Abstract

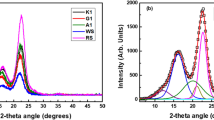

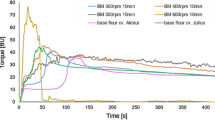

To investigate changes on the physicochemical characteristics of wheat straw by mechanical ultrafine grinding, wheat straw powders of four different particle sizes and distributions were produced using a sieve-based Retsch ZM100 grind mill and CJM-SY-B ultrafine vibration grind mill. Changes on the microstructure and physicochemical characteristics of the different powders were assessed by scanning electron microscopy, X-ray diffractometry, X-ray photoelectron spectroscopy, Fourier transform infrared spectroscopy, thermogravimetric analysis and relevant standard laboratory analysis methods. Ultrafine grinding reduced the crystallite size and crystallinity of the wheat straw. New surfaces were exposed on the ultrafine powder with high levels of cellulose/hemicelluloses components but there was no apparent change in chemical structure. Wheat straw powders were smaller in size but had a higher bulk density (from 0.19 to 0.54 g/mL) and angle of repose (from 46.02° to 55.61°) and slide (from 37.26° to 41.00°). The hydration properties (water-holding capacity and swelling capacity) decreased with reduction in particle size of the wheat straw. Both the sieve-based and ultrafine powder exhibited a good ability to remove Pb2+ and Cd2+ and there was marginal improvement when using the ultrafine powder. The thermal stability of the ultrafine powder measured by thermogravimetric analysis decreased significantly because of the low cellulose crystallinity.

Similar content being viewed by others

References

Adapa P, Tabil L, Schoenau G (2009) Compaction characteristics of barley, canola, oat and wheat straw. Biosyst Eng 104(3):335–344

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99(6):1664–1671

Auffret A, Ralet MC, Guillon F, Barry JL, Thibault JF (1994) Effect of grinding and experimental conditions on the measurement of hydration properties of dietary fibers. LWT Food Sci Technol 27(2):166–172

Binod P, Sindhu R, Singhania RR, Vikram S, Devi L, Nagalakshmi S, Kurien N, Sukumaran RK, Pandey A (2010) Bioethanol production from rice straw: an overview. Bioresour Technol 101(13):4767–4774

Chau CF, Wang YT, Wen YL (2007) Different micronization methods significantly improve the functionality of carrot insoluble fibre. Food Chem 100(4):1402–1408

Chen W, Yu H, Liu Y (2011) Preparation of millimeter-long cellulose I nanofibers with diameters of 30–80 nm from bamboo fibers. Carbohydr Polym 86(2):453–461

Chundawat SP, Venkatesh B, Dale BE (2007) Effect of particle size based separation of milled corn stover on AFEX pretreatment and enzymatic digestibility. Biotech Bio 96(2):219–231. doi:10.1002/bit.21132

Dorris GM, Gray DG (1978a) The surface analysis of paper and wood fibers by ESCA.I. Application to cellulose and lignin. Cellul Chem Technol 12:9–23

Dorris GM, Gray DG (1978b) The surface analysis of paper and wood fibers by ESCA.II. Surface composition of mechanical pulp. Cellul Chem Technol 12:721–734

Fadda S, Cincotti A, Concas A, Pisu M, Cao G (2009) Modelling breakage and reagglomeration during fine dry grinding in ball milling devices. Powder Technol 194(3):207–216. doi:10.1016/j.powtec.2009.04.009

French AD (2013) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose. doi:10.1007/s10570-013-0030-4

French AD, Santiago Cintrón M (2012) Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20(1):583–588. doi:10.1007/s10570-012-9833-y

Gao H, Liu Y, Zeng G, Xu W, Li T, Xia W (2008) Characterization of Cr(VI) removal from aqueous solutions by a surplus agricultural waste–rice straw. J Hazard M 150(2):446–452. doi:10.1016/j.jhazmat.2007.04.126

Han KH, Ko JH, Yang SH (2007) Optimizing lignocellulosic feedstock for improved biofuel productivity and processing. Biofuels Bioprod Bioref 1:135–146

Hu J, Chen Y, Ni D (2012) Effect of superfine grinding on quality and antioxidant property of fine green tea powders. LWT Food Sci Technol 45(1):8–12. doi:10.1016/j.lwt.2011.08.002

Hua X, Kaliaguine S, Kokta BV, Adnot A (1993) Surface analysis of different wood. Wood Sci Technol 27:449–459

Ileleji KE, Zhou B (2008) The angle of repose of bulk corn stover particles. Powder Technol 187(2):110–118

Jin S, Chen H (2006) Superfine grinding of steam-exploded rice straw and its enzymatic hydrolysis. Biochem Eng J 30(3):225–230

Jongaroontaprangsee S, Tritrong W, Chokanaporn W, Methacanon P, Devahastin S, Chiewchan N (2007) Effects of drying temperature and particle size on hydration properties of dietary fiber powder from lime and cabbage by-products. Int J Food Prop 10(4):887–897

Keshwani DR, Cheng JJ (2009) Switchgrass for bioethanol and other value-added applications: a review. Bioresour Technol 100(4):1515–1523

Kuan CY, Yuen KH, Bhat R, Liong MT (2011) Physicochemical characterization of alkali treated fractions from corncob and wheat straw and the production of nanofibres. Food Res Int 44(9):2822–2829

Lesmana SO, Febriana N, Soetaredjo FE, Sunarso J, Ismadji S (2009) Studies on potential applications of biomass for the separation of heavy metals from water and wastewater. Bioch Eng J 44(1):19–41. doi:10.1016/j.bej.2008.12.009

Mandalari G, Faulds CB, Sancho AI, Saija A, Bisignano G, LoCurto R, Waldron KW (2005) Fractionation and characterisation of arabinoxylans from brewers’ spent grain and wheat bran. J Cereal Sci 42(2):205–212. doi:10.1016/j.jcs.2005.03.001

Mani S, Tabil LG, Sokhansanj S (2004) Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenerg 27(4):339–352

Raghavendra SN, Rastogi NK, Raghavarao KSMS, Tharanathan RN (2004) Dietary fiber from coconut residue: effects of different treatments and particle size on the hydration properties. Eur Food Res Technol 218(6):563–567

Robertson JA, de Monredon FD, Dysseler P, Guillon F, Amado R, Thibault JF (2000) Hydration properties of dietary fibre and resistant starch: a European collaborative study. LWT Food Sci Technol 33(2):72–79

Sain M, Panthapulakkal S (2006) Bioprocess preparation of wheat straw fibers and their characterization. Ind Crop Prod 23(1):1–8

Sánchez OJ, Cardona CA (2008) Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour Technol 99(13):5270–5295

Sangnark A, Noomhorm A (2003) Effect of particle sizes on functional properties of dietary fibre. Food Chem 80:221–229

Scherrer P (1918) Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachr Ges Wiss Göttingen 26:98–100

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Silva GGD, Couturier M, Berrin JG, Buléon A, Rouau X (2012) Effects of grinding processes on enzymatic degradation of wheat straw. Bioresour Technol 103(1):192–200

Stewart D, Wilson HM, Hendra PJ, Hendra PJ (1995) Fourier-transform infrared and Raman spectroscopic study of biochemical and chemical treatments of oak wood. J Agric Food Chem 43:2219–2225

Wang J, Chen C (2009) Biosorbents for heavy metals removal and their future. Biotech Adv 27(2):195–226. doi:10.1016/j.biotechadv.2008.11.002

Wang Z, McDonald AG, Westerhof RJM, Kersten SRA, Cuba-Torres CM, Ha S, Pecha B, Garcia-Perez M (2013) Effect of cellulose crystallinity on the formation of a liquid intermediate and on product distribution during pyrolysis. J Anal Appl Pyrolysis 100:56–66

Wu G-C, Zhang M, Wang Y-Q, Mothibe KJ, Chen W-X (2012) Production of silver carp bone powder using superfine grinding technology: suitable production parameters and its properties. J Food Eng 109(4):730–735. doi:10.1016/j.jfoodeng.2011.11.013

Xiao B, Sun XF, Sun RC (2001) Chemical, structural and thermal characterization of alkali soluble lignins and hemicelluloses and cellulose from maize stems, rye straw and rice straw. Polym Degrad Stabil 74(2):307–319

Yu H, Liu R, Qiu L, Huang Y (2007) Composition of the cell wall in the stem and leaf sheath of wheat straw. J Appl Polym Sci 104(2):1236–1240

Zhang M, Zhang C-J, Shrestha S (2005) Study on the preparation technology of superfine ground powder of Agrocybe chaxingu Huang. J Food Eng 67(3):333–337. doi:10.1016/j.jfoodeng.2004.04.036

Zhao H, Kwak JH, Wang Y, Franz JA, White JM, Holladay JE (2006) Effects of Crystallinity on Dilute Acid Hydrolysis of Cellulose by Cellulose Ball-Milling Study. Energ Fuel 20:807–811

Zhao X, Yang Z, Gai G, Yang Y (2009) Effect of superfine grinding on properties of ginger powder. J Food Eng 91(2):217–222

Zhao X, Chen J, Chen F, Wang X, Zhu Q, Ao Q (2013) Surface characterization of corn stalk superfine powder studied by FTIR and XRD. Coll Surf B 104:207–212. doi:10.1016/j.colsurfb.2012.12.003

Zhu K, Huang S, Peng W, Qian H, Zhou H (2010) Effect of ultrafine grinding on hydration and antioxidant properties of wheat bran dietary fiber. Food Res Int 43(4):943–948

Acknowledgments

This study was funded by the National Natural Science Foundation of China (No. 31271611) and Special Research Found for the Doctoral Program of Higher Education (20130008130004). Thank Alfred D. French for supply of crystal information files (.cif) and kindly comments on preliminary versions of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Yang Yang and Guanya Ji have contributed equally to this work and should be considered co-first authors.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, Y., Ji, G., Xiao, W. et al. Changes to the physicochemical characteristics of wheat straw by mechanical ultrafine grinding. Cellulose 21, 3257–3268 (2014). https://doi.org/10.1007/s10570-014-0381-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0381-5