Abstract

A case history is presented for a reinforced concrete water seal constructed to resist high-pressure water inflows in a deep coal mine in China. A 3-D numerical model of the structure, developed using FLAC3D, provided a better understanding of the distribution of stresses and displacements and the extent of plastic zones in the rock surrounding the water seal structure. The modeling showed that about 80 % of the total stress caused by the water pressure acted on the water side of the first tapered plug and that the magnitude of the total stress caused by the water pressure gradually decreases along the axial direction of the chamber behind the seal. Based on the modeling, a full-face curtain grouting scheme was proposed to improve the effectiveness of the reinforced concrete water seal. To assess the proposed grouting scheme, an area behind the seal was filled with water and the stability of the surrounding rock was monitored. The conclusions regarding the effectiveness of the grouting and water seal construction techniques may provide valuable guidance for the construction of other water seals.

Zusammenfassung

Es wird eine Fallstudie vorgestellt, in welcher eine Wassersperre aus armiertem Beton gebaut wurde, welche unter hohem Druck in eine tiefe Kohlenmine in China zufließenden Wässern widerstehen sollte. Ein mittels FLAC3D erstelltes räumliches numerisches Modell half, die Verteilung von Spannungen, Verformungen und plastischen Zonen in der das Sperrbauwerk umgebenden Felsmasse besser zu verstehen. Die Modellierung zeigte, daß etwa 80 % der aus dem Wasserdruck resultierenden totalen Spannung wasserseitig auf den konischen Verschlußstopfen einwirkten, und daß die Größe der durch den Wasserdruck aufgebrachten Gesamtspannung parallel zur axialen Richtung der Kammer hinter dem Propfen allmählich absinkt. Auf Grund der Modellierung wurde ein räumliches Injektionsschema vorgeschlagen, um die Wirkamkeit der Wassersperre aus bewehrtem Beton zu erhöhen. Um das Injektionsschema zu bewerten, wurde ein Bereich hinter der Sperre mit Wasser gefüllt und die Stabilität des umgebenden Gebirges überwacht. Folgerungen in Bezug auf die Wirksamkeit der Injektions- und Wassersperrkonstruktionstechniken können wertvolle Leitlinien für den Bau anderer Wassersperren darstellen.

Resumen

Se analiza un caso para el reforzamiento de concreto en un sello para agua construido para resistir influjos de agua a alta presión en una mina profunda de carbón en China. Un modelo numérico 3-D de la estructura, desarrollado usando FLAC3D, proveyó una mejor comprensión de la distribución de estreses y desplazamientos y la extensión de zonas plásticas en la roca alrededor de la estructura que sella el agua. El modelado mostró que aproximadamente el 80 % del estrés total causado por la presión del agua actuó sobre el lado del agua del tapón cónico y que la magnitud del estrés total causado por la presión del agua desciende gradualmente a lo largo de la dirección axial de la cámara al lado del sello. Basado en el modelado, se propuso un esquema de cobertura de toda la cara con lechada de cemento para mejorar la eficiencia del refuerzo de concreto para el sello de agua. Para analizar el esquema propuesto, un área al lado del sello fue llenada con agua y se analizó la estabilidad de la roca circundante. Las conclusiones respecto de la efectividad del procedimiento y de las técnicas de construcción de sellos para el agua pueden proveer una guía valiosa para la construcción de otros sellos similares.

摘要

介绍了中国某深部开采煤矿用钢筋混凝水闸墙抵抗高压突水的案例。利用FLAC3D建立水闸墙3-D结构模型,以分析水闸墙周围岩石的应力与位移分布及塑性区范围。模拟结果显示,由水压引起的总应力的80 %作用在第一个锥形塞的迎水边,并且水压引起的总应力沿水闸墙室轴向方向逐渐降低。基于模拟结果,提出了钢筋混凝水闸墙的全断面帷幕灌浆方案。为了评价注浆方案合理性,水闸墙后一定范围充水并监测围岩稳定性。注浆效果分析及水闸墙设计方法等对其它类型水闸建造具有借鉴和指导意义。

Similar content being viewed by others

References

Auld FA (1983) Design of underground plugs. Int J Min Eng 1(3):189–228

China Coal Industry Bureau (1999) Code for design of chambers around pit-bottom of coal mine (MT/T5026-1999). China Coal Industry Press, Beijing

Coal Industrial Ministry of People's Republic of China (1984) Rules of hydrogeology of coal mines. Coal Publ House, Beijing

Ding HD, Miao X, Ju F, Wang L, Wang QC (2014) Strata behavior investigation for high-intensity mining in the water-rich coal seam. Int J Min Sci Technol 24(3):299–304

Djahanguiri F, Abel JF (1997) Design and construction of a water seal for a simulated underground leaching stope. Min Eng 49(1):57–64

Donnelly LJ (2006) A review of coal mining induced fault reactivation in Great Britain. Q J Eng Geol Hydrogeol 39(1):5–50

Garrett WS, Campbell-Pitt LT (1958) Tests on an experimental underground water seal for high pressures. J SAIMM 10:123–143

Garrett WS, Campbell-Pitt LT (1961) Design and construction of underground water seals and water barriers. In: Proceedings of seventh commonwealth mining and metallurgical conference, Johannesburg, pp 1283–1301

Han J, Shi LQ, Yu XG, Wei JC, Li SC (2009) Mechanism of mine water-inrush through a fault from the floor. Min Sci Technol 19(3):276–281

Harteis SP, Dolinar DR (2006) Water and slurry water seals in underground coal mines: design, monitoring and safety concerns. Min Eng 58(12):41–47

Harteis SP, Dolinar DR, Taylor TM (2008) Guidelines for permitting, construction, and monitoring of retention water seals in underground coal mines. IC 9506, National Institute for Occupational Safety and Health, Pittsburgh

Ji HD, Cui WC, Zhang SK (2001) Ultimate strength analysis of corrugated water seals considering influence of shear force and adjoining structures. J Constr Steel Res 57(5):525–545

Klose CD (2007) Mine water discharge and flooding: a cause of severe earthquakes. Mine Water Environ 26(3):172–180

Masumoto K, Sugita Y, Fujita T, Martino JB, Kozak ET, Dixon DA (2007) A clay grouting technique for granitic rock adjacent to clay water seal. Phys Chem Earth 32(8–14):691–700

Pacovský J (1999) Continuous measurements of stress and temperature during testing of a fibre shotcrete pressure plug. Geotech Geolog Eng 17(3–4):335–349

Sui WH, Liu JY, Yang SG, Chen ZS, Hu YS (2011) Hydrogeological analysis and salvage of a deep coalmine after a groundwater inrush. Environ Earth Sci 62(4):735–749

Vutukuri VS, Singh RN (1995) Mine inundation-case histories. Mine Water Environ 14(1):107–130

Wang J-A, Park HD (2003) Coal mining above a confined aquifer. Int J Rock Mech Min Sci 40(4):537–551

Wells MF, Msaimm A (1999) Construction of a concrete plug in South Deep’s main shaft to seal off a major water intersection. J South Afr Inst Min Metall 99(4):213–226

Wiprut D, Zoback MD (2000) Fault reactivation and fluid flow along a previously dormant normal fault in the northern North Sea. Geology 28(7):595–598

Wu Q, Wang M, Wu X (2004) Investigations of groundwater bursting into coal mine seam floors from fault zones. Int J Rock Mech Min Sci 41(4):557–571

Yin S-X, Zhang J (2005) Impacts of karst paleo-sinkholes on mining and environment in northern China. Environ Geol 48(8):1077–1083

Zhang JC (2005) Investigations of water inrushes from aquifers under coal seams. Int J Rock Mech Min Sci 42(3):350–360

Zhang JC, Shen BH (2004) Coal mining under aquifers in China: a case study. Int J Rock Mech Min Sci 41(4):629–639

Zhang R, Jiang Z, Zhou H, Yang C, Xiao S (2014) Groundwater outbursts from faults above a confined aquifer in the coal mining. Nat Hazards 71:1861–1872

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51408338), the Shandong Provincial Natural Science Foundation of China (No. ZR2014EEQ 009), and the China Postdoctoral Science Foundation Special Funded Project (No. 2014T70641), the State Key Development Program for Basic Research Program of China (No. 2013CB036000), the State Key Program of National Natural Science Foundation of China (No. 51139004), and the National Natural Science Foundation of China (No. 51479106). The authors also thank the reviewers for their valuable comments and suggestions that improved the quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

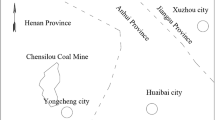

Supplemental Figure 1

Location of the Xinyang coal mine (PDF 16 kb)

Appendix

Appendix

According to the Chinese code for design of a waterproof coal pillar (Coal Industrial Ministry of People's Republic of China 1984), the required width of a protective coal pillar can be obtained from:

where L is the minimum width of the waterproof coal pillar (m), K is the security coefficient (value ranges from 2 to 5), M is the coal thickness or the mining height (m), P is the hydrostatic water pressure (MPa), and K p is the tensile strength of the coal (MPa).

Rights and permissions

About this article

Cite this article

Li, Sc., Xu, F., Zhang, Qq. et al. Analysis and Construction Techniques for a Water Seal for Underground Mines Subjected to Water Inrush. Mine Water Environ 35, 168–179 (2016). https://doi.org/10.1007/s10230-015-0359-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-015-0359-z