereby separation of the two liquids (Costa et al. 2019a). LMWS generally consist of a hydrophilic “head” and a hydrophobic “tail,” classified by their hydrophilic–lipophilic balance value, which indicates the type of emulsion that the stabiliser will preferentially form (O/W or W/O, for high and low values, respectively) (Bastida-Rodríguez 2013). Proteins, as biopolymeric HMWS possessing much more complex structures, cannot be classified in this way, but can generally provide excellent stabilisation of O/W emulsions. Over the last 20 years, the use of solid particles, or “Pickering” particles as emulsion stabilisers has received great interest. Pickering stabilisation has been studied for at least 100 years and occurs naturally in many types of emulsion. More recently, however, particle stabilisation has received much renewed interest (Hunter et al. 2008; Rousseau 2013; Murray 2019b).

Even more recently, microgels have emerged as a separate class of stabiliser, as an alternative to LMWS, HMWS or solid particles. Microgels can help form highly stable emulsions due to the formation of thick, long-lasting viscoelastic layers at the interface (Schmitt and Ravaine 2013; Dickinson 2015). In comparison to LMWS, HMWS and particles, microgel interfacial behaviour is somewhat more complicated to predict, since the stabiliser combines the properties of both a polymer and particle (Dickinson 2015). Microgels can undergo structural rearrangement at the interface but are also considered to be irreversibly adsorbed, due to the high binding energy per particle. Characterised as “soft” colloidal particles, microgels can deform when adsorbed to an interface, changing their size and shape depending on their surrounding environment. Microgel emulsion systems are sometimes referred to as “Mickering emulsions,” reflecting their similarities and differences to Pickering emulsions (Gong et al. 2014).

Size, morphology and packing of microgels interfaces

Most microgels display interesting interfacial properties, regardless of whether they are amphiphilic in nature (Plamper and Richtering 2017). Emulsifying activity can be imparted via weakly surface-active polymers through microgel formation and/or “trapping” of certain structures through gelation. For example, in proteins a trapped, unfolded state may result in increased exposure of hydrophobic/hydrophilic groups and a higher surface activity (Ishii et al. 2018; Murray 2019a; Zembyla et al. 2020). Microgels change morphology upon adsorption from bulk solution to an interface (Geisel et al. 2015) and can stretch out in order to reduce the interfacial energy. FreSCa cryo-SEM images revealed that PNIPAM-based microgels flatten and almost double in size when adsorbed at the interface, compared to in bulk water (Geisel et al. 2012). Furthermore, in the absence of strong interfacial effects, microgels may adopt asymmetric shapes due to the difference in microgel solubility in the two liquid phases, swelling and collapsing for respective high and low affinities (Rey et al. 2020). This is sometimes referred to as a “double-lens” configuration, due to the different curvatures in water and oil (Fig. 5a) (Tay and Bresme 2006; Geisel et al. 2012).

(a) Illustration of a microgel particle at an oil–water interface, showing different curvatures and degrees of swelling in each liquid phase (so-called “double lens” configuration). ho and hw give the height protrusions in oil and water, respectively; (b) microgel-stabilised oil droplets in water with ‘stiff’ microgels giving a homogenous protecting layer (left) and core–shell microgels giving a heterogeneous protecting layer and exhibiting bridging flocculation (right)

Microgel properties such as size and cross-link density influence how they behave at an interface. For example, it was shown that small microgels may pack tightly and uniformly in a homogenous manner, whilst larger microgels may pack more sparsely giving a combination of dense cores and thin shells at the interface. Heterogeneous surface-packing can lead to a more rigid oil–water interface in emulsions, encouraging bridging flocculation (Fig. 5b) (Schmitt and Ravaine 2013; Destribats et al. 2014a). Cross-link density affects the swelling capacity and deformability of a microgel, or in other words how “soft” it is (Rey et al. 2020). In general, microgels in a bulk suspension can be described by a “core–shell” model with a dense cross-linked interior and a soft exterior of dangling chains, and therefore do not have a uniform cross-link density throughout their microstructures. For core–shell microgels, a “fried-egg” morphology has been observed at the interface (Pinaud et al. 2014) describing the highly deformed corona (outer region) which flattens and spreads over the interface and the less deformable core (inner region), which is comparatively rigid (Rey et al. 2020).

The equilibrium size and shape that microgels adopt at an oil–water interface is consequently related to the balance of solvation between the two liquid phases, microgel interfacial activity and microgel elasticity (Geisel et al. 2012). The ratio between the radius (R) and the elastocapillary length (L) of the microgel particles can be a useful prediction for the degree of deformation that will occur at an interface, where the lower the value of R/L, the greater the extent of deformation. In other words, for small microgels (low R) with less cross-links, deformability is high and particles may even be considered as a liquid at the interface whilst when R is large relative to L, the particles can be considered as effectively rigid and may adopt more spherical shapes, similar to microgels in bulk solution (Rey et al. 2020). It is also important to note that other factors such as pH and temperature may affect the form that microgels adopt at an interface, depending on the nature of the polymer (Destribats et al. 2014b).

Stability of microgel-stabilized emulsions

The ability of microgels to spread, interpenetrate and/or cross-link at the interface, plus their relatively large thickness at the interface, leads to the formation of very stable emulsions. The polymers within the gel network have been shown to stretch and rearrange over time, increasing the area of the interface that the microgel covers, reducing the interfacial tension (energy) (Geisel et al. 2014). S. Chattopadhyay et al. showed that physically crossed-linked nanogels could even form ultrathin films when adsorbed at solid interfaces, due to “unfolding” which may be a result of stresses induced on adsorption (Chattopadhyay et al. 2016). Furthermore, highly deformable microgels may spontaneously absorb and simultaneously compress at the interface if an excess of microgel is present in the continuous phase, increasing the surface coverage over time (Pinaud et al. 2014). Full coverage of the interface, however, is not always necessary, as seen for Pickering emulsions: if a rigid network is formed at the interface, a sufficiently high steric barrier will prevent droplet coalescence for long time periods (Destribats et al. 2014b).

Aqueous versus non-aqueous microgels

Most of the literature on microgel particles as emulsion stabilisers focusses on aqueous microgels, which are largely composed of water (Murray 2019a) and therefore have a higher affinity for the more hydrophilic phase at an oil–water interface. Aqueous microgels tend to swell in the water phase and partially collapse in the oil phase, yielding a contact angle which favours O/W emulsion-type stabilization (Geisel et al. 2012; Rey et al. 2020). Some microgels have been shown to stabilise W/O emulsions where the oil is more polar, for example 1-undecanol (Tsuji and Kawaguchi 2008) and fatty alcohols (Destribats et al. 2011), whilst hydrophobic particles have been incorporated into microgels in order to increase their affinity for the hydrophobic phase (Watanabe et al. 2019). Non-aqueous microgels which swell in organic solvents have also been fabricated, either by freeze-drying, rotary evaporation or washing at the end of microgel synthesis followed by transfer into organic solvents, or by directly carrying out the polymerisation in a non-aqueous solvent (Bonham et al. 2014).

Controlling emulsion type

Predicting the type of emulsion that will form with a particular microgel stabiliser is more complicated compared to surfactant and solid particle systems. Microgels can be described as having an adjustable surface activity and as a result cannot be defined by a distinct contact angle (Murray 2019a). In cases where severe deformation occurs at an interface, there is discussion of two effective contact angles developing: one in the water phase and one in the oil phase (Geisel et al. 2012). However, there is no sharp boundary between the solvent trapped in the microgel network and the surrounding solvent, since exchange between the two environments alters the microgel size and shape (Plamper and Richtering 2017). The size, shape, deformability and therefore the behaviour of microgels at an interface must be controlled at the earlier stages of synthesis. Hydrophobic nanoparticles have been incorporated into synthetic microgels in order to control the emulsion type: high amounts for W/O, low amounts for O/W (Watanabe et al. 2019).

It has been reported, however, that the water/oil ratio, microgel concentration and applied shear rate can all have an effect on the emulsion type and stability for PNIPAM-co-methacrylic acid microgel stabilisers. Lower shear rates favoured the formation of O/W emulsions, since a higher amount of energy is required to split water into droplets and form W/O emulsions. Higher microgel concentrations also increased the viscosity and prevented dispersion of the water phase, but W/O emulsions were formed if sufficiently high energy emulsification was employed in order to overcome viscosity effects, by generating a strong shear flow (Brugger et al. 2008). Both W/O and O/W emulsions could be formed using poly-(4-vinylpyridine)-silica nanocomposite microgels, with the polarity of the oil phase and the particle purity determining the emulsions type (Fujii et al. 2006).

In summary, further work is required to fully understand the interfacial properties and behaviour of microgels, however promising studies suggest that they may be suitable for both W/O and O/W emulsification and therefore possess a tuneable surface-activity (Brugger et al. 2008). It has been shown that the same microgel particles can act as stabilisers for both W/O and O/W systems, where the emulsion type is controlled through water–oil ratio, emulsification conditions and microgel concentration (Fujii et al. 2006; Brugger et al. 2008). The ability to control the stability and type of emulsion formed is important in many processes such as oil extraction and recovery, heterogeneous and multiphase catalysis (Wang and Wang 2016), food processing and drug delivery (Xie et al. 2012, 2020). Using a single, “multi-purpose” stabiliser to fabricate emulsions with switchable behaviour could be hugely advantageous in many fields.

Regenerated cellulose as an emulsion stabiliser

Cellulose is being increasingly considered for its amphiphilic properties and potential oil–water surface activity (Lindman et al. 2010), with structural studies revealing that cellulose possesses hydrophobic character due to the presence of C–H groups in axial positions, whilst the glucose ring with O–H groups positioned in the equatorial plane are clearly hydrophilic (Fig. 6a, b, respectively) (Kalashnikova et al. 2012; Rein et al. 2012). However, these surfaces are often hidden in native cellulose due to its highly repeating polymer conformation, which allows close packing of individual chains and the development of many inter- and intra-molecular hydrogen bonds (H-bonds), as well as hydrophobic and van der Waals interactions (Wang et al. 2016). As a result, cellulose clumps and sediments in both water and oil, as well as in many other common solvents, making it unsuitable as a stabiliser. In order to expose the amphiphilic character of cellulose and harness its surface activity, hydrogen bonds and hydrophobic interactions must be prevented from re-forming during reprecipitation. This may be achieved by changing the morphology and characteristics of the cellulose particles via regeneration or more specifically, by forming a cellulose gel. Both cellulose particle-stabilisers and CMG-stabilisers are reviewed in the following section.

Cellulose particles in emulsion stabilisation

Cellulose particles obtained from dissolution-regeneration methods can have both crystalline and amorphous character, depending on the source and coagulation conditions, and both types have been used to stabilise emulsions (Costa et al. 2019a). Jia et al. reported that highly amorphous cellulose particles (with up to 87% recovery of the original cellulose biomass) were obtained when coagulated with water from a phosphoric acid solution followed by centrifugation (Jia et al. 2013). The regenerated amorphous cellulose displayed much better O/W emulsion stabilising capacity compared to the original MCC, via a combination of Pickering and network stabilization (Jia et al. 2015). Interestingly, the cellulose suspensions in water were stable over a range of pH values, suggesting that the stability of amorphous cellulose in aqueous media is not due to electrostatic stabilisation. Similarly, it was shown that in situ regeneration of cellulose from a phosphoric acid solution with dispersed oil droplets led to the formation of highly stable O/W emulsions, whilst non-regenerated cellulose still in its dissolved state was less effective (Costa et al. 2019b).

CNCs have also been extensively employed as Pickering stabilisers for O/W emulsions (Kalashnikova et al. 2011, 2012; Li et al. 2018a; Bertsch et al. 2019; Mackie et al. 2019). Charged groups are formed on cellulose chains when it is hydrolysed using sulfuric or phosphoric acid, giving the resultant CNCs high colloidal stability (Cherhal et al. 2016). It was shown that sulfated (charged) CNCs assembled to form a monolayer at the oil–water interface, whilst de-sulfated (neutral) CNCs formed a thicker, but more porous layer due to the deposition of aggregates on the surface (Cherhal et al. 2016). MCC particles have also been successfully employed as O/W stabilisers and are reported to form thick layers around oil droplets (Oza and Frank 1986, 1989). Increasing the concentration of stabiliser leads to the formation of MCC particle networks in the aqueous phase, which increases the viscosity and “traps” the dispersed phase, enhancing stability (Kargar et al. 2012).

Cellulose particles are better wetted by water than by oil and therefore have been less investigated as W/O emulsion stabilisers (Rein et al. 2012). This may be due to the fact that the hydrophobic surfaces of cellulose are the first to interact during coagulation: it has been shown that the glucopyranoside rings stack firstly through hydrophobic interactions and that this initial interaction has a large influence on the final structure of the regenerated material (Miyamoto et al. 2009; El Seoud et al. 2019). In these cases, both the solvent and the coagulant were aqueous and therefore it is unfavourable for the hydrophobic glucopyranoside ring planes to be exposed to the polar media (Isobe et al. 2012). Preventing the reformation of hydrophobic interactions during coagulation and favouring the exposure of the hydrophobic (200) edge (Cellulose Iβ) (French 2014) may be possible using a less-polar coagulant or through cellulose gelation, in order to make the coagulated cellulose more suitable as a W/O stabiliser. Added surfactants and other amphiphilic molecules have also been found to reduce the reformation of hydrophobic interactions during aggregation (Medronho et al. 2015).

Cellulose microgels in emulsion stabilisation

As previously mentioned, (“Cellulose gels” section), generally highly polar anti-solvents are employed in cellulose gelation from a solution, generating a cellulose hydrogel. Therefore, the obtained CMGs are typically hydrophilic and swollen in water. If the microgel is at all surface active, this will therefore favour its stabilisation of O/W emulsions. Cellulose hydrogels coagulated from aqueous-NaOH solutions displayed good O/W emulsifying ability when broken down, with the fraction of oil effecting the size of emulsion droplets as well as droplet aggregate size (Alfassi et al. 2019). A cellulose hydrogel formed via coagulation from EmimAc was also used to form O/W emulsions, which displayed excellent stability with no flocculation or coalescence occurring within a year (Rein et al. 2012). The cellulose is described to be acting as a coating or “encapsulating cellulose shell,” as opposed to a CMG Mickering-type stabiliser. Cellulose/IL solutions were shown to form stable O/W emulsions stabilised by CMGs, however the IL was included within the emulsion to allow stabilization with a higher concentration of cellulose. Removal of the IL led to much larger size distributions of microgel aqueous dispersions at lower cellulose concentrations (Napso et al. 2016).

W/O emulsions have apparently been stabilised by amorphous cellulose gels regenerated via two different approaches: (i) by formation of a cellulose hydrogel on addition of water to a cellulose/IL solution; (ii) by addition of oil and water directly into the cellulose/IL solution followed by dialysis, to completely remove the IL (Rein et al. 2012). Using the second approach, it was reasoned that regeneration of cellulose in the presence of a water–oil interface would affect the conformation of the polymer molecules and therefore the way in which they would reassemble. Whilst the influence of a water–oil interface during cellulose regeneration has been investigated for O/W emulsions (Costa et al. 2019b), it appears this aspect has yet to be addressed for W/O emulsions. Rein et al. also suggested that any W/O emulsions formed were much less stable than the equivalent O/W emulsions (Rein et al. 2012), so that much further work remains to optimise the conditions for W/O emulsion stabilisation. However, recent success in fabricating “hydrophobic” cellulose has been reported including CMG-emulsifiers for oil-based systems (Lefroy et al. 2020) as well as an interesting method for cellulose oleogelation, in which aqueous cellulose fibre dispersions were initially formed through shear-activation and then shear-mixed with either palm or olive oil (Phoon and Henry 2020). The resulting “jammed” W/O emulsion was then freeze-dried to form an oleogel, which contained a close-packed oil/cellulose continuous phase. This study provides a helpful reminder of the amphiphilic properties that cellulose chains possess and the potential for the hydrophobic surface to be exfoliated (Table 2).

Final remarks

The emergence of microgel particles as colloidal stabilisers has led to exciting possibilities in the areas of food, cosmetics, pharmaceuticals and more. Different preparation methods, conditions and polymers have been used to produce microgels with a range of interesting properties, including so-called “intelligent” microgels, which respond to a stimulus and display switchable behaviour. However, most of the literature to date concerns synthetic polymer microgels with covalent cross-links, whilst microgels based on natural materials, such as biopolymers, with physical cross-links are still rather novel. Furthermore, there remains much to be understood in terms of the interfacial behaviour of microgels, including their morphology, DOS and structural changes over time at an interface.

Microgelation of cellulose has more recently been investigated as a method of harnessing its amphiphilicity and improving its dispersibility in water and oil, therefore making it a suitable emulsion stabiliser. CMGs are obtained via a top-down approach, through breaking down cellulose-based gels obtained via a dissolution-regeneration method. Most efforts thus far have concentrated on the ability of CMGs to stabilise O/W emulsions, with little focus on the fabrication of non-aqueous CMGs for W/O emulsions. However, we highlight the versatility of the dissolution-reprecipitation approach and the potential for tuning the CMG properties through this regeneration method. We conclude by emphasising the fact that simple, “green” methods can be employed to fabricate CMGs and this opens up new possibilities for the functionalisation of cellulose.

References

Abbott AP, Capper G, Davies DL et al (2001) Preparation of novel, moisture-stable, lewis-acidic ionic liquids containing quaternary ammonium salts with functional side chains. Chem Commun 1:2010–2011. https://doi.org/10.1039/b106357j

Abbott AP, Bell TJ, Handa S, Stoddart B (2006) Cationic functionalisation of cellulose using a choline based ionic liquid analogue. Green Chem 8:784–786. https://doi.org/10.1039/b605258d

Abd El-Rehim HA (2005) Swelling of radiation crosslinked acrylamide-based microgels and their potential applications. Radiat Phys Chem 74:111–117. https://doi.org/10.1016/j.radphyschem.2005.01.002

Agrawal G, Agrawal R (2018) Functional microgels: recent advances in their biomedical applications. Small 14:1–18. https://doi.org/10.1002/smll.201801724

Alfassi G, Rein DM, Cohen Y (2019) Cellulose emulsions and their hydrolysis. J Chem Technol Biotechnol 94:178–184. https://doi.org/10.1002/jctb.5760

Amici E, Tetradis-Meris G, de Torres CP, Jousse F (2008) Alginate gelation in microfluidic channels. Food Hydrocoll 22:97–104. https://doi.org/10.1016/j.foodhyd.2007.01.022

Azarikia F, Wu B-C, Abbasi S, DJ MC (2015) Stabilization of biopolymer microgels formed by electrostatic complexation: influence of enzyme (laccase) cross-linking on pH, thermal, and mechanical stability. Food Res Int 78:18–26. https://doi.org/10.1016/j.foodres.2015.11.013

Bai L, Huan S, Xiang W, Rojas OJ (2018) Pickering emulsions by combining cellulose nanofibrils and nanocrystals: phase behavior and depletion stabilization. Green Chem 20:1571–1582. https://doi.org/10.1039/c8gc00134k

Baker WO (1949) Microgel: a new macromolecule. Ind Eng Chem 41:511–520. https://doi.org/10.1021/ie50471a016

Ballauff M, Lu Y (2007) “Smart” nanoparticles: preparation, characterization and applications. Polymer (Guildf) 48:1815–1823. https://doi.org/10.1016/j.polymer.2007.02.004

Bao W, Wang Z, Li Y (2003) Synthesis of chiral ionic liquids from natural amino acids. J Organomet Chem 68:591–593. https://doi.org/10.1021/jo020503i

Bastida-Rodríguez J (2013) The food additive polyglycerol polyricinoleate (E-476): structure, applications, and production methods. ISRN Chem Eng 2013:1–21. https://doi.org/10.1155/2013/124767

Battista OA, Smith PA (1962) Microcrystalline cellulose. Ind Eng Chem 54:20–29

Bertsch P, Arcari M, Geue T et al (2019) Designing cellulose nanofibrils for stabilization of fluid interfaces. Biomacromolecules 20:4574–4580. https://doi.org/10.1021/acs.biomac.9b01384

Bisht M, Venkatesu P (2017) Influence of cholinium-based ionic liquids on the structural stability and activity of α-chymotrypsin. New J Chem 41:13902–13911. https://doi.org/10.1039/c7nj03023a

Bonham JA, Faers MA, Van Duijneveldt JS (2014) Non-aqueous microgel particles: synthesis, properties and applications. Soft Matter 10:9384–9398. https://doi.org/10.1039/c4sm01834f

Boularas M, Radji S, Gombart E et al (2018) Functional film by trigger-free self-assembly of adhesive soft microgels at skin temperature. Mater Des 147:19–27. https://doi.org/10.1016/j.matdes.2018.02.073

Brinchi L, Cotana F, Fortunati E, Kenny JM (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohydr Polym 94:154–169

Brugger B, Rosen BA, Richtering W (2008) Microgels as stimuli-responsive stabilizers for emulsions. Langmuir 24:12202–12208. https://doi.org/10.1021/la8015854

Buffiere J, Balogh-Michels Z, Borrega M et al (2017) The chemical-free production of nanocelluloses from microcrystalline cellulose and their use as Pickering emulsion stabilizer. Carbohydr Polym 178:48–56. https://doi.org/10.1016/j.carbpol.2017.09.028

Burey P, Bhandari BR, Howes T, Gidley MJ (2008) Hydrocolloid gel particles: formation, characterization, and application. Crit Rev Food Sci Nutr 48:361–377. https://doi.org/10.1080/10408390701347801

Butun S, Ince FG, Erdugan H, Sahiner N (2011) One-step fabrication of biocompatible carboxymethyl cellulose polymeric particles for drug delivery systems. Carbohydr Polym 86:636–643. https://doi.org/10.1016/j.carbpol.2011.05.001

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539–548. https://doi.org/10.1002/mabi.200400222

Chang C, Zhang L (2011) Cellulose-based hydrogels: present status and application prospects. Carbohydr Polym 84:40–53. https://doi.org/10.1016/j.carbpol.2010.12.023

Chattopadhyay S, Heine E, Mourran A et al (2016) Waterborne physically crosslinked antimicrobial nanogels. Polym Chem 7:364–369. https://doi.org/10.1039/c5py01566a

Chen Z, Liu S, Li Z et al (2011) Dialkoxy functionalized quaternary ammonium ionic liquids as potential electrolytes and cellulose solvents. New J Chem 35:1596–1606. https://doi.org/10.1039/c1nj20062c

Chen YL, Zhang X, You TT, Xu F (2019) Deep eutectic solvents (DESs) for cellulose dissolution: a mini-review. Cellulose 26:205–213. https://doi.org/10.1007/s10570-018-2130-7

Cherhal F, Cousin F, Capron I (2016) Structural description of the interface of Pickering emulsions stabilized by cellulose nanocrystals. Biomacromolecules 17:496–502. https://doi.org/10.1021/acs.biomac.5b01413

Clough MT, Geyer K, Hunt PA et al (2015) Ionic liquids: not always innocent solvents for cellulose. Green Chem 17:231–243. https://doi.org/10.1039/c4gc01955e

Costa C, Medronho B, Filipe A et al (2019a) Emulsion formation and stabilization by biomolecules: the leading role of cellulose. Polymers (Basel) 11:1–18. https://doi.org/10.3390/polym11101570

Costa C, Mira I, Benjamins JW et al (2019b) Interfacial activity and emulsion stabilization of dissolved cellulose. J Mol Liq 292:111325. https://doi.org/10.1016/j.molliq.2019.111325

Cross CF, Bevan ET, Beadle C (1893) Thiokohlensäureester der cellulose. J Chem Inf Model 26:1090–1097. https://doi.org/10.1002/cber.189302601230

de Oliveira W, Glasser WG (1996) Hydrogels from polysaccharides. I. Cellulose beads for chromatographic support. J Appl Polym Sci 60:63–73. https://doi.org/10.1002/(sici)1097-4628(19960404)60:1<63::aid-app8>3.3.co;2-4

Demitri C, Del Sole R, Scalera F et al (2008) Novel superabsorbent cellulose-based hydrogels crosslinked with citric acid. J Appl Polym Sci 110:2453–2460. https://doi.org/10.1002/app

Dendukuri D, Doyle PS (2009) The synthesis and assembly of polymeric microparticles using microfluidics. Adv Mater 21:4071–4086. https://doi.org/10.1002/adma.200803386

Depoorter J, Mourlevat A, Sudre G et al (2019) Fully biosourced materials from combination of choline chloride-based deep eutectic solvents and guar gum. ACS Sustain Chem Eng 7:16747–16756. https://doi.org/10.1021/acssuschemeng.9b04228

Destribats M, Lapeyre V, Sellier E et al (2011) Water-in-oil emulsions stabilized by water-dispersible poly(N-isopropylacrylamide) microgels: understanding anti-Finkle behavior. Langmuir 27:14096–14107. https://doi.org/10.1021/la203476h

Destribats M, Eyharts M, Lapeyre V et al (2014a) Impact of pNIPAM microgel size on its ability to stabilize Pickering emulsions. Langmuir 30:1768–1777. https://doi.org/10.1021/la4044396

Destribats M, Rouvet M, Gehin-Delval C et al (2014b) Emulsions stabilised by whey protein microgel particles: towards food-grade Pickering emulsions. Soft Matter 10:6941–6954. https://doi.org/10.1039/c4sm00179f

Dickinson E (2015) Microgels—An alternative colloidal ingredient for stabilization of food emulsions. Trends Food Sci Technol 43:178–188. https://doi.org/10.1016/j.tifs.2015.02.006

Dowding PJ, Vincent B, Williams E (2000) Preparation and swelling properties of poly(NIPAM) “minigel” particles prepared by inverse suspension polymerization. J Colloid Interface Sci 221:268–272. https://doi.org/10.1006/jcis.1999.6593

El Seoud OA, Kostag M, Jedvert K, Malek NI (2019) Cellulose in ionic liquids and alkaline solutions: advances in the mechanisms of biopolymer dissolution and regeneration. Polymers (Basel) 11:1–28. https://doi.org/10.3390/polym11121917

Esparza Y, Ngo TD, Boluk Y (2020) Preparation of powdered oil particles by spray drying of cellulose nanocrystals stabilized Pickering hempseed oil emulsions. Colloids Surf A 598:124823. https://doi.org/10.1016/j.colsurfa.2020.124823

Fan Z, Chen J, Guo W et al (2017) Crystallinity of regenerated cellulose from [Bmim]Cl dependent on the hydrogen bond acidity/basicity of anti-solvents. RSC Adv 7:41004–41010. https://doi.org/10.1039/c7ra08178b

Fan Z, Chen J, Guo W et al (2018) Anti-solvents tuning cellulose nanoparticles through two competitive regeneration routes. Cellulose 25:4513–4523. https://doi.org/10.1007/s10570-018-1897-x

Feng X, Pelton R, Leduc M, Champ S (2007) Colloidal complexes from poly(vinyl amine) and carboxymethyl cellulose mixtures. Langmuir 23:2970–2976. https://doi.org/10.1021/la0628064

Fraeye I, Doungla E, Duvetter T et al (2009) Influence of intrinsic and extrinsic factors on rheology of pectin-calcium gels. Food Hydrocoll 23:2069–2077. https://doi.org/10.1016/j.foodhyd.2009.03.022

Fraeye I, Colle I, Vandevenne E et al (2010) Influence of pectin structure on texture of pectin-calcium gels. Innov Food Sci Emerg Technol 11:401–409. https://doi.org/10.1016/j.ifset.2009.08.015

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Fryczkowska B, Kowalska M, Binias D et al (2018) Properties and structure of cellulosic membranes obtained from solutions in ionic liquids coagulated in primary alcohols. Autex Res J 18:232–242. https://doi.org/10.1515/aut-2017-0036

Fu LH, Qi C, Ma MG, Wan P (2019) Multifunctional cellulose-based hydrogels for biomedical applications. J Mater Chem B 7:1541–1562. https://doi.org/10.1039/c8tb02331j

Fujii S, Armes SP, Binks BP, Murakami R (2006) Stimulus-responsive particulate emulsifiers based on lightly cross-linked poly(4-vinylpyridine)—silica nanocomposite microgels. Langmuir 22:6818–6825. https://doi.org/10.1021/la060349l

Gagnaire D, Mancier D, Vincendon M (1980) Cellulose organic solutions: a nuclear magnetic resonance investigation. J Polym Sci Polym Chem Ed 18:13–25. https://doi.org/10.1002/pol.1980.170180102

Gavrilov AA, Rudyak VY, Chertovich AV (2020) Computer simulation of the core-shell microgels synthesis via precipitation polymerization. J Colloid Interface Sci 574:393–398. https://doi.org/10.1016/j.jcis.2020.04.064

Geisel K, Isa L, Richtering W (2012) Unraveling the 3D localization and deformation of responsive microgels at oil/water interfaces: a step forward in understanding soft emulsion stabilizers. Langmuir 28:15770–15776. https://doi.org/10.1021/la302974j

Geisel K, Richtering W, Isa L (2014) Highly ordered 2D microgel arrays: compression versus self-assembly. Soft Matter 10:7968–7976. https://doi.org/10.1039/c4sm01166j

Geisel K, Henzler K, Guttmann P, Richtering W (2015) New insight into microgel-stabilized emulsions using transmission X-ray microscopy: nonuniform deformation and arrangement of microgels at liquid interfaces. Langmuir 31:83–89. https://doi.org/10.1021/la503959n

Gericke M, Fardim P, Heinze T (2012) Ionic liquids—promising but challenging solvents for homogeneous derivatization of cellulose. Molecules 17:7458–7502

Gokmen MT, Du Prez FE (2012) Porous polymer particles—a comprehensive guide to synthesis, characterization, functionalization and applications. Prog Polym Sci 37:365–405. https://doi.org/10.1016/j.progpolymsci.2011.07.006

Gong X, Hua L, Wei J, Ngai T (2014) Tuning the particle-surface interactions in aqueous solutions by soft microgel particles. Langmuir 30:13182–13190. https://doi.org/10.1021/la503573u

Graenacher C (1934) Cellulose solution. U.S. Patent 1943176

Grinberg VY, Burova TV, Grinberg NV et al (2020) Functionalized thermoresponsive microgels based on N-isopropylacrylamide: energetics and mechanism of phase transitions. Eur Polym J 133:109722. https://doi.org/10.1016/j.eurpolymj.2020.109722

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500. https://doi.org/10.1021/cr900339w

Haider I, Siddiq M, Shah SM, Ur Rehman S (2014) Synthesis and characterization of multi-responsive poly (NIPAm-co-AAc) microgels. IOP Conf Ser Mater Sci Eng 60:012046. https://doi.org/10.1088/1757-899X/60/1/012046

Halder P, Kundu S, Patel S et al (2019) Progress on the pre-treatment of lignocellulosic biomass employing ionic liquids. Renew Sust Energ Rev 105:268–292

Handy ST, Okello M, Dickenson G (2003) Solvents from biorenewable sources: ionic liquids based on fructose. Org Lett 5:2513–2515. https://doi.org/10.1021/ol034778b

Hedlund A, Köhnke T, Hagman J et al (2019) Microstructures of cellulose coagulated in water and alcohols from 1-ethyl-3-methylimidazolium acetate: contrasting coagulation mechanisms. Cellulose 26:1545–1563. https://doi.org/10.1007/s10570-018-2168-6

Hossain MM, Rawal A, Aldous L (2019) Aprotic vs protic ionic liquids for lignocellulosic biomass pretreatment: anion effects, enzymatic hydrolysis, solid-state NMR, distillation, and recycle. ACS Sustain Chem Eng 7:11928–11936. https://doi.org/10.1021/acssuschemeng.8b05987

Huddleston JG, Visser AE, Reichert WM et al (2001) Characterization and comparison of hydrophilic and hydrophobic room temperature ionic liquids incorporating the imidazolium cation. Green Chem 3:156–164. https://doi.org/10.1039/b103275p

Hulsbosch J, De Vos DE, Binnemans K, Ameloot R (2016) Biobased ionic liquids: solvents for a green processing industry? ACS Sustain Chem Eng 4:2917–2931. https://doi.org/10.1021/acssuschemeng.6b00553

Hunter TN, Pugh RJ, Franks GV, Jameson GJ (2008) The role of particles in stabilising foams and emulsions. Adv Colloid Interf Sci 137:57–81. https://doi.org/10.1016/j.cis.2007.07.007

Ignatyev IA, Mertens PGN, Van Doorslaer C et al (2010) Cellulose conversion into alkylglycosides in the ionic liquid 1-butyl-3-methylimidazolium chloride. Green Chem 12:1790–1795. https://doi.org/10.1039/c0gc00192a

Ikkai F, Iwamoto S, Adachi E, Nakajima M (2005) New method of producing mono-sized polymer gel particles using microchannel emulsification and UV irradiation. Colloid Polym Sci 283:1149–1153. https://doi.org/10.1007/s00396-005-1271-z

Ilyin SO, Makarova VV, Anokhina TS et al (2018) Diffusion and phase separation at the morphology formation of cellulose membranes by regeneration from N-methylmorpholine N-oxide solutions. Cellulose 25:2515–2530. https://doi.org/10.1007/s10570-018-1756-9

Ishii T, Matsumiya K, Aoshima M, Matsumura Y (2018) Microgelation imparts emulsifying ability to surface-inactive polysaccharides—bottom-up vs top-down approaches. npj Sci Food 2:1–12. https://doi.org/10.1038/s41538-018-0023-7

Isobe N, Kimura S, Wada M, Kuga S (2012) Mechanism of cellulose gelation from aqueous alkali-urea solution. Carbohydr Polym 89:1298–1300. https://doi.org/10.1016/j.carbpol.2012.03.023

Jia X, Chen Y, Shi C et al (2013) Preparation and characterization of cellulose regenerated from phosphoric acid. J Agric Food Chem 61:12405–12414. https://doi.org/10.1021/jf4042358

Jia X, Xu R, Shen W et al (2015) Stabilizing oil-in-water emulsion with amorphous cellulose. Food Hydrocoll 43:275–282. https://doi.org/10.1016/j.foodhyd.2014.05.024

Jiang C, Li W, Nian J et al (2018) Tribological evaluation of environmentally friendly ionic liquids derived from renewable biomaterials. Friction 6:208–218. https://doi.org/10.1007/s40544-017-0170-x

Jiao B, Shi A, Wang Q, Binks BP (2018) High-internal-phase Pickering emulsions stabilized solely by peanut-protein-isolate microgel particles with multiple potential applications. Angew Chem Int Ed 57:9274–9278. https://doi.org/10.1002/anie.201801350

Johnson DL (1969) United States Patent Office. J Am Soc Nav Eng 39:620–622

Kabir SMF, Sikdar PP, Haque B et al (2018) Cellulose-based hydrogel materials: chemistry, properties and their prospective applications. Prog Biomater 7:153–174. https://doi.org/10.1007/s40204-018-0095-0

Kadokawa J-I, Murakami MA, Kaneko Y (2008) A facile preparation of gel materials from a solution of cellulose in ionic liquid. Carbohydr Res 343:769–772. https://doi.org/10.1016/j.carres.2008.01.017

Kalashnikova I, Bizot H, Cathala B, Capron I (2011) New Pickering emulsions stabilized by bacterial cellulose nanocrystals. Langmuir 27:7471–7479. https://doi.org/10.1021/la200971f

Kalashnikova I, Bizot H, Cathala B, Capron I (2012) Modulation of cellulose nanocrystals amphiphilic properties to stabilize oil/water interface. Biomacromolecules 13:267–275. https://doi.org/10.1021/bm201599j

Kang H, Liu R, Huang Y (2016) Cellulose-Based Gels. Macromol Chem Phys 217:1322–1334. https://doi.org/10.1002/macp.201500493

Kargar M, Fayazmanesh K, Alavi M et al (2012) Investigation into the potential ability of Pickering emulsions (food-grade particles) to enhance the oxidative stability of oil-in-water emulsions. J Colloid Interface Sci 366:209–215. https://doi.org/10.1016/j.jcis.2011.09.073

Kyrey T, Witte J, Feoktystov A et al (2019) Inner structure and dynamics of microgels with low and medium crosslinker content prepared: via surfactant-free precipitation polymerization and continuous monomer feeding approach. Soft Matter 15:6536–6546. https://doi.org/10.1039/c9sm01161g

Lan W, Liu CF, Yue FX et al (2011) Ultrasound-assisted dissolution of cellulose in ionic liquid. Carbohydr Polym 86:672–677. https://doi.org/10.1016/j.carbpol.2011.05.013

Lefroy KS, Murray BS, Ries ME, Curwen TD (2020) A natural, cellulose-based microgel for water-in-oil emulsions. Food Hydrocoll 106408. https://doi.org/10.1016j.foodhyd.2020.106408

Li L, Lin Z, Yang X et al (2009) A novel cellulose hydrogel prepared from its ionic liquid solution. Chin Sci Bull 54:1622–1625. https://doi.org/10.1007/s11434-009-0207-2

Li P, Sirviö JA, Haapala A, Liimatainen H (2017) Cellulose nanofibrils from nonderivatizing urea-based deep eutectic solvent pretreatments. ACS Appl Mater Interfaces 9:2846–2855. https://doi.org/10.1021/acsami.6b13625

Li X, Li J, Gong J et al (2018a) Cellulose nanocrystals (CNCs) with different crystalline allomorph for oil in water Pickering emulsions. Carbohydr Polym 183:303–310. https://doi.org/10.1016/j.carbpol.2017.12.085

Li Z, Wu H, Yang M et al (2018b) Stability mechanism of O/W Pickering emulsions stabilized with regenerated cellulose. Carbohydr Polym 181:224–233. https://doi.org/10.1016/j.carbpol.2017.10.080

Li X, Li J, Kuang Y et al (2020) Stabilization of Pickering emulsions with cellulose nanofibers derived from oil palm fruit bunch. Cellulose 27:839–851. https://doi.org/10.1007/s10570-019-02803-4

Liebert T (2010) Cellulose solvents—remarkable history, bright future. In: Liebert TF, Heinze TJ, Edgar KJ (eds) Cellulose solvents: for analysis, shaping and chemical modification. American Chemical Society, pp 3–54

Lindman B, Karlström G, Stigsson L (2010) On the mechanism of dissolution of cellulose. J Mol Liq 156:76–81. https://doi.org/10.1016/j.molliq.2010.04.016

Ling Z, Edwards JV, Guo Z et al (2019) Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: micro and nano scale. Cellulose 26:861–876. https://doi.org/10.1007/s10570-018-2092-9

Liu Z, Sun X, Hao M et al (2015) Preparation and characterization of regenerated cellulose from ionic liquid using different methods. Carbohydr Polym 117:54–62. https://doi.org/10.1016/j.carbpol.2014.09.053

Lovell CS, Walker A, Damion RA et al (2010) Influence of cellulose on ion diffusivity in 1-ethyl-3-methyl-imidazolium acetate cellulose solutions. Biomacromolecules 11:2927–2935. https://doi.org/10.1021/bm1006807

Lu X, Hu Z, Gao J (2000) Synthesis and light scattering study of hydroxypropyl cellulose microgels. Macromolecules 33:8698–8702. https://doi.org/10.1021/ma000776k

Lu X, Zhang H, Li Y, Huang Q (2018) Fabrication of milled cellulose particles-stabilized Pickering emulsions. Food Hydrocoll 77:427–435. https://doi.org/10.1016/j.foodhyd.2017.10.019

Ma Y, Xia Q, Liu Y et al (2019) Production of nanocellulose using hydrated deep eutectic solvent combined with ultrasonic treatment. ACS Omega 4:8539–8547. https://doi.org/10.1021/acsomega.9b00519

MacHado AHE, Lundberg D, Ribeiro AJ et al (2012) Preparation of calcium alginate nanoparticles using water-in-oil (W/O) nanoemulsions. Langmuir 28:4131–4141. https://doi.org/10.1021/la204944j

Mackie A, Gourcy S, Rigby N et al (2019) The fate of cellulose nanocrystal stabilised emulsions after simulated gastrointestinal digestion and exposure to intestinal mucosa. Nanoscale 11:2991–2998. https://doi.org/10.1039/c8nr05860a

Man Z, Muhammad N, Sarwono A et al (2011) Preparation of cellulose nanocrystals using an ionic liquid. J Polym Environ 19:726–731. https://doi.org/10.1007/s10924-011-0323-3

Matsumiya K, Murray BS (2016) Soybean protein isolate gel particles as foaming and emulsifying agents. Food Hydrocoll 60:206–215. https://doi.org/10.1016/j.foodhyd.2016.03.028

McPhee W, Tam KC, Pelton R (1993) Poly(N-isopropylacrylamide) latices prepared with sodium dodecyl sulfate. J Colloid Interface Sci 156:24–30

Medronho B, Duarte H, Alves L et al (2015) Cellulose dissolution and regeneration: systems and interactions probing cellulose amphiphilicity. Nord Pulp Pap Res J 30:1–3

Meenatchi B, Renuga V, Manikandan A (2017) Cellulose dissolution and regeneration using various imidazolium based protic ionic liquids. J Mol Liq 238:582–588. https://doi.org/10.1016/j.molliq.2016.05.008

Miyamoto H, Umemura M, Aoyagi T et al (2009) Structural reorganization of molecular sheets derived from cellulose II by molecular dynamics simulations. Carbohydr Res 344:1085–1094. https://doi.org/10.1016/j.carres.2009.03.014

Mukherjee SM, Sikorski J, Woods HJ (1952) Electron-microscopy of degraded cellulose fibres. J Text Inst Trans 43:T563–T564

Murray BS (2019a) Microgels at fluid-fluid interfaces for food and drinks. Adv Colloid Interf Sci 271:101990. https://doi.org/10.1016/j.cis.2019.101990

Murray BS (2019b) Pickering emulsions for food and drinks. Curr Opin Food Sci 27:57–63. https://doi.org/10.1016/j.cofs.2019.05.004

Nageshwar D, Rao DM, Acharyulu PVR (2009) Terpenes to ionic liquids: synthesis and characterization of citronellal-based chiral ionic liquids. Synth Commun 39:3357–3368. https://doi.org/10.1080/00397910902768226

Napso S, Rein DM, Khalfin R et al (2016) Cellulose gel dispersion: from pure hydrogel suspensions to encapsulated oil-in-water emulsions. Colloids Surf B 137:70–76. https://doi.org/10.1016/j.colsurfb.2015.05.039

Napso S, Rein DM, Fu Z et al (2018) Structural analysis of cellulose-coated oil-in-water emulsions fabricated from molecular solution. Langmuir 34:8857–8865. https://doi.org/10.1021/acs.langmuir.8b01325

Ni Y, Li J, Fan L (2020) Production of nanocellulose with different length from ginkgo seed shells and applications for oil in water Pickering emulsions. Int J Biol Macromol 149:617–626. https://doi.org/10.1016/j.ijbiomac.2020.01.263

Olsson C, Westman G (2013) Direct dissolution of cellulose: background, means and applications. In: Cellulose—fundamental aspects. IntechOpen. https://doi.org/10.5772/52144

Ossowicz P, Klebeko J, Roman B et al (2019) The relationship between the structure and properties of amino acid ionic liquids. Molecules 24:3252. https://doi.org/10.3390/molecules24183252

Östlund Å, Lundberg D, Nordstierna L et al (2009) Dissolution and gelation of cellulose in TBAF/DMSO solutions: the roles of fluoride ions and water. Biomacromolecules 10:2401–2407. https://doi.org/10.1021/bm900667q

Östlund Å, Idström A, Olsson C et al (2013) Modification of crystallinity and pore size distribution in coagulated cellulose films. Cellulose 20:1657–1667. https://doi.org/10.1007/s10570-013-9982-7

Oza KP, Frank SG (1986) Microcrystalline cellulose stabilized emulsions. J Dispers Sci Technol 7:543–561. https://doi.org/10.1080/01932698608943478

Oza KP, Frank SG (1989) Multiple emulsions stabilized by colloidal microcrystalline cellulose. J Dispers Sci Technol 10:163–185. https://doi.org/10.1080/01932698908943168

Pelton R (2000) Temperature-sensitive aqueous microgels. Adv Colloid Interface Sci 85:1–33

Pelton RH, Chibante P (1986) Preparation of aqueous latices with N-isopropylacrylamide. Colloids Surf A 20:247–256. https://doi.org/10.1016/0166-6622(86)80274-8

Pelton R, Hoare T (2011) Microgels and their synthesis: an introduction. In: Fernandez-Nieves A, Wyss HM, Mattsson J, Weitz DA (eds) Microgel suspensions. Wiley-VCH, Weinheim, pp 1–32

Phoon PY, Henry CJ (2020) Fibre-based oleogels: effect of the structure of insoluble fibre on its physical properties. Food Funct 11:1349–1361. https://doi.org/10.1039/c9fo02431j

Pich A, Richtering W (2010) Microgels by precipitation polymerization: synthesis, characterization, and functionalization. In: Pich A, Richtering W (eds) Chemical design of responsive microgels, 234th edn. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 1–37

Pinaud F, Geisel K, Massé P et al (2014) Adsorption of microgels at an oil-water interface: correlation between packing and 2D elasticity. Soft Matter 10:6963–6974. https://doi.org/10.1039/c4sm00562g

Plamper FA, Richtering W (2017) Functional microgels and microgel systems. Acc Chem Res 50:131–140. https://doi.org/10.1021/acs.accounts.6b00544

Pravinata L, Akhtar M, Bentley PJ et al (2016) Preparation of alginate microgels in a simple one step process via the Leeds Jet Homogenizer. Food Hydrocoll 61:77–84. https://doi.org/10.1016/j.foodhyd.2016.04.025

Qi H, Yang Q, Zhang L et al (2011) The dissolution of cellulose in NaOH-based aqueous system by two-step process. Cellulose 18:237–245. https://doi.org/10.1007/s10570-010-9477-8

Rajeev A, Basavaraj MG (2019) Colloidal particle-induced microstructural transition in cellulose/ionic liquid/water mixtures. Langmuir 35:12428–12438. https://doi.org/10.1021/acs.langmuir.9b01457

Rajeev A, Deshpande AP, Basavaraj MG (2018) Rheology and microstructure of concentrated microcrystalline cellulose (MCC)/1-allyl-3-methylimidazolium chloride (AmimCl)/water mixtures. Soft Matter 14:7615–7624. https://doi.org/10.1039/c8sm01448e

Rånby BG (1949) Aqueous colloidal solutions of cellulose micelles. Acta Chem Scand 3:649–650

Rein DM, Khalfin R, Cohen Y (2012) Cellulose as a novel amphiphilic coating for oil-in-water and water-in-oil dispersions. J Colloid Interface Sci 386:456–463. https://doi.org/10.1016/j.jcis.2012.07.053

Rey M, Fernandez-Rodriguez MA, Karg M et al (2020) Poly-N-isopropylacrylamide nanogels and microgels at fluid interfaces. Acc Chem Res 53:414. https://doi.org/10.1021/acs.accounts.9b00528