Abstract

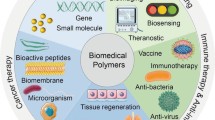

Polymeric materials have a broad range of mechanical and physical properties. They have been widely used in material science, biomedical engineering, chemical engineering, and mechanical engineering. The introduction of active elements into the soft matrix of polymers has enabled much more diversified functionalities of polymeric materials, such as self-healing, electroactive, magnetosensitive, pH-responsive, and many others. To further enable applications of these multifunctional polymers, a mechanistic modeling method is required and of great significance, as it can provide links between materials’ micro/nano-structures and their macroscopic mechanical behaviors. Towards this goal, molecular simulation plays an important role in understanding the deformation and evolution of polymer networks under external loads and stimuli. These molecular insights provide physical guidance in the formulation of mechanistic-based continuum models for multifunctional polymers. In this perspective, we present a molecular simulation-guided and physics-informed modeling framework for polymeric materials. Firstly, the physical theory for polymer chains and their networks is briefly introduced. It serves as the foundation for mechanistic-models of polymers, linking their chemistry, physics, and mechanics together. Secondly, the deformation of the polymer network is used to derive the strain energy density functions. Thus, the corresponding continuum models can capture the intrinsic deformation mechanisms of polymer networks. We then highlight several representative examples across multiphysics coupling problems to describe in detail for this proposed framework. Last but not least, we discuss potential challenges and opportunities in the modeling of multifunctional polymers for future research directions.

Similar content being viewed by others

References

Rogers, J.A., Someya, T., Huang, Y.: Materials and mechanics for stretchable electronics. Science 327(5973), 1603–1607 (2010)

Stoppa, M., Chiolerio, A.: Wearable electronics and smart textiles: a critical review. Sensors 14(7), 11957–11992 (2014)

Zeng, W., Shu, L., Li, Q., et al.: Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications. Adv. Mater. 26(31), 5310–5336 (2014)

Yu, Y., Nyein, H.Y.Y., Gao, W., et al.: Flexible electrochemical bioelectronics: the rise of in situ bioanalysis. Adv. Mater. 32(15), 1902083 (2020)

Kim, S., Byun, J., Choi, S., et al.: Negatively strain-dependent electrical resistance of magnetically arranged nickel composites: Application to highly stretchable electrodes and stretchable lighting devices. Adv. Mater. 26(19), 3094–3099 (2014)

Jeong, J., Wang, Q., Cha, J., et al.: Remote heteroepitaxy of gan microrod heterostructures for deformable light-emitting diodes and wafer recycle. Sci. Adv. 6(23), eaaz5180 (2020)

Trivedi, D., Rahn, C.D., Kier, W.M., et al.: Soft robotics: Biological inspiration, state of the art, and future research. Appl. Bionics Biomech. 5(3), 99–117 (2008)

Ilievski, F., Mazzeo, A.D., Shepherd, R.F., et al.: Soft robotics for chemists. Angew. Chem. Int. Ed. 123(8), 1930–1935 (2011)

Kim, S., Laschi, C., Trimmer, B.: Soft robotics: a bioinspired evolution in robotics. Trends Biotechnol. 31(5), 287–294 (2013)

Someya, T., Sekitani, T., Iba, S., et al.: A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proc. Natl. Acad. Sci. USA 101(27), 9966–9970 (2004)

Tee, B.C., Wang, C., Allen, R., et al.: An electrically and mechanically self-healing composite with pressure-and flexion-sensitive properties for electronic skin applications. Nat. Nanotechnol. 7(12), 825–832 (2012)

Hammock, M.L., Chortos, A., Tee, B.C.-K., et al.: 25th anniversary article: the evolution of electronic skin (e-skin): a brief history, design considerations, and recent progress. Adv. Mater. 25(42), 5997–6038 (2013)

Berger, J., Reist, M., Mayer, J.M., et al.: Structure and interactions in covalently and ionically crosslinked chitosan hydrogels for biomedical applications. Eur. J. Pharm. Biopharm. 57(1), 19–34 (2004)

Seliktar, D.: Designing cell-compatible hydrogels for biomedical applications. Science 336(6085), 1124–1128 (2012)

Hoffman, A.S.: Hydrogels for biomedical applications. Adv. Drug Delivery Rev. 64, 18–23 (2012)

Wang, X.-Q., Yang, Q.-S.: A general solution for one dimensional chemo-mechanical coupled hydrogel rod. Acta. Mech. Sin. 34(2), 392–399 (2018)

Lei, J., Li, Z., Xu, S., et al.: Recent advances of hydrogel network models for studies on mechanical behaviors. Acta Mech. Sin., page 1, (2021)

Dargazany, R., Khiem, V.N., Itskov, M.: A generalized network decomposition model for the quasi-static inelastic behavior of filled elastomers. Int. J. Plast 63, 94–109 (2014)

Filipcsei, G., Feher, J., Zrınyi, M.: Electric field sensitive neutral polymer gels. J. Mol. Struct. 554(1), 109–117 (2000)

Schindler, F., Lupton, J.M., Müller, J., et al.: How single conjugated polymer molecules respond to electric fields. Nat. Mater. 5(2), 141–146 (2006)

Lu, S., Ramos, J., Forcada, J.: Self-stabilized magnetic polymeric composite nanoparticles by emulsifier-free miniemulsion polymerization. Langmuir 23(26), 12893–12900 (2007)

Ramajo, L.A., Cristóbal, A.A., Botta, P.M., et al.: Dielectric and magnetic response of fe3o4/epoxy composites. Compos. Part A Appl. Sci. Manuf. 40(4), 388–393 (2009)

Schmaljohann, D.: Thermo-and ph-responsive polymers in drug delivery. Adv. Drug Delivery Rev. 58(15), 1655–1670 (2006)

Dai, S., Ravi, P., Tam, K.C.: ph-responsive polymers: synthesis, properties and applications. Soft Matter 4(3), 435–449 (2008)

Prabaharan, M., Mano, J.F.: Stimuli-responsive hydrogels based on polysaccharides incorporated with thermo-responsive polymers as novel biomaterials. Macromol. Biosci. 6(12), 991–1008 (2006)

Kim, Y.-J., Matsunaga, Y.T.: Thermo-responsive polymers and their application as smart biomaterials. J. Mater. Chem. B 5(23), 4307–4321 (2017)

Brighenti, R., Li, Y., Vernerey, F.J.: Smart polymers for advanced applications: a mechanical perspective review. Front, Mater (2020)

Ogden, R.W.: Recent advances in the phenomenological theory of rubber elasticity. Rubber Chem. Technol. 59(3), 361–383 (1986)

Ogden, R.W.: Large deformation isotropic elasticity-on the correlation of theory and experiment for incompressible rubberlike solids. Proc. Math. Phys. Eng. Sci. 326(1567), 565–584 (1972)

Holzapfel, A.G.: Nonlinear Solid Mechanics II. Wiley, Hoboken (2000)

Boyce, M.C., Arruda, E.M.: Constitutive models of rubber elasticity: a review. Rubber Chem. Technol. 73(3), 504–523 (2000)

Serra-Aguila, A., Puigoriol-Forcada, J., Reyes, G., et al.: Viscoelastic models revisited: Characteristics and interconversion formulas for generalized kelvin-voigt and maxwell models. Acta. Mech. Sin. 35(6), 1191–1209 (2019)

Li, H., Liang, X., Song, W.: Buckling-controlled two-way shape memory effect in a ring-shaped bilayer. Acta. Mech. Sin. 35(6), 1217–1225 (2019)

Li, Y., Tang, S., Abberton, B.C., et al.: A predictive multiscale computational framework for viscoelastic properties of linear polymers. Polymer 53(25), 5935–5952 (2012)

Zhao, Q., Qi, H.J., Xie, T.: Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 49, 79–120 (2015)

Li, Y., Tang, S., Kröger, M., et al.: Molecular simulation guided constitutive modeling on finite strain viscoelasticity of elastomers. J. Mech. Phys. Solids 88, 204–226 (2016)

Jancar, J., Douglas, J., Starr, F.W., et al.: Current issues in research on structure-property relationships in polymer nanocomposites. Polymer 51(15), 3321–3343 (2010)

Fetters, L., Lohse, D., Richter, D., et al.: Connection between polymer molecular weight, density, chain dimensions, and melt viscoelastic properties. Macromolecules 27(17), 4639–4647 (1994)

Kim, C., Chandrasekaran, A., Huan, T.D., et al.: Polymer genome: a data-powered polymer informatics platform for property predictions. J. Phys. Chem. C 122(31), 17575–17585 (2018)

Chen, G., Shen, Z., Iyer, A., et al.: Machine-learning-assisted de novo design of organic molecules and polymers: Opportunities and challenges. Polymers 12(1), 163 (2020)

Brinson, L.C., Deagen, M., Chen, W., et al.: Polymer nanocomposite data: curation, frameworks, access, and potential for discovery and design. ACS Macro Lett. 9(8), 1086–1094 (2020)

Sánchez, P.A., Minina, E.S., Kantorovich, S.S., et al.: Surface relief of magnetoactive elastomeric films in a homogeneous magnetic field: molecular dynamics simulations. Soft Matter 15(2), 175–189 (2019)

Harrison, I.P., Spada, F.: Hydrogels for atopic dermatitis and wound management: a superior drug delivery vehicle. Pharmaceutics 10(2), 71 (2018)

Liu, D., Broer, D.J.: Liquid crystal polymer networks: preparation, properties, and applications of films with patterned molecular alignment. Langmuir 30(45), 13499–13509 (2014)

Yu, K., Xin, A., Wang, Q.: Mechanics of self-healing polymer networks crosslinked by dynamic bonds. J. Mech. Phys. Solids 121, 409–431 (2018)

Liu, W.K., Karpov, E.G., Park, H.S.: Nano Mechanics and Materials: Theory. Multiscale Methods and Applications. Wiley, Hoboken (2006)

Li, Y., Abberton, B.C., Kröger, M., et al.: Challenges in multiscale modeling of polymer dynamics. Polymers 5(2), 751–832 (2013)

Li, Y., Kröger, M., Liu, W.K.: Nanoparticle effect on the dynamics of polymer chains and their entanglement network. Phys. Rev. Lett. 109(11), 118001 (2012)

Li, Y., Kröger, M., Liu, W.K.: Nanoparticle geometrical effect on structure, dynamics and anisotropic viscosity of polyethylene nanocomposites. Macromolecules 45(4), 2099–2112 (2012)

Li, Y., Kröger, M., Liu, W.K.: Primitive chain network study on uncrosslinked and crosslinked cis-polyisoprene polymers. Polymer 52(25), 5867–5878 (2011)

Arruda, E.M., Boyce, M.C.: A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J. Mech. Phys. Solids 41(2), 389–412 (1993)

Davidson, J.D., Goulbourne, N.: A nonaffine network model for elastomers undergoing finite deformations. J. Mech. Phys. Solids 61(8), 1784–1797 (2013)

Rubinstein, M., Colby, R.H., et al.: Polymer Physics, vol. 23. Oxford University Press, New York (2003)

Doi, M., Edwards, S.F.: The Theory of Polymer Dynamics, vol. 73. Oxford University Press, Oxford (1988)

Miehe, C., Göktepe, S., Lulei, F.: A micro-macro approach to rubber-like materials-part i: the non-affine micro-sphere model of rubber elasticity. J. Mech. Phys. Solids 52(11), 2617–2660 (2004)

Darabi, E., Itskov, M.: A generalized tube model of rubber elasticity. Soft Matter 17, 1675–1684 (2021)

Weiner J. H.: Statistical mechanics of elasticity. Courier Corporation, (2012)

James, H.M., Guth, E.: Theory of the elastic properties of rubber. J. Chem. Phys. 11(10), 455–481 (1943)

Rubinstein, M., Panyukov, S.: Nonaffine deformation and elasticity of polymer networks. Macromolecules 30(25), 8036–8044 (1997)

Rubinstein, M., Panyukov, S.: Elasticity of polymer networks. Macromolecules 35(17), 6670–6686 (2002)

Akagi, Y., Gong, J.P., Chung, U.-I., et al.: Transition between phantom and affine network model observed in polymer gels with controlled network structure. Macromolecules 46(3), 1035–1040 (2013)

Frenkel, D., Smit, B.: Understanding Molecular Simulation: From Algorithms to Applications, vol. 1. Elsevier, Amsterdam (2001)

Grest, G.S., Dünweg, B., Kremer, K.: Vectorized link cell fortran code for molecular dynamics simulations for a large number of particles. Comput. Phys. Commun. 55(3), 269–285 (1989)

Kadau, K., Germann, T.C., Lomdahl, P.S.: Molecular dynamics comes of age: 320 billion atom simulation on bluegene/l. Int. J. Mod. Phys. C 17(12), 1755–1761 (2006)

Ye, H., Xian, W., Li, Y.: Machine learning of coarse-grained models for organic molecules and polymers: Progress, opportunities, and challenges. ACS Omega 6(3), 1758–1772 (2021)

Cleri, F., Yip, S., Wolf, D., et al.: Atomic-scale mechanism of crack-tip plasticity: dislocation nucleation and crack-tip shielding. Phys. Rev. Lett. 79(7), 1309 (1997)

Yamakov, V., Wolf, D., Phillpot, S., et al.: Deformation-mechanism map for nanocrystalline metals by molecular-dynamics simulation. Nat. Mater. 3(1), 43–47 (2004)

Jang, D., Li, X., Gao, H., et al.: Deformation mechanisms in nanotwinned metal nanopillars. Nat. Nanotechnol. 7(9), 594 (2012)

Buehler, M.J.: Nature designs tough collagen: explaining the nanostructure of collagen fibrils. Proc. Natl. Acad. Sci. USA 103(33), 12285–12290 (2006)

Buehler, M.J.: Nanomechanics of collagen fibrils under varying cross-link densities: atomistic and continuum studies. J. Mech. Behav. Biomed. Mater. 1(1), 59–67 (2008)

Nova, A., Keten, S., Pugno, N.M., et al.: Molecular and nanostructural mechanisms of deformation, strength and toughness of spider silk fibrils. Nano Lett. 10(7), 2626–2634 (2010)

Shi, X., von Dem Bussche, A., Hurt, R.H., et al.: Cell entry of one-dimensional nanomaterials occurs by tip recognition and rotation. Nat. Nanotechnol. 6(11), 714–719 (2011)

Zhang, S., Gao, H., Bao, G.: Physical principles of nanoparticle cellular endocytosis. ACS Nano 9(9), 8655–8671 (2015)

Binder, K.: Monte Carlo and Molecular Dynamics Simulations in Polymer Science. Oxford University Press, Oxford (1995)

Wasserman, Z., Salemme, F.: A molecular dynamics investigation of the elastomeric restoring force in elastin. Biopolymers 29(12–13), 1613–1631 (1990)

Hossain, D., Tschopp, M.A., Ward, D., et al.: Molecular dynamics simulations of deformation mechanisms of amorphous polyethylene. Polymer 51(25), 6071–6083 (2010)

Li, C., Strachan, A.: Molecular dynamics predictions of thermal and mechanical properties of thermoset polymer epon862/detda. Polymer 52(13), 2920–2928 (2011)

Hong, W., Zhao, X., Zhou, J., et al.: A theory of coupled diffusion and large deformation in polymeric gels. J. Mech. Phys. Solids 56(5), 1779–1793 (2008)

Dorfmann, L., Ogden, R.W.: Nonlinear Theory of Electroelastic and Magnetoelastic Interactions, vol. 1. Springer, New York (2014)

Stephanou, P.S., Baig, C., Tsolou, G., et al.: Quantifying chain reptation in entangled polymer melts: Topological and dynamical mapping of atomistic simulation results onto the tube model. J. Chem. Phys. 132(12), 124904 (2010)

de Gennes, P.-G.: Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 55(2), 572–579 (1971)

Kröger, M.: Shortest multiple disconnected path for the analysis of entanglements in two-and three-dimensional polymeric systems. Comput. Phys. Commun. 168(3), 209–232 (2005)

Viovy, J.: Constraint release in the slip-link model and the viscoelastic properties of polymers. J. Phys. I 46(5), 847–853 (1985)

Marrucci, G.: Relaxation by reptation and tube enlargement: A model for polydisperse polymers. J. Polym. Sci. B. Polym. Phys. 23(1), 159–177 (1985)

Pattamaprom, C., Larson, R.G., Sirivat, A.: Determining polymer molecular weight distributions from rheological properties using the dual-constraint model. Rheol. Acta 47(7), 689–700 (2008)

Pattamaprom, C., Larson, R.G., Van Dyke, T.J.: Quantitative predictions of linear viscoelastic rheological properties of entangled polymers. Rheol. Acta 39(6), 517–531 (2000)

Bergström, J.S., Boyce, M.C.: Constitutive modeling of the large strain time-dependent behavior of elastomers. J. Mech. Phys. Solids 46(5), 931–954 (1998)

He, G., Liu, Y., Deng, X., et al.: Constitutive modeling of viscoelastic-viscoplastic behavior of short fiber reinforced polymers coupled with anisotropic damage and moisture effects. Acta. Mech. Sin. 35(3), 495–506 (2019)

Miehe, C., Göktepe, S.: A micro–macro approach to rubber-like materials. part ii: The micro-sphere model of finite rubber viscoelasticity. J. Mech. Phys. Solids 53(10), 2231–2258 (2005)

Tang, S., Greene, M.S., Liu, W.K.: Two-scale mechanism-based theory of nonlinear viscoelasticity. J. Mech. Phys. Solids 60(2), 199–226 (2012)

Zhou, J., Jiang, L., Khayat, R.E.: A micro-macro constitutive model for finite-deformation viscoelasticity of elastomers with nonlinear viscosity. J. Mech. Phys. Solids 110, 137–154 (2018)

Xiang, Y., Zhong, D., Wang, P., et al.: A general constitutive model of soft elastomers. J. Mech. Phys. Solids 117, 110–122 (2018)

Xiang, Y., Zhong, D., Wang, P., et al.: A physically based visco-hyperelastic constitutive model for soft materials. J. Mech. Phys. Solids 128, 208–218 (2019)

Xiang, Y., Zhong, D., Rudykh, S., et al.: A review of physically based and thermodynamically based constitutive models for soft materials. J. Appl. Mech., 87(11), (2020)

Straube, E., Urban, V., Pyckhout-Hintzen, W., et al.: Small-angle neutron scattering investigation of topological constraints and tube deformation in networks. Phys. Rev. Lett. 74(22), 4464 (1995)

Pyckhout-Hintzen, W., Westermann, S., Wischnewski, A., et al.: Direct observation of nonaffine tube deformation in strained polymer networks. Phys. Rev. Lett. 110(19), 196002 (2013)

Ott, M., Pérez-Aparicio, R., Schneider, H., et al.: Microscopic study of chain deformation and orientation in uniaxially strained polymer networks: Nmr results versus different network models. Macromolecules 47(21), 7597–7611 (2014)

Li, Y., Liu, Z., Jia, Z., et al.: Modular-based multiscale modeling on viscoelasticity of polymer nanocomposites. Comput. Mech. 59(2), 187–201 (2017)

Dorfmann, A., Ogden, R.W.: A constitutive model for the mullins effect with permanent set in particle-reinforced rubber. Int. J. Solids Struct. 41(7), 1855–1878 (2004)

Merckel, Y., Diani, J., Brieu, M., et al.: Constitutive modeling of the anisotropic behavior of mullins softened filled rubbers. Mech. Mater. 57, 30–41 (2013)

Raghunath, R., Juhre, D., Klüppel, M.: A physically motivated model for filled elastomers including strain rate and amplitude dependency in finite viscoelasticity. Int. J. Plast 78, 223–241 (2016)

Khajehsaeid, H.: Development of a network alteration theory for the mullins-softening of filled elastomers based on the morphology of filler-chain interactions. Int. J. Solids Struct. 80, 158–167 (2016)

Plagge, J., Klüppel, M.: A physically based model of stress softening and hysteresis of filled rubber including rate-and temperature dependency. Int. J. Plast 89, 173–196 (2017)

Wang, M.-J.: Effect of polymer-filler and filler-filler interactions on dynamic properties of filled vulcanizates. Rubber Chem. Technol. 71(3), 520–589 (1998)

Bouvard, J.-L., Francis, D.K., Tschopp, M.A., et al.: An internal state variable material model for predicting the time, thermomechanical, and stress state dependence of amorphous glassy polymers under large deformation. Int. J. Plast. 42, 168–193 (2013)

Wu, F.-G., Yu, J.-S., Sun, S.-F., et al.: Stepwise ordering of imidazolium-based cationic surfactants during cooling-induced crystallization. Langmuir 28(19), 7350–7359 (2012)

Kong, W., Zhu, B., Su, F., et al.: Melting temperature, concentration and cooling rate-dependent nucleating ability of a self-assembly aryl amide nucleator on poly (lactic acid) crystallization. Polymer 168, 77–85 (2019)

Lohwongwatana, B., Schroers, J., Johnson, W.L.: Strain rate induced crystallization in bulk metallic glass-forming liquid. Phys. Rev. Lett. 96(7), 075503 (2006)

Meng, Y., Jiang, J., Anthamatten, M.: Shape actuation via internal stress-induced crystallization of dual-cure networks. ACS Macro Lett. 4(1), 115–118 (2015)

Susca, E.M., Beaucage, P.A., Thedford, R.P., et al.: Preparation of macroscopic block-copolymer-based gyroidal mesoscale single crystals by solvent evaporation. Adv. Mater. 31(40), 1902565 (2019)

Li, Y., Salvator, V., Wijshoff, H., et al.: Evaporation-induced crystallization of surfactants in sessile multicomponent droplets. Langmuir 36(26), 7545–7552 (2020)

Schrauwen, B.A., Janssen, R.P., Govaert, L.E., et al.: Intrinsic deformation behavior of semicrystalline polymers. Macromolecules 37(16), 6069–6078 (2004)

Peterlin, A.: Morphology and properties of crystalline polymers with fiber structure. Text. Res. J. 42(1), 20–30 (1972)

Bowden, P., Young, R.: Deformation mechanisms in crystalline polymers. J. Mater. Sci. 9(12), 2034–2051 (1974)

Mandelkern, L.: The relation between structure and properties of crystalline polymers. Polym. J. 17(1), 337–350 (1985)

Humbert, S., Lame, O., Vigier, G.: Polyethylene yielding behaviour: What is behind the correlation between yield stress and crystallinity? Polymer 50(15), 3755–3761 (2009)

Zhai, Z., Fusco, C., Morthomas, J., et al.: Disentangling and lamellar thickening of linear polymers during crystallization: Simulation of bimodal and unimodal molecular weight distribution systems. ACS Nano 13(10), 11310–11319 (2019)

Bouvard, J.-L., Ward, D.K., Hossain, D., et al.: A general inelastic internal state variable model for amorphous glassy polymers. Acta Mech. 213(1–2), 71–96 (2010)

Wang, C., Wu, H., Chen, Z., et al.: Self-healing chemistry enables the stable operation of silicon microparticle anodes for high-energy lithium-ion batteries. Nat. Chem. 5(12), 1042 (2013)

Brochu, A.B., Craig, S.L., Reichert, W.M.: Self-healing biomaterials. J. Biomed. Mater. Res. Part A 96(2), 492–506 (2011)

Terryn, S., Brancart, J., Lefeber, D., Van Assche, G., Vanderborght, B.: Self-healing soft pneumatic robots. Sci. Rob. 2, 9 (2017)

Yang, Y., Urban, M.W.: Self-healing polymeric materials. Chem. Soc. Rev. 42(17), 7446–7467 (2013)

Wei, Z., Yang, J.H., Zhou, J., et al.: Self-healing gels based on constitutional dynamic chemistry and their potential applications. Chem. Soc. Rev. 43(23), 8114–8131 (2014)

Thakur, V.K., Kessler, M.R.: Self-healing polymer nanocomposite materials: A review. Polymer 69, 369–383 (2015)

Wu, D.Y., Meure, S., Solomon, D.: Self-healing polymeric materials: a review of recent developments. Prog. Polym. Sci. 33(5), 479–522 (2008)

White, S.R., Sottos, N.R., Geubelle, P.H., et al.: Autonomic healing of polymer composites. Nature 409(6822), 794–797 (2001)

Toohey, K.S., Sottos, N.R., Lewis, J.A., et al.: Self-healing materials with microvascular networks. Nat. Mater. 6(8), 581–585 (2007)

Chen, X., Dam, M.A., Ono, K., et al.: A thermally re-mendable cross-linked polymeric material. Science 295(5560), 1698–1702 (2002)

Ghosh, B., Urban, M.W.: Self-repairing oxetane-substituted chitosan polyurethane networks. Science 323(5920), 1458–1460 (2009)

Imato, K., Nishihara, M., Kanehara, T., et al.: Self-healing of chemical gels cross-linked by diarylbibenzofuranone-based trigger-free dynamic covalent bonds at room temperature. Angew. Chem. Int. Ed. 124(5), 1164–1168 (2012)

Lu, Y.-X., Guan, Z.: Olefin metathesis for effective polymer healing via dynamic exchange of strong carbon-carbon double bonds. J. Am. Chem. Soc. 134(34), 14226–14231 (2012)

Cordier, P., Tournilhac, F., Soulié-Ziakovic, C., et al.: Self-healing and thermoreversible rubber from supramolecular assembly. Nature 451(7181), 977–980 (2008)

Chen, Y., Kushner, A.M., Williams, G.A., et al.: Multiphase design of autonomic self-healing thermoplastic elastomers. Nat. Chem. 4(6), 467 (2012)

Wang, Q., Mynar, J.L., Yoshida, M., et al.: High-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature 463(7279), 339–343 (2010)

Sun, T.L., Kurokawa, T., Kuroda, S., et al.: Physical hydrogels composed of polyampholytes demonstrate high toughness and viscoelasticity. Nat. Mater. 12(10), 932–937 (2013)

Wool, R., Oconnor, K.: A theory crack healing in polymers. J. Appl. Phys. 52(10), 5953–5963 (1981)

Wool, R.P.: Self-healing materials: a review. Soft Matter 4(3), 400–418 (2008)

Stukalin, E.B., Cai, L.-H., Kumar, N.A., et al.: Self-healing of unentangled polymer networks with reversible bonds. Macromolecules 46(18), 7525–7541 (2013)

Balazs, A.C.: Modeling self-healing materials. Mater. Today 10(9), 18–23 (2007)

Zheng, Z., Xia, X., Zeng, X., et al.: Theoretical model of time-temperature superposition principle of the self-healing kinetics of supramolecular polymer nanocomposites. Macromol. Rapid Commun. 39(20), 1800382 (2018)

Fang, Y., Yue, T., Li, S., et al.: Molecular dynamics simulations of self-healing topological copolymers with a comblike structure. Macromolecules 54, 1095–1105 (2021)

Wang, Q., Gao, Z.: A constitutive model of nanocomposite hydrogels with nanoparticle crosslinkers. J. Mech. Phys. Solids 94, 127–147 (2016)

Wang, Q., Gao, Z., Yu, K.: Interfacial self-healing of nanocomposite hydrogels: Theory and experiment. J. Mech. Phys. Solids 109, 288–306 (2017)

Yu, K., Xin, A., Wang, Q.: Mechanics of light-activated self-healing polymer networks. J. Mech. Phys. Solids 124, 643–662 (2019)

Xin, A., Zhang, R., Yu, K., et al.: Mechanics of electrophoresis-induced reversible hydrogel adhesion. J. Mech. Phys. Solids 125, 1–21 (2019)

Guadagno, L., Raimondo, M., Naddeo, C., et al.: Self-healing polymers: from principles to applications. Application of Self-Healing Materials in Aerospace Engineering, pp. 401–412, (2013)

Wang, Q., Gossweiler, G.R., Craig, S.L., et al.: Mechanics of mechanochemically responsive elastomers. J. Mech. Phys. Solids 82, 320–344 (2015)

Bell, G.I.: Models for the specific adhesion of cells to cells. Science 200(4342), 618–627 (1978)

De Gennes, P.-G., Gennes, P.-G.: Scaling Concepts in Polymer Physics. Cornell University Press, Ithaca (1979)

Shen, Z., Ye, H., Wang, Q., et al.: Sticky rouse time features the self-healing of supramolecular polymer networks. Macromolecules, page In Revision, (2021)

Yu, K., Xin, A., Feng, Z., et al.: Mechanics of self-healing thermoplastic elastomers. J. Mech. Phys. Solids 137, 103831 (2020)

Ihsan, A.B., Sun, T.L., Kurokawa, T., et al.: Self-healing behaviors of tough polyampholyte hydrogels. Macromolecules 49(11), 4245–4252 (2016)

Dunn, M., Taya, M.: Micromechanics predictions of the effective electroelastic moduli of piezoelectric composites. Int. J. Solids Struct. 30(2), 161–175 (1993)

Ramadan, K.S., Sameoto, D., Evoy, S.: A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 23(3), 033001 (2014)

Wang, X., Meguid, S.: On the electroelastic behaviour of a thin piezoelectric actuator attached to an infinite host structure. Int. J. Solids Struct. 37(23), 3231–3251 (2000)

Dorfmann, A., Ogden, R.: Nonlinear electroelasticity. Acta Mech. 174(3–4), 167–183 (2005)

Dorfmann, A., Ogden, R.: Nonlinear electroelastic deformations. J. Elast. 82(2), 99–127 (2006)

Liu, H., Bian, K., Xiong, K.: Large nonlinear deflection behavior of ipmc actuators analyzed with an electromechanical model. Acta. Mech. Sin. 35(5), 992–1000 (2019)

Suo, Z., Zhao, X., Greene, W.H.: A nonlinear field theory of deformable dielectrics. J. Mech. Phys. Solids 56(2), 467–486 (2008)

Suo, Z.: Theory of dielectric elastomers. Acta Mech. Solida Sin. 23(6), 549–578 (2010)

Cohen, N., Dayal, K., deBotton, G.: Electroelasticity of polymer networks. J. Mech. Phys. Solids 92, 105–126 (2016)

Itskov, M., Khiêm, V.N., Waluyo, S.: Electroelasticity of dielectric elastomers based on molecular chain statistics. Math. Mech. Solids 24(3), 862–873 (2019)

Cohen, N., deBotton, G.: Electromechanical interplay in deformable dielectric elastomer networks. Phys. Rev. Lett. 116(20), 208303 (2016)

Bastola, A. K., Hossain, M.: A review on magneto-mechanical characterizations of magnetorheological elastomers. Compos. B. Eng., p. 108348, (2020)

Davino, D., Visone, C., Ambrosino, C., et al.: Compensation of hysteresis in magnetic field sensors employing fiber Bragg grating and magneto-elastic materials. Sens. Actuators A 147(1), 127–136 (2008)

Snyder, R., Nguyen, V., Ramanujan, R.: Design parameters for magneto-elastic soft actuators. Smart Mater. Struct. 19(5), 055017 (2010)

Hu, W., Lum, G.Z., Mastrangeli, M., et al.: Small-scale soft-bodied robot with multimodal locomotion. Nature 554(7690), 81–85 (2018)

Alapan, Y., Karacakol, A.C., Guzelhan, S.N., et al.: Reprogrammable shape morphing of magnetic soft machines. Sci. Adv. 6(38), eabc6414 (2020)

Brigadnov, I., Dorfmann, A.: Mathematical modeling of magneto-sensitive elastomers. Int. J. Solids Struct. 40(18), 4659–4674 (2003)

Dorfmann, A., Ogden, R.: Magnetoelastic modelling of elastomers. Eur. J. Mech. A. Solids 22(4), 497–507 (2003)

Saxena, P., Hossain, M., Steinmann, P.: A theory of finite deformation magneto-viscoelasticity. Int. J. Solids Struct. 50(24), 3886–3897 (2013)

Zhao, R., Kim, Y., Chester, S.A., et al.: Mechanics of hard-magnetic soft materials. J. Mech. Phys. Solids 124, 244–263 (2019)

Sánchez, P.A., Cerda, J.J., Sintes, T.M., et al.: The effect of links on the interparticle dipolar correlations in supramolecular magnetic filaments. Soft Matter 11(15), 2963–2972 (2015)

Sánchez, P.A., Gundermann, T., Dobroserdova, A., et al.: Importance of matrix inelastic deformations in the initial response of magnetic elastomers. Soft Matter 14(11), 2170–2183 (2018)

Rozhkov, D., Pyanzina, E., Novak, E., et al.: Self-assembly of polymer-like structures of magnetic colloids: Langevin dynamics study of basic topologies. Mol. Simul. 44(6), 507–515 (2018)

Sánchez, P.A., Stolbov, O.V., Kantorovich, S.S., et al.: Modeling the magnetostriction effect in elastomers with magnetically soft and hard particles. Soft Matter 15(36), 7145–7158 (2019)

Garcia-Gonzalez, D., Hossain, M.: A microstructural-based approach to model magneto-viscoelastic materials at finite strains. Int. J, Solids Struct (2020)

Ahmed, E.M.: Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 6(2), 105–121 (2015)

Sun, J.-Y., Zhao, X., Illeperuma, W.R., et al.: Highly stretchable and tough hydrogels. Nature 489(7414), 133–136 (2012)

Zhang, Y.S., Khademhosseini, A.: Advances in engineering hydrogels. Science 356(6337), (2017)

Han, L., Lu, X., Wang, M., et al.: A mussel-inspired conductive, self-adhesive, and self-healable tough hydrogel as cell stimulators and implantable bioelectronics. Small 13(2), 1601916 (2017)

Yuk, H., Lu, B., Zhao, X.: Hydrogel bioelectronics. Chem. Soc. Rev. 48(6), 1642–1667 (2019)

Yang, C., Suo, Z.: Hydrogel ionotronics. Nat. Rev. Mater. 3(6), 125 (2018)

Wan, C., Xiao, K., Angelin, A., et al.: The rise of bioinspired ionotronics. Adv. Intell. Syst. 1(7), 1900073 (2019)

Cai, S., Suo, Z.: Mechanics and chemical thermodynamics of phase transition in temperature-sensitive hydrogels. J. Mech. Phys. Solids 59(11), 2259–2278 (2011)

Liu, Z., Toh, W., Ng, T.Y.: Advances in mechanics of soft materials: A review of large deformation behavior of hydrogels. Int. J. Appl. Mech. 7(05), 1530001 (2015)

Tamai, Y., Tanaka, H., Nakanishi, K.: Molecular dynamics study of polymer- water interaction in hydrogels. 1. hydrogen-bond structure. Macromolecules 29(21), 6750–6760 (1996)

Tamai, Y., Tanaka, H., Nakanishi, K.: Molecular dynamics study of polymer–water interaction in hydrogels. 2. Hydrogen-bond dynamics. Macromolecules 29(21), 6761–6769 (1996)

Chiessi, E., Cavalieri, F., Paradossi, G.: Water and polymer dynamics in chemically cross-linked hydrogels of poly (vinyl alcohol): A molecular dynamics simulation study. J. Phys. Chem. B 111(11), 2820–2827 (2007)

Walter, J., Sehrt, J., Vrabec, J., et al.: Molecular dynamics and experimental study of conformation change of poly (n-isopropylacrylamide) hydrogels in mixtures of water and methanol. J. Phys. Chem. B 116(17), 5251–5259 (2012)

Jackson Jr, W.J.: Liquid crystal polymers. iv. liquid crystalline aromatic polyesters. Br. Polym. J. 12(4), 154–162 (1980)

Jackson, W., Jr., Kuhfuss, H.: Liquid crystal polymers. i. preparation and properties of p-hydroxybenzoic acid copolyesters. J. Polym. Sci., Part A: Polym. Chem. 34(15), 3031–3046 (1996)

Sastri, V. R.: Plastics in medical devices: properties, requirements, and applications. William Andrew, (2013)

Jawaid, M., Khan, M.M.: Polymer-Based Nanocomposites for Energy and Environmental Applications. Woodhead Publishing, Sawston (2018)

Pang, X., Lv, J.-A., Zhu, C., et al.: Photodeformable azobenzene-containing liquid crystal polymers and soft actuators. Adv. Mater. 31(52), 1904224 (2019)

Liu, Y., Wu, W., Wei, J., et al.: Visible light responsive liquid crystal polymers containing reactive moieties with good processability. ACS Appl. Mater. Interfaces 9(1), 782–789 (2017)

da Cunha, M.P., Debije, M.G., Schenning, A.P.: Bioinspired light-driven soft robots based on liquid crystal polymers. Chem. Soc, Rev (2020)

White, T.J., Broer, D.J.: Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nat. Mater. 14(11), 1087–1098 (2015)

Corbett, D., Warner, M.: Nonlinear photoresponse of disordered elastomers. Phys. Rev. Lett. 96(23), 237802 (2006)

van Oosten, C.L., Corbett, D., Davies, D., et al.: Bending dynamics and directionality reversal in liquid crystal network photoactuators. Macromolecules 41(22), 8592–8596 (2008)

Jin, L., Zeng, Z., Huo, Y.: Thermomechanical modeling of the thermo-order-mechanical coupling behaviors in liquid crystal elastomers. J. Mech. Phys. Solids 58(11), 1907–1927 (2010)

Patnaik, S., Pachter, R.: Anchoring characteristics and interfacial interactions in a polymer dispersed liquid crystal: a molecular dynamics study. Polymer 40(23), 6507–6519 (1999)

Brostow, W., Cunha, A.M., Quintanilla, J., et al.: Crack formation and propagation in molecular dynamics simulations of polymer liquid crystals. Macromol. Theory Simul. 11(3), 308–314 (2002)

Stimson, L.M., Wilson, M.R.: Molecular dynamics simulations of side chain liquid crystal polymer molecules in isotropic and liquid-crystalline melts. J. Chem. Phys. 123(3), 034908 (2005)

Wilson, M.R.: Progress in computer simulations of liquid crystals. Int. Rev. Phys. Chem. 24(3–4), 421–455 (2005)

Muliana, A., Li, K.-A.: Time-dependent response of active composites with thermal, electrical, and mechanical coupling effect. Int. J. Eng. Sci. 48(11), 1481–1497 (2010)

Hiemenz, P.C., Lodge, T.P.: Polymer Chemistry. CRC Press, Boca Raton (2007)

Zhong, M., Wang, R., Kawamoto, K., et al.: Quantifying the impact of molecular defects on polymer network elasticity. Science 353(6305), 1264–1268 (2016)

Itskov, M., Knyazeva, A.: A rubber elasticity and softening model based on chain length statistics. Int. J. Solids Struct. 80, 512–519 (2016)

Verron, E., Gros, A.: An equal force theory for network models of soft materials with arbitrary molecular weight distribution. J. Mech. Phys. Solids 106, 176–190 (2017)

Lin, S., Zhao, X.: Fracture of polymer networks with diverse topological defects. Phys. Rev. E 102(5), 052503 (2020)

Tang, S., Zhang, G., Yang, H., et al.: Map123: A data-driven approach to use 1d data for 3d nonlinear elastic materials modeling. Comput. Methods Appl. Mech. Eng. 357, 112587 (2019)

Tang, S., Li, Y., Qiu, H., et al.: Map123-ep: A mechanistic-based data-driven approach for numerical elastoplastic analysis. Comput. Methods Appl. Mech. Eng. 364, 112955 (2020)

Tang, S., Yang, H., Qiu, H., et al.: Map123-epf: A mechanistic-based data-driven approach for numerical elastoplastic modeling at finite strain. Comput. Methods Appl. Mech. Eng., 373:113484

Saha, S., Gan, Z., Cheng, L., et al.: Hierarchical deep learning neural network (hidenn): An artificial intelligence (ai) framework for computational science and engineering. Comput. Methods Appl. Mech. Eng., 373:113452

Ghaderi, A., Morovati, V., Dargazany, R.: A physics-informed assembly of feed-forward neural network engines to predict inelasticity in cross-linked polymers. Polymers 12(11), 2628 (2020)

Acknowledgements

Y.L. would like to thank the support from the Interdisciplinary Multi-Investigator Materials Proposals (IMMP) program of the Institute of Materials Science at the University of Connecticut, and the funding support from the National Science Foundation (CMMI-1762661 and CMMI-1934829). Q.W. acknowledges the funding support from the National Science Foundation (CMMI-1762567 and CMMI-1943598). The authors acknowledge the Texas Advanced Computing Center (TACC) at The University of Texas at Austin for providing HPC resources (Frontera project and the National Science Foundation Award 1818253) that have contributed to the research results reported within this paper. This research benefited in part from the computational resources and staff contributions provided by the Booth Engineering Center for Advanced Technology (BECAT) at the University of Connecticut.

Author information

Authors and Affiliations

Corresponding author

Additional information

Executive Editor: Shaoxing Qu

Rights and permissions

About this article

Cite this article

Chen, G., Xian, W., Wang, Q. et al. Molecular simulation-guided and physics-informed mechanistic modeling of multifunctional polymers. Acta Mech. Sin. 37, 725–745 (2021). https://doi.org/10.1007/s10409-021-01100-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-021-01100-3