Abstract

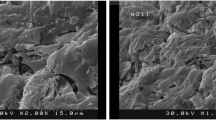

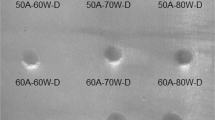

This work tested continuous CO2 laser as a surface treatment to dental porcelain and compared it to oven glaze (auto-glaze) by means of roughness and color parameters. Three commercial veneering porcelains with different crystalline content were tested: VM7, VM9, and VM13. Porcelain discs (3.5 × 2.0 mm, diameter × height) were sintered and had one side ground by a diamond bur (45 μm) simulating a chairside adjustment in a clinical office. Specimens (n = 7) were divided into the following groups: C—control (no treatment), G—auto-glaze (oven), and L—surface continuous irradiation with CO2 laser (Gem Laser, Coherent; λ = 10.6 μm). Laser was tested in three exposure times (3, 4, or 5 min) and two irradiances (45 and 50 W/cm2). Roughness parameters (Ra, Rz, and Rpm/Rz) were measured using a rugosimeter (Surftest 301, Mitutoyo). Color differences (ΔE) between the G and L groups were calculated (VITA Easyshade); ΔE values up to 3.3 were considered as not perceivable. A surface analysis was conducted by stereomicroscopy (Olympus SZ61) and SEM (Stereoscan 440, LEO). Crystalline content of specimens from groups C and L (50 W/cm2, 5 min) was assessed by X-ray diffraction and then compared. Surface roughness (Ra and Rz) observed for laser-irradiated groups was similar to G for all studied porcelains. Rpm/Rz ratios were near 1.0 for all groups that indicated a sharp ridge profile for all specimens. Only one laser condition studied (50 W/cm2, 3 min) from VM7 porcelain resulted in color difference (ΔE = 3.5) to G. Specimens irradiated with 50 W/cm2 for 5 min presented the smoother surface observed by SEM, comparable to G. X-ray diffraction data revealed an increase in leucite crystallite size for VM9 and VM13 porcelains after laser treatment. Regarding roughness, continuous CO2 laser applied on porcelain surface was as effective as conventional oven auto-glaze.

Similar content being viewed by others

References

Kelly JR (1997) Ceramics in restorative and prosthetic dentistry. Annu Rev Mater Sci 27:443–468

St John KR (2007) Biocompatibility of dental materials. Dent Clin N Am 51(3):747–760

Raigrodski AJ, Chiche GJ (2001) The safety and efficacy of anterior ceramic fixed partial dentures: a review of the literature. J Prosthet Dent 86(5):520–525

Gonzaga CC, Okada CY, Cesar PF, Miranda WG Jr, Yoshimura HN (2009) Effect of processing induced particle alignment on the fracture toughness and fracture behavior of multiphase dental ceramics. Dent Mater 25(11):1293–1301

Morena R, Lockwood PE, Fairhurst CW (1986) Fracture toughness of commercial dental porcelains. Dent Mater 2(2):58–62

Raigrodski AJ (2004) Contemporary materials and technologies for all-ceramic fixed partial dentures: a review of the literature. J Prosthet Dent 92(6):557–562

Scherrer SS, Kelly JR, Quinn GD, Xu K (1999) Fracture toughness (KIc) of a dental porcelain determined by fractographic analysis. Dent Mater 15(5):342–348

Griggs JA, Thompson JY, Anusavice KJ (1996) Effects of flaw size and auto-glaze treatment on porcelain strength. J Dent Res 75(6):1414–1417

Chang CW, Waddell JN, Lyons KM, Swain MV (2011) Cracking of porcelain surfaces arising from abrasive grinding with a dental air turbine. J Prosthodont 20(8):613–620

Quinn GD, Hoffman K, Quinn JB (2012) Strength and fracture origins of a feldspathic porcelain. Dent Mater 28(5):502–511

Baharav H, Laufer BZ, Pilo R, Cardash HS (1999) Effect of glaze thickness on the fracture toughness and hardness of alumina-reinforced porcelain. J Prosthet Dent 81(5):515–519

al-Wahadni A, Martin DM (1998) Glazing and finishing dental porcelain: a literature review. J Am Dent Assoc 64(8):580–583

Yuzugullu B, Celik C, Erkut S, Ozcelik TB (2009) The effects of extraoral porcelain polishing sequences on surface roughness and color of feldspathic porcelain. Int J Prosthodont 22(5):472–475

Hulterstrom AK, Bergman M (1993) Polishing systems for dental ceramics. Acta Odontol Scand 51(4):229–234

Sarikaya I, Guler AU (2010) Effects of different polishing techniques on the surface roughness of dental porcelains. J Appl Oral Sci 18(1):10–16

Motro PF, Kursoglu P, Kazazoglu E (2012) Effects of different surface treatments on stainability of ceramics. J Prosthet Dent 108(4):231–237

Yilmaz K, Ozkan P (2010) The methods for the generation of smoothness in dental ceramics. Compend Contin Educ Dent 31(1):30–2, 34, 36–8 passim; quiz 42, 44

Barghi N, Alexander L, Draugh RA (1976) When to glaze—an electron microscope study. J Prosthet Dent 35(6):648–653

Podshadley AG, Harrison JD (1966) Rat connective tissue response to pontic materials. J Prosthet Dent 16(1):110–118

Brentel AS, Kantorski KZ, Valandro LF, Fucio SB, Puppin-Rontani RM, Bottino MA (2011) Confocal laser microscopic analysis of biofilm on newer feldspar ceramic. Oper Dent 36(1):43–51

Prasad S, Monaco EA Jr, Kim H, Davis EL, Brewer JD (2009) Comparison of porcelain surface and flexural strength obtained by microwave and conventional oven glazing. J Prosthet Dent 101(1):20–28

Li X, Shaw LL (2005) Microstructure of dental porcelains in a laser-assisted rapid prototyping process. Dent Mater 21(4):336–346

Sgura R, Reis M, Andreeta MRB, Hernandes AC, Medeiros IS (2013) Sintering dental porcelain with CO2 laser: porosity and mechanical characterization. Brazilian Dental Science 16(1): in press

Kelly JR, Benetti P (2011) Ceramic materials in dentistry: historical evolution and current practice. Aust Dent J 56(Suppl 1):84–96

Gostemeyer G, Jendras M, Borchers L, Bach FW, Stiesch M, Kohorst P (2011) Effect of thermal expansion mismatch on the Y-TZP/veneer interfacial adhesion determined by strain energy release rate. J Prosthodont Res 56(2):93–101

Vichi A, Louca C, Corciolani G, Ferrari M (2011) Color related to ceramic and zirconia restorations: a review. Dent Mater 27(1):97–108

Vichi A, Ferrari M, Davidson CL (2004) Color and opacity variations in three different resin-based composite products after water aging. Dent Mater 20(6):530–534

Whitehead SA, Shearer AC, Watts DC, Wilson NH (1996) Surface texture changes of a composite brushed with "tooth whitening" dentifrices. Dent Mater 12(5):315–318

Yilmaz K, Ozkan P (2010) Profilometer evaluation of the effect of various polishing methods on the surface roughness in dental ceramics of different structures subjected to repeated firings. Quintessence Int 41(7):e125–31

Guler AU, Sarikaya IB, Guler E, Yucel A (2009) Effect of filler ratio in adhesive systems on the shear bond strength of resin composite to porcelains. Oper Dent 34(3):299–305

de Tholt de Vasconcellos B, Miranda-Junior WG, Prioli R, Thompson J, Oda M (2006) Surface roughness in ceramics with different finishing techniques using atomic force microscope and profilometer. Oper Dent 31(4):442–449

Azer SS, Ayash GM, Johnston WM, Khalil MF, Rosenstiel SF (2006) Effect of esthetic core shades on the final color of IPS Empress all-ceramic crowns. J Prosthet Dent 96(6):397–401

Barath VS, Faber FJ, Westland S, Niedermeier W (2003) Spectrophotometric analysis of all-ceramic materials and their interaction with luting agents and different backgrounds. Adv Dent Res 17:55–60

Chu FC, Chow TW, Chai J (2007) Contrast ratios and masking ability of three types of ceramic veneers. J Prosthet Dent 98(5):359–364

Uludag B, Usumez A, Sahin V, Eser K, Ercoban E (2007) The effect of ceramic thickness and number of firings on the color of ceramic systems: an in vitro study. J Prosthet Dent 97(1):25–31

Rosenstiel SF, Johnston WM (1988) The effects of manipulative variables on the color of ceramic metal restorations. J Prosthet Dent 60(3):297–303

Anusavice KJ, Zhang NZ, Moorhead JE (1994) Influence of P205, AgNO3, and FeCl3 on color and translucency of lithia-based glass-ceramics. Dent Mater 10(4):230–235

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sgura, R., Reis, M.C., Hernandes, A.C. et al. Surface treatment of dental porcelain: CO2 laser as an alternative to oven glaze. Lasers Med Sci 30, 661–667 (2015). https://doi.org/10.1007/s10103-013-1392-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10103-013-1392-4