Abstract

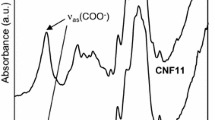

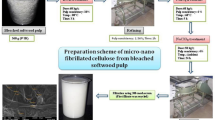

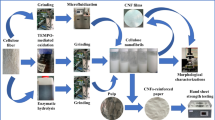

The papermaking industry competitiveness has been exponentially increasing. In order to improve the paper properties, processes have to be optimized in such a way that new horizons, such as the synthesis of new materials, are in sight. The present paper deals with the production of cellulose nanofibrils (CNF) from bleached Eucalyptus kraft pulp by carboxymethylation and TEMPO-mediated oxidation, followed by high pressure homogenisation. The main purpose of the work was to increase the filler retention and mechanical strength of printing and writing paper grades. Mineral fillers are of utmost importance in papermaking and therefore a thorough study of the CNF influence in filler-containing handsheets is mandatory. In this sense, flocculation studies revealed the extraordinary ability of CNF to flocculate calcium carbonate, which was translated into high filler retentions in the paper matrix. Moreover, the interactions between bleached pulp, CNF, mineral fillers and common paper additives, such as cationic starch, alkenyl succinic anhydride and cationic polyacrylamide, were investigated. The results allowed concluding that, depending on the materials applied, CNF are able to promote an adequate bonding between fibres and filler aggregates, reducing the requirements for the additives. The addition of carboxymethylated or TEMPO-oxidised CNF to the fibrous matrix led to handsheets with better structural, mechanical and optical properties than those of reference handsheets (without CNF and with additives).

Graphical Abstract

Similar content being viewed by others

References

Abdul Khalil HPS, Davoudpour Y, Nazrul Islam M, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohydr Polym 99:649–665

Ahola S, Österberg M, Laine J (2008) Cellulose nanofibrils–adsorption with poly(amideamine) epichlorohydrin studied by QCM-D and application as a paper strength additive. Cellulose 15:303–314

Ämmälä A, Liimatainen H, Burmeister C, Niinimäki J (2013) Effect of tempo and periodate-chlorite oxidized nanofibrils on ground calcium carbonate flocculation and retention in sheet forming and on the physical properties of sheets. Cellulose 20:2451–2460

Aulin C, Gällstedt M, Lindström T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Brodin F, Eriksen Ø (2016) Preparation of individualised lignocellulose microfibrils based on thermomechanical pulp and their effect on paper properties. Nordic Pulp Paper Res. J 30:443–451

Brodin FW, Lund K, Brelid H, Theliander H (2012) Reinforced absorbent material: a cellulosic composite of TEMPO-oxidized MFC and CTMP fibres. Cellulose 19:1413–1423

Brodin FW, Gregersen ØW, Syverud K (2014) Cellulose nanofibrils: challenges and possibilities as a paper additive or coating material—a review. Nordic Pulp Paper Res J. 29:156–166

Chen Y, Wan J, Dong X, Ma Y (2013) Fiber properties of eucalyptus kraft pulp with different carboxyl group contents. Cellulose 20:2839–2846

Delgado-Aguilar M, González I, Tarrés Q, Alcalà M, Pèlach MÀ (2015) Approaching a low-cost production of cellulose nanofibers for papermaking applications. BioResources 10:5345–5355

Eyholzer Ch, Bordeanu N, Lopez-Suevos F, Rentsch D, Zimmermann T, Oksman K (2010) Preparation and characterization of water-redispersible nanofibrillated cellulose in powder form. Cellulose 17:19–30

Gandini A, Pasquini D (2012) Review: the impact of cellulose fibre surface modification on some physico-chemical properties of the ensuing papers. Ind Crops Prod 35:15–21

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7:5167–5180

He M, Cho BU, Won JM (2016) Effect of precipitated calcium carbonate–cellulose nanofibrils composite filler on paper properties. Carbohydr Polym 136:820–825

Henriksson M, Berglund LA, Isaksson P, Lindstro T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromol 9:1579–1585

Huang X, Sun Z, Qian X, Li J, Shen J (2014) Correction to “starch/sodium oleate/calcium chloride modified filler for papermaking: impact of filler modification process conditions and retention systems as evaluated by filler bondability factor in combination with other parameters. Ind Eng Chem Res 53(20):8665

Isogai A, Saito T, Fukuzimi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Kekäläinen K, Liimatainen H, Illikainen M, Maloney TC, Niinimäki J (2014) The role of hornification in the disintegration behaviour of TEMPO-oxidized bleached hardwood fibres in a high-shear homogenizer. Cellulose 21:1163–1174

Kobayashi Y, Gondo T, Yamamoto M, Saito T, Isogai A (2016) Fundamental properties of handsheets containing TEMPO-oxidized pulp in various weight ratios. Nord Pulp Pap Res J 31:248–254

Kontturi E, Mitikka-Eklund M, Vuorinen T (2008) Strength enhancement of a fiber network by carboxymethyl cellulose during oxygen delignification of kraft pulp. BioResources 3:34–45

Korhonen MHJ, Laine J (2014) Flocculation and retention of fillers with nanocelluloses. Nordic Pulp Paper Res J 29:119–128

Laine J, Lindström T, Nordmark GG, Risinger G (2002) Studies on topochemical modification of cellulosic fibres. Part 2. The effect of its carboxymethyl cellulose attachment on fibre swelling and paper strength. Nordic Pulp Paper Res J 17:50–56

Lindström T, Naderi A, Wiberg A (2015) Large scale applications of nanocellulosic materials–a comprehensive review. J Korea TAPPI 47:5–21

Lourenço AF, Gamelas JAF, Ferreira PJ (2014) Increase of the filler content by using a silica-coated PCC filler. Nordic Pulp Paper Res J 29(2):240–245

Lourenço AF, Gamelas JAF, Nunes T, Amaral J, Mutjé P, Ferreira PJ (2017) Influence of TEMPO-oxidized cellulose nanofibrils on the properties of filler-containing papers. Cellulose 24:349–362

Naderi A, Lindström T, Torbjörn T (2014) The state of carboxymethylated nanofibrils after homogenization-aided dilution from concentrated suspensions: a rheological perspective. Cellulose 21:2357–2368

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Osong SH, Norgren S, Engstrand P (2016) Processing of wood-based microfibrillated cellulose and nanofibrillated cellulose, and applications relating to papermaking: a review. Cellulose 23:93–123

Ottesen V, Syverud K, Gregersen ØW (2016) Mixing of cellulose nanofibrils and individual furnish components: effects on paper properties and structure. Nordic Pulp Paper Res J 31(3):441–447

Pedrosa J, Gamelas JAF, Lourenço AF, Ferreira PJ (2016) Surface properties of calcium carbonate modified with silica by sol-gel method. Colloids Surf A 497:1–7

Rasteiro MG, Garcia FAP, Ferreira P, Blanco A, Negro C, Antunes E (2008) Evaluation of flocs resistance and reflocculation capacity using the LDS technique. Powder Technol 183:231–238

Saito T, Isogai A (2007) Wet strength improvement of TEMPO-oxidized cellulose sheets prepared with cationic polymers. Ind Eng Chem Res 46:773–780

Siró I, Plackett D, Hedenqvist M, Ankerfors M, Lindström T (2011) Highly transparent films from carboxymethylated microfibrillated cellulose–the effect of multiple homogenization steps on key properties. J Appl Polym Sci 119:2652–2660

Song S, Wang P, Zhang M (2018) Filler bondability factor as a tool for maximizing the potential of mineral additives in paper production. BioResources 13(3):4770–4772

Sousa S, Pedrosa J, Ramos A, Ferreira PJ, Gamelas JAF (2016) Surface properties of xylan and xylan derivatives measured by inverse gas chromatography. Colloids Surf A 506:600–606

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020

Tarrés Q, Oliver-Ortega H, Alcalà M, Merayo N, Balea A, Blanco A, Mutjé P, Delgado-Aguilar M (2018) Combined effect of sodium carboxymethyl cellulose, cellulose nanofibers and drainage aids in recycled paper production process. Carbohyd Polym 183:201–206

Wågberg L, Winter L, Ödberg L, Lindström T (1987) On the charge stoichiometry upon adsorption of a cationic polyelectrolyte on cellulosic materials. Colloids Surf 27:163–173

Wågberg L, Decher G, Norgren M, Lindström T, Ankerfors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24:784–795

Walecka JA (1956) An investigation of low degree of subsitution carboxymethylcelluloses. Doctor’s Dissertation, The Institute of Paper Chemistry, Wisconsin

Acknowledgments

Ana F. Lourenço would like to acknowledge Fundação para a Ciência e Tecnologia (FCT), Portugal, for PhD Grant SFRH/BDE/108095/2015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lourenço, A.F., Godinho, D., Gamelas, J.A.F. et al. Carboxymethylated cellulose nanofibrils in papermaking: influence on filler retention and paper properties. Cellulose 26, 3489–3502 (2019). https://doi.org/10.1007/s10570-019-02303-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02303-5