Abstract

Polymeric graphitic carbon nitride (g-C3N4) is a layered graphite-like nitrogen-rich material, bearing the potential ability to reductively adsorb molecular oxygen for catalytic allylic oxidation. Furthermore, N-hydroxyphthalimide (NHPI) has been recognized as an efficient catalyst for aerobic oxidation of various organic compounds under mild conditions in the presence of various co-catalysts. We present here a promising strategy for employing such nitride-rich g-C3N4 combined with NHPI to form an all-organic metal-free composite and have examined its activity for allylic oxidation with molecular oxygen as the primary terminal oxidant. In the case of allylic oxidation α-isophorone catalyzed by g-C3N4/NHPI gave priority to its corresponding carbonyl compound and epoxide. The effects of various reaction conditions on the catalytic reaction were optimized, affording 74.8 % conversion with 44.4 % selectivity of ketoisophorone at 130 °C in 5 h. Repeated runs demonstrated that the catalyst was stable for at least three cycles without noticeable loss of its catalytic activity.

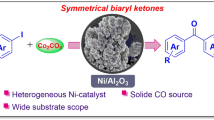

Graphical Abstract

Similar content being viewed by others

1 Introduction

Selective allylic oxidation has been studied comprehensively over the past decade, for its extensive application in organic synthesis and industrial chemistry [1, 2]. Of the variety oxidants employed so far, the noteworthy examples include metal salts (SeO2 [3], CrO3 [4]), tert-butyl hydroperoxide (TBHP) [5], hydrogen peroxide (H2O2) [6] and molecular oxygen (O2) [7, 8]. Among these oxidants, although metal salts could obtain ideal conversion and selectivity, they bore certain defects such as environmental hazards, high expense and waste of metal resources. TBHP and H2O2 are obviously more environmentally benign than metal salts, however, for safety, there is a need to remove the excess oxidants, except that, TBHP is so expensive for large-scale industrial application. Molecular oxygen is cheap, forms water as the only by-product and obtains maximum atom efficiency [9], O2 is more ideal oxidant for both economical and environmental benefits. However, molecular oxygen is a relatively unreactive oxidation toward the strong bonds of C–H for its triplet ground state structure [10]. Heretofore, many catalysts which can efficiently catalyze allylic oxidation with molecular oxygen have been reported, such as heteropoly acid [11], phthalocyanine [12], Schiff-base transition metals (Mn, Cu, Co, Ni) [13–15]. Even so, rigorous solvent (DMSO) [11] and combination with metal ions made them unacceptable for the sustainability of the process. Bearing in mind these concepts, efficient metal-free catalyst, which can active molecular oxygen, is indispensable from the eco-friendly point of view.

In our preceding papers, the organic catalyst, N-hydroxyphthalimide (NHPI) has been recognized as a remarkable catalyst for aerobic oxidation of various organic substrates via hydrogen abstraction by intermediate phthalimide-N-oxyl (PINO) radical [16]. Although the generation of the PINO radicals through the precursors NHPI can be achieved efficiently by using transition metal salts [10, 16, 17] as the mediators, the catalytic system is detrimental to environment. Green chemistry teaches us that there is an urgent need for eco-friendly methods to carry out organic reactions. Then creating a system based on NHPI and a recoverable co-catalyst is one feasible access to obviate this disadvantage. Currently, a nitrogen-rich graphitic carbon nitride (g-C3N4) [18, 19], a solid-state semiconductor, has attracted much attention. This material resembles the polymeric melamine and is regarded as the most stable allotrope of covalent carbon nitride solids at ambient conditions, owing to the fact that it is formed by the sp 2 hybridization of carbon and nitrogen generating the heptazine heterocyclic ring (C6N7) unit, later that the rings are linked by edge N forming the ∏ conjugated graphitic layers [20]. Beyond that, g-C3N4 exhibits good stability, ease of reusability, electronic and catalytic properties [21], which make it promising applications as heterogeneous metal-free catalysts for selective alcohol oxidation [22], coupling of amines [23], selective oxidation of primary carbon hydrogen bonds [21], and hydrogen evolution by splitting water [24]. Very recently, Li and co-workers [25] have applied g-C3N4 assisted by N-hydroxy compounds in selective allylic oxidation with molecular oxygen under visible light irradiation. However, visible light spectrum (400–800 nm) only takes possession 46 % of the solar spectrum. In addition, common glass apparatus is of inhibition effect on the absorption of light, and the quartz glass instrument is demanded. Employing stainless steel autoclave as reaction vessel under heating alone is more convenient for industrial production. Inspired by these previous findings, we would like to build a catalytic system of combining g-C3N4 with NHPI as catalyst and molecular oxygen as the primary terminal oxidant in the allylic oxidation under heating alone within stainless steel autoclave, which is unprecedented and seems to be a intriguing method for converting hydrocarbons into their corresponding carbonyl compounds.

2 Experimental

2.1 Materials and Methods

All the chemicals were of analytical grade apart from industrial-grade α-isophorone. They were commercially purchased and used without further treatment. Infrared spectra were determined on a Nicolet NEXUS 670 FT-IR spectrophotometer using KBr discs in the 400–4,000 cm−1 region. Powder X-ray diffraction (XRD) patterns of the heterogeneous samples were measured with Rigaku D/Max III VC diffractometer with Cu KR radiation at 40 kV and 40 mA in the range of 2θ = 2–9°. The reaction products of oxidation were determined by AGILENT QP2010 GC/MS instrument and analyzed by GC-7890II gas chromatograph with a 50 m × 0.25 mm × 0.25 μm OV-1701 column.

2.2 Preparation of Catalyst

The g-C3N4 was prepared by heating melamine directly according the previous reports [26, 27]. In a typical procedure, melamine was put into an alumina crucible with a cover, heated at a rate of 3 °C/min reaching temperature of 550 °C in a muffle furnace, treated at this temperature for further 4 h. When cooling to room temperature, grinding the pale yellow polymer obtained the g-C3N4 powder.

2.3 Oxidation Reaction

Reactions were carried out in a 100 mL stainless steel autoclave with a magnetic stirrer. α-Isophorone (α-IP, 10 mmol), solvent acetonitrile (10 mL) were placed in the vessel together with g-C3N4 (200 mg), NHPI (1 mmol, 10 mol%), and the reactor was sealed. Prior to heating to desired temperature (130 °C) under stirring, the atmosphere over the autoclave reactor was replaced three times with O2 and pressurized with O2 (1.2 MPa). When the reaction was finished, the autoclave reactor was cooled to the ambient temperature and slowly depressurized. The reaction mixture was analyzed by GC–MS and GC.

3 Results and Discussion

3.1 Characterization of g-C3N4

In Fig. 1, XRD patterns of the samples show the characteristic (002) interplanar stacking peak around 27.4°, corresponding to the interlayer distance of aromatic systems of d = 0.326 nm, suggesting the formation of well-built g-C3N4 layer structure [28]. Another peak at 13.1° agrees with (100) interplanar of tri-triazine units, which is indexed as the 100 peak [29]. Anything else, no obvious difference can be detected between the recycled and fresh g-C3N4, which indicates that the g-C3N4 is of good stability.

The FT-IR spectra of fresh and recycled g-C3N4 are shown in Fig. 2. Several bands in the 1,200–1,600 cm−1 are ascribed to the stretching vibration of the heterocyclic aromatic ring units, while the sharp absorption peak at 800 cm−1 is considered as the characteristic breathing mode of the triazine cycle [30]. In addition, the broad absorption peak located at 3,000–3,300 cm−1 corresponding to the N–H components (uncondensed amino) and the O–H bands (the absorbed H2O molecules) are observed [31]. Upon comparison, the fresh and recycled g-C3N4 bear similarity to each other, which correspond to the literature report.

Figure 3 depicts the scanning electron micrograph (SEM) images of fresh and recycled g-C3N4 and shows the typical stacked lamellar structure, and it has the basic characteristic of g-C3N4 of a graphite-like structure [30]. Beyond that, no obvious change of the catalyst g-C3N4 is viewed after the reaction.

3.2 Effect of Various Reaction Conditions on the Catalytic Reaction

3.2.1 Effect of Reaction Temperature and Time

The effects of reaction temperature and time on the oxidation were examined using 200 mg g-C3N4 and 5 mol% NHPI, and the results are shown in Table 1. As expected, the conversion of α-isophorone went up with the concomitant gradual increase of temperature and reached a maximum at 130 °C (entry 3) and then changed slightly even at higher temperature. However, no significant variation in the selectivity of ketoisophorone (KIP) was observed during the course of the reaction. This fact has mainly been caused by the following accounts: under low temperature, the energy was not sufficient for g-C3N4 to activate oxygen molecule, α-IP was hardly oxidized. As illustrated, with prolonging reaction time from 3 to 5 h, the conversion of α-IP increased from 33.9 to 60.7 % (entries 6 and 8). While as the reaction continued, the selectivity of KIP and α-IP conversion remained almost unchanged. Hence, 130 °C and 5 h should be the suitable reaction conditions.

3.2.2 Effect of Oxygen Pressure

It is interesting to note that the pressure of molecular oxygen has significant influence on the allylic oxidation of α-IP (Fig. 4). Below 1.2 MPa a positive impact of O2 pressure on the reaction is observed clearly. The α-IP conversion improves from 29.5 to 60.7 % with increasing O2 pressure from 0.6 to 1.2 MPa, and then changes very slightly after that. The selectivity of KIP has always been rather constant. It has been generally accepted that the dioxygen solubility in the liquid phase increases with the increase of dioxygen pressure. At a lower O2 pressure, the O2 concentration in solution is so low that insufficient O2 could be activated by catalysts, which contributes to the lower conversion. When the oxygen solubility in the solution reaches saturation, excessive oxygen pressure has no much influence on the oxidation efficiency.

3.2.3 Effect of Catalyst Amount

From Table 2, it is observed that the conversion of α-IP improves with the increase of g-C3N4 amount until 300 mg (entries 1–3). After that, the conversion decreases slightly, due to the solution can’t stir evenly. The selectivity decreases obviously (42.4 and 34.3 %, respectively) with increasing the amount of g-C3N4 from 200 to 300 mg. Taking both conversion and selectivity into consideration, 200 mg g-C3N4 is the suitable amount. Needless to say, it is difficult to promote this oxidation with g-C3N4 or NHPI alone (entries 5 and 6). To further make clear the effect of NHPI, different amount of NHPI was added into the reaction, the catalytic efficiency was achieved to the maximum using 10 mol% of NHPI with 74.8 % conversion of α-IP and 44.4 % KIP selectivity (entry 9). Even though more quantity of NHPI was added, the α-IP conversion and the KIP selectivity changed slightly (entry 10).

3.2.4 Oxidation of Different Hydrocarbons Catalyzed by g-C3N4/NHPI

To further probe the generality of this metal-free catalytic system, further researches were studied to oxidize various hydrocarbons by g-C3N4/NHPI with O2 under heating alone (Table 3). Tetralin afforded a remarkably high conversion of 95.7 % towards the formation of tetralone with 60.1 % selectivity. In the case of oxidizing toluene, the benzoic acid was obtained as the main product giving 89.4 % conversion and 69.7 % selectivity (entry 2). Furthermore, the reaction system was found to be acceptable for oxidizing indane and fluorene to indanone and fluorenone affording the satisfactory selectivity of 72.2, 87.3 % and the conversion of 54.3, 66.4 %, respectively (entries 3 and 4). 64.9 % cyclohexene was also converted into corresponding 2-cyclohexene-1-one with 82.1 % selectivity (entry 5).

3.2.5 Proposed Oxidation Mechanism

Based on the results, a possible catalytic mechanism of g-C3N4/NHPI in the allylic oxidation of α-isophorone is proposed and is given in Scheme 1. The electrons in g-C3N4 can be activated and transmit from valence band to conduction band under heating [32, 33]. The superoxide radical anion (O2 −) formed by molecular oxygen absorbing the excited electrons from the conduction band of the g-C3N4 [22], captures a hydrogen from NHPI generating PINO. At the same time, the O2 − forms HOO− which can oxidize another NHPI to PINO. Then, PINO abstracts a hydrogen atom from α-IP forming α-IP radical, while PINO itself converted into NHPI again [34]. Synchronously, the newly formed α-IP radical is trapped by O2 producing peroxy radical, which finally results in oxygenated products.

3.2.6 Reused of g-C3N4

After the first oxidation reaction, the g-C3N4 can be easily recovered simply by washing with 0.2 M NaOH [22] and then dried in a vacuum oven at 65 °C overnight. Then, the obtained g-C3N4 was used directly in subsequent reaction cycles and no obvious loss of its catalytic activity and selectivity were observed, as shown in Fig. 5, giving 74.8, 72.9, 71.8 % conversion for the first, second, third runs, respectively. That means the g-C3N4 was stable in the catalytic reaction media.

4 Conclusion

In summary, the fangled metal-free, heterogeneous catalysis protocol consisting of g-C3N4 combined with NHPI was applied to catalyze allylic oxidation of α-isophorone into ketoisophorone using molecular oxygen as the primary terminal oxidant. 74.8 % conversion of α-IP and 44.4 % selectivity of KIP were obtained under optimized reaction conditions (10 mmol α-IP, 200 mg g-C3N4, 10 mol% NHPI, 1.2 MPa O2, 130 °C, 5 h). This catalytic process could eliminate the employment of any metal derivative, g-C3N4 was found to be stable and reusable. The clean and one pot reaction process described here provided a potential way to oxidize various compounds possessing these analogous structures.

References

Ganji S, Bykya P, Vakati V, Rama Rao KS, Burri DR (2013) Catal. Sci Technol 3:409

Islam SM, Roy AS, Mondal P, Salam N (2012) J Inorg Organomet Polym 22:717

Kende AS, Mineur CM, Lachicotte RJ (1999) Tetrahedron Lett 40:7901

Liu J, Zhu HY, Cheng XH (2009) Synth Commun 39:1076

Marwah P, Marwah A, Lardy HA (2004) Green Chem 6:570

Maksimchuk NV, Melgunov MS, Mrowiec-Bialon J, Jarzebski AB, Kholdeeva OA (2005) J Catal 235:175

Kishore D, Rodrigues AE (2007) Catal Commun 8:1156

Zheng GX, Liu CH, Wang QF, Wang MY, Yang GY (2009) Adv Synth Catal 351:2638

Dhakshinamoorthy A, Alvaro M, Garcia H (2012) J Catal 289:259

Yang XM, Zhou LP, Chen Y, Chen C, Su YL, Miao H, Xu J (2009) Catal Commun 11:171

Liu CH, Li F, Tang RR (2010) Bull Korean Chem Soc 32:1723

Tonucci L, Nicastro M, d’Alessandro N, Bressan M, D’Ambrosio P, Morvillo A (2009) Green Chem 11:816

Li ZY, Tang RR, Liu GY (2013) Catal Lett 143:592

Mukherjee S, Samanta S, Roy BC, Bhaumik A (2006) Appl Catal A 301:79

Chang Y, Lv YR, Lu F, Zha F, Lei ZQ (2010) J Mol Catal A 320:56

Chen LH, Tang RR, Li ZY, Liang S (2012) Bull Korean Chem Soc 33:459

Yao Z, Hu XB, Mao JY, Li HR (2009) Green Chem 11:2013

Wang Y, Wang XC, Antonietti M (2012) Angew Chem Int Ed 51:68

Dong GH, Zhao K, Zhang LZ (2012) Chem Commun 48:6178

Zheng HR, Zhang JS, Wang XC, Fu XZ (2012) Acta Phys Chim Sin 28:2336

Li XH, Wang XC, Antonietti M (2012) ACS Catal 2:2082

Su FZ, Mathew SC, Lipner G, Fu XZ, Antonietti M, Blechert S, Wang XC (2010) J Am Chem Soc 132:16299

Su FZ, Mathew SC, Mohlmann L, Antonietti M, Wang XC, Blechert S (2011) Angew Chem Int Ed 50:657

Wang XC, Maeda K, Chen XF, Takanabe K, Domen K, Hou YD, Fu XZ, Antonietti M (2009) J Am Chem Soc 131:1680

Zhang PF, Wang Y, Yao J, Wang CM, Yan C, Antonietti M, Li HR (2011) Adv Synth Catal 353:1447

Yang JH, Wu XT, Li XF, Liu Y, Gao M, Liu XY, Kong LN, Yang SY (2011) Appl Phys A 105:161

Zhai HS, Cao L, Xia XH (2013) Chin Chem Lett 24:103

Zhang JS, Chen XF, Takanabe K, Maeda K, Domen K, Epping JD, Fu XZ, Antonietti M, Wang XC (2010) Angew Chem Int Ed 49:441

Yan HJ, Chen Y, Xu SM (2012) Int J Hydrog Energy 37:125

Chai B, Peng TY, Mao J, Li K, Zan L (2012) Phys Chem Chem Phys 14:16745

Zhang GG, Zhang JS, Zhang MW, Wang XC (2012) J Mater Chem 22:8033

Osa MN, Shimamura S (2001) Mater Sci Res Int 7:2

Oriov AM, Skvortsov AA, Pirogov AV, Froiov VA (1999) Tech Phys Lett 25:191–193

Melone L, Punta C (2013) Beilstein J Org Chem 9:1296

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 21071152).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Liu, G., Tang, R. & Wang, Z. Metal-Free Allylic Oxidation with Molecular Oxygen Catalyzed by g-C3N4 and N-Hydroxyphthalimide. Catal Lett 144, 717–722 (2014). https://doi.org/10.1007/s10562-014-1200-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1200-1